Abstract

Coal is a low-cost and high-calorific-value fuel. The coal mining industry worldwide has been suffering from severe accidents due to coal dust explosion hazards since its inception. Statistically, it was observed that 12,489 fatalities had occurred in 104 reported mining accidents from coal dust explosions during 1900–2020. There are numerous methods for detection, prevention, and control of coal dust explosions in mines. The underground mining environment is unpredictable and has an array of variables. These undulating factors make it difficult to prevent or control the coal dust explosion hazard. However, coal mining is done aggressively throughout the world, especially in developing countries as coal is a major source of thermal energy used in power plants contributing to about 38% (IEA, (2019), World Energy Outlook, IEA, Paris https://www.iea.org/reports/world-energy-outlook-2019.) of world electricity. Worldwide, coal dust explosibility studies are carried out in experimental mines, laboratories, and simulations. The complexity, lack of proper infrastructure, and unavailability of laboratory equipment sometimes make it difficult to study coal dust explosibility. The authors have discussed in detail and proposed that the CFD modelling can be a viable option for studying and evaluating coal dust explosibility.

Similar content being viewed by others

References

Stroch P (2016) Do not underestimate danger of explosion; Even dust can destroy equipment and kill. Perspect Sci 7:312–316. https://doi.org/10.1016/j.pisc.2015.11.048 (ISSN 2213-0209)

Yuan Z, Khakzad N, Khan F, Amyotte P (2016) Dust explosions: A threat to the process industries. Process Saf Environ Prot 98:57–71. https://doi.org/10.1016/j.psep.2015.06.008 (ISSN 0957-5820)

Yan X-Q, Yu J-L (2012) Dust explosion incidents in China. Proc Saf Prog 31:187–189. https://doi.org/10.1002/prs.11482

Eckhoff RK (2009) Understanding dust explosions. The role of powder science and technology. J Loss Prev Process Ind 22(1):105–116. https://doi.org/10.1016/j.jlp.2008.07.006 (ISSN 0950-4230)

Taveau J (2017) Dust explosion propagation and isolation. J Loss Prev Process Ind 48:320–330. https://doi.org/10.1016/j.jlp.2017.04.019 (ISSN 0950-4230)

Brune J.F., Cashdollar K.L., Zipf R.K. (2007) Explosion prevention in United States coal mines. Proceedings of the 32nd International Conference of Safety in Mines Research Institutes, September 28–29, Beijing, China. Beijing, China: National Center for International Exchange & Cooperation on Work Safety (SAWS), 2007 Sep :121–125

Litton CD, Perera IE, Harteis SP, Teacoach KA, DeRosa MI, Thomas RA, Smith AC (2018) Some relevant parameters for assessing fire hazards of combustible mine materials using laboratory scale experiments. Fuel 218:306–315. https://doi.org/10.1016/j.fuel.2017.12.106

Cashdollar K., Sapko M., Weiss E., and Hertzberg M (1987) Laboratory and Mine Dust Explosion Research at the Bureau of Mines. Industrial Dust Explosions, ed. K. Cashdollar and M. Hertzberg (West Conshohocken, PA: ASTM International, 1987): 107–123. https://doi.org/10.1520/STP28169S

Mattes, R H, Bacho, A, and Wade, L V (1983) Lake Lynn Laboratory: construction, physical description, and capability. Information circular/1983. United States: N. p. Web.

Sapko, M. J. & Weiss, E. S. & Watson, Richard William. & United States. Bureau of Mines (1987) Size scaling of gas explosions Bruceton Experimental Mine versus the Lake Lynn Mine. Pittsburgh, Pa: U.S. Dept. of the Interior, Bureau of Mines

Skjold, T., Eckhoff, R.K., Arntzen, B.J., Lebecki, K., Dyduch, Z., Klemens, R., & Zydak, P (2007) Simplified modelling of explosion propagation by dust lifting in coal mines.

Cashdollar KL, Hertzberg M (1985) 20-L explosibility test chamber for dusts and gases. Rev Sci Instrum 56:596–602. https://doi.org/10.1063/1.1138295

Siwek R (1985) Development of a 20 L laboratory apparatus und its application for the investigation of combustible dusts Basel. Switzerland; Ciba Geigy AG,

Siwek R (1988) Reliable determination of the safety characteristics in 20-L apparatus. In Flammable Dust Explosion (November 2–4. 19X8. Sr. Lou is, MO) (pp. 529–573). Hollis ton. MA: IBC USA.

Bartknecht W (1981) Explosions: course, prevention, protection. Springer, Berlin

Bartknecht, W (1989). Dust explosions- course, prevention, protection Berlin: Springer.

du Plessis JJL (2015) Active explosion barrier performance against methane and coal dust explosions. Int J Coal Sci Technol 2:261–268. https://doi.org/10.1007/s40789-015-0097-7

Wu H. W. et al. (2009) Australian Sealing Practice and Use of Risk Assessment Criteria - ACARP Project C17015, Queensland Mining Industry Health and Safety Conference 2009, Queensland Mining Industry, Aug 2009.

Zhu Y, Wang D, Shao Z, Chaohang X, Zhu X, Qi X, Liu F (2019) A statistical analysis of coalmine fires and explosions in China. Process Saf Environ Prot 121:357–366. https://doi.org/10.1016/j.psep.2018.11.013 (ISSN 0957-5820)

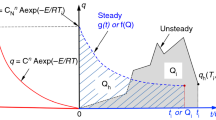

Jianwei C, Zhou F (2015) Revised Explosibility Diagram to Judge Best Practice of Controlling an Explosive Gas-Mixture. Fire Technol 51:293–308. https://doi.org/10.1007/s10694-014-0387-4

Jianwei C, Cheng W, Zhang S (2012) Methods to determine the mine gas explosibility - An overview. J Loss Prev Process Ind 25(3):425–435. https://doi.org/10.1016/j.jlp.2011.12.001

Duzgun, S and Evren DY (2016) An evaluation of Soma underground coal mine disaster with respect to risk acceptance and risk perception. In: Proceeding of 3rd International Symposium on Mine Safety Science and Engineering, Montreal 1–7

Report MSHA (2014) Discussion Paper Safety of Persons in Proximity to Underground Coal Mine Openings. Mine Safety Institute of Australia Pty Ltd., Australia, p 43

MSHA: Coal Mine Safety and Health, 2011. Report of Investigation – Fatal underground mine explosion, April 5, 2010.

IEA (2020) World total coal production, 1971–2020, IEA, Paris https://www.iea.org/data-and-statistics/charts/world-total-coal-production-1971-2020.

Hansen, R (2010) Overview of fire and smoke spread in underground mines.

Amyotte PR, Pegg Michael J (1993) Explosion hazards in underground coal mines. Toxicol Environ Chem 40(1–4):189–199. https://doi.org/10.1080/02772249309357943

Eckhoff RK (2005) Current status and expected future trends in dust explosion research. J Loss Prev Process Ind 18(4–6):225–237. https://doi.org/10.1016/j.jlp.2005.06.012 (ISSN 0950-4230)

Si Rj, Li Rz, Wang L (2009) Experiment study on the propagation laws of gas and coal dust explosion in coal mine. J Coal Sci Eng China 15:262–266. https://doi.org/10.1007/s12404-009-0309-0

Piotr W (1992) Dust explosion research in Poland. Powder Technol 71(2):197–206. https://doi.org/10.1016/0032-5910(92)80009-L (ISSN 0032-5910)

Tasneem A, Abbasi SA (2007) Dust explosions–Cases, causes, consequences, and control. J Hazard Mater 140(1–2):7–44. https://doi.org/10.1016/j.jhazmat.2006.11.007 (ISSN 0304-3894)

Amyotte Paul R, Pegg MJ, Khan FI (2009) Application of inherent safety principles to dust explosion prevention and mitigation. Process Saf Environ Prot 87(1):35–39. https://doi.org/10.1016/j.psep.2008.06.007 (ISSN 0957-5820)

Yan X, Jianliang Y, Gao W (2015) Flame behaviors and pressure characteristics of vented dust explosions at elevated static activation overpressures. J Loss Prev Process Ind 33:101–108. https://doi.org/10.1016/j.jlp.2014.11.012 (ISSN 0950-4230)

Amyotte PR, Eckhoff Rolf K (2010) Dust explosion causation, prevention and mitigation: An overview. J Chem Health Saf 17(1):15–28. https://doi.org/10.1016/j.jchas.2009.05.002 (ISSN 1871-5532)

Amyotte Paul R (2014) Some myths and realities about dust explosions. Process Saf Environ Prot 92(4):292–299. https://doi.org/10.1016/j.psep.2014.02.013 (ISSN 0957-5820)

Kumar RS, Kumar MN, Mobin KA, Debashish M, Kumar VN, Krishna PJ, Kumar SP (2020) CFD modeling to study the effect of particle size on dispersion in 20l explosion chamber: An overview. Int J Min Sci Technol 30(3):321–327. https://doi.org/10.1016/j.ijmst.2020.04.005 (ISSN 2095-2686)

Vahid E (2010) Dust explosion hazard assessment. J Loss Prev Process Ind 23(6):907–912. https://doi.org/10.1016/j.jlp.2010.05.006 (ISSN 0950-4230)

Baichao S, Li Y (2020) Study on propagation characteristics of the secondary explosion of coal dust. Int J Low-Carbon Technol 15(1):89–96. https://doi.org/10.1093/ijlct/ctz061

OSHA Instruction - CPL 03–00–008 - Combustible Dust National Emphasis Program (Reissued) 03/11/2008

Sen H, Liu Z, Zhao E, Lin S, Qiu L, Qian J, Liu H, Xia S (2017) Comparison of behavior and microscopic characteristics of first and secondary explosions of coal dust. J Loss Prev Process Ind 49(Part B):382–394. https://doi.org/10.1016/j.jlp.2017.08.005

Lin S, Liu Z, Qian J, Li X (2019) Comparison on the explosivity of coal dust and of its explosion solid residues to assess the severity of re-explosion. Fuel 251:438–446. https://doi.org/10.1016/j.fuel.2019.04.080

Yifan S, Qi Z (2019) Multiple explosions induced by the deposited dust layer in enclosed pipeline. J Hazard Mater 371:423–432. https://doi.org/10.1016/j.jhazmat.2019.03.040

Hartmann, I (1954) Dust Explosions in Coal Mines and Industry. The Scientific Monthly, 79(2): 97–108. Retrieved March 5, 2021, from http://www.jstor.org/stable/20919.

Weiwei W, Lijuan L, Qi Z (2017) A new 20 L experimental vessel for dust explosion and measurement of local concentration. J Loss Prev Process Ind 49(5):299–309. https://doi.org/10.1016/j.jlp.2017.07.012 (ISSN 0950-4230)

Qingming L, Chunhua B, Xiaodong L, Li J, Wenxi D (2010) Coal dust/air explosions in a large-scale tube. Fuel 89(2):329–335. https://doi.org/10.1016/j.fuel.2009.07.010 (ISSN 0016-2361)

Herrera EC., Montes AB., Escobar J.M (2014) Evaluation of parameters to determine the degree of coal dust explosibility 36: 42-54. https://doi.org/10.15446/RBCT.N36.46203

Cashdollar Kenneth L (1996) Coal dust explosibility. J Loss Prev Process Ind 9(1):65–76. https://doi.org/10.1016/0950-4230(95)00050-X (ISSN 0950-4230)

Gaetano C, Silvestro C, Enzo F, Francesco N, Gennaro R (1991) Coal dust explosions in a spherical bomb. J Loss Prev Process Ind 4(4):223–229. https://doi.org/10.1016/0950-4230(91)85004-D

Torrent JG, Armada IS, Pedreira Ramon A (1988) A correlation between composition and explosibility index for coal dust. Fuel 67(12):1629–1632. https://doi.org/10.1016/0016-2361(88)90206-2 (ISSN 0016-2361)

Tamanini F (1990) Turbulence effects on dust explosion venting. Plant/Oper Prog 9:52–60. https://doi.org/10.1002/prsb.720090111

Francesco T (1996) The role of turbulence in dust explosions Paper presented at the Seventh Colloquium on Dust Explosions, Bergen, Norway, 23–26 June 1996. J Loss Prev Process Ind 11(1):1–10. https://doi.org/10.1016/S0950-4230(97)00026-0 (ISSN 0950-4230)

Gao W, Mogi T, Jianliang Y, Yan X, Sun J, Dobashi R (2015) Flame propagation mechanisms in dust explosions. J Loss Prev Process Ind 36:186–194. https://doi.org/10.1016/j.jlp.2014.12.021 (ISSN 0950-4230)

Rice G S, Frazer J C.W., Larsen A, Haas F, Scholz C (1911) Explosibility of coal dust. United States: N. p., 1911. Web.

Rice G.S., Paul J.W., Greenwald H.P. (1927). Coal-Dust Explosion Tests in the Experimental Mine, 1919–24, Inclusive. Washington, D.C.: U.S. Bureau of Mines, Bulletin 268

Cashdollar et al., (2010) Recommendations for a New Rock Dusting Standard to Prevent Coal Dust Explosions in Intake Airways. CDC NIOSH RI no. 9679, Pittsburgh, 12 p.

Rice, G.S., Greenwald, H.P., Howarth, H.C., and Avins, S. (1931). Concrete Stoppings in Coal Mines for Resisting Explosions: Detailed Tests of Typical Stoppings and Strength of Coal as a Buttress. Pittsburgh, PA: U.S.Department of Commerce, Bureau of Mines, Bulletin 345.

Sapko M.J., Weiss E.S., Harteis S.P (2005) Methods for Evaluating Explosion Resistant Structures. In Proceedings of the 8th International Mine Ventilation Congress, Brisbane, Australia, July 6–8, 2005.

Sapko M.J., Verakis H (2006) Technical evaluation of the coal dust explosibility meter. In Transactions of the 2006 Society for Mining, Metallurgy and Exploration (SME) Annual Meeting, St. Louis, MO, March 26–29, 2006.

Cybulski W. (1975). Coal dust explosions and their suppression (Vol. 73, No. 54001). Foreign Scientific Publications Department, National Center for Scientific, Technical and Economic Information.

Cybulski WB (1971) Detonation of coal dust. Bulletin De L Academie Polonaise Des Sciences-Serie Des Sciences Techniques 19(5):381

Wolanski P (1982) Fuel-AirExposions, University of Waterloo Press,Waterloo, Ont., 1982, pp. 603–621.

NCB (1964); National Coal Board Mining Research Establishment, Isleworth, Middlesex, England, Bulletin No. 5, September, 1964.

Maguire B.A., Casswell C., (1970); “Fineness of Coal Dust Deposited on the Roof and Sides of a Mine Roadway”, NCB SMRE Research Report 268, 1970.

Dheyaa K, Wijayanuddin AM, Abdullah T, Amran T (2021) Mechanisms, Severity and Ignitability Factors, Explosibility Testing Method, Explosion Severity Characteristics, and Damage Control for Dust Explosion: A Concise Review. J Phys: Conf Ser 1892:012023. https://doi.org/10.1088/1742-6596/1892/1/012023

Pilao R, Ramalho E, Pinho C (2006) Overall characterization of cork dust explosion. J Hazard Mater 133(1–3):183–195. https://doi.org/10.1016/j.jhazmat.2005.10.015 (ISSN 0304-3894)

Jiangshi Z, Peihui X, Longhao S, Wenyue Z, Jianghong J (2018) Factors influencing and a statistical method for describing dust explosion parameters: A review. J Loss Prev Process Ind 56:386–401. https://doi.org/10.1016/j.jlp.2018.09.005 (ISSN 0950-4230)

Fedir W (1988) Explosibility of Victorian brown coal dust. Fuel 67(8):1062–1068. https://doi.org/10.1016/0016-2361(88)90371-7 (ISSN 0016-2361)

Dorsett HG, Jacobson M, Nagy J, Williams RP (1960) Laboratory equipment and test procedures for evaluating explosibility of dusts. U.S. Bureau of Mines RI 5624, 21pp.

Hattwig M, Steen H (2004) Handbook of Explosion Prevention and Protection. Wiely CSH Verlag GmbH.

Eckhoff RK (2003) Dust Explosions in the Process Industries, Butterworth, Oxford: Butterworth-Heinemann, United Kingdom.

ISO 6184/1 (1985) Explosion Protection Systems- Part 1 Determination of Explosion Indices of Combustible Dusts in Air, Switzerland: International Organization for Standardization.

ISO 6184/2 (1985) Explosion Protection Systems- Part 2: Determination of Explosion Indices of Combustible Gases in Air, Switzerland: International Organization for Standardization.

Chatrathi K (1994) Dust and hybrid explosibility in a 1 m3 spherical chamber. Process Safety Progress 13: n. pag.

Mittal, M (2013) Study of Explosibility Data of Coal Dust for Designing Explosion Safety Measures. Int J Adv Engg Tech/IV/III/July-Sept.,2013/82–91.

ASTM E1226 (2010) Standard Test Method for Explosibility of Dust Clouds.

Bing D, Huang W, Liu L, Zhang T, Li H, Ren Y, Wang H (2015) Visualization and analysis of dispersion process of combustible dust in a transparent Siwek 20-L chamber. J Loss Prev Process Ind 33:213–221. https://doi.org/10.1016/j.jlp.2014.12.017 (ISSN 0950-4230)

Jingjie Y, Wenyun W, Weixing H, Bing D, Liu L, Zhu J (2014) Experimental investigations on the roles of moisture in coal dust explosion. J Taiwan Inst Chem Eng 45(5):2325–2333. https://doi.org/10.1016/j.jtice.2014.05.022 (ISSN 1876-1070)

Sapko MJ, Weiss ES, Cashdollar KL, Zlochower Isaac A (2000) Experimental mine and laboratory dust explosion research at NIOSH. J Loss Prev Process Ind 13(3–5):229–242. https://doi.org/10.1016/S0950-4230(99)00038-8 (ISSN 0950-4230)

Weiguo C, Qingfeng Q, Wei C, Yanhua L, Chen Teng X, Sen CX (2017) Experimental and numerical studies on the explosion severities of coal dust/air mixtures in a 20-L spherical vessel. Powder Technol 310:17–23. https://doi.org/10.1016/j.powtec.2017.01.019 (ISSN 0032-5910)

Jingjie Y, Weixing H, Bing D, Kuai N, Li Z, Tan J (2012) An Extensive Discussion on Experimental Test of Dust Minimum Explosible Concentration. Procedia Eng 43:343–347. https://doi.org/10.1016/j.proeng.2012.08.059 (ISSN 1877-7058)

Garcia TJ et al (2016) Ignition and explosion parameters of Colombian coals. J Loss Prev Process Ind 43:706–713. https://doi.org/10.1016/j.jlp.2016.06.007 (ISSN 0950-4230)

Li Q, Wang K, Zheng Y, Ruan M, Mei X, Lin B (2016) Experimental research of particle size and size dispersity on the explosibility characteristics of coal dust. Powder Technol 292:290–297. https://doi.org/10.1016/j.powtec.2016.01.035 (ISSN 0032-5910)

Zhang J, Sun L, Nie F, Zhou H (2019) Effects of particle size distribution on the explosion severity of coal dust. Energy Sources, Part A: Recovery, Util Environ Eff. https://doi.org/10.1080/15567036.2019.1654562

Nifuku M, Katoh H (2001) Incendiary characteristics of electrostatic discharge for dust and gas explosion. J Loss Prev Process Ind 14(6):547–551. https://doi.org/10.1016/S0950-4230(01)00046-8 (ISSN 0950-4230)

Man CK, Harris ML (2014) Participation of large particles in coal dust explosions. Journal of Loss Prevention in the Process Industries 27:49–54. https://doi.org/10.1016/j.jlp.2013.11.004 (ISSN 0950-4230)

Weiguo C, Liyuan H, Jianxin Z, Sen X, Qiu S, Pan F (2012) Research on Characteristic Parameters of Coal-dust Explosion. Procedia Engineering 45:442–447. https://doi.org/10.1016/j.proeng.2012.08.183 (ISSN 1877-7058)

Turkevich LA, Dastidar AG, Zachary H, Michael L (2015) Potential explosion hazard of carbonaceous nanoparticles: Explosion parameters of selected materials. J Hazard Mater 295:97–103. https://doi.org/10.1016/j.jhazmat.2015.03.069 (ISSN 0304-3894)

Eckhoff Rolf K (2012) Does the dust explosion risk increase when moving from μm-particle powders to powders of nm-particles? J Loss Prev Process Ind 25(3):0950–4230. https://doi.org/10.1016/j.jlp.2011.11.011 (ISSN 448–459)

Norman F, Berghmans J, Verplaetsen F (2012) The Dust Explosion Characteristics of Coal Dust in an Oxygen Enriched Atmosphere. Procedia Eng 45:399–402. https://doi.org/10.1016/j.proeng.2012.08.177 (ISSN 1877-7058)

Man C, Teacoach K (2009) How does limestone rock dust prevent coal dust explosions in coal mines. Min Eng 61:69–69

Amyotte Paul R (2006) Solid inertants and their use in dust explosion prevention and mitigation. J Loss Prev Process Ind 19(2–3):161–173. https://doi.org/10.1016/j.jlp.2005.05.008 (ISSN 0950-4230)

Zlochower IA, Sapko MJ, Perera IE, Brown CB, Harris ML, Rayyan NS (2018) Influence of specific surface area on coal dust explosibility using the 20-L chamber. J Loss Prev Process Ind 54:103–109. https://doi.org/10.1016/j.jlp.2018.03.004

Johnston HG, Chowdhury AY, Mannan MS, Petersen EL (2016) Effect of coal-limestone mixtures on dust dispersion behind a moving shock wave. J Loss Prev Process Ind 44:551–563. https://doi.org/10.1016/j.jlp.2016.07.006 (ISSN 0950-4230)

Kwasi AE, Dieter G, Ulrich K (2016) Experimental investigations of the minimum ignition energy and the minimum ignition temperature of inert and combustible dust cloud mixtures. J Hazard Mater 307:302–311. https://doi.org/10.1016/j.jhazmat.2016.01.018 (ISSN 0304-3894)

Qingqing H, Rick H (2016) Recent trends in rock dust modifications for improved dispersion and coal dust explosion mitigation. J Loss Prev Process Ind 41:121–128. https://doi.org/10.1016/j.jlp.2016.03.009

Sapko MJ, Cashdollar KL, Green Gregory M (2007) Coal dust particle size survey of US mines. J Loss Prev Process Ind 20(4–6):616–620. https://doi.org/10.1016/j.jlp.2007.04.014

Niansheng K, Weixing H, Jingjie Y, Bing, Li Z, Yi W (2011) Experimental investigations of coal dust-inertant mixture explosion behaviors. Procedia Eng 26:1337–1345. https://doi.org/10.1016/j.proeng.2011.11.2309 (ISSN 1877-7058)

Dastidar AG, Amyotte PR, Pegg Michael J (1997) Factors influencing the suppression of coal dust explosions. Fuel 76(7):663–670. https://doi.org/10.1016/S0016-2361(97)00039-2 (ISSN 0016-2361)

Cashdollar KL, Weiss ES, Montgomery TG, Going John E (2007) Post-explosion observations of experimental mine and laboratory coal dust explosions. J Loss Prev Process Ind 20(4–6):607–615. https://doi.org/10.1016/j.jlp.2007.04.013 (ISSN 0950-4230)

Cook P. M (1993) The Inhibition of Coal Dust Explosions in a Large-Scale Explosion Gallery CSIR (South Africa) Report ENER 93001.

Du Plessis, Jan JL, Vassard Pierre S (1999) Performance of distributed bagged stone dust barrier in combating coal-dust explosions.

Du Plessis JJL, Brandt MP, Vassard PS (1995) Assessment of explosion barriers. SIMRAC Research Report, COL 010

Knoetze TP, Kessler IIM, Brandt MP (1993) The explosibility of South African coals as determined in the 40–litre explosion vessel. J SAIMM 93(8):203–206

Humphreys DR, (2000), “Stone Dust Requirements and Options”, ACARP Project Report 8011

Ajrash M. J., Zanganeh J., Eschebach D., Kundu S., Moghtaderi B. (2015). Effect of methane and coal dust concentrations on explosion pressure rise. In Proceeding s of the Australian Combustion Symposium (ACS), Editors: Yi Yang, Nigel Smith, University of Melbourne (pp. 252–255).

Hassan J, Khan F, Amyotte P, Ferdous R (2014) Industry specific dust explosion likelihood assessment model with case studies. J Chem Health Saf 21(2):13–27. https://doi.org/10.1016/j.jchas.2013.11.005

Di BA, Russo P (2007) Thermo-kinetic modelling of dust explosions. J Loss Prev Process Ind 20(4–6):303–309. https://doi.org/10.1016/j.jlp.2007.04.001 (ISSN 0950-4230)

Dejian W, Vanierschot M, Verplaetsen F, Berghmans J, Van den Bulck E (2016) Numerical study on the ignition behavior of coal dust layers in air and O2/CO2 atmospheres. Appl Thermal Eng 109(4):709–717. https://doi.org/10.1016/j.applthermaleng.2016.08.124 (ISSN 1359-4311)

Zhi Y, Nima K, Faisal K, Paul A (2016) Domino effect analysis of dust explosions using Bayesian networks. Process Saf Environ Prot 100:108–116. https://doi.org/10.1016/j.psep.2016.01.005 (ISSN 0957-5820)

Shen R, Jiao Z, Parker T, Sun Y, Wang Q (2020) Recent application of Computational Fluid Dynamics (CFD) in process safety and loss prevention: A review. J Loss Prev Process Ind 67:104252. https://doi.org/10.1016/j.jlp.2020.104252 (ISSN 0950-4230)

Bind VK, Roy S, Rajagopal C (2011) CFD modelling of dust explosions: Rapid combustion in a 20 L apparatus. Can J Chem Eng 89:663–670. https://doi.org/10.1002/cjce.20419

Salamonowicz Z, Kotowski M, Półka M, Barnat W (2015) Numerical simulation of dust explosion in the spherical 20l vessel. Bulletin of the Polish Academy of Sciences Technical Sciences. 63https://doi.org/10.1515/bpasts-2015-0033

Weiguo C, Wei G, Yuhuai P, Jiyuan L, Feng P, Sen X (2014) Experimental and numerical study on flame propagation behaviors in coal dust explosions. Powder Technol 266:456–462. https://doi.org/10.1016/j.powtec.2014.06.063 (ISSN 0032-5910)

Desjonqueres P, Berlemont A, Gouesbet G (1988) A lagrangian approach for the prediction of particle dispersion in turbulent flows. J Aerosol Sci 19(1):99–103. https://doi.org/10.1016/0021-8502(88)90258-3 (ISSN 0021-8502)

Liu T, Cai Z, Wang N, Li Y (2020) Experimental and numerical study on flame propagation characteristics of coal dust explosion in small-scale space. Alexandria Eng J. https://doi.org/10.1016/j.aej.2020.10.034 (ISSN 1110-0168)

Di Benedetto A, Russo P, Amyotte P, Marchand N (2010) Modelling the effect of particle size on dust explosions. Chem Eng Sci 65(2):772–779. https://doi.org/10.1016/j.ces.2009.09.029 (ISSN 0009-2509)

Kumar BV, Shantanu R, Rajagopal C (2012) A reaction engineering approach to modeling dust explosions. Chem Eng J 207–208:625–634. https://doi.org/10.1016/j.cej.2012.07.026 (ISSN 1385-8947)

Portarapillo M, Trofa M, Sanchirico R, Di Benedetto A (2021) CFD Simulations of the Effect of Dust Diameter on the Dispersion in the 1 m3 Explosion Vessel. Chem Eng Trans 86:343–348. https://doi.org/10.3303/CET2186058

Sarli V. Di, Russo P., Sanchirico R., Benedetto A. D (2014) CFD simulations of dust dispersion in the 20 L vessel: Effect of nominal dust concentration. Journal of Loss Prevention in the Process Industries 27(8–12), ISSN 0950–4230, https://doi.org/10.1016/j.jlp.2013.10.015.

Di Benedetto A, Russo P, Sanchirico R, Di Sarli V (2013) CFD simulations of turbulent fluid flow and dust dispersion in the 20 liter explosion vessel. AIChE J 59:2485–2496. https://doi.org/10.1002/aic.14029

Murillo C, Dufaud O, Bardin-Monnier N, Lopez O, Munoz F, Perrin L (2013) Dust explosions: CFD modeling as a tool to characterize the relevant parameters of the dust dispersion. Chem Eng Sci 104:103–116. https://doi.org/10.1016/j.ces.2013.07.029 (ISSN 0009-2509)

Zhong S, Teodorczyk A, Deng X, Dang J (2002) Modeling and simulation of coal dust explosions. J Phys IV France 12(7):141–147. https://doi.org/10.1051/jp4:20020277

Maier P, Hartlieb P, Brune JF (2020) Laboratory Scaled Coal Dust Explosions and Physical Test Results for CFD Explosion Models. Berg Huettenmaenn Monatsh 165:265–269. https://doi.org/10.1007/s00501-020-00985-0

Murillo C, Dufaud O, Lopez O, Perrin L, Vignes A, Muñoz F (2013) CFD Modelling of Nanoparticles Dispersion in a Dust Explosion Apparatus. Chem Eng Trans 31:889–894

Angarita Pinilla, Andres Jorge (2017) CFD study on the incidence of the change of nozzle on the dust dispersion in the 20 liters sphere. Master thesis, Universidad de los Andes. http://hdl.handle.net/1992/13958

Cloney CT, Ripley RC, Amyotte PR, Khan Faisal I (2013) Quantifying the effect of strong ignition sources on particle preconditioning and distribution in the 20-L chamber. J Loss Prev Process Ind 26(6):1574–1582. https://doi.org/10.1016/j.jlp.2013.08.010 (ISSN 0950-4230)

Portarapillo M, Sanchirico R, Di Benedetto A (2021) Effect of turbulence spatial distribution on the deflagration index: Comparison between 20 L and 1 m3 vessels. J Loss Prev Process Ind 71:104484. https://doi.org/10.1016/j.jlp.2021.104484

Sarli V, Sanchirico R, Russo P, Benedetto AD (2015) CFD modeling and simulation of turbulent fluid flow and dust dispersion in the 20-L explosion vessel equipped with the perforated annular nozzle. J Loss Prev Process Ind 38:204–213

Sinha K, Balasridhar SJ (2013) Conservative Formulation of the Turbulence Model for Shock-Turbulence Interaction. AIAA J 51:1872–1882. https://doi.org/10.2514/1.J052289

Edwards J C, Hwang C. C (1999) Proceedings of the Eighth US Mine Ventilation Symposium, Rolla, Missouri, June 11–17, 1999. Rolla, Missouri: University of Missouri-Rolla Press, 1999 Jun :417–422.

Castellanos D, Carreto V, Skjold T, Yuan S, Chaudhari P, Mannan MS, Mashuga C (2018) Construction of a 36 L dust explosion apparatus and turbulence flow field comparison with a standard 20 L dust explosion vessel. J Loss Prev Process Ind 55:113–123. https://doi.org/10.1016/j.jlp.2018.05.014 (ISSN 0950-4230)

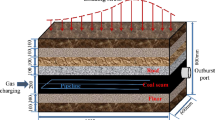

Humphreys David, Collecutt Greg, Proud D. (2010) CFD simulation of underground coal dust explosions and active explosion barriers, in Naj Aziz and Bob Kininmonth (eds.). Proceedings of the 2010 Coal Operators' Conference, Mining Engineering, University of Wollongong. https://ro.uow.edu.au/coal/318.

Wang X, Huang X, Zhang X, Zhang Y, Zhang Y (2019) Numerical simulation of coal dust explosion suppression by inert particles in spherical confined storage space. Fuel 253:1342–1350. https://doi.org/10.1016/j.fuel.2019.05.102 (ISSN 0016-2361)

Brune J, Grubb J, Bogin G, Marts J, Gilmore R, Saki S (2016) Lessons learned from research about methane explosive gas zones in coal mine gobs. Int J Min Mineral Eng 7:155. https://doi.org/10.1504/IJMME.2016.076498

Brune J, Saki S (2017) Prevention of gob ignitions and explosions in longwall mining using dynamic seals. Int J Min Sci Technol 27(6):999–1003. https://doi.org/10.1016/j.ijmst.2017.06.026

Juganda A, Strebinger C, Brune J, Bogin G (2020) Discrete modelling of a longwall coal mine gob for CFD simulation. Int J Min Sci Technol 30(4):463–469. https://doi.org/10.1016/j.ijmst.2020.05.004

ASTM E1226-19 (2019) Standard test method for explosibility of dust clouds. American society for testing and materials, West Conshohocken, PA, 14.01:1–15. https://doi.org/10.1520/E1226-19

Cheng W, Xinzhuang D, Jianxu D, Baisheng N (2014) Numerical investigation on the spraying and explosibility characteristics of coal dust. Int J Min Reclam Environ 28(5):287–296. https://doi.org/10.1080/17480930.2014.964041

IEA (2019) World Energy Outlook 2019, Part A: Global energy trends. IEA, Paris, 1:35–78. https://www.iea.org/reports/world-energyoutlook-2019

Acknowledgements

The authors are grateful to the Ministry of Coal, Government of India (Grant ID: CIL/R&D/01/60/2016) forfunding. The authors are grateful to Director, CSIR-Central Institute of Mining and Fuel Research, Dhanbad, India for approving to publish this article. The authors are deeply indebted to the anonymous reviewers and editors for their valuable suggestions which enriched the quality of the article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, A.M., Ray, S.K., Mohalik, N.K. et al. Experimental and CFD Simulation Techniques for Coal Dust Explosibility: A Review. Mining, Metallurgy & Exploration 39, 1445–1463 (2022). https://doi.org/10.1007/s42461-022-00631-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42461-022-00631-y