Abstract

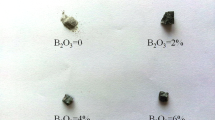

Because the formation behavior of primary slag which decomposed from complex calcium ferrite (SFCA-I and SFCA) is not quite clear, the migration behavior of CaO and Al2O3 derived from high basicity or high alumina sinter is always worth studying. The reducibility of three representative sinter samples and the formation behavior of primary slag during reduction process were investigated via X-ray diffraction, scanning electron microscopy, and energy-dispersive spectroscopy characterization. The results show that the reducibility of high basicity sinter is superior to that of high alumina sinter. Minerals with poor reducibility like hercynite and brownmillerite and with large-grained particles like free alumina and silica form in sinters with basicity of 2.4 and Al2O3 content of 4 wt.%, respectively. The appearance of these minerals can well explain the reduction stagnation phenomenon occurring in these sinter samples. The migration behavior of CaO and Al2O3 during slag formation process is different. CaO can easily combine with SiO2 to form silicate phase or firstly form calcium-rich ferro-aluminate solid solution and then transform to silicate phase, while Al2O3 firstly combines with CaO and FeO to form solid solution and then, gradually combines with SiO2 to form calcium aluminum silicate phase.

Similar content being viewed by others

References

T. Nkogatse, A. Garbers-Craig, Miner. Process. Extr. Metall. Rev. 43 (2022) 300–312.

Y.H. Yu, G.S. Feng, D.X. Su, J. Iron Steel Res. Int. 15 (2008) No. 5, 9–12.

N.A.S. Webster, M.I. Pownceby, I.C. Madsen, A.J. Studer, J.R. Manuel, J.A. Kimpton, Metall. Mater. Trans. B 45 (2014) 2097–2105.

A. Cores, A. Babich, M. Muñiz, S. Ferreira, J. Mochon, ISIJ Int. 50 (2010) 1089–1098.

D.C. Liles, J.P.R. de Villiers, V. Kahlenberg, Miner. Petrol. 110 (2016) 141–147.

X. Ding, X.M. Guo, Metall. Mater. Trans. B 45 (2014) 1221–1231.

H. Guo, X.M. Guo, Metall. Mater. Trans. B 49 (2018) 1974–1984.

N.A.S. Webster, M.I. Pownceby, J.R. Manuel, R. Pattel, J.A. Kimpton, JOM 73 (2021) 299–305.

K. Sugiyama, A. Monkawa, T. Sugiyama, ISIJ Int. 45 (2005) 560–568.

N.A.S. Webster, D.P. O'dea, B.G. Ellis, M.I. Pownceby, ISIJ Int. 57 (2017) 41–47.

N.V.Y. Scarlett, M.I. Pownceby, I.C. Madsen, A.N. Christensen, Metall. Mater. Trans. B 35 (2004) 929–936.

D.Q. Zhu, Y.X. Xue, J. Pan, C.C. Yang, Z.Q. Guo, H.Y. Tian, D.Z. Wang, Y. Shi, J. Mater. Res. Technol. 9 (2020) 10223–10234.

N.A.S. Webster, M.I. Pownceby, I.C. Madsen, ISIJ Int. 53 (2013) 1334–1340.

N.A.S. Webster, M.I. Pownceby, I.C. Madsen, J.A. Kimpton, Metall. Mater. Trans. B 43 (2012) 1344–1357.

T.R.C. Patrick, M.I. Pownceby, Metall. Mater. Trans. B 33 (2002) 79–89.

J. Hancart, V. Leroy, A. Bragard, CNRM Metall. Rep. 11 (1967) 3–7.

K. Inoue, T. Ikeda, Tetsu-to-Hagane 68 (1982) 2190–2199.

N.A.S. Webster, J.G. Churchill, F. Tufaile, M.I. Pownceby, J.R. Manuel, J.A. Kimpton, ISIJ Int. 56 (2016) 1715–1722.

F. Liao, X.M. Guo, Minerals 9 (2019) 101.

F. Liao, X.M. Guo, Mater. Res. Express 6 (2019) 106501.

M.I. Pownceby, J.M.F. Clout, Miner. Process. Extr. Metall. 112 (2003) 44–51.

F.J. Meng, C.Y. Sun, T.L. Li, Q. Wang, Iron and Steel 53 (2018) No. 7, 16–23.

S.J. Zhang, S.T. Wang, Iron and Steel 27 (1992) No. 7, 7–12.

L.G. Yan, Y.F. Wang, L.M. Cui, C.Q. Hu, Foundry Technology 38 (2017) 889–892.

N.V.Y. Scarlett, I.C. Madsen, M.I. Pownceby, A.N. Christensen, J. Appl. Cryst. 37 (2004) 362–368.

E.A. Mousa, D. Senk, A. Babich, H.W. Gudenau, Ironmak. Steelmak. 37 (2010) 219–228.

Y.X. Liu, J.L. Zhang, Z.Y. Wang, K.X. Jiao, G.H. Zhang, K.C. Chou, Int. J. Miner. Metall. Mater. 24 (2017) 130–138.

P.A. Tanskanen, S.M. Huttunen, P.H. Mannila, J.J. Härkki, Ironmak. Steelmak. 29 (2002) 281–286.

Y.N. Qie, Q. Lyu, C.C. Lan, S.H. Zhang, R. Liu, J. Iron Steel Res. Int. 27 (2020) 132–140.

T.L. Li, C.Y. Sun, X.Y. Liu, S. Song, Q. Wang, Ironmak. Steelmak. 45 (2018) 755–763.

K.K. Bai, H.B. Zuo, W.G. Liu, J.S. Wang, J.S. Chen, Q.G. Xue, J. Iron Steel Res. Int. (2021) https://doi.org/10.1007/s42243-021-00656-5.

Y.F. Li, Z.J. He, W.L. Zhan, W.G. Kong, P. Han, J.H. Zhang, Q.H. Pang, Metals 10 (2020) 1254.

S.L. Wu, L.X. Wang, Y.J. Wang, J.C. Zhang, Chin. J. Eng. 38 (2016) 1546–1552.

S.J. Lian, L.X. Xu, Sinter. Pelletiz. 31 (2006) No. 4, 7–10.

Z.Y. Zhang, X.S. Wang, G.H. Zhao, J. Anhui Univ. Technol. (Nat. Sci.) 32 (2015) 99–104.

N. Taguchi, T. Otomo, K. Tasaka, Tetsu-to-Hagane 69 (1983) 1409–1416.

D.Q. Zhu, Y.X. Xue, J. Pan, X.L. Zhou, J. Mater. Metall. 16 (2017) 1–7.

K. Higuchi, M. Naito, M. Nakano, Y. Takamoto, ISIJ Int. 44 (2004) 2057–2066.

X.A. Wang, X. Jiang, Y. Gao, H.Y. Huo, F.M. Shen, Iron and Steel 54 (2019) No. 5, 9–13.

S.V. Ott, Sintering properties of platinum nanoparticles on different oxide-based substrates, Ruprecht-Karls-Universität, Heidelberg, Germany, 2020.

S.J. Chen, F.R. Tian, G.H. Li, Y. Zhang, Phase diagram analysis and application, Metallurgical Industry Press, Beijing, China, 2007.

Z. Wang, J.L. Zhang, H.B. Zuo, B. Gao, F.G. Li, R.B. Wang, Iron and Steel 50 (2015) No. 7, 20–25+76.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51634004).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, Fj., Sun, Cy., Li, Tl. et al. Primary slag formation behavior during reduction process of SFCA-I and SFCA. J. Iron Steel Res. Int. 29, 1748–1759 (2022). https://doi.org/10.1007/s42243-022-00794-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00794-4