Abstract

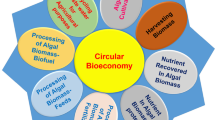

The world is experiencing an energy crisis and environmental issues due to the depletion of fossil fuels and the continuous increase in carbon dioxide concentrations. Microalgal biofuels are produced using sunlight, water, and simple salt minerals. Their high growth rate, photosynthesis, and carbon dioxide sequestration capacity make them one of the most important biorefinery platforms. Furthermore, microalgae's ability to alter their metabolism in response to environmental stresses to produce relatively high levels of high-value compounds makes them a promising alternative to fossil fuels. As a result, microalgae can significantly contribute to long-term solutions to critical global issues such as the energy crisis and climate change. The environmental benefits of algal biofuel have been demonstrated by significant reductions in carbon dioxide, nitrogen oxide, and sulfur oxide emissions. Microalgae-derived biomass has the potential to generate a wide range of commercially important high-value compounds, novel materials, and feedstock for a variety of industries, including cosmetics, food, and feed. This review evaluates the potential of using microalgal biomass to produce a variety of bioenergy carriers, including biodiesel from stored lipids, alcohols from reserved carbohydrate fermentation, and hydrogen, syngas, methane, biochar and bio-oils via anaerobic digestion, pyrolysis, and gasification. Furthermore, the potential use of microalgal biomass in carbon sequestration routes as an atmospheric carbon removal approach is being evaluated. The cost of algal biofuel production is primarily determined by culturing (77%), harvesting (12%), and lipid extraction (7.9%). As a result, the choice of microalgal species and cultivation mode (autotrophic, heterotrophic, and mixotrophic) are important factors in controlling biomass and bioenergy production, as well as fuel properties. The simultaneous production of microalgal biomass in agricultural, municipal, or industrial wastewater is a low-cost option that could significantly reduce economic and environmental costs while also providing a valuable remediation service. Microalgae have also been proposed as a viable candidate for carbon dioxide capture from the atmosphere or an industrial point source. Microalgae can sequester 1.3 kg of carbon dioxide to produce 1 kg of biomass. Using potent microalgal strains in efficient design bioreactors for carbon dioxide sequestration is thus a challenge. Microalgae can theoretically use up to 9% of light energy to capture and convert 513 tons of carbon dioxide into 280 tons of dry biomass per hectare per year in open and closed cultures. Using an integrated microalgal bio-refinery to recover high-value-added products could reduce waste and create efficient biomass processing into bioenergy. To design an efficient atmospheric carbon removal system, algal biomass cultivation should be coupled with thermochemical technologies, such as pyrolysis.

Similar content being viewed by others

Introduction

Developing alternative energy sources has become necessary due to the world's economy and population growth, as well as the resulting demand for oil and gas resources (Razeghifard 2013; Shuba and Kifle, 2018). This rising energy demand is related to the transportation sector, where the most demand is met by using fossil-based fuels (Asomaning et al. 2016); the transportation sector consumes approximately 28% of total global energy and is heavily reliant on fossil fuels. Nevertheless, 71% of crude oil contributes significantly to total greenhouse gas emissions (Leite et al. 2013). The use of fossil fuels has significantly contributed to air, water, and soil pollution, which has a negative impact on public health, an energy crisis caused by the irreversible depletion of global fossil-fuel reserves, and increased climate change (Fawzy et al. 2020). Biomass is the world's third-largest energy resource after coal and oil (Tumuluru et al. 2011; Osman et al. 2021a, b). Biomass for power generation is gaining popularity globally due to its long-term sustainability, potential, and environmental benefits. Furthermore, the produced biomass is almost carbon neutral and has the potential to significantly reduce net carbon emissions as well as hazardous emissions (Tumuluru et al. 2012); therefore, the need for sustainable and renewable energy sources has become an urgent demand (Silva et al. 2019).

Biofuels are typically derived from biomass and are composed of organic or biological components that can exist as solid, liquid, or vapors (Osman et al. 2021a). Over the last five decades, researchers have developed biomass as a feedstock for the first, second, third, and fourth generations of bio-based energy (Chowdhury et al. 2019). Third-generation biofuels, which are primarily based on microalgae, are thought to be a viable solution to the problems associated with first and second-generation biofuels. Algae (Fig. 1) are ubiquitous organisms in various habitats, but their commercialization as a substitute for fossil fuels is limited (Gajraj et al. 2018). Because of their rapid growth rate and high lipids, protein, minerals, and carbohydrate contents, microalgae are regarded as a viable feedstock for various bioproducts and bioenergy carriers (Hamed et al. 2020). On an industrial scale, the literature clearly demonstrates algae-based biofuels' positive economic and environmental impacts (Hamed et al. 2020a; Efroymson et al. 2021; El Shimi et al. 2018). After lipid extraction, the algal biomass residue can be converted into a variety of biofuels, including biomethane, bioethanol, and biohydrogen (Lam et al. 2019; Hamed et al. 2017).

Different types of algae cultivation, either in open or closed ponds. Algae growth is influenced by water supply and cultivation mode. Microalgae can be grown in two different ways. Ponds and lakes are examples of open systems, whereas photobioreactors are examples of closed systems. Every system has its benefits and drawbacks. Open farming (open pond) is regarded as the most basic and oldest method of producing and cultivating microalgae on a large scale

Microalgae are photosynthetic microorganisms that form the foundation of most aquatic food chains and contribute significantly to oxygen production (Chen et al. 2018). Numerous studies have examined how their mixotrophic nutrition on organic compounds during growth aided carbon transformation and storage (Hamed et al. 2021; Abomohra et al. 2014; Heredia-Arroyo et al. 2011). They have been shown to use nutrients from wastewater (Abou-Shanab et al. 2014; Dong et al. 2014; Pittman et al. 2011), carbon dioxide and exhaust gases emitted through industrial processes (Lizzul et al. 2014). As a result, producing microalgal biomass concurrently with existing industrial or municipal treatment activities could significantly reduce economic and environmental costs while also providing a valuable remediation service (Mishra et al. 2017; Karpagam et al. 2021; Rawat et al. 2011; Park et al. 2011).

Microalgae produce a variety of biotic substances with diverse applications in the chemical, food, pharmaceutical, carbon sequestration, and biofuels industries (Siddiki et al. 2022). Due to technical challenges, large-scale microalgae cultivation is limited, which is one of the major influences on its commercialization (Lam et al. 2019; Hamed et al. 2020). Therefore, this review aims to evaluate and critically describe the key factors that can be used to improve microalgae-based biofuels production by utilising potential microalgal species while highlighting related technologies and problematic issues in their production. Furthermore, evaluate the application of microalgae in atmospheric carbon removal as a carbon sequestration tool.

Applications

Biodiesel has recently received much attention as a renewable, biodegradable, and non-toxic fuel that emits fewer pollutants than regular diesel (Antolın et al. 2002; Lang et al. 2001; Vicente et al. 2004). Biodiesel has better chemical and physical properties than petro-diesel fuel, such as a higher cetane number, lower sulfur concentration, higher flash point, and better lubricating efficiency due to the contained oxygen (Goodrum et al. 2005; Anastopoulos et al. 2001; Nabi et al. 2006). Compared to diesel, direct use of biodiesel or biodiesel blends positively affects exhaust gases (Nabi et al. 2006, Knothe 2006, Schumacher et al. 1996). Biodiesel's relatively high oxygen content significantly reduced combustion gases and decreased carbon monoxide emissions.

Moreover, biodiesel is free of aromatic compounds and other chemical substances; thus, it has no negative environmental impact. In 2003, global biodiesel production was around 1.8 billion liters (Fulton 2004). In recent years, there has been a significant increase in biodiesel production. Biodiesel production is expected to increase in response to increased global demand for fuels and cleaner energy. Microalgae-derived biodiesel can completely replace petroleum; however, the cost of microalgal oil production must first fall from approximately $ 2.80/L to $ 0.48/L (Chisti 2007).

Compared to other feedstocks, microalgae-based biofuels are the most cost-effective; photoautotrophic microalgae, for example, convert sunlight into biomass more efficiently than higher plants (Demirbas et al. 2011). Whereas terrestrial plants have a photosynthetic efficiency of less than 4%, algae have a photosynthetic efficiency of 3–9% (Dismukes et al. 2008). The high growth rate of microalgae and consecutive biomass production reflect this light utilisation efficiency. Furthermore, algae are more tolerant to a wide range of light intensities than higher plants, allowing them to live autotrophically through photosynthesis. Meanwhile, some microalgal species can produce a relatively high content of energy-rich compounds by utilizing organic carbon sources such as glucose (Lee, 2001; Hamed and Klöck, 2014; Hassan et al. 2012).

Heterotrophs are algae that can grow in the absence of light energy but feed on organic carbon (Heredia-Arroyo et al. 2011; Joun et al. 2021; Feng et al. 2014; Shen et al. 2019). Heterotrophic microalgal growth is less efficient than phototrophic growth because the organic source required in heterotrophic growth is produced by another photosynthetic crop (Heredia-Arroyo et al. 2011; Patil et al. 2008). As a result, energy must first be used to grow the crop in the heterotrophic mode, whereas in the photoautotrophic mode, energy is used directly for algae growth.

Algae have adapted to live in various ecosystems ranging from hot springs to snow (Harwood et al. 2009). Some algal species live in terrestrial habitats, but the majority live in water bodies, including freshwater, brackish, marine, and hyper-saline waters (Hu et al. 2008). Algae are classified into nine main groups: green algae, cyanobacteria (blue-green microalgae), diatoms, yellow-green algae, golden algae, red algae, brown algae, dinoflagellates, and pico-plankton (Hu et al. 2008). Because algae are diverse and largely unexplored organisms, there is potential for further developments and applications. Their diverse genetic and biochemical composition could explain their ability to survive in many environments (Faramarzi et al. 2008).

To summarize, there is real potential for using algae in biodiesel production; however, the cost of microalgal oil production must first fall from around $ 2.80/L to $ 0.48/L. Algae's ability to live in various harsh conditions makes them ideal for various applications, with the potential to further explore undiscovered organisms within algae.

Algal biomass

Sources

Freshwater

Freshwater accounts for less than 3% of all water on the planet. Approximately 69% of the Earth's freshwater is inaccessible to humans, such as ice in glaciers and polar ice caps and groundwater. The world's available surface fresh water is not distributed evenly. The majority of the world's surface freshwater is located in Brazil, Russia, Canada, Indonesia, China, Columbia, and the United States. Lakes, rivers, wetlands, streams, and ponds are examples of freshwater habitats. Various types of algae and cyanobacteria can be found in low salt concentration ponds and freshwater lakes that can support diverse flora and fauna. For example, favorable conditions such as nutrient availability, adequate light, and temperature promote algal bloom biomass production (Gatamaneni et al. 2018). To reduce the negative environmental impact of algal blooms, researchers converted naturally occurring algal blooms into biofuel production (Kuo 2011; Ghosh et al. 2019). Streams and rivers have different environments, such as higher oxygen levels and faster flow. Because of agricultural runoff, streams have high nutrient content, such as nitrogen and phosphorus (Díez-Montero et al. 2020). Algae are usually abundant in the middle of the river due to the lower water flow in this section than in others. The river mouth is unsuitable for algal growth as the water becomes murky. Algal growth is also diminished due to limited light penetration and stagnant water conditions (Chew et al. 2018). Overall, using freshwater resources for algal biomass production is not economically feasible.

Saltwater

Saline or salt water constitutes the vast bulk of Earth's water. Saline water includes oceans, marginal seas, saline groundwater, and closed lakes. The availability of saltwater from the oceans introduces a low-cost option for microalgae growth and biomass production. The marine ecosystem is home to a diverse range of algae, including microalgae cyanobacteria as well as macroalgal species. Marine macroalgae are commonly known as seaweeds, which include three different classes red algae (Rhodophyta), brown (Phaeophyta) and green macroalgae (Chlorophyta). Marine macroalgae commonly occupy intertidal and sublittoral-to-littoral zones on rocks and other hard substrata. Marine algae are an important component of the marine ecosystem because they absorb sunlight energy, water and carbon dioxide to produce organic compounds and release oxygen to the ambient environment. This cycle contributes to the balance of the ocean's life cycle.

The unicellular microalgae, known as phytoplankton, constitute the base of the marine food chain. It is typically found near the water's surface, capturing sunlight. Marine phytoplankton plays a critical role in the biogeochemical cycling of the oceans. Their varied genome structure explains their adaptation to thrive in various conditions. Microalgae have become a dominant force within marine ecosystems. For example, coastal regions' microalgae are contended with high nutrients, low light and turbulence conditions, whereas open ocean microalgae are adapted with low nutrients and high irradiance. Polar microalgae are acclimatized to high nutrients with freezing temperatures and long periods of light and darkness.

Because salinity is an important factor in these environments, saltwater is a typically ideal condition for developing microalgae resistant species to high salinity. The average salinity of marine water is 35%, though this varies slightly according to the amount of runoff received from surrounding lands and rainfalls. Overall, marine water is an attractive resource for microalgae scales up, however cultivation in the marine environment requires careful monitoring to ensure optimal biomass productivity.

Wastewater

Wastewater is a rich nutrients source for microalgae growth. Phyco-remediation is a wastewater treatment method that employs microalgae for nutrient removal from wastewater, which can then be reused for multiple purposes (Lage et al. 2018). There are several types of wastewaters, including industrial, domestic, refinery, agricultural, and leachate. The organic composition of all wastewaters is comparable; however, the inorganic content varies among wastewater sources. Carbohydrates, proteins, lipids, amino acids, and volatile acids account for three-quarters of the organic carbon in sewage.

These wastewaters typically contain high nitrogen, phosphorus, and other inorganic compounds, which cause eutrophication to local water sources and impose ecological risk to aquatic life. Thus, employing wastewater for algal mass production could be a promising solution to replace synthetic culture media, which is currently prohibitively expensive to use on an algal scale. For instance, wastewaters of palm fertiliser, fruit bunches, and palm oil mill effluent are rich with high nitrogen and other nutrients content; they have been proposed as good culture media.

Although high nutrient levels in wastewater promote algal growth, the high levels of toxic compounds, emerging contaminants and pathogens can inhibit algal growth. Therefore, resistant microalgal species that adapt to the wastewater environment must be carefully selected for optimal growth and high biomass yields. For example, struvite is a wastewater nutritive medium that has been investigated as a microalgal supporting medium to reduce cultivation costs (Chew et al. 2018).

Types

Freshwater species

Freshwater microalgae could provide a promising feedstock for biofuels production due to their fast growth rates, high biomass yields, high carbon dioxide sequestration ability, and their strong potential to grow on marginal lands that do not compete with agricultural crops (Yun et al. 2014; Ramaraj et al. 2010; Saraf and Dutt, 2021; Al-Lwayzy et al. 2014). Every species has a distinct growth rate and innate metabolic profile. Consequently, selecting microalgal species with high biomass production and promising properties for large-scale production are important factors for sustainable biofuel technology.

Freshwater microalgae have been previously used for human and animal nutrition. These species can rapidly absorb nutrients from the liquid phase and thrive in the environment. Numerous studies showed the high ability of freshwater microalgae in biomass for bio-based energy production, such as Chlorella vulgaris (Al-Lwayzy et al. 2014), Chlorella pyrenoidosa (Yang et al. 2015), Muriellopsis sp. and Scenedesmus subpicatus (Gómez-Serrano et al. 2015), Ankistrodesmus falcatus (George et al. 2014), Coelastrella sp. (Narayanan et al. 2018), Asterarcys quadricellulare (Sangapillai and Marimuthu, 2019), Scenedesmus obliquus (Liu et al. 2013) and Tribonema sp. (Wang et al. 2014a).

Significant efforts have been made to use marine macroalgae and cyanobacteria for the biofuels industry; however, much less concern has been placed on using freshwater macroalgae (e.g. eukaryotic Chlorophyta) (Yun et al. 2014; Grayburn et al. 2013; Lawton et al. 2013; Demirbas 2010; Khola and Ghazala 2012). Nevertheless, freshwater macroalgae may have significant potential for liquid and solid biofuels that can be combusted directly or co-combusted with more traditional energy sources (Tumuluru et al. 2012; Grayburn et al. 2013). Moreover, biomass harvesting, represented as dense floating mats, is much easier and cheaper than dewatering equivalent biomass of suspended microalgae (Grayburn et al. 2013; Hillebrand 1983). For example, using an algal turf scrubber for large-scale freshwater macroalgae cultivation has been elucidated as a cost-effective and eco-friendly approach (Yun 2014). This technology combines nutrient removal in wastewater with bioenergy production. Several common freshwater macroalgal taxa, e.g., Oedogonium, Rhizoclonium, Ulothrix, and Microspora, have been reported (Adey et al. 2011, Kebede‐Westhead et al. 2003, Mulbry et al. 2008a, Pizarro et al. 2006).

Although the elemental biomass composition of common freshwater macroalgae has been analyzed, relatively few studies have evaluated the efficiency of freshwater macroalgae as a feedstock for biofuel (Tumuluru et al. 2012; Lawton et al. 2013). At the industrial scale, it is critical to investigate how variable environmental conditions such as temperature, salinity, light, and nutrient availability affect the growth of freshwater macroalgae, biomass productivity, and energy efficiency (Smith et al. 2010; Sturm et al. 2012; Shurin et al. 2013). In this context, nutrient limitation remarkably induced lipids accumulation in several eukaryotic algae; however, the yields and productivity of algal biomass were noticeably reduced (Shurin et al. 2013; Subramanian et al. 2013).

As a result, determining the net energy yield of freshwater macroalgal cultivation systems necessitates a thorough examination of biomass productivity and energy content. In this study, the exhaust emissions and fuel characteristics of the biodiesel produced from a mixture of freshwater macroalgae Cladophora and Rhizoclonium were nearly identical to petro-diesel (Grayburn et al. 2013). Furthermore, three common freshwater macroalgal species were found to have high bioenergy potential in terms of higher heating value and productivity (Lawton et al. 2013). Hence, more investigations on the effectiveness of freshwater macroalgae as a bio-based energy carrier are needed.

Marine or saltwater species

Marine microalgae are less diverse than freshwater microalgae due to their toxic and hazardous nature (Chew et al. 2018). Because of their large surface area, algae in seawater and oceans have evolved to outperform freshwater algae. The photoconversion rate of marine microalgae has increased to better use the abundant sunlight and synthesize biomass more quickly (Wei et al. 2013). Certain algal species can accelerate the production of valuable byproducts if exposed to harsh environmental conditions. The laboratory study of Rodolfi et al. (2009) on 21 different marine microalgal strains, e.g. Tetraselmis suecica, Phaeodactylum tricornutum, Chaetoceros calcitrans, Isochrysis galbana Nannochloropsis oculata, Pavlova lutheri, Skeletonema sp. revealed variable biomass productivities which ranged between 0.04 and 0.37 g/L/day and lipid productivity (17.4–61.0 mg/L/day) (Table 1). The marine diatom Chaetoceros muelleri exhibited moderate growth production (0.272 g/L/day) and high lipid productivity (51 mg/L/day) on synthetic saline water medium under phototrophic cultivation with high carbon dioxide aeration levels (10–20%) (Wang et al. 2014b) (Table 1). The marine microalgal strains Chlorella salina, Neochloris sp. and Nannochloropsis sp. were demonstrated for lipid-rich biomass production with lipid contents 28, 46 and 52% using synthetic medium and enriched seawater medium under phototrophic growth conditions (Surendhiran et al. 2014; Moazami et al. 2011). This implies the possibility of lowering the cost of biomass-derived biofuel production, which is currently not economically viable.

Wastewater species

The commercialization of algae-based biotechnology for the manufacturing of bio-based energy is restricted by the high production costs (Hamed et al. 2020). Thus, several ways have been proposed to make this technology economically feasible, such as using industrial effluent (Gómez-Serrano et al. 2015; Kim et al. 2015), municipal wastewater (Abou-Shanab et al. 2014; Dong et al. 2014; Sturm et al. 2012; Zhang et al. 2014; Han et al. 2016; Mahapatra et al. 2014), and dairy manure effluent (Kebede‐Westhead et al. 2003; Mulbry et al. 2008a; Pizarro et al. 2006; Wahal and Viamajala, 2016) as a culture media to reduce cultivation costs and freshwater requirements.

No specific species can grow in wastewater; instead, robust strains should be carefully chosen to survive under these harsh conditions (Lage et al. 2018). Oscillatoria, Euglena, Chlamydomonas, Chlorella, Scenedesmus, Navicula Nitzschia, and Stigeoclonium are the eighth-most tolerant genera (Randrianarison et al. 2017). Scenedesmus sp. (He et al. 2019) and Chlorella sp. (Makareviciene et al. 2011) are widespread in freshwater bodies of various types as primary producers cleansing the eutrophic waters (Abdel-Raouf et al. 2012).

Several laboratory studies on microalgae biomass production using wastewater have been investigated either in bioreactors, small semi-continuous culture systems, or batch cultures. Data in Table 1 showed that microalgae yielded differential lipid contents ranging from moderate such as Botryococcus braunii (17.85% dry wt) (Órpez et al. 2009), to high lipid content 23, 30 and 40% in Micractinium reisseri (Abou-Shanab et al. 2014), Chlorococcum sp. RAP13 (42%) (Ummalyma and Sukumaran, 2014), Chlorella sorokiniana (61.52%) (Ramanna et al. 2014). The study of Chinnasamy et al. (2010) revealed that Butyraceous Braunii, Chlorella saccharophila and Dunaliella tertiolecta grown in industrial wastewater (treated carpet mill) showed biomass productivity ranging from 0.016 to 0.038 g/L/day, and the estimated lipid productivity was ranged from 2.72 to 4.4 mg/L/day depending on species type. Implying that this kind of wastewater could be a sensible option for biomass-derived energy yield.

In this context, the green microalga Chlamydomonas reinhardtii grown in batch culture using 100% municipal wastewater showed reasonable lipid productivity (16.6% dry wt) coupled with high biomass productivity (Kong et al. 2010). Moreover, this green microalga had the potential to grow vigorously in the wastewater for 1 month when transferred to a biocoil with a relatively high lipid content (25.25% dry wt) and considerable biomass and lipid productivities of 2.0 g/L/day and 505 mg/ L/day in addition to high removal efficiency of nitrogen and phosphorous from the ambient medium, as shown in Table 1 (Kong et al. 2010). Botryococcus braunii grown in secondary treated municipal wastewater showed considerable levels of total lipid content (17.9% dry weight) and biomass productivity of 0.35 g/L/day, indicating that wastewater nutrient status influences biomass and lipid synthesis (Órpez et al. 2009).

The use of dairy manure as a microalgae nutritive supplement could increase the algae-based biofuel production potential. Where the lipid content of microalgal consortia of Chlorella sp. Micractinium sp. and Actinastrum sp. grown in anaerobically digested dairy manure wastewater in outdoor batch culture showed considerable lipid content of 14 to 29% dry wt depending on the used concentration of wastewater, giving estimated biomass and lipid productivity of 0.06 g/L/day and 17 mg/L/day (Woertz et al. 2009). A similar finding has been reported in Chlorella sp. using 20% diluted anaerobic digester effluent samples treated with dairy waste giving biomass and lipid productivity 0.34 g/L/day and 37.0 mg/L/day (Wahal and Viamajala, 2016). Remarkable increases in biomass and lipids productivity were observed in Rhizoclonium hieroglyphicum grown in dairy effluent enriched with carbon dioxide and manure (Mulbry et al. 2008b) and in Chlorococcum sp. RAP13 when grown in dairy effluent supplemented with 6 % waste glycerol (Ummalyma and Sukumaran, 2014).

To summarize, the high production costs limit the commercialization of algae-based biotechnology for the production of bio-based energy. Microalgal biomass production in agricultural, municipal, or industrial wastewater is a low-cost option that could significantly reduce economic and environmental costs while also providing a valuable remediation service.

Characterization

Microalgae have fast-growing cycles, more acceptable forms of stored carbon, and their ability to survive in sewage or saline water, making them a more appealing biofuel feedstock. The number of microalgae species ranges from 70,000 to one million. Only about 44,000 species are known, with new species and genera being discovered all the time. The continuous discovery of new species adds to the search for strains capable of high growth rates and lipid accumulation. A combination of microscopic and phylogenetic analysis is used to classify the performance of strains (Chew et al. 2018; Neofotis et al. 2016).

Potential as a fuel

Biofuel has been proposed as a potential future energy source. Liquid biofuels have experienced a rapid global expansion in recent years. The first-generation biofuels mainly depend on using sucrose producing plants (e.g. sugar cane, sugar beet and sweet sorghum) or starch-based crops such as wheat, corn and barely. This kind of biofuel is already commercially viable in the United States, Brazil, and the European Union. The impact of the first generation biofuels on the transportation industry is currently limited due to increased competition on agricultural land for food production. The second-generation biofuels are derived from agricultural lignocellulosic waste and non-edible crops, including agricultural residues, wood chips, straw and grass. Nevertheless, cereal and sugar crops have also been used as feedstocks for second generation processing technologies. Also, plant-based biodiesel production necessitates the utilization of cultivable lands for food production to grow oil producing crops such as palm soybean, oilseed rape and sunflower, which negatively affects food security. Therefore, governments limited the amount of these feedstocks for biofuel production (Shuba and Kifle 2018). At the economic scale, second generation biofuels have been reported to be not commercially viable due to extensive processing technologies, poor conversion rates and low net energy production (Milano et al. 2016, 2018).

Furthermore, vegetable and animal fats have been proposed to produce biodiesel using nonpolar solvents and catalyst, but there damaging effect on diesel engines, low oxidation stability and volatility, increased viscosity and density, fuel atomization, and a higher ratio of greenhouse gases emissions make them an unacceptable option. The third-generation biofuels are derived from microalgae and are considered to be a viable alternative energy resource. Microalgae have an ability to grow quickly and they can survive under harsh environments. Their metabolic profile can be easily engineered to produce high value added byproducts by selecting appropriate species and adjusting cultivation conditions (Milano et al. 2016).

Microalgae biomass is regarded as one of the most efficient renewable energy sources for bio-oil production with increased energy demands in addition to their role in mitigation of greenhouse gas emissions Lee et al. (2011). Algal oil (oilage) is a biodegradable compound that has gained popularity as a primary substrate for biodiesel manufacturing, due to its low emissions and adequate physio-chemical properties that positively affect efficiency of diesel engines. Algal biodiesel is produced through transesterification of algal lipids in a two steps process which, yields more fatty acid methyl esters than the direct transesterification process. Previous studies revealed that oilage feedstock surpasses the best seed crop oil in terms of productivity (Arvindnarayan et al. 2017). Algae-based fuels are environmentally friendly, non-toxic, and potentially reduce global carbon dioxide emissions (Pienkos et al. 2009). It has been stated that 1 kg of algal biomass can fix 1.83 kg of carbon dioxide. Interestingly some microalgal species can also fix sulfur and nitrogen oxides as nutrients source (Tu et al., 2019).

In conclusion, microalgae as a feedstock can be viewed as a potential alternative for balancing and compensating for the rising demands for biofuels. In terms of nutrient requirements and carbon dioxide sequestration capacity, wastewater combined with an inorganic carbon source (industrial flue gases) may be the most economically viable option for scale-up over freshwater resources. However, algal fuel technology is still in its early stages, and more work is required for commercialization.

Cultivation

One of the most critical stages in the development of algal biomass is the design of affordable and efficient microalgae culture. The medium is considered a necessary component in cultivation because it regulates algae growth and reproduction. As a result, the medium must contain all necessary components for growth, including minerals such as phosphorus, nitrogen, magnesium, sulfur, calcium, manganese, silicon, and iron in sufficient quantities. Successful microalgae cultivation for sustainable biofuel production requires a high rate of productivity, a low cost of production, and a low cost of maintenance (Voloshin et al. 2016; Ullah et al. 2015). Microalgae can be grown in two different ways; indoor (closed system) such as tubular, flat-panel and vertical column photobioreactors and outdoor (open system) conditions such as ponds and lakes. Every system has its benefits and drawbacks. Open farming is regarded as the most basic and oldest method of producing and cultivating microalgae on a large scale (Fig. 3).

Influence of cultivation conditions on biomass and lipid productivity

Developing novel strategies for increasing microalgal biomass rich with lipid content would result in a low-cost, long-term biofuel production process. Several publications in the last decade investigated various strategies for inducing biomass production and lipid accumulation in microalgal biomass. This section will look at strategies that include various species types under various cultivation conditions. Cultivation conditions significantly impact microalgal growth characteristics and composition. There are four types of microalgal cultivation conditions: photoautotrophic, mixotrophic, heterotrophic and photoheterotrophic. The biomass and lipid productivity of different microalgal species under different cultivation conditions are summarized in Table 1, where the following sections discuss each type of cultivation in more detail.

Phototrophic cultivation

The most frequently used conditions for microalgae cultivation were reported in many publications (Illman et al. 2000; Mandal and Mallick, 2009; Liu et al. 2013; George et al. 2014; Mandotra et al. 2016; Narayanan et al. 2018; Sangapillai and Marimuthu, 2019; Saraf and Dutt, 2021). Microalgae use inorganic carbon sources (e.g., carbon dioxide) and light as the energy source to produce high energy organic compounds via the photosynthesis process. Overview of phototrophic cultivation conditions (Table 1) revealed a large variation in the biomass productivity of microalgae, ranging from 0.01 (Takagi and Yoshida 2006; Liang et al. 2009) to 0.7 g/L/day (Gómez-Serrano et al. 2015; An et al. 2003) and lipid productivity ranged between to 0.2 mg/L/day to (Illman et al. 2000) to 505 mg/L/day (Kong et al. 2010) depending on the type of microalgal species, cultivation system and nutrient status. Previous studies revealed significant increases in the lipid content of microalgae when nitrogen or nutrient deficiency was applied (Fernandes et al. 2013; Li et al. 2013; Hamed et al. 2020). However, achieving significant lipid productivity resulted in lower biomass production. Thus, lipid content is not the only factor influencing the energy value of microalgae. As a result, both biomass and lipid productivities should be considered simultaneously. Lipid productivity is a more accurate indicator of a microalga's ability to produce lipid because it combines the effects of lipid content and biomass production. Chlamydomonas reinhardtii recorded the highest lipid productivity by 505 mg/L/day under phototrophic cultivation. The microalga was grown in a biocoil photobioreactor using municipal wastewater (the centrate) (Kong et al. 2010) (Table 1). In this context, remarkably high lipid productivity was found in Chlorella sp. (121.3–178.8 mg/L/day) and Nannochloropsis oculata NCTU-3 (84.0‒142.0 mg/L/day) under phototrophic condition supplemented with different carbon dioxide concentration (2%, 5%, 10%, and 15%) (Chiu et al. 2008). The use of autotrophic cultivation for microalgal growth and lipid production has a significant benefit in terms of carbon dioxide sequestration as an essential carbon source. Accordingly, the microalgae's cultivation sites should be close to power plants or factories in order to provide a sustainable source of carbon dioxide for microalgal growth. Furthermore, autotrophic cultivation has a lower contamination rate than other types of cultivation. As a result, phototrophic cultivation conditions, such as open ponds and raceway ponds, are commonly used in microalgal outdoor scale-up.

Heterotrophic cultivation

Similar to bacteria, some microalgal species can grow in the absence of light by utilising organic carbon as a source of energy and carbon. This mode of nutrition is known as heterotrophic cultivation (Xu et al. 2006; Cheng et al. 2009; Ummalyma and Sukumaran, 2014). This cultivation method is suitable for large-scale photobioreactors as it avoids the hurdles of light limitation in the phototrophic conditions that could impede high cell density. Compared to other cultivation methods, heterotrophic cultivation recorded the highest biomass and lipid productivities (Xu et al. 2006; Li et al. 2007; Xiong et al. 2008; Cheng et al. 2009; Gao et al. 2010) (Table 1). Changing the cultivation conditions from phototrophic to heterotrophic induced lipid content in Chlorella protothecoides by 40% (Xu et al. 2006). Variable organic carbon sources, such as glycerol, glucose-fructose, sucrose, acetate, mannose, lactose and galactose, have been shown to promote microalgae growth under heterotrophic conditions (Xu et al. 2006; Liang et al. 2009; Heredia-Arroyo et al. 2011; Ummalyma and Sukumaran 2014). Many trials showed that using low-cost alternative organic carbon sources makes this process economically viable. For example, using corn powder hydrolysate and sweet sorghum hydrolysate in the culture of Chlorella protothecoides increased the biomass productivity to 2 g/L/day and 1.2 g/L/day, and lipid productivity was markedly induced to 932 mg/L/d and 586.8 mg/L/d as shown in Table 1 (Xu et al. 2006; Gao et al. 2010). The productivity of both lipids and biomass under heterotrophic cultivation is 20 times greater than that obtained under phototrophic cultivation. So far, Chlorella protothecoides achieved the highest lipid productivity (3700 mg/L/day) using a 5-L fermenter with an optimized fed-batch culture strategy of glucose and yeast extract (Xiong et al. 2008). Contamination is, however, a common issue in sugar-based heterotrophic cultivation; additionally, the economic feasibility of this system is still debatable.

Mixotrophic cultivation

In this process, microalgae assimilate inorganic carbon (carbon dioxide) through photosynthesis and utilize exogenous organic carbon sources for growth (Hamed and Klöck, 2014). Therefore, some microalgal species can live under different cultivation systems, heterotrophic or phototrophic conditions, or mixotrophic. Microalgae obtain their energy from the assimilation of organic carbon, and the released carbon dioxide during the respiration process is sequestered by the photosynthetic machinery. Compared to common propagation modes, microalgae experienced better growth and lipid productivity under mixotrophic conditions (Table 1). This mode has been proposed to combine the benefits of autotrophic and heterotrophic cultivation systems. For instance, Chlorella vulgaris 259 showed significant biomass (0.25 g/L/day) and lipid (54 mg/L/day) productivity under mixotrophic cultivation when compared with both autotrophic and heterotrophic (Liang et al. 2009). The highest productivity of biomass (0.39–1.87 g/L/day) and lipid (120–250 mg/L/day) was reported in a green microalgal species Chlorella vulgaris 2714 using mixotrophic cultivation with different initial glucose: glycerol concentrations (Heredia-Arroyo et al. 2011). Moreover, considerable biomass productivity (0.879 mg/L/day) was obtained by Parachlorella kessleri 211–11G under mixotrophic growth conditions using glucose in fermented brewery wastewater (O'Rourke et al. 2016). A similar finding was stated in different green microalgal species such as Chlorella pyrenoidosa using alcohol wastewater and anaerobically digested starch wastewater (Yang et al. 2015), Chlorella sp. using anaerobic digester effluent treated with dairy waste (Wahal and Viamajala 2016), and C. zofingiensis using artificial wastewater with repetitive injection with acetic acid (Zhu et al. 2014) as shown in Table 1.

Photoheterotrophic cultivation

This growth mode is like mixotrophic cultivation requires the addition of an organic carbon source. However, photoheterotrophic cultivation also needs light as the energy source. In contrast to the mixotrophic mode, photoheterotrophic microalgae cannot absorb and metabolise carbon dioxide. Whereas in a mixotrophic mode, algae can use organic compounds and replenish cell energy through photosynthesis. Therefore, the photoheterotrophic mode requires both carbon and light sources. Although the production of some light-dependent valuable metabolites by Euglena gracilis has been improved under photoheterotrophic cultivation, however using this cultivation mode for biofuel production is not economically feasible compared to mixotrophic cultivation.

In conclusion, this subsection covered the four main microalgal cultivation conditions: photoautotrophic, mixotrophic, heterotrophic, and photoheterotrophic. Open ponds and raceway ponds are common phototrophic cultivation conditions used in microalgal outdoor scale-up. While contamination is a common problem in sugar-based heterotrophic cultivation, the economic feasibility of this type is still being debated.

Economic evaluation of different cultivation modes

Table 1 revealed that taxonomic groups likely had different biomass and lipid productivities. According to the literature, the heterotrophic cultivation mode could provide higher oil and biomass productivity than other cultivation modes. As a result, this approach has sparked much interest. However, culture contamination problems impose technical hurdles in heterotrophic cultivation, especially in open systems. Additionally, from a commercial perspective, the cost of the organic carbon source is another major constrain. Phototrophic cultivation is the easiest mode for scale-up and the most frequently used in outdoor systems. In this cultivation mode, carbon dioxide and flue gas from power plants and factories could be employed in microalgae propagation and lipid production (Lizzul et al. 2014; Yadav et al. 2019).

Nevertheless, cell growth, biomass and lipid productivity are typically much lower than those of heterotrophic cultivation. At the economic scale, the low production cost of biomass by phototrophic mode suggests that this method is most attractive. So far, the available information on using photoheterotrophic and mixotrophic modes for microalgae biomass-derived biodiesel production is very limited.

Furthermore, the two cultivation modes' contamination risk and light requirements restricted their commercialization. Thus, scaling up under these conditions may require a special photobioreactor design which could increase the cost of operation. As a result, the use of autotrophic cultivation mode under well-adjusted conditions, e.g., light intensity, carbon dioxide levels, temperature, nutrient status of the culture, is a reliable and cost-efficient option.

Open ponds

Open ponds are large-scale outdoor algae cultivation systems in various sizes and shapes, including huge shallow ponds, circular ponds, close ponds, and raceway ponds. The pond's location is a critical factor because it affects the pond's type, used algal strain, and culture conditions (e.g. light availability, outdoor temperature, rain fall, time of day (Harun et al. 2010). The open pond system is associated with ease and low-cost design, high efficiency and low maintenance costs compared to closed-system bioreactors (Dahiya, 2015).

The open ponds system is more vulnerable to changing meteorological conditions, which primarily affect the temperature of the water and rate of evaporation. These factors can impact growth rates and biomass algal productivity (El Shenawy et al., 2020). Scenedesmus, Spirulina, and Chlorella are the most cultivated microalgal species in outdoor ponds system. This system is best suited for areas with high light irradiance and with open access to a water source. the Coastal zones are typically the most preferable sites. In this system, microalgae can be grown either in natural or artificial ponds, and microalgae mass production is maintained through a proper supply of necessary nutrients. For example, the biomass yield of a cyanobacterium Arthospira sp. has reached up to 40 tons per year near lake of Chad.

Circular ponds are another kind of artificial pond and are used for commercial-scale microalgae cultivation. Propagation in these ponds is usually restricted by size, as their huge diameters are not financially acceptable because of increased energy expenses required for rotor rotation (Voloshin et al., 2016). Raceway ponds are one of the best available options for cultivation due to their energy efficiency. A single paddle wheel is required to provide agitation in the area of 5 hectares (Siddiki et al., 2022).

Photobioreactors

Photobioreactors are classified as closed systems because they provide a controlled environment for the growth of photosynthetic algae in sterile environments (Dahiya 2015). Photobioreactors can provide increased photosynthetic efficiency, biomass production and cell density. Photobioreactor’s efficiency can be determined by integrating light capturing, transportation, distribution, and increased utilization by microalgae which increases biomass formation. In this system the composition of the nutrient medium can be controlled to maintain growth with optimal yields. Photobioreactors have been demonstrated to reduce capital and operational cost while minimizing energy consumption (Wang et al. 2012).

Productivity is one of the most important factors that determine the success of a bioreactor technology. Comparing productivity of bioreactors is difficult because of variable used microalgal strains and different operation settings. At the industrial scale, tubular photobioreactor (TPBR) and plate types photobioreactor are more appropriate for outdoor cultivation than conventional photobioreactors. The large illumination surface area of these bioreactors is achieved through utilizing translucent tubing and is considered the primary reason for its outdoor adaptability. The tubing system can be manipulated in various configurations to fit system design (Harun et al. 2010).

The low rate of water loss induced by evaporation, low risk of contamination, increased photosynthetic efficiency, increased cells density per unit area are considered the most important advantages of closed system bioreactors (Fig. 2) (Veerabadhran et al. 2021a). Continuous efforts are paid to improve the photobioreactor technologies to boost algal cultures and biomass productivity. For instance, maximizing the utilization capacity of solar radiation under outdoor conditions is a challenge in the design of high-efficiency photobioreactors. Commercial-scale outdoor photobioreactors must have large volumes and surfaces should be transparent with increased illuminating area with high mass transfer rates.

Rainwater affects the salinity and pH by diluting the culture medium. Erosion of the bank occurs due to water turbidity and leakage. Microalgal cultures can be easily contaminated, causing formation of a mixed biomass from various microbial species. Contamination can have adverse effects on microalgae yield due to growth inhibition or toxicity induced by other contaminants. Carbon source is the basic necessity for cell growth. A carbon source other than atmospheric carbon dioxide is required to fulfil optimum cell growth conditions; the carbon source can be organic or inorganic. Light intensity and temperature also vary with the time throughout the day in the case of open ponds (Siddiki et al. 2022; Voloshin et al. 2016). CO2 is referred to carbon dioxide

One of the major disadvantages of microalgae cultivation technology in developed countries is the requirement for wide land areas and cost pressures. As a result intensive efforts are being paid by scientists to increase the algal biomass production through looking for suitable cultivation sites and refining the biomass to multiple high value-added compounds to compensate the operation costs (Ugwu et al. 2008).

Photobioreactors and open ponds are used to produce a wide range of commercially important high-value compounds, novel materials, and feedstock for various industries, including cosmetics, food, and feed. Photobioreactors have high biomass productivity with the best use of the land area and a better ability to capture light irradiance (Fig. 3). Photobioreactors are particularly used to produce biomass-derived pharmaceutical products, food, and cosmetics due to low contamination risk with bacteria and fungi. In contrast, open ponds system is more cost-effective, however more vulnerable to contamination risk. Thus this system is used to produce biomass-based biofuels, biopolymers and chemicals. In addition few number of microalgal strains can grow in open pond system. Therefore, a cost-effective and efficient photobioreactor design is required to achieve high energy efficiency with positive net energy (Jorquera et al. 2010).

Photobioreactors are classified into three basic categories. Tubular, flat-panel and vertical column photobioreactors can be used for outdoor cultures as well. Biomass productivity is good due to high mass transfer opportunities and high surface illumination properties. All three photobioreactors are costly, limiting their use as they decline the whole process's cost efficiency (Siddiki et al. 2022; Voloshin et al. 2016; Harun et al. 2010; Wang et al. 2012; Ugwu et al. 2008). PBR is referring to a photobioreactor, while TPBR is a tubular photobioreactor. O2 is oxygen, and CO2 is carbon dioxide

In conclusion, the cost of algal biofuel production was primarily determined by culturing (77%), harvesting (12%), and lipid extraction (7.9%). As a result, the choice of microalgal species and cultivation modes such as autotrophic, heterotrophic, or mixotrophic are crucial factors in controlling biomass and bioenergy production, as well as fuel properties.

Conversion technologies

Following the biomass cultivation and preparation stages comes the stage of actual conversion into biofuels. There are numerous strategies for biofuel conversion, regardless of the nature of the biomass. They are generally classified into three types based on cost, end-product, and eco-friendliness (Voloshin et al. 2016).

Bioconversion

Anaerobic digestion, bioethanol and biogas production, and photobiological hydrogen or biohydrogen production are examples of how microalgae biomass can be converted (Osman et al. 2020; Osman et al. 2022a).

Fermentation

To reduce gas emissions, algal biomass and its derivatives can be used as gasoline, octane enhancers, or bioethanol diesel mixers (El-Mekkawi et al. 2019). Bioethanol can be used in place of gasoline due to its similar physicochemical properties. The biochemical composition of the biomass feedstock is used as a decisive factor for bioethanol yield. Carbohydrate-rich biomasses are typically used as a substrate in yeast-based fermentation to produce bioethanol (Fig. 4). (Kannah et al. 2021a; Abd El-Malek et al. 2021).

Finely ground biomass is converted to sugars with the help of enzymes or acids in a normal fomentation process. Then sugars are transformed into ethanol by yeasts. Ethanol is then separated using a distillation column. The high concentration ethanol stream is liquefied, making liquefied ethanol a substitute for gasoline in automobiles. The solid deposit can be used as cattle feed and gasification

Polysaccharides in the form of starch soluble and insoluble sugars and cellulose are abundant in algal biomass, for these reasons, algal biomass is regarded as an efficient feedstock for bioethanol synthesis. In a standard fermentation process, finely ground biomass is converted to sugars with the help of specific enzymes or acids, and sugars are then converted into ethanol by a yeast’s fermentation process. The ethanol is eventually separated using a distillation column. The highly concentrated ethanol stream is liquefied to be used as a gasoline alternative in automobiles. The residual solid deposits can be used for cattle feed and gasification process. This helps to reduce feedstock prices, which account for 55 to 80% of the total alcohol cost. Ethanol production from algal biomass requires an additional pretreatment phase in which content is mechanically or enzymatically hydrolyzed. Concentrated sulfuric acid is frequently used to decompose the biomass's intra and inter H-bonds, the acid is then neutralized and produced sugars are separated for fermentation process (Hossain et al. 2019).

Carbohydrate, crystalline cellulose, hemicellulose, and amorphous cellulose are generally hydrolyzed using various biological catalysts or enzymes. Specific functional enzymes such as cellulase have been extensively used to decompose cellulose polymer into simple glucose units, which could improve the process (Dayton and Foust, 2019).

The yeast-based biomass fermentation process does not require dewatering steps or the addition of toxic chemicals for extraction, which are considered important benefits of this technology. Combining sonication, enzyme and heat treatment during continuous bioethanol production from mixed microalgal biomass has been proposed by Hwang et al. (2016). In the microbial fermentation method, various pretreatments steps are required, resulting in varying degrees of cell lysis. Filamentous microalgae are usually hydrolyzed by sonication pretreatment, while a diatom species such as cyclotella, cells were destroyed by combining sonication and enzymatic hydrolysis. The sonication heat and enzymatic treatments increased the concentration of dissolved carbohydrates, which improved ethanol formation during microbial fermentation. It has been found that microbial species likely exhibited differential fermentation abilities. Thus, the selection of efficient microbial strains is pivotal factor in this technology. For instance, the increased activity of sugars fermenting enzymes produced by a yeast species Dekkera bruxellensis resulted in higher ethanol production when compared with mixed bacterial culture (Hwang et al. 2016). A study by El-Dalatony et al. (2019) revealed that three consecutive steps are required during microbial fermentation of microalgal biomass into biofuels. In phase I, carbohydrate is fermented to produce bioethanol and then residual proteins in biomass are fermented for increased alcohol production (phase II). Whereas, phase III involves in transesterification of remaining fatty acids into biodiesel. This approach allows for the most efficient recovery of energy careers from algal biomass.

Enzymatic and acidic hydrolysis of Chlorella vulgaris and Scenedesmus obliquus biomass were analyzed to evaluate the optimum yeast inoculum required for better hydrolysate's fermentation (Silva et al. 2018). Acidic hydrolysis with 3% sulfuric acid at 121 ℃ and 30 min of reaction time provided 90% of sugar recovery and are considered optimum conditions for biomass pretreatment. Ultrasonication is an efficient method for biomass pretreatment to increase enzyme availability. Whereas, combining ultrasonication with a cocktail of hydrolyzing enzymes (amylase, cellulase, hemicellulase, and pectinases) resulted in 90% sugar recovery in 8 h (Silva et al. 2018) (Table 2).

Anaerobic digestion

Anaerobic digestion is an effective strategy for converting organic wastes and biomass with high moisture content to high heating value gases. In this technology, microbes anaerobically degrade the organic matter through a series of biochemical processes into biogas containing carbon dioxide, methane, and other gases such as nitrogen and hydrogen sulfides. The composition and type of cell wall significantly influence the biodegradability of microalgae. In marine species, biodegradability is influenced by ammonia toxicity due to high cellular protein and sodium contents. Microalgae can be used as a renewable and sustainable substrate for biogas production through anaerobic digestion technology. The cost-efficiency of anaerobic digestion using microalgal biomass significantly impacts the prospect of energy sustainability. Thus, much work is needed to improve this technology(Veerabadhran et al. 2021b).

The biodegradable composition of microalgae biomass makes it an ideal substrate for anaerobic digestion and methane generation (Perazzoli et al. 2016). Anaerobic digestion comprises of a sequence of metabolic processes, including hydrolysis, acidification, acetogenesis and methanogenesis by diverse microbial groups. The first microbial group hydrolyzed complex chemical substances to monomers by using enzymes which are then transformed into volatile fatty acids, hydrogen and acetic acid. The volatile fatty acids, such as propionic and butyric acid, are converted to hydrogen, carbon dioxide, and acetic acid by acetogens. Hydrogen, carbon dioxide and acetate are eventually converted to methane and carbon dioxide by methanogenic bacteria (Kwietniewska et al. 2014). Various factors such as substrate status or co-digestion with other materials could reduce the anaerobic digestion. The methane yield, on the other hand, could be increased by adapting the microbial community to microalgal biomass digestion.

Nutrient-rich wastewater has been used as culture media for microalgae propagation (Perazzoli et al. 2016). This strategy contributes to wastewater bioremediation and provides multiple bioproducts and energy carriers from algal biomass (Gonzalez-Fernandez et al. 2015).

The study of Membere and Sallis (2018) showed that biogas and methane yields using Laminaria digitata, brown macroalgal species, are significantly influenced by temperature over 40 days experiments. Their results indicated that biogas could be produced at variable degrees of digestion temperatures and impacted biogas yield. For example the yields of methane gas were 318, 293, 271 and 352 mL methane/g volatile solids at 25, 35, 45 and 55 °C. According to their findings, the highest cumulative biogas output was achieved at 35 °C, while overall methane dual potential was optimum at 55 °C (Membere and Sallis 2018).

Biogas production efficiency could also be enhanced by using nanoparticle catalysts such as Fe3C nanoparticles 3 along with iron oxide nanoparticles (Fe3O4). The addition of Fe3O4 nanoparticles to an anaerobic waste digester resulted in a 180% increase in biogas content and a 234% increase in methane production at an ambient temperature of 37 °C for 60 days (Rahman et al. 2016).

Nickel and cobalt nanoparticles, as well as some metal oxide nanoparticles like Fe2O3 and MgO induced higher biogas and hydrogen production yields with variable degrees (Zaidi et al. 2018).

Anaerobic digestion has a number of advantages when compared to other biofuel industries, such as high energy yields of biogas compared to biodiesel, drying is not required, microalgal biomass mineral composition meets the requirements of anaerobic methanogens, the possibility of co-digestion, the culture used for biogas production can be reused for biogas upgrading through carbon dioxide sequestration, the offensive odor is reduced below the specified unprocessed waste odor levels, harmful gas emissions are reduced, reduces oxygen demand in wastewater, and production of valuable byproducts such as fertilizers and compost. The disadvantages of anaerobic digestion include a low carbon to nitrogen ratio due to the high nitrogen content of microalgal biomass, the existence of cell wall which reduces the bioavailability of intracellular compounds, a high capital cost, anaerobic digestion is only feasible for larger farms, a lengthy operational and maintenance period, and the use of a large piece of land (Hossain et al. 2019; Sakarika et al. 2019).

Biohydrogen production

Hydrogen is a high heating value gas (141.6 MJ/kg), clean, more versatile, efficient, and sustainable renewable energy carrier that can replace fossil fuels due to hydrogen’s high energy yield compared to typical hydrocarbon fuels. Biological hydrogen production is a method of producing hydrogen gas that involves the use of microbes (Khetkorn et al. 2017). Microalgae can produce hydrogen photobiologically due to their metabolic and enzymatic properties. Under anaerobic conditions, eukaryotic microalgae can produce H+ and oxygen while fixing carbon dioxide. In the presence of hydrogenases enzymes (Fe-hydrogenase and Ni-hydrogenase), hydrogen ions are reduced to produce hydrogen gas molecules. Various hydrogen production pathways are directed by either acetate or butyrate production using glucose as a model substrate.

It should be noted that both dark and photo fermentation are viable options for anaerobic hydrogen production. Acid fermentation consumes less energy than butyrate fermentation. Furthermore, the former approach produces hydrogen, which is theoretically superior to the latter (Hossain et al. 2019; Sambusiti et al. 2015).

The use of deoiled microalgal biomass as feedstock for anaerobic digestion is seen as a cost-effective and ecofriendly approach which resulted in zero waste, as shown in Fig. 5. The nature of deoiled microalgal biomass, including lignin-free cellulose, makes deoiled microalgal biomass an excellent substrate for dark fermentative hydrogen production. The efficiency of hydrogen production from a deoiled algal cake is influenced by various factors, including physical, biological, and operational factors. The conversion of deoiled microalgal biomass to hydrogen takes place in two stages. The first stage involves hydrolysis of the deoiled algal biomass to simple sugars. The second stage includes acidogenic bacteria fermentation, in which sugars are converted into hydrogen (Subhash et al. 2014).

Deoiled microalgal biomass nature, including lignin-free cellulose, makes it a good substrate for dark fermentative hydrogen production. In the process of dark fermentation two phases are involved in the conversion of deoiled microalgal biomass to hydrogen. The first stage comprises hydrolysis of the deoiled algal biomass while producing simple sugars. The second stage includes acidogenic bacteria fomentation where simple sugars are converted into hydrogen

In all bioconversion processes, the suitability of fermenting microbes to substrate feedstock and the values of product output are critical. Clostridium sp. is a common bacterial model used for hydrogen generation from organic substrates (Ferreira et al. 2013). Ding et al. (2016) stated that carbon-rich macroalgae produce hydrogen and methane when combined with nitrogen-rich microalgae in a two-stage process. Hydrolysis and acidogenesis were aided by the co-fermenting process resulting in 15.5–18.5% more hydrogen yield using Laminarial digitilia biomass. A considerable amount of energy left in hydrogenogenic effluents was recovered as biomethane in the second stage of methane co-fermentation, increasing energy efficiency from 4.6 to 6.6% during hydrogen fermentation from 57 to 70.9% in combined hydrogen and methane generation (Ding et al. 2016).

Strategies for increasing hydrogen production employ cutting-edge approaches such as genetic engineering, microalgae bacteria consortia, advanced biohydrogenation method, and nanomaterials for enzyme stability and hydrolytic efficiency. Dark fermentation is preferred over photo fermentation, biophotolysis, and microbial electrolysis because dark fermentation can produce hydrogen repeatedly and does not require sunlight.

Thermal conversion

Microalgae are the most suitable and promising organisms, possessing the morphological and physiological characteristics required for large-scale biomass production. Following the cultivation and preparation of biomass, microalgae are converted into biofuel using various techniques, the most common of which are thermochemical approaches. Thermal conversion methods subject the feedstock to higher temperatures and pressures to obtain compounds with low molecular weight and oxygen content through pyrolysis, gasification, and combustion processes.

Direct combustion

Direct combustion of biomass in the presence of excess air is used to convert chemical energy into heat while also producing carbon dioxide and sulfur dioxide/nitrogen dioxide. These emissions, as well as the energy yield generated throughout the process, are determined by the operating temperature and biomass content. Incomplete biomass combustion emits carbon monoxide, methane, and particulate matter. Notably, these emissions can be reduced to some extent by using certain catalysts such as copper chloride and magnesium oxide during the combustion of algal biomass. Emissions from direct or partial combustion cause secondary pollution. (Bhushan et al. 2020).

Direct combustion necessitates the use of microalgae with less than 50% moisture. As a result, the energy requirements and additional cost of drying and grinding microalgae for efficient combustion are rising. The efficient use of heat generated by direct combustion of microalgae can eliminate the need for additional drying and grinding. Co-firing coal with algae has the potential to reduce greenhouse gas emissions caused by combusting coal alone (Halder and Azad 2019).

Pyrolysis

Pyrolysis occurs at higher temperatures (typically from 500 to 800 °C) in the absence of oxygen, as well as in the absence or presence of a catalyst. Biomass is decomposed over a certain time at various temperatures to produce fuels with calorific values ranging from medium to low. Pyrolysis produces solid biochar, bio-oil, or gaseous materials (Fawzy et al. 2021, Osman et al. 2022b). The temperature is mostly between 300 and 600 °C during pyrolysis, while the temperature can exceed 800 or 900 °C in certain situations. Microalgae cells are generally small, considering other forms of biomass; therefore, no shredding is necessary. Microalgal biomass should include minimum moisture content for successful pyrolysis to reduce the cost of technology implementation (Chernova et al. 2020).

Chlorella protothecoides, Chlorella vulgaris, Scenedesmus sp., Microcystis aeruginosa, Nannochloropsis sp. and Chlorella vulgaris residues along with others, are among the most common algal species used for biofuel conversion. The conversion of algae to biofuel in the pyrolysis process is feasible due to its sustainability and economic viability for both industrial and residential uses. Heterotrophic cells produce more bio-oil than autotrophic cells. During rapid pyrolysis, bio-oil produced by heterotrophic cells has a high heating value, lower oxygen content, density, and viscosity. The increased storage stability is due to lower oxygen levels (Das et al. 2021a).

Parameters such as process temperature, heating rate, residence time or catalyst, along with others, affect the pyrolysis of microalgal biomass. Variation in these process parameters can lead to a change in the composition of the final product. For example, increasing temperature above 550 ℃ has decreased bio-oil yield, and a decrease in temperature increases biochar yield. Algal biomass is enriched in sodium, potassium, magnesium and calcium, which is suitable as a fertilizer when converted to biochar, while higher oil yield is obtained when the lipid content in algal biomass is high. The presence of carrier gas significantly increases the performance of the pyrolysis process. The type of catalyst that can be used to optimize the final product yield as acid catalysts improve the yield of biochar, while base catalyst improves the yield of bio-oil (Das et al. 2021b).

Gasification

Gasification produces syngas, which contains hydrogen, carbon monoxide, carbon dioxide, and methane due to partial oxidation of biomass. The composition of the selected algal biomass influences the final production and composition of syngas. Dried algal biomass reacts with water at high temperatures and 10 bar pressure. Algal biomass is converted into various gaseous products via combustion, dehydration, devolatilization, and gasification. The syngas can be used as fuel in engines or further processed into a liquid fluid. Catalyst improves gasification by increasing hydrogen yielding low-cost solid and gaseous products.

Several factors influence the gasification of microalgal biomass. Hydrogen production increases with increasing the temperature, while methane, carbon dioxide, char, and tar decrease. Temperature increases cause an increase in energy consumption. Carbon gasification becomes inefficient as operational pressure is increased. A catalyst such as ruthenium on titania (Ru/TiO2) or nickel-based improves process efficiency while increasing tar removal efficiency to 80–100%. A higher equivalence ratio improves fuel quality and conversion efficiency (Das et al. 2021b).

Moisture content and biomass availability are crucial elements for thermochemical conversion. Microalgae have 70 to 80% moisture content; therefore, bulk cultivation is a futuristic challenge. Low-cost drying techniques are required for thermochemical conversion (Bhushan et al. 2020). Because of the product's gaseous nature, storage and transportation are difficult, and thermal conversion of algal biomass has disadvantages (Aravind et al. 2020) (Table 3).

Chemical conversion

This route employs base, acid catalysts or enzyme catalysts, as well as supercritical transesterification. Because base catalysts cannot be recycled or reused, while acid catalysts are thought to be slower than base catalysts and are ideal for obtaining oils. The enzyme catalyst technique is time-consuming and hazardous to commercial biodiesel production. For oil extraction, supercritical transesterification requires a temperature of up to 250 °C and constant pressure. In this process, a catalyst is an option. (Chamola et al. 2020). Transesterification is the reaction of triglyceride with alcohol to form esters and glycerol. During this esterification process, in the presence of sodium or potassium hydroxide as a catalyst, triglyceride reacts with alcohol. Excess alcohol is utilized to ensure complete esterification. Mono alkyl ester is formed, an active ingredient of biodiesel with the reaction of alcohol and fats, whereas glycerol is also produced. At the end of the reaction, separating the oil phase from the rest of the esters and the glycerol layer is achieved (Demirbas 2009).

Biodiesel must undergo testing prior to commercialization. The absence of glycerol, catalyst, unreacted alcohol, and free fatty acids are all important properties of biodiesel. There is a need to introduce energy-efficient, low-cost liquid extraction and transesterification procedures for algal biodiesel production. After liquid extraction, biomass can be used efficiently to generate biogas via anaerobic digestion. Biogas can be produced as a byproduct without interfering with biodiesel production. Commercializing biogas will reduce overall costs while increasing biofuel production (Sialve et al. 2009; Wiley et al. 2011; Subhadra et al. 2011).

Acid catalysts are combined with the base catalyst in a two-stage process. High fatty acids containing low-cost feedstock, i.e., waste oil, are also processed through this method. In the first stage, methyl esters are formed by converting fatty acids, while the base catalyst transforms leftover triglycerides into methyl esters (Pragya et al. 2013).

Among all conversion processes, anaerobic digestion is an energy-efficient procedure for generating biogas as biomass with high moisture content is tolerable compared to thermal conversion processes. However, anaerobic digestion requires long periods. For biomass conversion to bio-oil, esterification (acid catalyst) is widely used.

Downstream processing

Sedimentation is considered an efficient method of harvesting microalgal mass because sedimentation involves biomass settling due to gravity forces. This approach is particularly appealing in terms of energy and cost because this method uses very little energy and has less expensive equipment and operational costs. Lamella settling tanks are simple settling tanks that are commonly used equipment. Lamella settling tanks are frequently chosen because the available settling surface is significantly increased in this form. The main disadvantage of this method is the time required for microalgal settling (Esteves et al. 2020). Downstream processing is an energy-efficient approach that is widely used to separate microalgae from water. The sedimentation technique has the potential to successfully separate microalgae such as Spirulina, which settle due to their increased density and size (Pragya et al. 2013). Before the sedimentation procedure, flocculation and coagulation occur.

Other harvesting processes, including coagulation-flocculation and flocculation-flocculation, are frequently employed in conjunction with flocculation. This process can enhance the microalgal particle size for suspension through aggregation while also boosting the settling rate. Bio-flocculation, auto-flocculation, physio-chemical flocculation and physical-flocculation are the most common forms of flocculation (Japar et al. 2017). Flocculants can be polyelectrolyte, organic or inorganic based on their chemical makeup. Multivalent cations, for example, ferric sulfate, ferric chloride, and aluminum sulphate can create polyhydroxy complexes at ideal pH, neutralizing and reducing negative surface charges on microalgal cells. Inorganic chemical flocculants are employed to flocculate microalgal cells. Cationic, anionic or nonionic organic flocculants or polyelectrolytes are examples of organic flocculants. Because cationic polymers physically bind cells together, they flocculate, but anionic and nonionic polymers fail to produce flocs of microalgae owing to electro-repulsion.

The flocculating power of the polyelectrolytes is affected by the charge and functional group on the surface of the microorganism, the pH of the growth media and the density of the algal culture. Cationic polyelectrolytes with high density are more effective flocculants for energy-efficient harvesting. The coagulant's efficacy decreases as the coagulant's molecular weight increases, whereas ionic polyelectrolytes do not show this behaviour (Barros et al. 2015).

The high-volume microalgal cultures that must be processed, as well as the need for a universal method that can be used for a wide range of species, contribute to the safety of these procedures. The suspension is concentrated 20 to 100 times during the harvesting process. The suspension improves the efficient particle size before dewatering, significantly lowering the energy requirement. For low-cost microalgae harvesting, coagulation and flocculation are usually followed by gravity sedimentation. Unlike coagulation, which requires a pH change or the addition of electrolytes, flocculation is based on the addition of cationic polymers to the broth. Chemical coagulation and flocculation are defined as the agglomerates of particles that are finally split in suspension or to the larger aggregates, followed by their agglomeration into the large flocks that settle at the bottom of the vessel, leaving a clear supernatant (Barros et al. 2015). Chemical coagulants should ideally be sustainable and renewable, resulting in no biomass contamination, allowing them to use culture media, inexpensive, nontoxic, and efficient at low doses while being derived from renewable resources.

Flotation is a gravity separation methodology in which gas or air bubbles lift suspended particles to the top of a liquid surface, where they can be collected using a skimming process. Because some microalgal organisms have low density and self-float properties, this approach can be faster and more successful than sedimentation. Freshwater and marine microalgae can be harvested through flotation separation. Many factors influence the attachment of suspended particles to wear on gas bubbles, including particle size, adhesion and collision chances. The key advantages are the short operating time, low volume requirements, large-scale harvesting, and rate adaptability at a low starting cost. This procedure typically requires flocculants and is followed by coagulation and flocculation (Singh et al. 2018). Electrolytic flotation, dissolved air flotation, and dispersed flotation are three major types of floatation based on bubble size (Pragya et al. 2013). Dispersed air, micro-flotation, foam floatation, vacuum gas, dissolved air, flocculation flotation, electro flotation, and ozone flotation are the methods used for flotation (Japar et al. 2017).

Electrical filtration techniques such as electrocoagulation filtration, magnetically induced membrane filtration, and electrochemical sacrificial electrode filtration have also been investigated. Due to the fact that this environmentally friendly method does not target specific species, this filtration technique is both safe and cost-effective. During an electrical field, the negative charge of microalgal cells can separate, allowing for culture growth. Precipitates can form on electrodes and collect on the vessel's bottom (electrophoresis) (electro-flocculation). As the bubbles form, electro-flotation is generated from dissolved air flotation. Water electrolysis can generate hydrogen bubbles at a lower cost than dissolved air flotation. These bubbles can be generated by the node and then combined with electrocoagulation that occurs at the cathode due to electrolytic oxidation. This is referred to as electrocoagulation flotation (Barros et al. 2015).

Electrocoagulation flotation is a traditional mechanical harvesting process in which substances are separated based on density variation, with heavier particles moving away from the axis and lighter particles moving towards the axis. Various types of centrifuges are introduced for algal cell harvesting at varying levels of efficiency, either as a one-step procedure or as a two-step procedure incorporating biomass pre-concentration, due to their speed and dependability. Tubular and multi-chamber centrifuges are two traditional methods for harvesting algal biomass. Despite the tubular’s efficiency, a tubular centrifuge cannot be used continuously due to its inability to release solids. As a result, the performance of disc centrifuges and bench-scale harvesting can be predicted. A multi-chamber centrifuge's closed bowl is divided into concentric, vertical chambers (Mathimani et al. 2018).

Upon separation through centrifugation, algal culture is exposed to shear stresses and significant gravitational forces that can damage the structure of cells. The following are the numerous centrifugation technique types for systems available: solid bowl decanter, nozzle type, hydro-cyclone and solid ejecting disk (Enamala et al. 2018).