Abstract

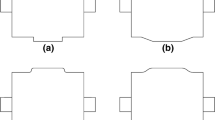

In this work, a curved surface convex roll (CSC-Roll) suitable for wide-thick slabs was designed. According to the field conditions and casting parameters, a 3D thermal-mechanical coupling model of CSC-Roll reduction was established, and the uneven solidification morphology of the slab was obtained. By analyzing the liquid core deformation rate, surface maximum stress and reduction force of the CSC-Roll with different shape parameters, the optimal shape parameters of the CSC-Roll were designed. By coupling the shrinkage void in the 3D thermal-mechanical coupling model, the coalescence degree of shrinkage voids under the flat reduction is calculated to be 8.78 pct, and that under CSC-Roll reduction is 9.68 pct, and the deformation degrees of the shrinkage voids in different directions were compared. The critical strain of slab surface crack propagation measured by high-temperature tensile test is 0.181. Based on the relationship between crack tip strain and initial crack length during reduction, the critical initial lengths of longitudinal and transverse crack propagation on slab surface were obtained to be 15.7 mm and 28.0 mm.

Similar content being viewed by others

References

S. Ogibayashi, M. Kobayashi, M. Yamada, and T. Mukai: ISIJ Int, 1991, vol. 31, pp. 1400–07.

H. Preßlinger, S. Ilie, P. Reisinger, A. Schiefermüller, A. Pissenberger, E. Parteder, and C. Bernhard: ISIJ Int, 2006, vol. 46, pp. 1845–51.

R. Thome and K. Harste: ISIJ Int, 2006, vol. 46, pp. 1839–44.

C. Ji, S. Luo, M.Y. Zhu, and Y. Sahai: ISIJ Int, 2014, vol. 54, pp. 103–11.

D.B. Jiang, L.F. Zhang, and M.Y. Zhu: Steel Res. Int, 2022, vol. 93, p. 2100569.

D.B. Jiang, W.L. Wang, and S. Luo: Int. J. Heat Mass Transfer, 2018, vol. 122, pp. 315–23.

M.O. El-Bealy: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 1488–1516.

H.B. Sun, L.L. Li, and J.H. Wang: Ironmak. Steelmak., 2018, vol. 45, pp. 708–13.

R.M.P. Huitron, P.E.R. Lopez, and E. Vuorinen: Mater. Sci. Eng. A, 2020, vol. 772, p. 138691.

N. Zong, H. Zhang, and Y. Liu: Ironmak. Steelmak., 2019, vol. 46, pp. 872–85.

M. Jiang, E.J. Yang, and Z.W. Hou: Metall. Mater. Trans. B, 2021, vol. 52, pp. 2753–59.

J.Y. Zhang, C.H. Wu, and C. Ji: Steel Res. Int, 2021, https://doi.org/10.1002/srin.202000601.

Z.J. Wei, C. Ji, and T.C. Chen: J. Iron Steel Res. Int., 2022, vol. 29, pp. 103–14.

Z.J. Wei, C. Ji, and T.C. Chen: Steel Res. Int, 2022, vol. 93, p. 2100348.

C. Ji, C.H. Wu, and M.Y. Zhu: JOM, 2016, vol. 68, pp. 3107–15.

G.L. Li, C. Ji, and M.Y. Zhu: Metall. Mater. Trans. B, 2021, vol. 52B, pp. 1164–78.

C.H. Wu, C. Ji, and M.Y. Zhu: J. Mater. Process. Technol, 2019, vol. 271, pp. 651–59.

C.H. Wu, C. Ji, and M.Y. Zhu: Metall. Mater. Trans. B, 2019, vol. 50B, pp. 2867–83.

C.H. Wu, C. Ji, and M.Y. Zhu: Metall. Mater. Trans. B, 2018, vol. 39B, pp. 1346–59.

C.H. Wu, C. Ji, and M.Y. Zhu: Metals, 2019, vol. 9, p. 128.

R. Guan, C. Ji, and C.H. Wu: Int. J. Heat Mass Transfer, 2019, vol. 141, pp. 503–16.

Y. Qi, C. Ji, and M.Y. Zhu: Metall. Mater. Trans. A, 2018, vol. 50, pp. 357–76.

I. Kohichi, M. Hirobumi, and S. Kiyomi: Tetsu-to-Hagane, 1994, vol. 80, pp. 42–47.

M. Okimori, R. Nishihara, S. Fukunaga, and Y. Okamioto: Tetsu-to-Hagane, 1994, vol. 80, pp. T120-23.

M. Takubo, Y. Matsuoka, Y. Miura, H. Higashi and S. Kittaka: The METEC and 2nd ESTAD. Session, 2015, pp. 307–18.

M.C. Ho, O.K. Shik, and L.J. Dong: ISIJ Int, 2012, vol. 52, pp. 1266–72.

T. Li, H. Li, and R. Li: ISIJ Int, 2019, vol. 59, pp. 1314–22.

C. Ji, G.L. Li, and C.H. Wu: Metall. Mater. Trans. B, 2019, vol. 50, pp. 110–22.

J.X. Fu, J.S. Li, and H. Zhang: Acta Metall. Sin, 2010, vol. 46, pp. 91–96.

C. Ji, Z.L. Wang, C.H. Wu, and M.Y. Zhu: Metall. Mater. Trans. B, 2018, vol. 49B, pp. 767–82.

Q. Zhou, C. Ji, and M.Y. Zhu: Mater. Res. Express, 2019, vol. 6, p. 12652.

Y. Hiroyuki, N. Yhkiichi, and M. Takasuke: ISIJ Int, 1981, vol. 21, pp. 469–76.

S. Punnose, A. Mukhopadhyay, and R. Sarkar: Mater. Sci. Eng. A, 2013, vol. 576, pp. 217–21.

N. Zong, Y. Liu, and H. Zhang: Metall. Res. Technol, 2017, vol. 114, p. 413.

Acknowledgments

The present work was financially supported by the National Natural Science Foundation of China (51974078), Liaoning Revitalization Talents Program (XLYC1907176) and the Fundamental Research Funds for the Central Universities of China (N2025012, N2125007). Special thanks are due to Ansteel Steel Company for facilitating the industrial trials and applications.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, Y., Ji, C. & Zhu, M. Design of Process and Equipment for Wide-Thick Slab CSC-Roll Reduction and Study of the Resulting Surface Crack Risk. Metall Mater Trans B 53, 2925–2941 (2022). https://doi.org/10.1007/s11663-022-02575-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-022-02575-6