Abstract

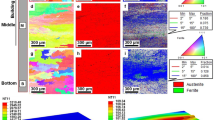

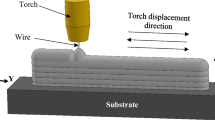

Additive manufacturing ensures the global adoption of zero-to-minimal waste and lean manufacturing systems. This is crucial for repairing, replacing, rebuilding, and rapidly producing components. The current study employs wire arc additive manufacturing (WAAM) with metal inert gas welding, which is affordable and versatile. The filler material used is Alloy 825, a highly corrosion-resistant alloy used extensively in the maritime and chemical sectors. The study compares the corrosion behavior of alloy 825 produced by the WAAM technique with that of wrought alloy 825. Electron backscatter diffraction analysis and hardness tests were also performed. Corrosion behavior was assessed using potentiodynamic polarization and electrochemical impedance spectroscopy. Wire arc additively manufactured alloy had a corrosion rate of 0.117 mmpy, while the wrought alloy had a corrosion rate of 0.066 mmpy. Tafel's extrapolation method computed corrosion current density and corrosion potentials. Electrochemical impedance spectroscopy studies were carried out using Bode impedance and phase angle plots. A scanning electron microscope examined the morphology, while energy-dispersive spectroscopy studied the chemical analysis of the corrosion region.

Similar content being viewed by others

References

Chen H, Zhang Y, Giam A, Yan W, Addit Manuf., (2022) 102645.

Qiu Z, Wu B, Zhu H, Wang Z, Hellier A, Ma Y, Li H, Muransky O, Wexler D, Mater Des., 195 (2020) 109007.

Mansoor O, Wahdatullah N, Harshavardhana N, Int Res J Eng Technol., 8 (2021) 1517–1528.

Sayiram G, Arivazhagan N, Mater Charact., 102 (2015) 180–188.

Han JW, Jung SH, Lee HW, Met Mater Int., (2021).

Kangazian J, Shamanian M, J Manuf Process., 26 (2017) 407–418.

Bharat Kumar CH, Anandakrishnan V, Mater Today Proc., 21 (2020) 622–627.

Safari M, Mostaan H, Derakhshan E, J Mar Eng Technol, 19 (2020) 176–185.

Guo C, Ying M, Dang H, Hu R, Chen F, Mater Res Express, 8 (2021).

Zhang Y, Jing H, Xu L, Han Y, Zhao L, Xiao B, Mater Charact, 139 (2018) 279–292.

Muralimohan CH, Ashfaq M, Ashiri R, Muthupandi V, Sivaprasad K, Metall Mater Trans A. 47 (2016) 347–59.

Kangazian J, Shamanian M, Ashrafi A, Corrosion, 74 (2018) 1259–1271.

Wu B, Pan Z, Li S, Cuiuri D, Ding D, Li H, Corros Sci., 137 (2018) 176–83.

Silva CC, Afonso CRM, Ramirez AJ, Motta MF, Miranda HC, Farias JP, J Alloys Compd., 684 (2016) 628–642.

Tang Y, Shen X, Qiao Y, Yang L, Chen J, Lu D, Zhang Z, J Mater Eng Perform, 30 (2021) 5506–5514.

Zhang LN, Ojo OA, J Alloys Compd, 829 (2020).

Juillet C, Oudriss A, Balmain J, Feaugas X, Pedraza F, Corros Sci., 142 (2018) 266–276.

Kim HI, Park HS, Koo JM, Yang SH, Kim MY, Seok CS, Key Eng Mater., 353 (2007) 519–522.

Abioye TE, McCartney DG, Clare AT, J Mater Process Technol., 217 (2015) 232–240.

Aytekin H, Akçin Y, Mater Des., 50 (2013) 515–521.

Kangazian J, Shamanian M, Trans Indian Inst Met., 71 (2018) 1747–1757.

Ghaffari M, Vahedi Nemani A, Nasiri A, Addit Manuf., (2021) 102374.

Vacchi S, Silva R, Kugelmeier CL, Beserra C, Martins J, Dainezi I, Alano JH, Mendes Filho AD, Ramos Osorio WR, Della Rovere CA, Metals, 11 (2021).

Alcisto J, Enriquez A, Garcia H, Hinkson S, Steelman T, Silverman E, Valdovino P, Gigerenzer H, Foyos J, Ogren J, Dorey J, J Mater Eng Perform., 20 (2011) 203–212.

Yangfan W, Xizhang C, Chuanchu S, Surf Coatings Technol., 374 (2019) 116–123.

A.Evangeline, Sathiya P, Mater Res Express, 6 (2019).

Dasari S, Sarkar A, Sharma A, Gwalani B, Choudhuri D, Soni V, Manda S, Samajdar I, Banerjee R, Acta Mater., 202 (2021) 448–62.

Nagaraju KVV, Kumaran S, Rao TS, Mater Lett., 302 (2021).

Cheepu M, Lee CI, Cho SM, Trans Indian Inst Met. 73 (2020) 1475–9.

Dong B, Cai X, Xia Y, Lin S, Fan C, Chen F, Addit Manuf., 48 (2021) 102453.

Park JH, Cheepu M, Cho SM, Metals. 10 (2020) 1–11.

Wu BB, Wang ZQ, Wang XL, Zhao JX, Shang CJ, Misra RDK, Mater Sci Technol., 35 (2019) 1803–1814.

Ralston KD, Birbilis N, Davies CHJ, Scr Mater, 63 (2010) 1201–4.

Siva Prasad M, Ashfaq M, Kishore Babu N, Sreekanth A, Sivaprasad K, Muthupandi V, Int J Miner Metall Mater, 24 (2017) 566–73.

Tejonadha Babu K, Muthukumaran S, Bharat Kumar CH, Sathiya Narayanan C, Mater Sci Forum, 969 (2019) 490–495.

Saikiran A, Hariprasad S, Arun S, Rameshbabu N, Surf Coatings Technol., 372 (2019) 239–251.

Eghlimi A, Shamanian M, Raeissi K, Surf Coatings Technol., 244 (2014) 45–51.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chigilipalli, B.K., Veeramani, A. Investigation of the Corrosion Behavior of Wire Arc Additively Manufactured Alloy 825. Trans Indian Inst Met 76, 279–286 (2023). https://doi.org/10.1007/s12666-022-02656-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02656-9