Abstract

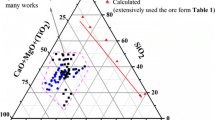

The fluidity and thermal stability properties of melting slag are closely related to the smooth production of the blast furnace. In this study, the viscosity and thermal stability properties of the chlorine-containing high-titanium melting slag (CaO–SiO2–MgO–Al2O3–TiO2–CaCl2) are investigated. The concept of “Extreme Heat Release of Slag” (EHRS) is proposed to quantitatively express the change in the thermal stability of the melting slag. Fourier transform infrared (FTIR) and Raman spectroscopy is used to analyze the structure evolution. The results indicate that chlorine can reduce the viscosity and simplify the structure of melting slag. Due to the evaporation of chlorine at high temperatures, the chlorine content decreases slightly in the viscosity test process. The changing trend of viscous flow activation energy is similar to that of viscosity. Increasing chlorine content could reduce the heat capacity but increase EHRS. The larger the EHRS is, the smaller the viscosity fluctuation. In addition, the [SiO4]-tetrahedral structures and Ti–O–(Ti or Si) bonds would be destroyed. The relative area fractions of Q2 and Q3 units transform to the Q0 and Q1 units, resulting in the decrease in the degree of polymerization of melting slag.

Similar content being viewed by others

References

Q. Guibao, L. Chen, J. Zhu, X. Lv, and C. Bai: Effect of Cr2O3 addition on viscosity and structure of Ti-bearing blast furnace slag. ISIJ Int., 2015, vol. 55(7), pp. 1367–76. https://doi.org/10.2355/isijinternational.55.1367.

M. Hengbao, K. Jiao, and J. Zhang: The influence of basicity and TiO2 on the crystallization behavior of high Ti-bearing slags. CrystEngComm, 2020, vol. 22(2), pp. 361–70. https://doi.org/10.1039/c9ce01695c.

Y. Zhiming, X. Lv, W. He, and J. Xu: Effect of TiO2 on the liquid zone and apparent viscosity of SiO2-CaO-8wt%MgO-14wt%Al2O3 system. ISIJ Int., 2017, vol. 57(1), pp. 31–36. https://doi.org/10.2355/isijinternational.ISIJINT-2016-420.

P. Zhengde, X. Lv, Y. Jiang, J. Ling, and Z. Yan: Blast furnace ironmaking process with super-high TiO2 in the slag: viscosity and melting properties of the slag. Metall. Mater. Trans. B, 2019, vol. 51B(2), pp. 722–31. https://doi.org/10.1007/s11663-019-01756-0.

N. Jian, S. Xu, H. Jin, Z. Wang, Y. Tu, and H. Liu: Chlorine release and migration characteristics during combustion of high chlorine coal. J. Combus. Sci. Technol., 2020, vol. 26(4), pp. 340–47. https://doi.org/10.11715/rskxjs.R202003016.

Z. Xu, J. Zhang, Z. Hu, H. Zuo, and H. Guo: Effect of CaCl2 on RDI and RI of sinter. J. Iron Steel Res. Int., 2010, vol. 17(11), pp. 7–12. https://doi.org/10.1016/S1006-706X(10)60162-8.

M. Okeda, M. Hasegawa, and M. Iwase: Solubilities of chlorine in CaO-SiO2-Al2O3-MgO slags: correlation between sulfide and chloride capacities. Metall. Mater. Trans. B, 2010, vol. 42(2), pp. 281–90. https://doi.org/10.1007/s11663-010-9465-2.

L. Wenguo, J. Qin, X. Xing, J. Wang, and H. Zuo: Viscosity and structure evolution of CaO–SiO2–MgO–Al2O3–BaO slag with the CaO/SiO2 mass ratio of 0.9. Ceram. Int., 2021, vol. 47(23), pp. 33483–89. https://doi.org/10.1016/j.ceramint.2021.08.255.

W. Zhanjun and I. Sohn: Effect of substituting CaO with BaO on the viscosity and structure of CaO-BaO-SiO2-MgO-Al2O3 slags. J. Am. Ceram. Soc., 2018, vol. 101(9), pp. 4285–96. https://doi.org/10.1111/jace.15559.

S. Amitabh, M. Görnerup, A.K. Lahiri, and S. Seetharaman: Experimental investigation of the viscosities in CaO-SiO2-MgO-Al2O3 and CaO-SiO2-MgO-Al2O3-TiO2 Slags. Metall. Mater. Trans. B., 2007, vol. 38B(6), pp. 911–15.

J. Kexin, J. Zhang, Z. Wang, C. Chen, and Y. Liu: Effect of TiO2 and FeO on the viscosity and structure of blast furnace primary slags. Steel Res. Int., 2017, https://doi.org/10.1002/srin.201600296.

F. Xiaoyue, J. Zhang, K. Jiao, R. Xu, and K. Wang: Influence of B2O3 on viscosity and structure of low MgO slag containing titanium. Metall. Res. Technol., 2018, https://doi.org/10.1051/metal/2017103.

R. Shan, J. Zhang, L. Wu, W. Liu, Y. Bai, X. Xing, B. Su, and D. Kong: Influence of B2O3 on viscosity of high Ti-bearing blast furnace slag. ISIJ Int., 2012, vol. 52(6), pp. 984–91. https://doi.org/10.2355/isijinternational.52.984.

W. Wanlin, S. Dai, L. Zhou, J. Zhang, W. Tian, and J. Xu: Viscosity and structure of MgO–SiO2-based slag melt with varying B2O3 content. Ceram. Int., 2020, vol. 46(3), pp. 3631–36. https://doi.org/10.1016/j.ceramint.2019.10.082.

L. Yinhe, L. Zhang, and X. Huang: Influence of CaF2 on the apparent viscosity of CaO-SiO2-MgO-Al2O3-TiO2 slags. Metall. Res. Technol., 2017, https://doi.org/10.1051/metal/2017067.

C.Z. Yu, K. Jiao, J. Zhang, X. Ning, and Z.Q. Liu: Effect of TiO2 and MnO on viscosity of blast furnace slag and thermodynamic analysis. ISIJ Int., 2018, vol. 58(12), pp. 2173–79. https://doi.org/10.2355/isijinternational.ISIJINT-2018-379.

Z. Jian, K. Jiao, J. Zhang, H. Ma, Y. Zong, Z. Guo, and Z. Wang: Thermal stability of molten slag in blast furnace hearth. ISIJ Int., 2021, vol. 61(8), pp. 2227–36. https://doi.org/10.2355/isijinternational.ISIJINT-2021-066.

C. Zhiyu, K. Jiao, X. Ning, and J. Zhang: Novel approach to studying influences of Na2O and K2O additions on viscosity and thermodynamic properties of BF slags. Metall. Mater. Trans. B, 2019, vol. 50B(3), pp. 1399–1406. https://doi.org/10.1007/s11663-019-01565-5.

J. Kexin, Z. Chang, C. Chen, and J. Zhang: Thermodynamic properties and viscosities of CaO-SiO2-MgO-Al2O3 slags. Metall. Mater. Trans. B, 2019, vol. 50B(2), pp. 1012–22. https://doi.org/10.1007/s11663-018-1490-6.

P. Zhuogang, X. Xing, J. Zheng, Y. Du, S. Ren and M. Lv. The effect of TiO2 on the thermal stability and structure of high acidity slag for mineral wool production. J Non-Cryst Solids, 2021. 571. https://doi.org/10.1016/j.jnoncrysol.2021.121071.

M. Hongwang, S. Zhang, Q. Lv, and Y. Sun: Experimental study on viscosity of high Alumina titanium blast furnace slag under neutral atmosphere. Iron Steel, 2021, vol. 47(6), pp. 18–22. https://doi.org/10.1007/s11783-011-0280-z.

Z. Jianlu, X. Xing, Z. Pang, S. Wang, Y. Du, and M. Lv: Effect of Na2CO3, HF, and CO2 treatment on the regeneration of exhausted activated carbon used in sintering flue gas. ACS Omega, 2021, vol. 6(39), pp. 25762–71. https://doi.org/10.1021/acsomega.1c04182.

W. Cui, J. Zhang, H. Zhang, K. Jiao, J. Yang, and K. Chou: Effect of chlorine on the viscosities and structures of blast furnace slags. Ironmak. Steelmak., 2016, vol. 43(10), pp. 769–74. https://doi.org/10.1080/03019233.2016.1234541.

L. Sunghee and D.J. Min: Anionic effect of chloride, fluoride, and sulfide ions on the viscosity of slag melt. J. Am. Ceram. Soc., 2017, vol. 100(6), pp. 2543–52. https://doi.org/10.1111/jace.14787.

S. Zhenghua, X. Xing, S. Wang, M. Lv, J. Li, and T. Li: Effect of K-modified blue coke-based activated carbon on low temperature catalytic performance of supported Mn–Ce/activated carbon. ACS Omega, 2022, vol. 7(10), pp. 8798–8808. https://doi.org/10.1021/acsomega.1c07076.

Z. Guohua, K. Chou, and J. Zhang: Influence of TiO2 on viscosity of aluminosilicate melts. Ironmak. Steelmak., 2013, vol. 41(1), pp. 47–50. https://doi.org/10.1179/1743281212Y.0000000093.

G. Zefeng, L. Kong, J. Bai, H. Zhao, X. Cao, H. Li, Z. Bai, B. Meyer, S. Guhl, P. Li, and W. Li: Effect of CaO/Fe2O3 ratio on slag viscosity behavior under entrained flow gasification conditions. Fuel, 2019, https://doi.org/10.1016/j.fuel.2019.116129.

X. Feng, D. Lu, H. Yang, and D. Dreisinger: Solvent extraction of silver and gold from alkaline cyanide solution with LIX 7950. Miner. Process Extr. Metall., 2013, vol. 35(4), pp. 229–38. https://doi.org/10.1080/08827508.2013.825615.

S. Dipankar and A.K. Chandra: Cl···Cl halogen bonding: nature and effect of substituent at electron donor Cl atom. ChemistrySelect, 2020, vol. 5(2), pp. 554–63. https://doi.org/10.1002/slct.201903546.

L.A. Swansbury, G. Mountjoy, X. Chen, N. Karpukhina, and R. Hill: Modeling the onset of phase separation in CaO-SiO2-CaCl2 chlorine-containing silicate glasses. J. Phys. Chem. B, 2017, vol. 121(22), pp. 5647–53. https://doi.org/10.1021/acs.jpcb.7b02986.

X. Xiangdong, P. Zhuogang, M. Chuan, W. Sha, and J. Jiantao: Effect of MgO and BaO on viscosity and structure of blast furnace slag. J. Non-Cryst. Solids, 2020, vol. 530, p. 119801. https://doi.org/10.1016/j.jnoncrysol.2019.119801.

B.O. Mysen, F.J. Ryerson, and D. Virgo: The influence of TiO2 on the structure and derivative properties of silicate melts. Am Mineral., 1980, vol. 1150(65), p. 1. https://doi.org/10.1007/BF02310052.

J.H. Park, D.J. Min, and H.S. Song: The effect of CaF2 on the viscosities and structures of CaO-SiO2(-MgO)-CaF2 slags. Metall. Mater. Trans. B, 2002, vol. 33B(4), pp. 723–29. https://doi.org/10.1007/s11663-002-0026-1.

C. Ziwei, H. Wang, Y. Sun, L. Liu, and X. Wang: Insight into the relationship between viscosity and structure of CaO-SiO2-MgO-Al2O3 Molten slags. Metall. Mater. Trans. B., 2019, vol. 50B(6), pp. 2930–41. https://doi.org/10.1007/s11663-019-01660-7.

Acknowledgment

The present work was financially supported by the Natural Science Basic foundation of China (Program No. 52174325) and China Postdoctoral Science Found (Grant No. 2019M663932XB). The authors gratefully acknowledge their support.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, J., Xing, X., Li, J. et al. Effect of Chlorine on the Fluidity and Thermal Stability Properties of High-Titanium Slags. Metall Mater Trans B 53, 2942–2952 (2022). https://doi.org/10.1007/s11663-022-02577-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02577-4