Abstract

Catalytic conversion of polysulfides is regarded as a crucial approach to enhancing kinetics and suppressing the shuttle effect in lithium–sulfur (Li–S) batteries. However, the activity prediction of Li–S catalysts remains elusive owing to the lack of mechanistic understanding of activity descriptors. Here, we report a volcano-shaped relationship between polysulfide adsorption ability and catalytic activity. In conjunction with theoretical analysis, we distinguish catalytic and anchoring effects to delineate the role of adsorption and emphasize the passivation of catalysts. These findings enable us to develop a composite catalyst, Co0.125Zn0.875S, which shows higher performance than simple binary compounds. Such a fundamental understanding of the intrinsic link between polysulfide adsorption and catalytic activity offers a rational viewpoint for designing Li–S catalysts and tuning their activities.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Source data are provided with this paper. All other data are available from the authors upon reasonable request.

References

Pu, J. et al. Electrodeposition technologies for Li-based batteries: new frontiers of energy storage. Adv. Mater. 32, 1903808 (2019).

Ji, X., Lee, K. T. & Nazar, L. F. A highly ordered nanostructured carbon–sulphur cathode for lithium–sulphur batteries. Nat. Mater. 8, 500–506 (2009).

Chu, H. et al. Achieving three-dimensional lithium sulfide growth in lithium-sulfur batteries using high-donor-number anions. Nat. Commun. 10, 188 (2019).

Pang, Q. et al. Tuning the electrolyte network structure to invoke quasi-solid state sulfur conversion and suppress lithium dendrite formation in Li–S batteries. Nat. Energy 3, 783–791 (2018).

Pu, J. et al. Conductivity and lithiophilicity gradients guide lithium deposition to mitigate short circuits. Nat. Commun. 10, 1896 (2019).

Jin, X. et al. Interfacial design principle of sodiophilicity-regulated interlayer deposition in a sandwiched sodium metal anode. Energy Storage Mater. 31, 221–229 (2020).

Sun, Z. et al. Conductive porous vanadium nitride/graphene composite as chemical anchor of polysulfides for lithium-sulfur batteries. Nat. Commun. 8, 14627 (2017).

Gao, X. et al. Incorporating the nanoscale encapsulation concept from liquid electrolytes into solid-state lithium–sulfur batteries. Nano Lett. 20, 5496–5503 (2020).

Zhang, L. et al. Enhanced polysulfide regulation via porous catalytic V2O3/V8C7 heterostructures derived from metal-organic frameworks toward high-performance Li–S batteries. ACS Nano 14, 8495–8507 (2020).

Baumann, A. E., Han, X., Butala, M. M. & Thoi, V. S. Lithium thiophosphate functionalized zirconium MOFs for Li–S batteries with enhanced rate capabilities. J. Am. Chem. Soc. 141, 17891–17899 (2019).

Wang, L. et al. To effectively drive the conversion of sulfur with electroactive niobium tungsten oxide microspheres for lithium–sulfur battery. Nano Energy 77, 105173 (2020).

Wang, Z.-Y., Wang, L., Liu, S., Li, G.-R. & Gao, X.-P. Conductive CoOOH as carbon‐free sulfur immobilizer to fabricate sulfur‐based composite for lithium–sulfur battery. Adv. Funct. Mater. 29, 1901051 (2019).

Wu, W. et al. Biomimetic bipolar microcapsules derived from Staphylococcus aureus for enhanced properties of lithium–sulfur battery cathodes. Adv. Energy Mater. 8, 1702373 (2018).

Yang, X. et al. Promoting the transformation of Li2S2 to Li2S: significantly increasing utilization of active materials for high-sulfur-loading Li–S batteries. Adv. Mater. 31, 1901220 (2019).

Wang, Z. et al. Self-supported and flexible sulfur cathode enabled via synergistic confinement for high-energy-density lithium–sulfur batteries. Adv. Mater. 31, 1902228 (2019).

Yao, Y. et al. A dual-functional conductive framework embedded with TiN-VN heterostructures for highly efficient polysulfide and lithium regulation toward stable Li–S full batteries. Adv. Mater. 32, 1905658 (2019).

Wang, R. et al. Highly dispersed cobalt clusters in nitrogen‐doped porous carbon enable multiple effects for high‐performance Li–S battery. Adv. Energy Mater. 10, 1903550 (2020).

Zhou, G. M. et al. Catalytic oxidation of Li2S on the surface of metal sulfides for Li–S batteries. Proc. Natl Acad. Sci. USA 114, 840–845 (2017).

Zhang, Z., Kong, L.-L., Liu, S., Li, G.-R. & Gao, X.-P. A high-efficiency sulfur/carbon composite based on 3D graphene nanosheet@carbon nanotube matrix as cathode for lithium–sulfur battery. Adv. Energy Mater. 7, 1602543 (2017).

Lin, H. et al. Electrocatalysis of polysulfide conversion by sulfur-deficient MoS2 nanoflakes for lithium–sulfur batteries. Energy Environ. Sci. 10, 1476–1486 (2017).

Al Salem, H., Babu, G., Rao, C. V. & Arava, L. M. R. Electrocatalytic polysulfide traps for controlling redox shuttle process of Li–S batteries. J. Am. Chem. Soc. 137, 11542–11545 (2015).

Wang, H. et al. A lithium-sulfur battery with a solution-mediated pathway operating under lean electrolyte conditions. Nano Energy 76, 105041 (2020).

Peng, L. et al. A fundamental look at electrocatalytic sulfur reduction reaction. Nat. Catal. 3, 762–770 (2020).

Xue, W. et al. Intercalation-conversion hybrid cathodes enabling Li–S full-cell architectures with jointly superior gravimetric and volumetric energy densities. Nat. Energy 4, 374–382 (2019).

Wang, Y. et al. Enhancing catalytic activity of titanium oxide in lithium–sulfur batteries by band engineering. Adv. Energy Mater. 9, 1900953 (2019).

Zhou, J. et al. Deciphering the modulation essence of p bands in Co-based compounds on Li-S chemistry. Joule 2, 2681–2693 (2018).

Seo, S. D., Park, D., Park, S. & Kim, D. W. “Brain‐coral‐like” mesoporous hollow CoS2@N‐doped graphitic carbon nanoshells as efficient sulfur reservoirs for lithium–sulfur batteries. Adv. Funct. Mater. 29, 1903712 (2019).

Pu, J. et al. Multifunctional Co3S4@sulfur nanotubes for enhanced lithium-sulfur battery performance. Nano Energy 37, 7–14 (2017).

Liu, Y. et al. Nitrogen doping improves the immobilization and catalytic effects of Co9S8 in Li‐S batteries. Adv. Funct. Mater. 30, 2002462 (2020).

Kitchin, J. R., Norskov, J. K., Barteau, M. A. & Chen, J. G. Role of strain and ligand effects in the modification of the electronic and chemical properties of bimetallic surfaces. Phys. Rev. Lett. 93, 156801 (2004).

Zhang, Y. et al. Hierarchical defective Fe3-xC@C hollow microsphere enables fast and long-lasting lithium–sulfur batteries. Adv. Funct. Mater. 30, 2001165 (2020).

Shen, Z. et al. Efficient Ni2Co4P3 nanowires catalysts enhance ultrahigh-loading lithium–sulfur conversion in a microreactor-like battery. Adv. Funct. Mater. 30, 1906661 (2020).

Shen, Z. et al. Rational design of a Ni3N0.85 electrocatalyst to accelerate polysulfide conversion in lithium–sulfur batteries. ACS Nano 14, 6673–6682 (2020).

Shen, J. et al. Mechanistic understanding of metal phosphide host for sulfur cathode in high-energy-density lithium–sulfur batteries. ACS Nano 13, 8986–8996 (2019).

Wang, R. et al. Bidirectional catalysts for liquid–solid redox conversion in lithium–sulfur batteries. Adv. Mater. 32, 2000315 (2020).

Li, R. et al. Sandwich-like catalyst–carbon–catalyst trilayer structure as a compact 2D host for highly stable lithium–sulfur batteries. Angew. Chem. Int. Ed. 59, 12129–12138 (2020).

Zhou, D. et al. Polyolefin-based Janus separator for rechargeable sodium batteries. Angew. Chem. Int. Ed. 59, 2–12 (2020).

Ye, H., Li, M., Liu, T., Li, Y. & Lu, J. Activating Li2S as the lithium-containing cathode in lithium–sulfur batteries. ACS Energy Lett. 5, 2234–2245 (2020).

Zeng, P. et al. Enhanced catalytic conversion of polysulfides using bimetallic Co7Fe3 for high-performance lithium–sulfur batteries. ACS Nano 14, 11558–11569 (2020).

Wang, W., Wang, D., Wang, G., Zheng, M. & Wang, G. Elastic, conductive coating layer for self‐standing sulfur cathode achieving long lifespan Li–S batteries. Adv. Energy Mater. 10, 1904026 (2020).

Zhang, D. et al. Catalytic conversion of polysulfides on single atom zinc implanted MXene toward high‐rate lithium–sulfur batteries. Adv. Funct. Mater. 30, 2002471 (2020).

Luo, L., Li, J., Asl, H. Y. & Manthiram, A. In-situ assembled VS4 as a polysulfide mediator for high-loading lithium–sulfur batteries. ACS Energy Lett. 5, 1177–1185 (2020).

Dronskowski, R. & Bloechl, P. E. Crystal orbital Hamilton populations (COHP): energy-resolved visualization of chemical bonding in solids based on density-functional calculations. J. Phys. Chem. 97, 8617–8624 (1993).

Deringer, V. L., Tchougréeff, A. L. & Dronskowski, R. Crystal orbital Hamilton population (COHP) analysis as projected from plane-wave basis sets. J. Phys. Chem. A 115, 5461–5466 (2011).

Wei, T.-R. et al. Exceptional plasticity in the bulk single-crystalline van der Waals semiconductor InSe. Science 369, 542–545 (2020).

Schubert, B., Avouris, P. & Hoffmann, R. A theoretical study of the initial stages of Si(111)-7×7 oxidation. II. The dissociated state and formation of SiO4. J. Chem. Phys. 98, 7606–7612 (1993).

van Santen, R. A., Neurock, M. & Shetty, S. G. Reactivity theory of transition-metal surfaces: a Brønsted–Evans–Polanyi linear activation energy–free-energy analysis. Chem. Rev. 110, 2005–2048 (2010).

Cheng, J. et al. Brønsted–Evans–Polanyi relation of multistep reactions and volcano curve in heterogeneous catalysis. J. Phys. Chem. C. 112, 1308–1311 (2008).

Bligaard, T. et al. The Brønsted–Evans–Polanyi relation and the volcano curve in heterogeneous catalysis. J. Catal. 224, 206–217 (2004).

Perdew, J. P., Burke, K. & Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 77, 3865–3868 (1996).

Acknowledgements

We acknowledge the financial support of the National Key Research and Development Program of China (2020YFA0406104) and the National Natural Science Foundation of China (22075131). The numerical calculations were carried out at the computing facilities in the High-Performance Computing Center (HPCC) of Nanjing University. Work at Argonne National Laboratory was supported by the US Department of Energy (DOE), Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office under the US-China Clean Energy Research Center (CERC-CVC2) programme. Argonne National Laboratory is operated for the DOE Office of Science by UChicago Argonne, LLC, under contract number DE-AC02-06CH11357.

Author information

Authors and Affiliations

Contributions

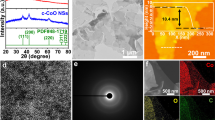

H.Z. and Z.S. conceived the idea and designed the project. Z.S., X.J. and J.T. performed the catalyst synthesis and carried out the electrochemical experiments. Z.S., M.L., Y.Y. and S.Z. conducted the morphology and structural characterizations. Z.S., H.Z. and X.J. conducted the DFT calculations and microkinetic modelling. S.F., X.F., W.X. and H.L. assisted with the the ex situ Raman measurements and analysed the spectra. H.Z. and J.L. supervised the project and wrote the manuscript. All authors analysed the data and discussed the results.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Catalysis thanks Mahbub Islam, Harry Hoster and Qianfan Zhang for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–28, Tables 1–4 and Notes 1–4.

Supplementary Video 1

TEM size analysis.

Supplementary Data 1

Atomic coordinates in the used models

Source data

Source Data Fig. 2

Electrochemical data.

Source Data Fig. 3

UV–vis spectra and calculation results.

Source Data Fig. 4

Modelling results.

Source Data Fig. 5

Electrochemical data.

Rights and permissions

About this article

Cite this article

Shen, Z., Jin, X., Tian, J. et al. Cation-doped ZnS catalysts for polysulfide conversion in lithium–sulfur batteries. Nat Catal 5, 555–563 (2022). https://doi.org/10.1038/s41929-022-00804-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41929-022-00804-4

This article is cited by

-

Optimizing potassium polysulfides for high performance potassium-sulfur batteries

Nature Communications (2024)

-

Developing high-power Li||S batteries via transition metal/carbon nanocomposite electrocatalyst engineering

Nature Nanotechnology (2024)

-

Chlorine bridge bond-enabled binuclear copper complex for electrocatalyzing lithium–sulfur reactions

Nature Communications (2024)

-

Promoting polysulfide bidirectional conversion by one-dimensional p-n junctions for Li-S batteries

Science China Materials (2024)

-

A flame-retardant binder with high polysulfide affinity for safe and stable lithium-sulfur batteries

Science China Chemistry (2024)