Abstract

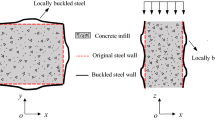

It has been found that the fatigue life of tubular joints is not only determined by the hot spot stress, but also by the stress distribution through the tube thickness represented as the degree of bending (DoB). Consequently, the DoB value should be determined to improve the accuracy of fatigue assessment for both stress-life curve and fracture mechanics methods. Currently, no DoB parametric formula is available for concrete-filled rectangular hollow section (CFRHS) K-joints, despite their wide use in bridge engineering. Therefore, a robust finite element (FE) analysis was carried out to calculate the DoB of CFRHS K-joints under balanced-axial loading. The FE model was developed and verified against a test result to ensure accuracy. A comprehensive parametric study including 190 models, was conducted to establish the relationships between the DoBs and four specific variables. Based on the numerical results, design equations to predict DoBs for CFRHS K-joints were proposed through multiple regression analysis. A reduction of 37.17% was discovered in the DoB, resulting in a decrease of 66.85% in the fatigue life. Inclusively, the CFRHS K-joints with same hot spot stresses, may have completely different fatigue lives due to the different DoBs.

Similar content being viewed by others

References

Han L H, Li W, Bjorhovde R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. Journal of Constructional Steel Research, 2014, 100: 211–228

Huang H H, Chen K M, Wu Q X, Wang Q. Study on fatigue cracking of joint in a half-through CFST truss arch rib joint. Engineering Mechanics, 2017, 34: 167–173

Xu F, Chen J, Jin W L. Experimental investigation of SCF distribution for thin-walled concrete-filled CHS joints under the axial tension loading. Thin-walled Structures, 2015, 93: 149–157

Tong L W, Chen K P, Xu G W, Zhao X L. Formulae for hot-spot stress concentration factors of concrete-filled CHS T-joints based on experiments and FE analysis. Thin-walled Structures, 2019, 136: 113–128

Zheng J, Nakamura S, Okumatsu T, Nishikawa T. Formulation of stress concentration factors for concrete-filled steel tubular (CFST) K-joints under the three loading conditions without shear forces. Engineering Structures, 2019, 190: 90–100

Musa I A, Mashiri F R, Zhu X Q, Tong L. Experimental stress concentration factor in concrete-filled steel tubular T-joints. Journal of Constructional Steel Research, 2018, 150: 442–451

Kim I G, Chung C H, Shim C S, Kim Y J. Stress concentration factors of N-joints of concrete-filled tubes subjected to axial loads. International Journal of Steel Structures, 2014, 14(1): 1–11

Jiang L, Liu Y J, Fam A. Stress concentration factors in joints of square hollow section (SHS) brace and concrete-filled SHS chord under axial tension in brace. Thin-walled Structures, 2018, 132: 79–92

Jiang L, Liu Y J, Fam A. Stress concentration factors in concrete-filled square hollow section joints with perfobond ribs. Engineering Structures, 2019, 181: 165–180

Jiang L, Liu Y J, Fam A, Liu J, Liu B. Stress concentration factor parametric formulae for concrete-filled rectangular hollow section K-joints with perfobond ribs. Journal of Constructional Steel Research, 2019, 160: 579–597

Jiang L, Liu Y, Liu J, Liu B. Experimental and numerical analysis on the SCF of concrete-filled square hollow section Y-joints stiffened with perfobond ribs. Advances in Structural Engineering, 2020, 23(5): 869–883

Jiang L, Liu Y J, Fam A, Liu B, Long X. Fatigue behavior of integral built-up box Y-joints between concrete-filled chords with perfobond ribs and hollow brace. Journal of Structural Engineering, 2020, 146(3): 04019218

Jiang L, Liu Y J, Fam A, Wang K. Fatigue behavior of nonintegral Y-joint of concrete-filled rectangular hollow section continuous chord stiffened with perfobond ribs. Engineering Structures, 2019, 191: 611–624

Li W, Cheng Y F, Wang D, Han L H, Zhao X L. Behavior of high-strength CFDST chord to CHS brace T-joint: Experiment. Engineering Structures, 2020, 219: 110780

Connolly M P M. A fracture mechanics approach to the fatigue assessment of tubular welded Y and K joints. Dissertation for the Doctoral Degree. London: University College London (University of London), 1987

Shen W, Choo Y S. Stress intensity factor for a tubular T-joint with grouted chord. Engineering Structures, 2012, 35: 37–47

Wei X, Wen Z, Xiao L, Wu C. Review of fatigue assessment approaches for tubular joints in CFST trusses. International Journal of Fatigue, 2018, 113: 43–53

Qian X, Jitpairod K, Marshall P, Swaddiwudhipong S, Ou Z, Zhang Y, Pradana M R. Fatigue and residual strength of concrete-filled tubular X-joints with full capacity welds. Journal of Constructional Steel Research, 2014, 100: 21–35

Chang E, Dover W D. Prediction of degree of bending in tubular X and DT joints. International Journal of Fatigue, 1999, 21(2): 147–161

Lee M M K, Bowness D. Estimation of stress intensity factor solutions for weld toe cracks in offshore tubular joints. International Journal of Fatigue, 2002, 24(8): 861–875

Berge S, Haswell J, Engesvik K. Fracture mechanics analysis of tubular joint tests degree of bending effects. In: International Conference on Offshore Mechanics and Arctic Engineering (OMAE-13). Houston: American Society of Mechanical Engineers, 1994

Ahmadi H, Lotfollahi-Yaghin M A, Asoodeh S. Degree of bending (DoB) in tubular K-joints of offshore structures subjected to inplane bending (IPB) loads: Study of geometrical effects and parametric formulation. Ocean Engineering, 2015, 102: 105–116

Ahmadi H, Asoodeh S. Parametric study of geometrical effects on the degree of bending (DoB) in offshore tubular K-joints under out-of-plane bending loads. Applied Ocean Research, 2016, 58: 1–10

Ahmadi H, Zavvar E. Degree of bending (DoB) in offshore tubular KT-joints under the axial, in-plane bending (IPB), and out-of-plane bending (OPB) loads. Applied Ocean Research, 2020, 95: 102015

Nie F, Zhang Q, Qin X, Sun Y. Degrees of bending (DoBs) in buldge formed K-joints under balanced axial loads. Ocean Engineering, 2018, 166: 358–369

GB/T 228.1-2010. Metallic Materials-Tensile Testing-Part 1: Method of Test at Room Temperature. Beijing: General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, 2010 (in Chinese)

JTG D64-2015. Specifications for Design of Highway Steel Bridge. Beijing: General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, 2015 (in Chinese)

GB/T 50081-2002. Standard for Test Method of Mechanical Properties on Ordinary Concrete. Beijing: General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, 2002 (in Chinese)

JTG 3360-2018. Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts. Beijing: General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, 2018 (in Chinese)

GB 50661-2011. Chinese Standard the Welding Code for Steel Structure. Beijing: China Building Industry Press, 2018 (in Chinese)

XV-582-85. Recommended Fatigue Design Procedure for Welded Hollow Section Joints, Part 1 Hot Spot Stress Method for Nodal Joints. Strasburg: IIW Subcommission XV-E, 1985.

Ma Y, Liu Y, Wang K, Liu J, Zhang Z. Axial stiffness of concrete filled rectangular steel tubular (CFRST) truss joints. Journal of Constructional Steel Research, 2021, 184: 106820

Ma Y, Liu Y, Ma T, Zafimandimby M N H. Flexural stiffness of rectangular hollow section (RHS) trusses. Engineering Structures, 2021, 239: 112336

Morgan M R, Lee M M K. Prediction of stress concentrations and degrees of bending in axially loaded tubular K-Joints. Journal of Constructional Steel Research, 1998, 45(1): 67–97

Shao Y B, Lie S. Parametric equation of stress intehsity factor for tubular K-joint under balanced axial loads. International Journal of Fatigue, 2005, 27(6): 666–679

UK Department of Energy (DoE). Background Notes to the Fatigue Guidance of Offshore Tubular Joints. London: UK Department of Energy, 1983

Paris P, Erdogan F. A critical analysis of crack propagation laws. Journal of Basic Engineering, 1963, 85(4): 528–533

Aaghaakouchak A, Glinka G, Dharmavasan S. A load shedding model for fracture mechanics analysis of fatigue cracks in tubular joints. In: The 8th International Conference on Offshore Mechanics And Arctic Engineering. The Hague: British Maritime Technology, 1989

Acknowledgements

This research was sponsored by the Fundamental Research Funds for the Central Universities, CHD (No. 300102211303) and the Scientific Innovation Practice Project of Postgraduates of Chang’an University (No. 300103714019).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, R., Liu, Y., Jiang, L. et al. Degree of bending of concrete-filled rectangular hollow section K-joints under balanced-axial loadings. Front. Struct. Civ. Eng. 16, 461–477 (2022). https://doi.org/10.1007/s11709-022-0818-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-022-0818-0