Abstract

Several eucalyptus pulps (85% of cellulose) with different lignin and HexA content (unbleached, TCF and ECF) as well as cotton linters (97% of cellulose) were treated with ozone (at different pH and ozone doses) in order to modify its fibre-components. Special interest was given in the introduction of functional groups in carbohydrates. The presence of these groups was mainly identified by the chain scissions due to carbonyl groups (CSC=O) produced in cellulose during viscosity measurement. At a dose of 0.5% odp of ozone, the greatest amount of CSC=O (0.5) was created at acidic pH and with the ECF pulp, followed by the TCF (0.3) and by the unbleached (0.2). The same CSC=O (0.2) was obtained in cotton pulp. In this pulp, the ozone concentration had to be increased for the treatment to be effective. A further increase in the accessibility in both pulps was achieved by applying a washing stage between two ozone stages at 0.5% (0.5 + 0.5). With this treatment, the CSC=O was increased to 5.3 in the ECF, to 0.8 in the TCF and only to 0.3 in cotton. Brightness reversion and the amount of DNPH consumed were also used to verify the presence of functional groups. At 0.5 + 0.5, brightness reversion was increased from 16 to 55% in ECF, from 27 to 46% in TCF and from 7 to 31% in cotton. Therefore, it is shown that functional groups can be introduced by ozone in carbohydrates, but this effect strongly depends on the lignin, HexA and hemicellulose content.

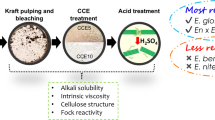

Graphical abstract

Similar content being viewed by others

Introduction

One of the greatest problems that society has to face is the ever-growing demand and use of fossil-based materials. These materials offer extremely versatile properties at a low market price. However, this low market price is attached to a high environmental cost. Finding biodegradable alternatives to the widespread fossil-based materials offers a solution that could reduce the negative effect we are having on the environment. In this sense, lignocellulosic biomass, one of the most abundant renewable resource on the planet could be a good candidate to provide these new biodegradable and sustainable biomaterials. As it is well known, the main components of lignocellulose (lignin, hemicelluloses and cellulose) can be separated and transformed to obtain new biomaterials, bioproducts and biofuels in the concept of a biorefinery.

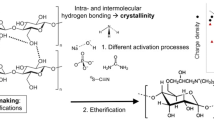

Due to the interesting chemical structure of cellulose, this natural polymer can be chemically, enzymatically or mechanically modified to obtain several bioproducts (Klemm et al. 2005). Hydroxyl groups at different points of the cellulose chain can be oxidized to carbonyl and carboxyl groups, depending on the type of oxidant used: the chemical oxidation with sodium periodate (NaIO4) at a low temperature creates mainly aldehyde groups at carbons 2 and 3 of the anhydroglucose units obtaining the cellulose dialdehyde (Calvini et al. 2006); the oxidative enzymatic system Laccase_Tempo (2,2,6,6-tetramethyl-1-piperidinyloxy) converts primary hydroxyl groups at carbon 6 to aldehyde or carboxyl forms (Aracri et al. 2011); lytic polysaccharide monooxygenases (LPMO), oxidatively cleave glycosidic linkages, leading to the formation of oxidized glucose units at different positions, resulting in the formation of aldonic acids at the carbon 1 position and/or 4-ketoaldoses (gemdiols) at the carbon 4 position (Ezeilo et al. 2017).

Ozone is a common agent used in pulp bleaching. In fact, this chemical is a good alternative for use as a bleaching agent in both, Totally Chlorine Free (TCF) and Elemental Chlorine Free (ECF) sequences. It is well known that during ozone treatment of pulp, carbonyl groups are introduced in cellulose chain (Roncero et al. 2003a; Pouyet et al. 2014). These groups induce cellulose degradation in alkaline conditions through β-elimination. It has been reported that ozone introduces ketone groups (Perrin et al. 2014) that are usually formed at carbon 2 and carbon 3 positions (Lemeune et al. 2004). Some studies also reported that the formation of these carbonyl groups can be increased by the presence of lignin or hexenuronic acids (HexA) due to the formation of hydroxyl radicals (Pouyet et al. 2014; Beheshti et al. 2017).

Recently, ozone has been used to improve cellulose functionalization. Some authors (Willberg-Keyriläinen et al. 2016, 2017) used ozone to decrease the molar mass of cellulose in order to functionalize cellulose with less chemical consumption. Other authors, combined ozone gas with UV light to oxidize the surface of cellulose (Gashti et al. 2013) or reported that ozonation facilitates the production of nanocellulose (Beheshti et al. 2017; Peretz et al. 2019). Nypelö et al. (2018) used ozone to oxidize a periodate oxidized film in order to convert aldehyde groups of one side of the film to carboxyl functionality. Several properties can be provided to cellulosic materials by introducing new functional groups, like paper wet strength (Aracri et al. 2011), or metal (Lei et al. 2020), dye (Batmaz et al. 2014) or enzyme (Vasconcelos et al. 2020) adsorption.

The main purpose of this work was to evaluate the ability of ozone as a green chemical agent to create new functional groups in carbohydrates. For this purpose, eucalyptus pulps with different content of lignin and HexA and also a raw material with high cellulose content (cotton linters) were used. Aldehyde and carboxyl groups were evaluated. The presence of carbonyl groups was evidenced by the chain scissions produced in cellulose during viscosity measurement, by an increase in pulp brightness reversion and also by the amount of reacted dinitrophenylhydrazine (DNPH). Several parameters of ozone treatment were analysed (like pH, ozone dose and ozone concentration) as well as the effects that the presence of lignin, hexenuronic acids (HexA), and hemicelluloses produced on the creation of these functional groups.

Materials and methods

Raw material

Three hardwood kraft pulps (one unbleached and two bleached) from Eucalyptus globulus with a xylan content around 15% (Beltramino et al. 2018) were used. The two bleached pulps were supplied by ENCE (Pontevedra, Spain). The Totally Chlorine Free (TCF) bleached pulp had a kappa number of 6.7, a brightness value of 78.1% ISO, 27.4 µmol g −1 of HexA, and the degree of polymerization (DP) was 2648. The ECF bleached pulp had a kappa number of 0.8, a brightness value of 83.5% ISO, 2.9 µmol g −1 of HexA, and the DP was 2260. The unbleached pulp, was oxygen-delignified and was supplied by the Torraspapel S.A mill (Zaragoza, Spain). This pulp had a kappa number of 10.2, a brightness value of 50.2%ISO, 48.3 µmol g −1 of HexA, and the DP was 3670.

Cotton linters used were obtained from the second cut and were supplied by CELESA (Celulosa de Levante S.A.), Tortosa, Spain. They had a brightness value of 87% ISO, and the DP was 2231. The xylan content was 2% ± 0.2 and the kappa number and the HexA content of this pulp were insignificant (Beltramino et al. 2018).

Ozone treatments

Ozone treatments were carried out using a system that allows the amount of ozone consumed to be known at all times. This system comprises an ozone generator, an ozone analyser, a flowmeter, a high-consistency reactor and a computer to control the equipment via a data acquisition card and a computer program. The ozone concentration is firstly measured at the input and once the reaction is started it measures the ozone concentration at the output (amount of ozone not reacting with the pulp) of the reactor. Therefore, the program calculates the amount of ozone that actually reacts with the pulp.

In eucalyptus pulps, ozone treatments were performed at a flow of 155 L h−1, with an ozone concentration of 30 mg L−1 at high consistency (40%). The pulp was fluffed before ozonation. With 0.12% oven-dried pulp (odp) of ozone dose, ozone treatments were performed at several pH: previous to ozonation, the pulp was treated at acidic (pH of 2.5), neutral (pH of 7) and alkaline (pH of 8 and 9) pHs. pH adjustment was performed at a consistency of 2.5% with H2SO4 or with NaOH during 15 min at room temperature. At acidic pH (2.5), several ozone doses were applied: 0.05, 0.12, 0.2, 0.5 and 1% odp. In order to increase ozone accessibility, the 1% dose was also applied with two consecutive ozone treatments at 0.5% with a pulp washing stage between the two ozone stages (0.5 + 0.5).

Ozone treatments in cotton linters were performed at a flow of 155 L h−1, with an ozone concentration of 30 or 50 mg L−1 at high consistency (40%). Ozone doses applied were 0.5% or 1% (applied with two stages 0.5 + 0.5).

After all the ozone treatments, the pulp was extensively washed.

Pulp properties

Kappa number and brightness were determined according to ISO 302 and ISO 5351/1, respectively. The former was measured in duplicate and the latter in quadruplicate. The hexenuronic acid (HexA) content was determined according to previous works (Chai et al. 2001; Zhu et al. 2014).

Degree of polymerization

Intrinsic viscosity (η) was determined according to ISO 5351:2010. The degree of polymerization was calculated from the intrinsic viscosity, using the equation of SCAN-CM15:88: DP0.85 = 1.1 · [η].

Carbonyl groups

The formation of carbonyl groups was indirectly assessed through viscosity measurements. Since viscosity measurements were conducted using alkaline Cuen solution, the carbonyl groups derived from ozone treatment may suffer β-elimination reactions, and the final viscosity results might be misunderstood (Godsay and Pearce 1984; Hosoya et al. 2018). This problem was avoided by treating the ozone-oxidized samples with 2% NaBH4 at 5% consistency at room temperature for 30 min in order to reduce carbonyl groups to hydroxyl groups. After this post-treatment, viscosity was determined again using Cuen solution. Recently, Zaccaron et al. (2022) have demonstrated that the DP measured in pulps reduced with borohydride provides similar values than the molar mass determined by gel permeation chromatography (GPC).

Pulp degradation was assessed via the number of scissions in the cellulose chain (CS), which is defined mathematically as (Lindholm 1990):

where DP0 is the degree of polymerization of the original pulp or previous stage and DP that at the end of the ozone treatment.

In pulp subjected to no borohydride post-treatment, CS is the combination of scissions caused by the oxidative treatment (CSZ) and the viscosity measurement procedure when carbonyl groups are present (CSC=O):

On the other hand, the CS value obtained after the reductive treatment (CSR) represents depolymerization exclusively due to the oxidative treatment, with exclusion of the contribution of β-elimination reactions occurring around carbonyl groups:

Subtracting Eq. (3) from Eq. (2) gives the number of chain scissions due to the presence of carbonyl groups (CSC=O):

Carbonyl groups were also evidenced by brightness reversion. Paper sheets before and after NaBH4 treatment were subjected to accelerated ageing by moist heating (80ºC, 65% RH) according to ISO 5630–3 in a Heraeus Vötsch HC 2020 climatic chamber for 144 h. Brightness reversion was determined according to Eq. 5:

where Br0 is the ISO brightness of the initial pulp and Brf that of pulp subjected to accelerated ageing.

Carbonyl group content was also assessed by using the UV-spectrophotometric method with 2,4-Dinitrophenylhydrazine (DNPH) in accordance with the method described in Tummalapalli and Gupta (2015) and Soni et al. (2022) but with some modifications. For DNPH preparation, 50 mg of DNPH was dissolved in concentrated sulfuric acid (2 mL) and the mixture was stirred to obtain a homogeneous solution. Ethanol (20 mL) was then added under continuous stirring at room temperature. The mixture was allowed to react for 10 min to achieve homogenization. The final volume was adjusted to 200 mL by adding water. In order to obtain a calibration curve, the prepared DNPH solution was diluted with water to different concentrations, and the absorbance at 362 nm was measured for each concentration using a spectrophotometer. The prepared DNPH solution was diluted to 31.25 mg/L; then, 5 mg of pulp samples were added to 5 mL of diluted DNPH, and the mixture was allowed to react for 72 h at room temperature. The absorbance was measured at 362 nm. This absorbance corresponded to the amount of non-reacted DNPH. The amount of reacted DNPH was obtained subtracting the concentration of non-reacted DNPH (mg/L) to the initial DNPH concentration (31.25 mg/L).

Aldehyde and carboxyl groups

Carboxyl groups were determined by measuring Methylene Blue adsorption onto cellulose fibres according to (Davidson 1948). To measure aldehyde groups samples were further oxidized with NaClO2 for selective conversion of aldehyde groups into carboxyl groups at room temperature for 48 h. The carboxyl content was determined with the above-described method. The carboxyl groups formed by effect of NaClO2 oxidation were assumed to derive from aldehyde groups originally present in the pulp. Three measures per sample were performed and the 95% confidence interval was calculated.

Results and discussion

Effect of pH during ozone treatments

Ozone has been widely studied in TCF bleaching of wood and non-wood pulps (Roncero et al. 2003b; Fillat et al. 2012) and also for paper decolorization (Valls et al. 2019). Although ozone produces high delignification rates, carbohydrates are also affected. The reason for the degradation of carbohydrates is generally held to be the presence of hydroxyl radicals (·OH) formed during the ozonation treatment (Eriksson and Gierer 1985; Ragnar et al. 1999). Koprivica et al., 2016 used alkaline medium during ozone treatment to regenerate spent periodate solutions since it favored the formation of free ºOH radicals. These radicals are more reactive and less selective for lignin than ozone, and therefore they produce a greater degradation of cellulose. Their formation can be enhanced by several parameters, like the pH, or the presence of lignin and HexA (Pouyet et al. 2014). Many studies demonstrate that pH has a considerable effect on ozone radical formation: the higher the pH, the greater the possibility of formation of hydroxyl radicals (Roncero et al. 2003b). They also stated that delignification and cromophore elimination was maximum at acidic pH. Moreover, ozone is 2.2 times more soluble at pH 2.5 than at pH 7 (Bouchard et al. 1995). For this reason, pulp bleaching with ozone is normally performed at acidic pH.

In order to produce several effects on carbohydrates, and therefore, functionalize fibres, ozone treatments were performed at different pH, since the functional groups are produced through the generated hydroxyl radicals. Two eucalyptus bleached kraft pulps (TCF and ECF) with low lignin content but with different HexA content were used. As previously reported (Beltramino et al. 2018), these pulps had similar carbohydrate composition (about 85% of glucan and 15% of xylan). However, as can be appreciated in Fig. 1, the TCF pulp contained higher amount of HexA. These compounds are not removed by those TCF sequences that only use oxygen or hydrogen peroxide since they are normally performed at alkaline conditions.

Before ozone treatment, pulps were submitted to acidic (pH 2.5), neutral (pH 7), and alkaline (pH 8 and 9) pretreatment stages at a consistency of 2.5% during 15 min at room temperature. As can be appreciated in Fig. 1, HexA were removed during the conditions of the acidic stage in both pulps, but not during the neutral and alkaline washing stages. This can be explained because the bonds between HexA groups and xylan chains are sensitive to acid hydrolysis and are not affected at neutral or alkaline conditions (Jaaskelainen and Poppius-Levlin 2000). Due to the higher HexA content of the TCF pulp a stronger effect was produced in this case during the acidic washing stage (73% of HexA removal vs. 47% in ECF). The ozonation stages (Z) were performed at a dose of 0.12%. During this stage, HexA were also only removed in the acidified pulps (around 70% of removal in both, TCF and ECF pulps), but not in the neutral and alkaline pulps. Therefore, if the pH of the pulp was not in acidic conditions, HexA were also not affected during the ozone stage.

Effects on carbohydrates can be evaluated by the chain scission (CS) produced during viscosity measurement. Since the amount of hemicelluloses in pulps is low with respect to the amount of cellulose, some authors have used this parameter to evaluate the degradation of cellulose produced by ozone (Roncero et al. 2002; Vrška et al. 2007). The CS of carbohydrates obtained by the viscosity measurement can be produced by the ozone direct degradation (CSZ) of them and by the presence of carbonyl groups, which produce cellulose β-degradation (CSC=O) under the alkaline conditions of the cuprietilenediamine solution. Roncero (2001) found a good relationship between the carbonyl content and the CSC=O. They also demonstrated that most groups formed during ozone treatment were ketone groups. It is well known that the presence of carbonyl groups in cellulose produces β-elimination at alkaline conditions. In fact, some authors have reported that this chain cleavage is more noticeable if carbonyl groups are present at C3 or C2 positions than if an oxidized group is present in C6 (Hosoya et al. 2018). Moreover, the severity of the degradation in cuprietilenediamine not only depends on the carbonyl content but also on the type of pulp and on the initial chain length (Ahn et al. 2019a). Roncero (2001) obtained improved DP results if viscosity measurements were performed after borohydride treatment. More recently, Zaccaron et al. (2022) showed that the DP during viscosity measurement after borohydride treatment correlated with the real molar mass determined by gel permeation chromatography (GPC) in the non-degrading solvent system DMAc/LiCl.

As can be appreciated in Fig. 2, the increase in pH promoted a greater CS in both, TCF and ECF pulps. The total CS value was similar in both pulps (around 0.35 at pH 2.5 and 0.7 at pH 9). However, some differences were appreciated between them. In the TCF pulp around 50% of the CS was produced by the presence of carbonyl groups. The CSC=O was around 0.2 at acidic pH and it increased to 0.3 at neutral and alkaline pH. The CSZ was around 0.2 up to pH 8, and then increased to 0.4 at pH 9. In the ECF pulp, a different effect in C = O formation was produced. At neutral and alkaline conditions ozone degraded basically cellulose whereas only a small formation of carbonyl groups was produced. These results are justified by the increased generation of radicals at alkaline pH that produce more cellulose degradation. Roncero et al. (2003b). reported that the rate constant of cellulose degradation is almost twice as high at pH 10 as at pH 2.5, indicating that cellulose degrades faster in an alkaline pH. Vrška et al. (2007) obtained that both, temperature and pH affected the progress of degradation reactions at the ozonation process. They also measured cellulose degradation according to CS but they obtained values lower than 0.35. At acidic pH, carbonyl groups were formed in a slightly higher amount than in the TCF pulp.

The main difference between the TCF and ECF pulps was the HexA content that before ozonation (after acidic washing stage) was 10 µmol g−1 odp in TCF and 1.5 µmol g−1 odp in ECF. Pouyet et al. (2014) reported that the presence of HexA increases the carbonyl formation of ozone, since HexA favours the formation of radicals. They also obtained that in a lignin and HexA free pulp only small amounts of carbonyl groups were created in cellulose. This fact doesn’t go in agreement with our results obtained at pH 2.5 in the ECF pulp. This pulp contains few amounts of lignin and HexA and carbonyl groups were formed in higher amounts than in TCF. Kishimoto and Nakatsubo (1998) claimed that under acidic pH, the oxidation of hydroxyl groups at C2, C3 and C6 positions into carbonyls was mainly caused by radical species. According to our results, higher amount of carbonyl groups were created in the TCF pulp at neutral and alkaline conditions.

Since the main goal of this work was to modify cellulose while keeping cellulose degradation at a minimum, it can be concluded from Fig. 2 that acidic pH seems to be the best choice. At this pH, more functional groups were created without the presence of HexA (in the ECF pulp).

Effect of the ozone dose at acidic pH

In order to diminish cellulose degradation and boost carbohydrate functionalization, an acidic pH was chosen for analyzing the effects produced by the ozone dose. Several ozone doses were tested: 0.05, 0.12, 0.2 and 0.5%.

Previous studies concluded that the presence of HexA affects the ozone oxidation of carbohydrates. Several authors have also reported this oxidation is also increased by the presence of lignin (Pouyet et al. 2014; Beheshti et al. 2017). Therefore, and in order to evaluate the effect produced by the presence of lignin and HexA in the eucalyptus pulp, an unbleached pulp was also used in this study. Results produced by unbleached and TCF were compared with the ECF (pulp with few lignin and HexA content).

Removal of lignin and HexA

Before analysing effects on carbohydrates, HexA and lignin removal was evaluated. As can be appreciated in Fig. 3a, the unbleached pulp had the highest HexA content. Small ozone doses (0.05%) produced around 50% of HexA elimination in all kinds of pulp (data not shown). This elimination was improved to around 70% at 0.12% of ozone. Higher doses of ozone produced only slight improvement in HexA elimination (77% at 0.5% of ozone). Interestingly, this behaviour was similar in the three kinds of pulp (unbleached, TCF and ECF). Thus, the initial HexA concentration or the presence of lignin did not affect to the effectivity of HexA removal by ozone. In fact, ozone reacts faster with HexA than with lignin (Ragnar 2001) and the oxidation and elimination of these groups takes place very early during the ozone stage (Pouyet et al. 2013).

HexA content (a), KN (b) and brightness (c) of unbleached, TCF and ECF pulps treated at several ozone doses (0.05, 0.12, 0.2, 0.5) and acidic pH. Confidence interval of KN and brightness properties were lower than 0.5 in all the cases. Values at 0% of ozone dose correspond to initial pulps after the pH washing stage at pH 2.5

As it is well known, HexA strongly contribute to the kappa number measurement (Vuorinen et al. 1996; Li and Gellerstedt 1997). Therefore, a diminution of kappa number will be produced by the removal of both, HexA and lignin. In unbleached pulp, the most significant diminution of kappa number was produced between 0 and 0.12% of ozone (from 10.6 to 4.6). A further increase of ozone dose until a dose of 0.2% also diminished kappa number to a value of 2, the same value that at a dose of 0.5%. In TCF pulp kappa number decreased from 3.4 to 0.8 at a dose of 0.12%. Due to the low kappa number, a further increase in the ozone dose did not produce more diminution. The ECF acidified pulp had a low kappa number value (0.8) that was reduced to 0.3 with all the ozone doses.

Brightness values go in accordance with kappa number. As expected, the most visible effect of this property was observed in the unbleached pulp due to the removal of both, HexA and lignin. Brightness was increased from 50 to 81% ISO. Unbleached pulp reached values of 10 µmol g−1 odp of HexA, a kappa number of 2 and 81% of ISO brightness at the highest ozone dose. Bleached pulps had high brightness values, 85% ISO in TCF and 88% ISO in ECF, and only slight improvements of this property were appreciated. In fact, in the ECF it increased to 93% ISO at 0.12% of ozone and then decreased to 92% ISO at higher doses.

Effects on carbohydrates

As can be appreciated in Fig. 4, during the ozone treatments, together with lignin and HexA removal, some effects were also produced in carbohydrates. A significant effect with the ozone dose was observed. Carbonyl groups were formed in all kinds of pulp at all the ozone doses tested. As previously obtained at acidic pH, the CSC=O was higher in ECF than in TCF pulp. As higher the ozone dose greater was also the CS produced. In the ECF pulp the CSC=O reached a value of 0.45 at 0.5% of ozone. This result was in agreement to that obtained by Roncero (2001) in a softwood ECF bleached kraft pulp. These authors obtained a CSC=O of 0.49 at a dose of 0.5% at a low consistence treatment of ozone. In the TCF pulp the highest CSC=O was 0.28. Concerning the cellulose degradation (CSZ), it was similar in TCF and ECF pulps.

In the unbleached pulp, the pulp with lignin and with the highest HexA content, a different behavior was appreciated. Concerning the CSC=O, it was similar or slightly lower than in TCF indicating the formation of small amounts of carbonyl groups that were also dependent on the ozone dose applied. However, a sudden increase in the CSZ was produced when ozone dose was raised to 0.2%, suggesting that high ozone doses produce great cellulose depolymerization. The CSZ at 0.5% was 0.9. Vrška et al. (2007) also obtained that CS increased with the ozone dose in oxygen delignified eucalyptus pulp. However, their CS values obtained were lower than 0.3 at 1% of ozone dose. The unbleached pulp used contains lignin and HexA. Therefore, ozone can react with both compounds, creating higher amounts of radicals. These radicals, which are very reactive species, will react close to where they were formed, i.e. with lignin and HexA. However, they may also degrade cellulose at acidic pH. Several authors stated that the presence of lignin or phenolic compounds generate hydroxyl radicals during ozonation. These radicals are needed to oxidize the cellulose surface (Kato et al. 1998; Ragnar et al. 1999; Lemeune et al. 2004; Beheshti et al. 2017).

CS results demonstrate the presence of carbonyl groups in the cellulose chain that may be an aldehyde group or a ketone group. When OH groups of cellulose are oxidized they can also be converted to carboxyl groups. Figure 5 shows the carboxyl and aldehyde content of the different pulps. As can be appreciated, the initial pulps did not almost contain aldehyde groups, and the highest amount of COOH groups was found in the TCF pulp. COOH groups were not significantly affected by the ozone treatment. On the other hand, aldehyde groups slightly increased with the ozone dose applied. Again, the highest amount of these groups was produced in the ECF pulp. Similar amounts of aldehyde and carboxyl groups were obtained by (Roncero 2001) in a softwood ECF pulp. These authors detected only small creation of aldehyde groups during ozone treatment, whereas the ketone groups produced were higher. Other authors have also reported that ozone introduces more ketone groups than aldehyde or carboxyl groups. These groups are usually formed at C2 and C3 positions (Lemeune et al. 2004; Perrin et al. 2014).

Therefore, results show that the highest amount of functional groups were created on the ECF pulp, the pulp that had the lowest amount of HexA and lignin. It can be stated that in this pulp, since there was no lignin or HexA to eliminate, ozone was more centered in attacking carbohydrates.

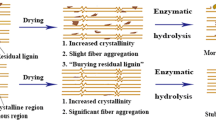

Increasing ozone accessibility

It has been demonstrated that functional groups can be introduced in bleached fibres treated with ozone. The next goal was to introduce more amount of carbonyl groups in order to increase the carbohydrate functionalization. For this reason, the ozone dose was increased to 1%. Unfortunately, at this dose, only 34% of the ozone injected reacted with the TCF pulp, lower to that at 0.5%, that was around 90% (Table 1). Thus, the 1% dose was applied in a different way: the pulp was washed between two ozonation stages of 0.5% (0.5% of ozone-washing stage-0.5% of ozone). With this treatment the ozone consumed was around 90% in both of the ozonation stages (0.5 + 0.5). In terms of KN, brightness and HexA, the effects produced with 1% dose were worse than at 0.5% (Table 1) whereas the effects produced with 0.5 + 0.5 were similar although KN was lower.

In accordance with the lower ozone consumed by the pulp, the effects on CS at 1% dose were smaller than with 0.5% (Fig. 6a). On the other hand, with two ozone stages (0.5 + 0.5) both, an increase in the carbonyl group formation and in cellulose degradation was produced. The CSC=O reached a value of 0.8, and the CSZ a value of 1.1. This fact can be explained by the higher accessibility of ozone after performing the first stage and washing the pulp.

The state of oxidation of carbohydrates can also be demonstrated by brightness reversion. Although several parameters affect brightness reversion like the presence of HexA (Granstrom et al. 2001; Sevastyanova et al. 2006; Cadena et al. 2010) or metals (Granstrom et al. 2002; Forsstrom et al. 2007), oxidized groups in carbohydrates like carbonyls and carboxyls have been recognized as the initiators of yellowing. Ahn et al. (2019a, b) reported that the carbonyl groups are the precursors for the chromophores that are formed later upon aging conditions. They state that chromophore formation increases strictly linearly with the carbonyl content at a constant given carboxyl content. Although carbonyl groups detected from viscosity measurement concern basically those groups created in cellulose, an increase in yellowing after ozone treatment may also reflect the state of oxidation of the hemicelluloses (xylans in eucalyptus pulp) and not exclusively that of cellulose.

The acidified TCF and ozone treated pulps at 0.5, 1, and 0.5 + 0.5% of ozone were subjected to aging conditions during 7 days (Fig. 6b). Brightness reversion of the acidified TCF pulp was 27%, probably due to the presence of HexA (7.5 µmol g−1 odp). A similar result was obtained by Cadena et al. (2010). The chromophoric compounds from HexA have been identified by Rosenau et al. (2017). After ozone treatment at 0.5 and 1%, brightness reversion was increased to 33 and 32%, respectively. Since HexA were reduced in these treatments, this increase in brightness reversion can be explained by the higher amounts of carbonyl groups. In accordance with the CSC=O produced in cellulose, the highest brightness reversion was produced with 0.5 + 0.5 treatment (46%). In order to corroborate that this brightness reversion was produced by the carbonyl groups created in carbohydrates, the paper sheets treated with NaBH4 treatment were also submitted to brightness reversion. NaBH4 reduces carbonyl groups to hydroxyl groups. As shown in Fig. 6, after this treatment brightness reversion was strongly diminished in all the ozone treated samples demonstrating again the presence of this carbonyl groups.

Since in the TCF pulp part of ozone was consumed in the oxidation of HexA, the same treatment 0.5 + 0.5 was performed in the ECF pulp. Similar than in TCF, the treatment with two ozone doses at 0.5% strongly increased the presence of carbonyl groups (Fig. 6c). The CSC=O increased from 0.45 at 0.5% dose to 5.3 at 0.5 + 0.5. CSZ also raised from 0.3 to 3.7. This was also translated into an increase in brightness reversion. Brightness reversion of initial acidified ECF pulp (16%) was lower than in TCF because of the lower amounts of HexA in this pulp (Fig. 6d). However, a considerable effect in brightness reversion was appreciated after ozone treatment at 0.5% and 0.5 + 0.5 since it was increased to 44% and 54%, respectively. This brightness reversion was reduced to 20 and 27% respectively, after NaBH4 treatment. It has to be noted that probably in this case not all the carbonyl groups were reduced with the borohydride treatment, for this reason brightness reversion slightly increased. Since the HexA content of these pulps was very low (around 0.3 µmol g−1 odp) pulp yellowing was mainly produced by the presence of carbonyl groups created during ozone treatments in cellulose or hemicelluloses.

Ozone oxidation to a high-cellulose content pulp

Once shown that carbonyl groups can be introduced to carbohydrates by ozone treatment in a eucalyptus pulp with few amounts of lignin and HexA, a raw material with high cellulose content (cotton linters) was also treated with ozone. Glucan percentage of cotton linters was 97.7 (Beltramino et al. 2018) whereas the xylan content was only 2%, lower than in eucalyptus that was 15%. Moreover, the amount of HexA was insignificant. When ozone was applied on this pulp in the same conditions than in the eucalyptus TCF and ECF pulps (0.5% of ozone at a concentration of 30 mg L−1), only 31% of the ozone injected reacted with the pulp, lower than in the ECF and TCF pulps that was around 90%. This fact corroborates that the reactivity of ozone with cellulose is low. In order to increase the ozone that reacted with the pulp, the concentration of ozone was raised to 50 mg L−1. The ozone that reacted with the pulp was now increased to 60% (Table 2). When this pulp was washed and another ozone treatment at 0.5% was applied (0.5 + 0.5) the ozone consumed was 100%. This fact can be explained since during the first ozone stage followed by pulp washing, more accessible zones of cellulose susceptible to be attacked by ozone were created. The real ozone dose consumed by cotton linters in each case is shown in Table 2. As higher was the ozone dose consumed by the pulp, greater were the CSC=O and CSZ produced in cellulose. The treatment that consumed 0.15% of ozone did not produce carbonyl groups in the pulp but a small cellulose degradation was produced. Carbonyl groups produced were increased at higher ozone doses, and at the ozone dose of 0.8%, CSC=O was 0.3. This value was lower than the CSC=O produced in the TCF and ECF eucalyptus pulps.

In cotton linters, the amount of CSZ was higher than the amount of CSC=O in all the ozone doses. In the TCF eucalyptus pulp, the values of CSZ and CSC=O were similar, whereas in the ECF pulp CSC=O were higher. The differences found in cotton linters and in TCF and ECF eucalyptus pulps, suggest that several factors affect the creation of functional groups in cellulose by ozone, like HexA or the hemicelluloses content. According to Pouyet et al. (2014), during the ozone treatment of pulp the carbonyl groups created on the carbohydrates may also be located on the xylans (by oxidation of the HexA), or at other places on the hemicelluloses. However, these authors, as well as Beheshti et al. (2017) state that carbonyl groups cannot be formed without the presence of HexA and lignin and this is not in agreement with the effects observed here in cotton linter pulps.

Brightness reversion also confirmed the creation of functional groups. Due to the low content of hemicelluloses in cotton linters, this brightness reversion can be attributed basically to the carbonyl groups formed in cellulose. Brightness reversion was very low (7%) in the initial pulp (Table 2). As can be appreciated, it was increased with the increase in CSC=O until a value of 31%. Although this value was lower than the brightness reversion obtained in the eucalyptus pulps (that were around 50%), it proves that some functional groups can also be created in cellulose without the presence of lignin and hexenuronic acids. Some authors state that reaction of ozone with cellulose leads to a minor oxidation reaction mostly at the C6 position (Kato et al. 1998; Lemeune et al. 2004).

The presence of carbonyl groups has been confirmed indirectly by CSC=O and by brightness reversion methods. In order to apply a direct method to verify the presence of these compounds, the DNPH method was used. The reaction of carbonyl compounds with DNPH forming the corresponding hydrazones is one of the most important qualitative methods in organic analysis. In 2015, Tummalapalli and Gupta (2015) developed a UV–Vis-based analytical technique to quantify the aldehyde content in periodate-oxidized polysaccharides. They used this method to analyse the aldehyde generation during periodate oxidation of pectin. More recently, Soni et al. (2022) used the same method to determine the oxidation of nanofibrillated cellulose with periodate. Then, initial pulps and oxidized samples of cotton, TCF and ECF pulps at 0.5 and 0.5 + 0.5% where analysed by this method. In Fig. 7 the amount of DNPH that reacted with the different samples is shown. This method is not as sensitive as some of the previous methods used to measure the carbonyl groups and does not determine the exact amount of them. In fact, carbonyl groups in cellulose can be present as hydrates and/or hemiacetals/hemiketals in addition to their free, double bonded form (Potthast et al. 2005). Therefore, it is difficult with some methods to exactly determine the real amounts of carbonyl groups. Potthast et al. (2005) state that by the method of fluorescence labelling, described in 2002 (Röhrling et al. 2002; Potthast et al. 2003), all these groups can be determined whereas with UV resonance Raman spectroscopy only the double bonded form is detected. This detection also depends on the drying state of the sample.

As can be appreciated in Fig. 7 the amount of DNPH that reacted with the pulp follow a logical trend that go in accordance with previous results. Initial pulps had a consumption about 11 and 16% of DNPH, that can be justified by a slight absorption by the pulp. In accordance with the low amount of CSC=O detected in cotton pulp at 0.5%, the DNPH consumed was not increased in this pulp. In eucalyptus TCF and ECF pulps at 0.5% the amount of DNPH consumed increased to 35 and 43%, respectively. This effect was increased until 44% in TCF and 50% in ECF at 0.5 + 0.5. In cotton pulp, the consumption at these conditions were around 33%. After borohydride treatment of the samples, the amount of reacted DNPH was strongly reduced, until similar levels to the initial pulps (data not shown). Therefore, a strong relationship was obtained between the DNPH consumed and the CSC=O of the samples verifying again the presence of carbonyl groups in the ozone treated samples.

Finally, it has been demonstrated that functional groups have been introduced to carbohydrates with ozone treatment. These ozone functionalized fibres could be applied in new advanced applications like dye or metal absorption (Batmaz et al. 2014), enzyme immobilization (Vasconcelos et al. 2020) or nanocellulose production (Peretz et al. 2019).

Conclusions

The creation of functional groups in carbohydrates during ozone treatment was identified by the chain scissions produced in cellulose due to the presence of carbonyl groups during viscosity measurements (CSC=O). The main effects were produced at acidic pH. In eucalyptus pulp (15% hemicelluloses) the formation of these groups was influenced by HexA and lignin: in the ECF pulp (low HexA content), the creation of these groups was the highest, followed by the TCF (pulp with high HexA) and unbleached (high HexA and lignin content) pulps. In cotton linter pulp (high cellulose content), the ozone concentration during the reaction was needed to be increased to 50 mg/L (30 mg/L in eucalyptus) to boost the ozone reaction with the pulp. Even so, lower effects than in eucalyptus pulps were achieved. In both, eucalyptus and cotton pulps, the ozone accessibility was increased by a washing stage between two ozone stages allowing to react 1% odp of ozone (0.5 + 0.5). Brightness reversion and the amount of DNPH that reacted with the pulp verified the creation of functional groups since they were increased in ozone treated pulps in accordance with CSC=O. Therefore, ozone treatment can introduce functional groups in carbohydrates making the treated-fibers able to be applied for new-advanced applications.

References

Ahn K, Zaccaron S, Rosenau T, Potthast A (2019a) How alkaline solvents in viscosity measurements affect data for oxidatively damaged celluloses: cupri-ethylenediamine. Biomacromol 20:4117–4125. https://doi.org/10.1021/acs.biomac.9b00956

Ahn K, Zaccaron S, Zwirchmayr NS et al (2019b) Yellowing and brightness reversion of celluloses: CO or COOH, who is the culprit? Cellulose 26:429–444. https://doi.org/10.1007/s10570-018-2200-x

Aracri E, Vidal T, Ragauskas AJ (2011) Wet strength development in sisal cellulose fibers by effect of a laccase–TEMPO treatment. Carbohydr Polym 84:1384–1390

Batmaz R, Mohammed N, Zaman M et al (2014) Cellulose nanocrystals as promising adsorbents for the removal of cationic dyes. Cellulose 21:1655–1665. https://doi.org/10.1007/s10570-014-0168-8

Beheshti Tabar I, Zhang X, Youngblood JP, Mosier NS (2017) Production of cellulose nanofibers using phenolic enhanced surface oxidation. Carbohydr Polym 174:120–127. https://doi.org/10.1016/j.carbpol.2017.06.058

Beltramino F, Roncero MB, Vidal T, Valls C (2018) Facilitating the selection of raw materials: evaluation of the effects of TCF and ECF bleaching sequences on different wood and non-wood pulps. Afinidad 75:91–96

Bouchard J, Nugent HM, Berry RM (1995) The role of water and hydrogen ion concentration in ozone bleaching of kraft pulp at medium consistency. Tappi J 78(1):74–82

Cadena EM, Vidal T, Torres AL (2010) Influence of the hexenuronic acid content on refining and ageing in eucalyptus TCF pulp. Bioresour Technol 101:3554–3560. https://doi.org/10.1016/j.biortech.2009.11.105

Calvini P, Conio G, Princi E et al (2006) Viscometric determination of dialdehyde content in periodate oxycellulose Part II. Topochem Oxid Cellul 13:571–579. https://doi.org/10.1007/s10570-005-9035-y

Chai XS, Zhu JY, Li J (2001) A simple and rapid method to determine hexeneuronic acid groups in chemical pulps. J Pulp Pap Sci 27:165–170

Davidson GF (1948) 6—the acidic properties of cotton cellulose and derived oxycelluloses. Part II. The absorption of methylene blue. J Text Inst Trans 39:T65–T86. https://doi.org/10.1080/19447024808659403

Eriksson G, Gierer J (1985) Studies on the ozonation of structural elements in residual kraft lignins. J Wood Chem Technol 5:53–84

Ezeilo UR, Zakaria II, Huyop F, Wahab RA (2017) Enzymatic breakdown of lignocellulosic biomass: the role of glycosyl hydrolases and lytic polysaccharide monooxygenases. Biotechnol Biotechnol Equip 31:647–662. https://doi.org/10.1080/13102818.2017.1330124

Fillat U, Roncero MB, Sacón VM, Bassa A (2012) Integrating a xylanase treatment into an industrial-type sequence for eucalyptus kraft pulp bleaching. Ind Eng Chem Res 51:2830–2837

Forsstrom A, Wackerberg E, Greschik T et al (2007) Alta estabilidade de alvura em sequencias ECF padrao; high brightness stability in standard ECF sequences. O Pap 68:101–112

Gashti MP, Pournaserani A, Ehsani H, Gashti MP (2013) Surface oxidation of cellulose by ozone-gas in a vacuum cylinder to improve the functionality of fluoromonomer. Vacuum 91:7–13. https://doi.org/10.1016/j.vacuum.2012.10.015

Godsay MP, Pearce EM (1984) Physico-chemical properties of ozone oxidized kraft pulps Title. Oxyg Delignification Tappi Symp San Fr 55–70

Granstrom A, Eriksson T, Gellerstedt G et al (2001) Variables affecting the thermal yellowing of TCF-bleached birch kraft pulps. Nord Pulp Pap Res J 16:18–23

Granstrom A, Gellerstedt G, Eriksson T (2002) On the chemical processes occurring during thermal yellowing of a TCF-bleached birch kraft pulp. Nord Pulp Pap Res J 17:427–433

Hosoya T, Bacher M, Potthast A et al (2018) Insights into degradation pathways of oxidized anhydroglucose units in cellulose by β-alkoxy-elimination: a combined theoretical and experimental approach. Cellulose 25:3797–3814. https://doi.org/10.1007/s10570-018-1835-y

Jaaskelainen A-S, Poppius-Levlin K (2000) Kinetics of delignification and hexenuronic acid decomposition during kraft pulp bleaching with peroxyacetic acid. Nord Pulp Pap Res J 15:142–148

Kato K, Vasilets VN, Fursa MN et al (1998) Surface oxidation of cellulose fibers. J Polym Sci Part A 37:357–361

Kishimoto T, Nakatsubo F (1998) Non-chlorine bleaching of kraft pulp. V. Participation of radical species in ozonation of methyl 4-O-ethyl-β-D-glucopyranoside. Holzforschung 52:185–190. https://doi.org/10.1515/hfsg.1998.52.2.185

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem 44:3358–3393. https://doi.org/10.1002/anie.200460587

Koprivica S, Siller M, Hosoya T et al (2016) Regeneration of aqueous periodate solutions by ozone treatment: a sustainable approach for dialdehyde cellulose production. Chemsuschem 9:825–833. https://doi.org/10.1002/cssc.201501639

Lei Z, Gao W, Zeng J et al (2020) The mechanism of Cu (II) adsorption onto 2,3-dialdehyde nano-fibrillated celluloses. Carbohydr Polym 230:115631. https://doi.org/10.1016/j.carbpol.2019.115631

Lemeune S, Jameel H, Chang HM, Kadla JF (2004) Effects of ozone and chlorine dioxide on the chemical properties of cellulose fibers. J Appl Polym Sci 93:1219–1223. https://doi.org/10.1002/app.20509

Li J, Gellerstedt G (1997) The contribution to kappa number from hexeneuronic acid groups in pulp xylan. Carbohydr Res 302:213–218. https://doi.org/10.1016/S0008-6215(97)00125-0

Lindholm CA (1990) Effect of dissolved reaction products on pulp viscosity in low consistency ozone bleaching. Pap Ja Puu/paper Timber 72:254–256

Nypelö T, Amer H, Konnerth J et al (2018) Self-standing nanocellulose janus-type films with aldehyde and carboxyl functionalities. Biomacromol 19:973–979. https://doi.org/10.1021/acs.biomac.7b01751

Peretz R, Sterenzon E, Gerchman Y et al (2019) Nanocellulose production from recycled paper mill sludge using ozonation pretreatment followed by recyclable maleic acid hydrolysis. Carbohydr Polym 216:343–351. https://doi.org/10.1016/j.carbpol.2019.04.003

Perrin J, Pouyet F, Chirat C, Lachenal D (2014) Cellulosic pulps: effect on alkali resistance. BioResources 9:7299–7310

Potthast A, Röhrling J, Rosenau T et al (2003) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labelling. 3. Monit Oxid Process Biomacromol 4:743–749. https://doi.org/10.1021/bm025759c

Potthast A, Rosenau T, Kosma P et al (2005) On the nature of carbonyl groups in cellulosic pulps. Cellulose 12:43–50. https://doi.org/10.1023/B:CELL.0000049347.01147.3d

Pouyet F, Lachenal D, Das S, Chirat C (2013) Minimizing viscosity loss during totally chlorine-free bleaching of hardwood kraft pulp. BioResources 8:238–249

Pouyet F, Chirat C, Potthast A, Lachenal D (2014) Formation of carbonyl groups on cellulose during ozone treatment of pulp: consequences for pulp bleaching. Carbohydr Polym 109:85–91. https://doi.org/10.1016/j.carbpol.2014.02.082

Ragnar M (2001) On the importance of the structural composition of pulp for the selectivity of ozone and chlorine dioxide bleaching. Nord Pulp Pap Res J 16:72–79. https://doi.org/10.3183/npprj-2001-16-01-p072-079

Ragnar M, Eriksson T, Reitberger T (1999) Radical formation in ozone reactions with lignin and carbohydrate model compounds. Holzforschung 53:292–298. https://doi.org/10.1515/HF.1999.049

Röhrling J, Potthast A, Rosenau T et al (2002) A novel method for the determination of carbonyl groups in cellulosics by fluorescence labeling. 2. Valid Appl Biomacromol 3:969–975. https://doi.org/10.1021/bm025759c

Roncero MB (2001) Obtención de una secuencia “TCF” con la aplicación de ozono y enzimas, para el blanqueo de pastas madereras y de origen agrícola. Optimización de la etapa Z. Análisis de los efectos en la fibra celulósica y sus componentes. PhD Dissertation. Universitat Politècnica de Catalunya. Terrassa, Spain

Roncero MB, Colom JF, Vidal T (2002) Application of post-treatments to the ozone bleaching of eucalypt kraft pulp to increase the selectivity. Part A. Appita J 55:305–309

Roncero MB, Colom JF, Vidal T (2003a) Cellulose protection during ozone treatments of oxygen delignified Eucalyptus kraft pulp. Carbohydr Polym 51:243–254

Roncero MB, Colom JF, Vidal T, Queral MA (2003b) Why acid pH increases the selectivity of the ozone bleaching processes. Ozone Sci Eng 25:523–534

Rosenau T, Potthast A, Zwirchmayr NS et al (2017) Chromophores from hexeneuronic acids: identification of HexA-derived chromophores. Cellulose 24:3671–3687. https://doi.org/10.1007/s10570-017-1397-4

Sevastyanova O, Li J, Gellerstedt G (2006) Influence of various oxidizable structures on the brightness stability of fully bleached chemical pulps. Nord Pulp Pap Res J 21:49–53

Soni R, Asoh TA, Hsu YI, Uyama H (2022) Freshwater-durable and marine-degradable cellulose nanofiber reinforced starch film. Cellulose 29:1667–1678. https://doi.org/10.1007/s10570-021-04410-8

Tummalapalli M, Gupta B (2015) A UV-Vis spectrophotometric method for the estimation of aldehyde groups in periodate-oxidized polysaccharides using 2,4-dinitrophenyl hydrazine. J Carbohydr Chem 34:338–348. https://doi.org/10.1080/07328303.2015.1068793

Valls C, Cusola O, Vidal T et al (2019) A straightforward bioprocess for a cleaner paper decolorization. J Clean Prod 236:117702. https://doi.org/10.1016/j.jclepro.2019.117702

Vasconcelos NF, Andrade FK, de Vieira L et al (2020) Oxidized bacterial cellulose membrane as support for enzyme immobilization: properties and morphological features. Cellulose 27:3055–3083. https://doi.org/10.1007/s10570-020-02966-5

Vrška M, Jablonský M, Tiňo R, Svetozár K (2007) Effect of pH and temperature on cellulose chain scission number in ozonization of oxygen delignified hardwood kraft pulp. Wood Res 52:49–56

Vuorinen T, Teleman A, Fagerström P, et al (1996) Selective hydrolysis of hexenuronic acid groups and its application in ECF and TCF bleaching of kraft pulps. Int Pulp Bleach Conf 43–51

Willberg-Keyriläinen P, Talja R, Asikainen S et al (2016) The effect of cellulose molar mass on the properties of palmitate esters. Carbohydr Polym 151:988–995. https://doi.org/10.1016/j.carbpol.2016.06.048

Willberg-Keyriläinen P, Vartiainen J, Harlin A, Ropponen J (2017) The effect of side-chain length of cellulose fatty acid esters on their thermal, barrier and mechanical properties. Cellulose 24:505–517. https://doi.org/10.1007/s10570-016-1165-x

Zaccaron S, Ahn K, Henniges U et al (2022) An improved, less erroneous protocol for the classical “cuen”, “cuoxam” or “cadoxen” viscosity measurements of pulps. Cellulose 29:3733–3744. https://doi.org/10.1007/s10570-022-04505-w

Zhu Y, Zhou H, Chai X et al (2014) Inter-laboratory comparisons of hexenuronic acid measurements in kraft eucalyptus pulps using a UV-Vis spectroscopic method. TAPPI J 13:57–61

Acknowledgments

This publication is part of the PID2020-114070RB-I00 (CELLECOPROD) project, funded by MCIN/AEI/10.13039/501100011033. Authors are grateful to Torraspapel S.A. (Zaragoza, Spain), ENCE (Pontevedra, Spain) and CELESA (Tortosa, Spain) for supplying the pulp used. Special thanks are also due to the Serra Hunter Fellow to Oriol Cusola.

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work was supported by the PID2020-114070RB-I00 (CELLECOPROD) project, funded by MCIN/AEI/10.13039/501100011033 and by the Serra Hunter Fellow to Oriol Cusola.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by CV and OC. The first draft of the manuscript was written by CV and MBR, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Valls, C., Cusola, O. & Roncero, M.B. Evaluating the potential of ozone in creating functional groups on cellulose. Cellulose 29, 6595–6610 (2022). https://doi.org/10.1007/s10570-022-04694-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04694-4