Abstract

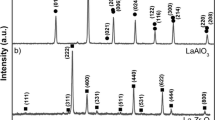

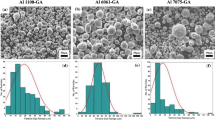

Aluminum nitride (AlN) coatings have been considered for corrosion-resistant materials applicable to the aluminum (Al) industry where the AlN comes in direct contact with molten Al above 933 K. AlN coatings were synthesized by suspension plasma spray (SPS) technology using Al powder mixed with melamine suspended in hexadecane. The use of fine Al (1-5 µm) particles did not yield more than 10% AlN in the coatings. Mixing the Al powder with promotional additives such as B, BN, Mo, Y2O3, AlN, or Al4C3 solves the fine particle agglomeration and stimulates the formation of AlN in the coatings which enhances their corrosion resistance. The optimum amount of AlN promoter was 0.22 wt.% of the total suspension mass, producing up to 72% AlN in the coating as determined by Rietveld quantitative analysis (RQA) using x-ray diffraction (XRD). Another way to improve the AlN formation in the coating by post-deposition nitridation and also solve fine Al particle agglomeration is to use a wide particle size distribution of Al, with the optimum ratio being 3:1, that is, (1-5 µm):(17-35 µm). XRD analysis indicated that the coating exhibited up to 80% AlN. The coatings Vickers hardness is related to their AlN content reaching 1644 Hv (80% AlN). The coatings were tested for corrosion resistance by direct contact with molten Al-5 wt.%Mg alloy at 1123 K and found to be stable. Ab initio Born–Oppenheimer molecular dynamics (BOMD) simulation predicted these experimental results. Indeed at 1200 K, molten Al and AlN exhibit weak van der Waals interactions. The AlN(s)-Al(l) interfacial energy was calculated to be 18.2 kJ mol−1 for hexagonal AlN phase and 56.4 kJ mol−1 for cubic AlN, which means that it lies within the physisorption regime, and therefore, no reaction occurs between Al(l) and AlN(s) which confirms non-wetting application in the Al industry.

Similar content being viewed by others

References

M.P. Thompson, G.W. Auner, T.S. Zheleva, K.A. Jones, S.J. Simko and J.N. Hilfiker, Deposition Factors and Band Gap of Zinc-Blende AIN, J. Appl. Phys., 2001, 89(6), p 3331-3336

M. Yamada, H. Nakamura, T. Yasui, M. Fukumoto and K. Takahashi, Influence of Substrate Materials upon Fabrication of Aluminum Nitride Coatings by Reactive RF Plasma Spraying, Mater. Trans., 2006, 47(7), p 1671-1676. https://doi.org/10.2320/matertrans.47.1671

S.M. Oh and D.W. Park, Preparation of AlN Fine Powder by Thermal Plasma Processing, Thin Solid Films, 1998, 316(1-2), p 189-194

M.-C. Sung, Y.-M. Kuo, L.-T. Hsieh and C.-H. Tsai, Two-Stage Plasma Nitridation Approach for Rapidly Synthesizing Aluminum Nitride Powders, J. Mater. Res., 2017, 32(07), p 1279-1286. https://doi.org/10.1557/jmr.2016.505

K. Kim, Plasma Synthesis and Characterization of Nanocrystalline Aluminum Nitride Particles by Aluminum Plasma Jet Discharge, J. Cryst. Growth, 2005, 283(3-4), p 540-546

B. Li, B. Wen, H. Chen, W. Zhang, X. Meng, M. Jia and F. Chen, Corrosion Behaviour and Related Mechanism of Lithium Vapour on Aluminium Nitride Ceramic, Corros. Sci., 2021, 178, p 109058. https://doi.org/10.1016/j.corsci.2020.109058

S. Pradhan, S.K. Jena, S.C. Patnaik, P.K. Swain and J. Majhi, Wear Characteristics of Al-AlN Composites Produced in Situ by Nitrogenation, IOP Conf. Ser. Mater. Sci. Eng., 2015, 75(1), p 012034

P. Fauchais and A. Vardelle, Solution and Suspension Plasma Spraying of Nanostructure Coatings, Advanced Plasma Spray Applications. H.S. Jazi Ed., BoD—Books on Demand, Norderstedt, 2012, p 149-188

J. Cao, Y. Liu and X.S. Ning, Influence of AlN(0001) Surface Reconstructions on the Wettability of an Al/AlN System: A First-Principle Study, Materials (Basel), 2018, 11(5), p 1-10

N.Y. Taranets and Y.V. Naidich, Wettability of Aluminum Nitride by Molten Metals, Powder Metall. Met. Ceram., 1996, 35, p 282-285. https://doi.org/10.1007/BF01328834

T.B. Jackson, A.V. Virkar, K.L. More, R.B. Dinwiddie and R.A. Cutler, High-Thermal-Conductivity Aluminum Nitride Ceramics: The Effect of Thermodynamic, Kinetic, and Microstructural Factors, J. Am. Ceram. Soc., 1997, 80(6), p 1421-1435

X.-X. Mao, J. Li, H.-L. Zhang, Y.-G. Xu and S.-W. Wang, Synthesis of AlN Powder by Carbothermal Reduction-Nitridation of Alumina/Carbon Black Foam, J. Ceram. Soc. Jpn., 2017, 32(10), p 377-382

A.C. Da Cruz and R.J. Munz, Review on the Vapour-Phase Synthesis of Aluminum Nitride Powder Using Thermal Plasmas, KONA Powder Part. J., 1999, 17, p 85-94

T.-H. Kim, S. Choi and D.-W. Park, Effects of NH3 Flow Rate on the Thermal Plasma Synthesis of AlN Nanoparticles, J. Korean Phys. Soc., 2013, 63(10), p 1864-1870. https://doi.org/10.3938/jkps.63.1864

J. Ahn, Y. Kim, J. Lee and D. Kim, Synthesis of AlN Particles by Chemical Route for Theral Interface Material, Adv. Mater. Lett., 2017, 8(9), p 939-943. https://doi.org/10.5185/amlett.2017.1666

J. Ahn, D. Kim, Y. Kim and J. Lee, Synthesis of AlN Particles by Microwave-Assisted Urea Route, Appl. Mech. Mater., 2016, 851, p 191-195. https://doi.org/10.4028/www.scientific.net/AMM.851.191

K. Sardar and C.N.R. Rao, AlN Nanocrystals by New Chemical Routes, Solid State Sci., 2005, 7(2), p 217-220

C. Grigoriu, M. Hirai, K. Nishiura, W. Jiang and K. Yatsui, Synthesis of Nanosized Aluminum Nitride Powders by Pulsed Laser Ablation, J. Am. Ceram. Soc., 2000, 83(10), p 2631-2633. https://doi.org/10.1111/j.1151-2916.2000.tb01604.x

S.A. Rounaghi, D.E.P. Vanpoucke, H. Eshghi, S. Scudino, E. Esmaeili, S. Oswald and J. Eckert, A Combined Experimental and Theoretical Investigation of the Al-Melamine Reactive Milling System: A Mechanistic Study towards AlN-Based Ceramics, J. Alloys Compd., 2017, 729, p 240-248. https://doi.org/10.1016/j.jallcom.2017.09.168

J. Zheng, Y. Yang, B. Yu, X. Song and X. Li, [0001] Oriented Aluminum Nitride One-Dimensional Nanostructures: Synthesis, Structure Evolution, and Electrical Properties, ACS Nano, 2008, 2(1), p 134-142

D. Chen, J. Colas, F. Mercier, R. Boichot, L. Charpentier, C. Escape, M. Balat-Pichelin and M. Pons, High Temperature Properties of AlN Coatings Deposited by Chemical Vapor Deposition for Solar Central Receivers, Surf. Coat. Technol., 2019, 377(July), p 124872. https://doi.org/10.1016/j.surfcoat.2019.07.083

M. Iwata, K. Adachi, S. Furukawa and T. Amakawa, Synthesis of Purified AlN Nano Powder by Transferred Type Arc Plasma, J. Phys. D Appl. Phys., 2004, 37(7), p 1041-1047

R.K. Choudhary, P. Mishra and R.C. Hubli, Optical Properties of Cubic AlN Films Grown by Sputtering, Surf. Eng., 2016, 32(4), p 304-306

A. Metel, S. Grigoriev, M. Volosova, Y. Melnik and E. Mustafaev, Synthesis of Aluminum Nitride Coatings Assisted by Fast Argon Atoms in a Magnetron Sputtering System with a Separate Input of Argon and Nitrogen, Surf. Coat. Technol., 2020, 398(April), p 126078. https://doi.org/10.1016/j.surfcoat.2020.126078

M.M. Mazur, S.A. Pianaro, K.F. Portella, P. Mengarda, M.D.O.G.P. Bragança, S. Ribeiro Junior, J.S. Santos de Melo and D.P. Cerqueira, Deposition and Characterization of AlN Thin Films on Ceramic Electric Insulators Using Pulsed DC Magnetron Sputtering, Surf. Coat. Technol., 2015, 284, p 247-251. https://doi.org/10.1016/j.surfcoat.2015.06.082

I. Musa, N. Qamhieh, K. Said, S.T. Mahmoud and H. Alawadhi, Fabrication and Characterization of Aluminum Nitride Nanoparticles by RF Magnetron Sputtering and Inert Gas Condensation Technique, Coatings, 2020, 10(4), p 411

F. Barandehfard, J. Aluha and F. Gitzhofer, Synthesis of Cubic Aluminum Nitride (AlN) Coatings Through Suspension Plasma Spray (SPS) Technology, Coatings, 2021, 11, p 500. https://doi.org/10.3390/coatings11050500

V.S. Kudyakova, R.A. Shishkin, A.A. Elagin, M.V. Baranov and A.R. Beketov, Aluminium Nitride Cubic Modifications Synthesis Methods and Its Features. Review, J. Eur. Ceram. Soc., 2017, 37, p 1143-1156. https://doi.org/10.1016/j.jeurceramsoc.2016.11.051

K.-I. Kim, S.-C. Choi, J.-H. Kim, W.-S. Cho, K.-T. Hwang and K.-S. Han, Synthesis and Characterization of High-Purity Aluminum Nitride Nanopowder by RF Induction Thermal Plasma, Ceram. Int., 2014, 40(6), p 8117-8123. https://doi.org/10.1016/j.ceramint.2014.01.006

M. Shahien, M. Yamada, T. Yasui and M. Fukumoto, N2 and H2 Plasma Gasses’ Effects in Reactive Plasma Spraying of Al2O3 Powder, Surf. Coat. Technol., 2013, 216, p 308-317

N. Venkatramani, Industrial Plasma Torches and Applications, Curr. Sci., 2002, 83(3), p 254-262

T. Kim, S. Choi, and D. Park, Chemical Reaction Considered Numerical Simulation on Preparation of AlN Nano Powder by Non-transferred Thermal Plasma, Ispc_20, 2011, p 3-6

F. Gitzhofer, E. Bouyer, and M. Boulos, Suspension Plasma Spray. U.S. Patent 5,609,921, 26, 1997

L. Pawlowski, Suspension and Solution Thermal Spray Coatings, Surf. Coat. Technol., 2009, 203(19), p 2807-2829. https://doi.org/10.1016/j.surfcoat.2009.03.005

P. Fauchais, V. Rat, J.F. Coudert, R. Etchart-Salas and G. Montavon, Operating Parameters for Suspension and Solution Plasma-Spray Coatings, Surf. Coat. Technol., 2008, 202(18), p 4309-4317

P. Fauchais and G. Montavon, Latest Developments in Suspension and Liquid Precursor Thermal Spraying, J. Therm. Spray Technol., 2010, 19(1-2), p 226-239

H. Kassner, R. Siegert, D. Hathiramani, R. Vassen and D. Stoever, Application of Suspension Plasma Spraying (SPS) for Manufacture of Ceramic Coatings, J. Therm. Spray Technol., 2008, 17(1), p 115-123

S. Joshi and P. Nylen, Advanced Coatings by Thermal Spray Processes, Technologies, 2019, 7(4), p 79

A. Pakseresht, Production, Properties, and Applications of High Temperature Coatings, IGI Global, London, 2018

B. Freiberg, Nitriding of Aluminum and Its Alloys, Heat Treat. Nonferrous Alloy., 2018, 4, p 302-307

K. Farokhzadeh and A. Edrisy, Surface Hardening by Gas Nitriding, Compr. Mater. Finish., 2017, 2-3, p 107-136

P. Visuttipitukul, T. Aizawa and H. Kuwahara, Advanced Plasma Nitriding for Aluminum and Aluminum Alloys, Mater. Trans., 2003, 44(12), p 2695-2700

M. Yamada, T. Inamoto, M. Fukumoto and T. Yasui, Fabrication of Silicon Nitride Thick Coatings by Reactive RF Plasma Spraying, Mater. Trans., 2004, 45(12), p 3304-3308. https://doi.org/10.2320/matertrans.45.3304

D. Smolen and P. Dominik, Synthesis of Aluminium Nitride Nanopowder, Ceram. Mater., 2013, 65(1), p 4-7

T. Kim, S. Choi, and D. Park, Chemical Reaction Considered Numerical Simulation on Preparation of AlN Nano Powder by Non-transferred Thermal Plasma, Ispc_20, 2011, (November 2014), p 3-6

J.F. Sun, M.Z. Wang, Y.C. Zhao, X.P. Li and B.Y. Liang, Synthesis of Titanium Nitride Powders by Reactive Ball Milling of Titanium and Urea, J. Alloys Compd., 2009, 482(1-2), p 29-31

S.A. Rounaghi, H. Eshghi, S. Scudino, A. Vyalikh, D.E.P. Vanpoucke, W. Gruner, S. Oswald, A.R. Kiani Rashid, M. Samadi Khoshkhoo, U. Scheler and J. Eckert, Mechanochemical Route to the Synthesis of Nanostructured Aluminium Nitride, Sci. Rep., 2016, 6, p 1-11

R. Dallaev, D. Sobola, P. Tofel, L. Škvarenina and L. Škvarenina, Aluminum Nitride Nanofilms by Atomic Layer Deposition Using Alternative Precursors Hydrazinium Chloride and Triisobutylaluminum, Coatings, 2020, 10, p 195. https://doi.org/10.3390/coatings10100954

A.I. Abdulagatov, S.M. Ramazanov, R.S. Dallaev, E.K. Murliev, D.K. Palchaev, M.K. Rabadanov and I.M. Abdulagatov, Atomic Layer Deposition of Aluminum Nitride Using Tris (Diethylamido) Aluminum and Hydrazine or Ammonia, Russ. Microelectron., 2018, 47(2), p 118-130

M. Shahien, M. Yamada, T. Yasui and M. Fukumoto, Reactive Atmospheric Plasma Spraying of AlN Coatings: Influence of Aluminum Feedstock Particle Size, J. Therm. Spray Technol., 2011, 20(3), p 580-589

M. Shahien, M. Yamada and M. Fukumoto, Influence of Transient Liquid Phase Promoting Additives upon Reactive Plasma Spraying of AlN Coatings and Its Properties, Adv. Eng. Mater., 2018, 20(6), p 1-14

T. Ide, K. Komeya, T. Meguro and J. Tatami, Synthesis of AlN Powder by Carbothermal Reduction-Nitridation of Various Al2O3 Powders with CaF2, J. Am. Ceram. Soc., 1999, 82(11), p 2993-2998

K. Bretterbauer and C. Schwarzinger, Melamine Derivatives—A Review on Synthesis and Application, Curr. Org. Synth., 2012, 9(3), p 342-356

M. Shahien, M. Yamada, T. Yasui and M. Fukumoto, In Situ Fabrication of AlN Coating by Reactive Plasma Spraying of Al/AlN Powder, Coatings, 2011, 1(2), p 88-107. https://doi.org/10.3390/coatings1020088

S.A. Rounaghi, A.R. Kiani Rashid, H. Eshghi and J. Vahdati Khaki, Formation of Nanocrystalline H-AlN during Mechanochemical Decomposition of Melamine in the Presence of Metallic Aluminum, J. Solid State Chem., 2012, 190, p 8-11. https://doi.org/10.1016/j.jssc.2012.01.005

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.H. Jung, Y.B. Kang, J. Melançon, A.D. Pelton, S. Petersen, C. Robelin., J. Sangster, and M.-A. Van Ende, FactSage Thermochemical Software and Databases, 2010-2016, Calphad, 2016, 54, p 35-53, www.factsage.com

P. Hohenberg and W. Kohn, Inhomogeneous Electron Gas, Phys. Rev., 1964, 136(1962), http://users.wfu.edu/natalie/s15phy752/lecturenote/HohenbergPhysRev.136.B864.pdf

W. Kohn and L.J. Sham, Self-consistent Equations Including Exchange and Correlation Effects, Phys. Rev., 1965, 140(5), p 1133-1138. https://doi.org/10.1103/PhysRev.140.A1133

J.P. Perdew, K. Burke and M. Ernzerhof, Generalized Gradient Approximation Made Simple, Phys. Rev. Lett., 1996, 77(18), p 3865-3868. https://doi.org/10.1103/PhysRevLett.77.3865

P. Giannozzi, QUANTUM ESPRESSO: A Modular and Open-Source Software Project for Quantum Simulations of Materials, J. Phys. Condens. Matter, 2009, 21(39), p 395502

P. Giannozzi, Advanced Capabilities for Materials Modelling with Quantum ESPRESSO, J. Phys. Condens. Matter, 2017, 29, p 1-30. https://doi.org/10.1088/1361-648X/aa8f79

S. Grimme, J. Antony, S. Ehrlich and H. Krieg, A Consistent and Accurate Ab Initio Parametrization of Density Functional Dispersion Correction (DFT-D) for the 94 Elements H-Pu, J. Chem. Phys., 2010, 132(15), p 154104

K. Lejaeghere, Reproducibility in Density Functional Theory Calculations of Solids, Science (80-. ), 2016, 351(6280), p aad3000

G. Prandini, A. Marrazzo, I.E. Castelli, N. Mounet and N. Marzari, Precision and Efficiency in Solid-State Pseudopotential Calculations, npj Comput. Mater., 2018, 4(1), p 1-13. https://doi.org/10.1038/s41524-018-0127-2

K. Hu, M. Wu, S. Hinokuma, T. Ohto, M. Wakisaka, J.I. Fujita and Y. Ito, Boosting Electrochemical Water Splitting: Via Ternary NiMoCo Hybrid Nanowire Arrays, J. Mater. Chem. A, 2019, 7(5), p 2156-2164

B.G. Pfrommer, M. Côté, S.G. Louie and M.L. Cohen, Relaxation of Crystals with the Quasi-Newton Method, J. Comput. Phys., 1997, 131(1), p 233-240

N. Marzari, D. Vanderbilt and M.C. Payne, Ensemble Density-Functional Theory for Ab Initio Molecular Dynamics of Metals and Finite-Temperature Insulators, Phys. Rev. Lett., 1997, 79(7), p 1337-1340

D. Raczkowski, A. Canning and L.W. Wang, Thomas-Fermi Charge Mixing for Obtaining Self-consistency in Density Functional Calculations, Phys. Rev. B Condens. Matter Mater. Phys., 2001, 64(12), p 1-4

B.T. Sutcliffe and R.G. Woolley, On the Quantum Theory of Molecules, J. Chem. Phys., 2012, 137(22), p 22A544

T.D. Kühne, M. Krack, F.R. Mohamed and M. Parrinello, Efficient and Accurate Car-Parrinello-Like Approach to Born–Oppenheimer Molecular Dynamics, Phys. Rev. Lett., 2007, 98(6), p 1-4

Dassault Systèmes BIOVIA. Materials Studio., 2019

Aluminum Association et al., Aluminum: Properties and Physical Metallurgy, J.E. Hatch, Ed., ASM International, 1984

P. Pulay and G. Fogarasi, Fock Matrix Dynamics, Chem. Phys. Lett., 2004, 386(4-6), p 272-278

M. Shahien, M. Yamada and M. Fukumoto, Challenges Upon Reactive Plasma Spray Nitriding: Al Powders and Fabrication of AlN Coatings as a Case Study, J. Therm. Spray Technol., 2016, 25(5), p 851-873

M. Vardelle, P. Fauchais, A. Vardelle, K.I. Li, B. Dussoubs and N.J. Themelis, Controlling Particle Injection in Plasma Spraying, J. Therm. Spray Technol., 2001, 10(2), p 267-284

H. Zhang, A. Vardelle and N.J. Themelis, In-Flight Oxidation and Evaporation of Plasma-Sprayed Iron Particles, High Temp. Mater. Process., 2003, 7, p 277-298

G. Espié, P. Fauchais, J.C. Labbe, A. Vardelle, and B. Hannoyer, Oxidation of Iron Particles During APS: Effect of the Process on Formed Oxide. Wetting of Droplets on Ceramics Substrates, Proceedings of the International Thermal Spray Conference, 2001, p 821-827

F. Reusch, D.U. Gmbh, and S. Rudolph, Use of Boron Nitride Coatings with Aluminum Casting Technology, Scanning, 2015, p 77-80, https://www.alu-stop.de/download/pdf/gi0893.pdf

H. Fujii, H. Nakae and K. Okada, Interfacial Reaction Wetting in the Boron Nitride/Molten Aluminum System, Acta Metall. Mater., 1993, 41(10), p 2963-2971

S. Bao, K. Tang, A. Kvithyld, T.A. Engbl, and M. Tangstad, Light Metals 2012, Light Metals 2012, Suarez C.E, Ed., 2016, p 1057-1062

H. Wang, J. Han, Z. Li and S. Du, Effect of Additives on Self-propagating High-Temperature Synthesis of AlN, J. Eur. Ceram. Soc., 2001, 21(12), p 2193-2198

M. Yamada, H. Nakamura, M. Fukumoto, T. Yasui and K. Takahashi, Fabrication of Aluminum Nitride Coating by Reactive RF Plasma Spraying, Yosetsu Gakkai Ronbunshu/Quarterly, J. Jpn. Weld. Soc., 2005, 23(1), p 143-149. https://doi.org/10.2207/qjjws.23.143

M. Shahien, M. Yamada, T. Yasui and M. Fukumoto, Cubic Aluminum Nitride Coating through Atmospheric Reactive Plasma Nitriding, J. Therm. Spray Technol., 2010, 19(3), p 635-641

D. Kubátová and M. Melichar, Uncertainty of Surface Measurement, Ann. DAAAM Proc. Int. DAAAM Symp., 2018, 29(1), p 1239-1248

Acknowledgments

We appreciate Dr. Kossi Eyadéma Béré for technical support on the plasma system at Université de Sherbrooke. We would like to express our gratitude to Mr. Alain Simard, Dr. Alireza Hekmat-Ardekani, and Mr. Maxime Drolet at the Research and Development Center of Pyrotek Inc., for financial support, for providing the facilities to conduct the laboratory tests, the corrosion test, and permission to publish the results. We thank Mr. Charles Bertrand and Mr. Stéphane Gutierrez for conducting the SEM analysis.

Funding

This project was financially supported by Pyrotek Inc. (Sherbrooke, QC, Canada) and Mitacs (No. IT15444) (Canada).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest. However, Pyrotek Inc. was involved in the design of the study, data collection, data analysis, providing the facilities and materials for the research, and granting permission to publish the results. Nonetheless, they played no role in influencing the presentation or interpretation of the reported research results.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barandehfard, F., Aluha, J., Ntho, T.A. et al. Synthesizing AlN Coatings Using Suspension Plasma Spraying: Effect of Promotional Additives and Aluminum Powder Particle Size. J Therm Spray Tech 31, 2091–2111 (2022). https://doi.org/10.1007/s11666-022-01414-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01414-z