Abstract

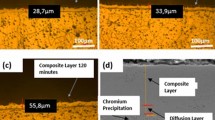

A novel liquid-metal-suction (LMS) method was performed to prepare diffusion couple specimens. The Al2O3/steel and MgO/steel interface characteristics were investigated after heat treatment at 1373 K (1100 °C) for 10 hours using an electron probe microanalyzer (EPMA) and scanning electron microscopy (SEM). The results indicated that the bulk oxide and steel combined tightly. After heat treatment, the diffusion of oxygen from the oxide to the steel matrix resulted in the formation of oxide particles in the particle precipitation zone (PPZ) on the steel side. At the Al2O3/steel interface, fine Al2O3 and coarse Al2O3 were observed in the PPZ after heat treatment. At the MgO/steel interface, MgO·Al2O3 (MA) spinel particles and dendritic Al2O3 were observed in the PPZ, and a thin MA spinel layer was detected on the bulk MgO side. After heating at 1373 K (1100 °C), the typical non-metallic inclusions (NMIs) in the low-density samples included AlN, MnS, AlN–MnS, and a small amount of Al2O3–MnS, whereas MnS-containing NMIs became spherical or near-spherical, and the number of fine AlN inclusions increased. In addition, the Mn diffusion from the steel matrix to the interface was revealed based on Fick’s second law, and the Mn contents detected through EPMA analysis after heat treatment were consistent with the theoretical calculation.

Similar content being viewed by others

References

I. Gutierrez-Urrutia: ISIJ Int., 2021, vol. 61, pp. 16–25. https://doi.org/10.2355/isijinternational.ISIJINT-2020-467.

S. Chen, R. Rana, A. Haldar, and R.K. Ray: Prog. Mater. Sci., 2017, vol. 89, pp. 345–91. https://doi.org/10.1016/j.pmatsci.2017.05.002.

D.W. Suh and N.J. Kim: Scr. Mater., 2013, vol. 68, pp. 337–38. https://doi.org/10.1016/j.scriptamat.2012.11.037.

H. Tervo, A. Kaijalainen, T. Pikkarainen, S. Mehtonen, and D. Porter: Mater. Sci. Eng. A, 2017, vol. 697, pp. 184–93. https://doi.org/10.1016/j.msea.2017.05.013.

R. VazPenna, L.N. Bartlett, and T. Constance: Int. J. Metalcast., 2019, vol. 13, pp. 286–99. https://doi.org/10.1007/s40962-018-0273-9s.

H. Suito and R. Inoue: ISIJ Int., 1996, vol. 36, pp. 528–36. https://doi.org/10.2355/isijinternational.36.528.

M. Nabeel, M. Alba, A. Karasev, P.G. Jönsson, and N. Dogan: Metall. Mater. Trans. B, 2019, vol. 50, pp. 1674–85. https://doi.org/10.1007/s11663-019-01605-0.

W. Wang, H. Zhu, Y. Han, J. Li, and Z. Xue: Steelmak, 2021, vol. 48, pp. 1038–47. https://doi.org/10.1080/03019233.2021.1909993.

D.J. Kim and J.H. Park: Metall. Mater. Trans. B, 2012, vol. 43, pp. 875–86. https://doi.org/10.1007/s11663-012-9667-x.

L. Wang, H. Zhu, J. Zhao, J. Li, and Z. Xue: Ceram. Int., 2022, vol. 48, pp. 1090–97. https://doi.org/10.1016/j.ceramint.2021.09.194.

Y. Ren, L. Zhang, and P.C. Pistorius: Metall. Mater. Trans. B, 2017, vol. 48, pp. 2281–92. https://doi.org/10.1007/s11663-017-1007-8.

W. Yang, S. Liu, S. Han, J. Wang, J. Guo, Y. Yan, and H. Guo: Materials, 2020, vol. 13, p. 5396. https://doi.org/10.3390/ma13235396.

K.H. Kim, S.J. Kim, H. Shibata, and S. Kitamura: ISIJ Int., 2014, vol. 54, pp. 2144–53. https://doi.org/10.2355/isijinternational.54.2144.

K.H. Kim, H. Shibata, and S. Kitamura: ISIJ Int., 2014, vol. 54, pp. 2678–86. https://doi.org/10.2355/isijinternational.54.2678.

C. Liu, S. Yang, K.H. Kim, J. Li, H. Shibata, and S. Kitamura: Int. J. Miner. Metall. Mater., 2015, vol. 22, pp. 811–19. https://doi.org/10.1007/s12613-015-1138-3.

C. Liu, K.H. Kim, S.J. Kim, J. Li, S. Ueda, X. Gao, H. Shibata, and S.Y. Kitamura: Metall. Materi. Trans. B, 2015, vol. 46, pp. 1875–84. https://doi.org/10.1007/s11663-015-0356-4.

X. Zhang, S. Yang, C. Liu, J. Li, Q. Liu, and G. Liu: J. Iron Steel Res. Int., 2018, vol. 25, pp. 1–8. https://doi.org/10.1007/s42243-017-0005-z.

S.J. Kim, H. Tago, K.H. Kim, S. Kitamura, and H. Shibata: Metall. Mater. Trans. B, 2018, vol. 49, pp. 977–87. https://doi.org/10.1007/s11663-018-1233-8.

W. Gan, C. Liu, K. Liao, H. Zhang, and H. Ni: Metall. Mater. Trans. B, 2022, vol. 53, pp. 485–502. https://doi.org/10.1007/s11663-021-02385-2.

A. Paul and S. Divinski: Handbook of Solid State Diffusion: Volume 2. 1st. ed. Oxford: Butterworth-Heinemann; 2017. Chapter 6, Diffusion couple technique: a research tool in materials science, pp. 207−75.

Y. Wang, L. Zhang, Y. Ren, H. Duan, and Q. Zhou: J. Mater. Res. Tech., 2022, vol. 18, pp. 159–70. https://doi.org/10.1016/j.jmrt.2022.02.084.

Y. Wang, A. Karasev, J.H. Park, W. Mu, and P.G. Jönsson: Metall. Mater. Trans. B, 2021, vol. 52, pp. 2459–73.

Y. Xia, J. Li, H. Dong, Y. Wan, and D. Fan: Ironmak. Steelmak., 2021, vol. 48, pp. 222–28. https://doi.org/10.1080/03019233.2020.1833676.

X. Shao, X. Wang, M. Jiang, W. Wang, and F. Huang: ISIJ Int., 2011, vol. 51, pp. 1995–2001. https://doi.org/10.2355/isijinternational.51.1995.

Y.V. Murty, T.Z. Kattamis, R. Mehrabian, and M.C. Flemings: Metall. Mater. Trans. A, 1977, vol. 8, pp. 1275–82. https://doi.org/10.1007/BF02643842.

P. Lu, H. Li, H. Feng, Z. Jiang, H. Zhu, Z. Liu, and T. He: Metall. Mater. Trans. B, 2021, vol. 52, pp. 2210–23. https://doi.org/10.1007/s11663-021-02171-0.

F.L. Alcântara, R.A.N.M. Barbosa, and M.A. Cunha: ISIJ Int., 2013, vol. 53, pp. 1211–14. https://doi.org/10.2355/isijinternational.53.1211.

G. Schimmel, J. Sorina-Müller, B. Kempf, and M. Rettenmayr: Acta Mater., 2010, vol. 58, pp. 2091–2102. https://doi.org/10.1016/j.actamat.2009.11.051.

S. Guruswamy, S.M. Park, J.P. Hirth, and R.A. Rapp: Oxid. Met., 1986, vol. 26, pp. 77–100. https://doi.org/10.1007/BF00664274.

Y. Shen, J. Liu, H. Xu, and H. Liu: Metall. Mater. Trans. B, 2020, vol. 51, pp. 2963–75. https://doi.org/10.1007/s11663-020-01982-x.

P. Jimbert, T. Guraya, I. Kaltzakorta, T. Gutiérrez, R. Elvira, and L.T. Khajavi: J. Materi. Eng. Perform., 2022, vol. 31, pp. 2878–88. https://doi.org/10.1007/s11665-021-06418-4.

Y. Tomota, N. Sekido, S. Harjo, T. Kawasaki, W. Gong, and A. Taniyama: ISIJ Int., 2017, vol. 57, pp. 2237–44. https://doi.org/10.2355/isijinternational.ISIJINT-2017-272.

K.Y. Tsai, M.H. Tsai, and J.W. Yeh: Acta Mater., 2013, vol. 61, pp. 4887–97. https://doi.org/10.1016/j.actamat.2013.04.058.

X. Yang, C. Shi, M. Zhang, G. Chai, and F. Wang: Metall. Mater. Trans. B, 2011, vol. 42, pp. 1150–80. https://doi.org/10.1007/s11663-011-9547-9.

Z. Luo: Acta Cryst. B, 2021, vol. 77, pp. 772–84. https://doi.org/10.1107/S2052520621008027.

J. Toofan and P.R. Watson: Surf. Sci., 1998, vol. 401, pp. 162–72. https://doi.org/10.1016/S0039-6028(97)01031-5.

L. Yang and G. Cheng: Int. J. Miner. Metall. Mater., 2017, vol. 24, pp. 869–75. https://doi.org/10.1007/s12613-017-1472-8.

Z. Deng, Z. Liu, M. Zhu, and L. Huo: ISIJ Int., 2021, vol. 61, pp. 1–5. https://doi.org/10.2355/isijinternational.ISIJINT-2020-352.

H. Matsuno and Y. Kikuchi: Tetsu-to-Hagane, 2002, vol. 88, pp. 48–50. https://doi.org/10.2355/tetsutohagane1955.88.1_48.

A.M.E. Raj, L.C. Nehru, M. Jayachandran, and C. Sanjeeviraja: Cryst. Res. Tech., 2007, vol. 42, pp. 867–75. https://doi.org/10.1002/crat.200710918.

A.R. Oganov, M.J. Gillan, and G.D. Price: J. Chem. Phy., 2003, vol. 118, pp. 10174–82. https://doi.org/10.1063/1.1570394.

J.H. Park and H. Todoroki: ISIJ Int., 2010, vol. 50, pp. 1333–46. https://doi.org/10.2355/isijinternational.50.1333.

V. Brabie: Mechanism of reaction between refractory materials and aluminum deoxidized molten steel. ISIJ Int., 1996, vol. 36, pp. S109-112. https://doi.org/10.2355/isijinternational.36.Suppl_S109.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 52074199).

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, W., Zhu, H., Zhou, J. et al. Interaction Between Oxide Inclusions and Low-Density Steel During Heat Treatment. Metall Mater Trans B 53, 2991–3002 (2022). https://doi.org/10.1007/s11663-022-02580-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02580-9