Abstract

This study concerns the substitution of copper for nickel in the Ni–Ti system in order to obtain a molar ratio of Ni40Ti50Cu10. Effects of preheating temperature were studied to understand the morphology, phase transformation, and microstructure of the samples by using self-propagating high-temperature synthesis. Therefore, three distinct preheating temperatures (230 °C, 320 °C, and 410 °C) were used for the study. The thermochemical calculations performed with FactSage presented similar results with the experimental data in terms of solid–liquid ratios and adiabatic temperature during the reactions. An increase in the preheating temperature very slightly changed the transformation temperature, but it was shown to be insignificant. B2 crystal structure was found as the main phase besides a small amount of martensite, Ti2Ni(Cu), and Ni(Cu)2Ti–Ni(Cu)3Ti by various characterization methods. The monoclinic twinned martensitic (B19′) structure was encountered in transmission electron microscopy analyses.

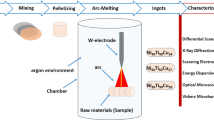

Graphical abstract

Similar content being viewed by others

References

Jani J M, Leary M, Subic A, and Gibson M A, Mater Des 56 (2014) 1078.

Nam T H, Saburi T, and Shimizu K I, JIM 31 (1990) 959.

Otsuka K, and Ren X, Prog Mater Sci 50 (2005) 511.

Nam T H, Saburi T, Nakata Y, and Shimizu K I, Mater Trans JIM 31 (1990) 1050.

Goryczka T, and Van Humbeeck J, J Alloys Compd 456 (2008) 194.

Nespoli A, Villa E, and Besseghini S, J Alloys Compd 509 (2011: 644.

Lo Y, Wu S, and Horng H, Acta Metall Mater 41 (1993) 747.

Oliveira J P, Miranda R M, and Braz Fernandes F M, Prog Mater Sci 88 (2017) 412.

Elahinia M H, Hashemi M, Tabesh M, and Bhaduri S B, Prog Mater Sci 57 (2012) 911.

Parvizi S, Hashemi S M, Asgarinia F, Nematollahi M, and Elahinia M, Prog Mater Sci 117 (2020) 100739

Xiong Z, Li Z, Sun Z, Hao S, Yang Y, Li M, Song C, Qiu P, and Cui L, J Mater Sci Technol 35 (2019) 2238.

Bram M, Ahmad-Khanlou A, Heckmann A, Fuchs B, Buchkremer H P, and Stöver D, Mater Sci Eng A 337 (2002) 254.

Kılıç M, Yenigun B, Bati S, Balalan Z, and Kirik I, Mater Test 61 (2019) 1140.

Yeh C L, and Sung W Y, J Alloys Compd 376 (2004) 79.

Li B, Rong L J, Li Y-Y, and Gjunter V, Acta Mater 48 (2000) 3895.

Jiang H C, and Rong L J, Mater Sci Eng A 438–440 (2006) 883.

Bassani P, Giuliani P, Tuissi A, and Zanotti C, J Mater Eng Perform 18 (2009) 594.

CRCT, GCT, Factsage https://www.factsage.com, Accessed 28 November 2021.

Novák P, Mejzlíková L, Michalcová A, Čapek J, Beran P, and Vojtěch D, Intermetallics 42 (2013) 85.

Tay B Y, Goh C W, Gu Y W, Lim C S, Yong M S, Ho M K, and Myint M H, J Mater Process Technol 202 (2008) 359.

Fukuda T, Saburi T, Chihara T, and Tsuzuki Y, Mater Trans 36 (1995) 1244.

Tadaki T, and Wayman C M, Metallography 15 (1982) 247.

Tang M, Zhang Y, Jiang S, Yu J, Yan B, Zhao C, and Yan B, Intermetallics 118 (2020) 106700

Acknowledgements

The authors are pleased to acknowledge the financial support from The Scientific and Technological Research of Turkey (TUBITAK, Project No: 213M556).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Keskin, B., Bassani, P., Bakan, F. et al. Synthesis and Microstructure Investigation of Ni40Ti50Cu10 Intermetallic Shape Memory Alloys by Self-Propagating Combustion Method. Trans Indian Inst Met 75, 2749–2758 (2022). https://doi.org/10.1007/s12666-022-02657-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-022-02657-8