Abstract

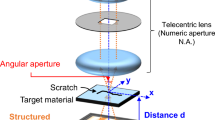

Machine vision system has great significance for the automatic inspection to enhance unclear defects. For the purpose of the improvement of the recognition accuracy in the automation inspection, in addition to development of image-processing technology, the optical technology is also required to emphasize the contrast of defects difficult to find in a camera. Here, we develop both the optical-engineering and image-processing technology with high throughput to enhance defects in transparent material, using the phase-shift illumination method with striped structured illumination. We succeeded in the enhancement of shape defects difficult to visualize in a bright-field observation with our approach to construct the composite image from a few pictures. Our theoretical model clarified the relationship of the composite image to parameters about optical configuration and edge sharpness of surface structures in a target material, and reproduced dependencies of the index in the experiment. Based on the theoretical model, we proposed the optimum design parameters of the equipment for enhancing the scratches in our transmissive phase-shift-illumination method, so that we can maximize the magnitude of enhancement due to the refraction of light rays in the defect shape.

Similar content being viewed by others

References

Yang, J., Xu, Y., Rong, H.-J., Du, S., Zhang, H.: A method for wafer defect detection using spatial feature points guided affine iterative closest point algorithm. IEEE Access. 8, 79056–79068 (2020). https://doi.org/10.1109/ACCESS.2020.2990535

Li, M., Jia, J., Lu, X., Zhang, Y.: A method of surface defect detection of irregular industrial products based on machine vision. Wirel. Commun. Mob. Comput. 2021, 1–10 (2021). https://doi.org/10.1155/2021/6630802

Nguyen, H.T., Yu, G.-H., Shin, N.-R., Kwon, G.-J., Kwak, W.-Y., Kim, J.-Y.: Defective product classification system for smart factory based on deep learning. Electronics 10, 826 (2021). https://doi.org/10.3390/electronics10070826

Jian, C., Gao, J., Ao, Y.: Imbalanced defect classification for mobile phone screen glass using multifractal features and a new sampling method. Multimed. Tools Appl. 76, 24413–24434 (2017). https://doi.org/10.1007/s11042-016-4199-z

Benbarrad, T., Salhaoui, M., Kenitar, S.B., Arioua, M.: Intelligent machine vision model for defective product inspection based on machine learning. J. Sens. Actuat. Netw. 10, 7 (2021). https://doi.org/10.3390/jsan10010007

Zhou, X., Wang, Y., Zhu, Q., Liu, X., Xiao, Z., Xiao, C., Chen, T.: Machine vision based automatic apparatus and method for surface defect detection. In: 2018 13th World Congress on Intelligent Control and Automation (WCICA). pp. 1697–1702 (2018)

Li, C., Zhang, X., Huang, Y., Tang, C., Fatikow, S.: A novel algorithm for defect extraction and classification of mobile phone screen based on machine vision. Comput. Ind. Eng. 146, 106530 (2020). https://doi.org/10.1016/j.cie.2020.106530

Jian, C., Gao, J., Ao, Y.: Automatic surface defect detection for mobile phone screen glass based on machine vision. Appl. Soft Comput. 52, 348–358 (2017). https://doi.org/10.1016/j.asoc.2016.10.030

Li, D., Liang, L.-Q., Zhang, W.-J.: Defect inspection and extraction of the mobile phone cover glass based on the principal components analysis. Int. J. Adv. Manuf. Technol. 73, 1605–1614 (2014). https://doi.org/10.1007/s00170-014-5871-y

Le Tuyen, N., Wang, J.-W., Shih, M.-H., Wang, C.-C.: Novel framework for optical film defect detection and classification. IEEE Access. 8, 60964–60978 (2020). https://doi.org/10.1109/ACCESS.2020.2982250

Cai, L., Li, J.: Research on phone shell detection based on machine vision. J. Phys. Conf. Ser. 1885, 042006 (2021). https://doi.org/10.1088/1742-6596/1885/4/042006

Jiang, J., Cao, P., Lu, Z., Lou, W., Yang, Y.: Surface defect detection for mobile phone back glass based on symmetric convolutional neural network deep learning. Appl. Sci. 10, 3621 (2020). https://doi.org/10.3390/app10103621

Molina, L., Carvalho, E.A.N., Freire, E.O., Montalvão-Filho, J.R., Chagas, F. de A.: A robotic vision system using a modified Hough transform to perform weld line detection on storage tanks. In: 2008 IEEE Latin American Robotic Symposium. pp. 45–50 (2008)

Dong, Z., Mai, Z., Yin, S., Wang, J., Yuan, J., Fei, Y.: A weld line detection robot based on structure light for automatic NDT. Int. J. Adv. Manuf. Technol. 111, 1831–1845 (2020). https://doi.org/10.1007/s00170-020-05964-w

Zhang, L., Ye, Q., Yang, W., Jiao, J.: Weld line detection and tracking via spatial-temporal cascaded hidden markov models and cross structured light. IEEE Trans. Instrum. Meas. 63, 742–753 (2014). https://doi.org/10.1109/TIM.2013.2283139

Nguyen, V.H., Pham, V.H., Cui, X., Ma, M., Kim, H.: Design and evaluation of features and classifiers for OLED panel defect recognition in machine vision. J. Inf. Telecommun. 1, 334–350 (2017). https://doi.org/10.1080/24751839.2017.1355717

Yuan, L., Zhang, Z., Tao, X.: The development and prospect of surface defect detection based on vision measurement method. In: 2016 12th World Congress on Intelligent Control and Automation (WCICA). pp. 1382–1387 (2016)

Im, J., Fujii, H., Yamashita, A., Asama, H.: Multi-modal diagnostic method for detection of concrete crack direction using light-section method and hammering test. In: 2017 14th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI). pp. 922–927 (2017)

Tao, J., Zhu, Y., Liu, W., Jiang, F., Liu, H.: Smooth surface defect detection by deep learning based on wrapped phase map. IEEE Sens. J. 21, 16236–16244 (2021). https://doi.org/10.1109/JSEN.2021.3076610

Su, X.-Y., Zarubin, A.M., von Bally, G.: Modulation analysis of phase-shifted holographic interferograms. Opt. Commun. 105, 379–387 (1994). https://doi.org/10.1016/0030-4018(94)90412-X

Ströbel, B.: Processing of interferometric phase maps as complex-valued phasor images. Appl. Opt. 35, 2192 (1996). https://doi.org/10.1364/AO.35.002192

Xue, L., Su, X.: Phase-unwrapping algorithm based on frequency analysis for measurement of a complex object by the phase-measuring-profilometry method. Appl. Opt. 40, 1207 (2001). https://doi.org/10.1364/AO.40.001207

Han, J., Shao, L., Xu, D., Shotton, J.: Enhanced computer vision with microsoft kinect sensor: a review. IEEE Trans. Cybern. 43, 1318–1334 (2013). https://doi.org/10.1109/TCYB.2013.2265378

Gorthi, S.S., Rastogi, P.: Fringe projection techniques: whither we are? Opt. Lasers Eng. 48, 133–140 (2010)

Chan, F.W.Y.: Reflective fringe pattern technique for subsurface crack detection. NDT E Int. 41, 602–610 (2008). https://doi.org/10.1016/j.ndteint.2008.06.003

Geng, J.: Structured-light 3D surface imaging: a tutorial. Adv. Opt. Photonics. 3, 128 (2011). https://doi.org/10.1364/AOP.3.000128

Matsuoka, M., Serikawa, S., 欠陥検査装置及び欠陥検査方法, Japan Patent P2019-105458 (2019)

Born, M., Wolf, E.: Principles of optics: electromagnetic theory of propagation, interference and diffraction of light. Elsevier (2013)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Derivation of Eq. 6 \({\varvec{\Gamma}}\left({\varvec{x}},{\varvec{y}}\right)\)

In Eqs. 2 and 3, \(S\left(x,y\right)\) and \(C\left(x,y\right)\) are newly defined by the following equations:

and

respectively. Here, \(\Gamma \left(x,y\right)\) can be represented with \(\Gamma \left(x,y\right)=\sqrt{S{\left(x,y\right)}^{2}+C{\left(x,y\right)}^{2}}=\left|C\left(x,y\right)+iS\left(x,y\right)\right|\) in complex form.

Substituting Eq. 4 for \({I}_{\uppsi }\left(x,y\right)\), and then Eq. 5 for \({B}_{\uppsi }(x, y;\uptheta ,\upphi )\) in \(S\left(x,y\right)\), we obtain \(S\left(x,y\right)\). From

and

\(S\left(x,y\right)\) is given as

Similarly, \(C\left(x,y\right)\) is obtained as

Hence, \(\Gamma \left(x,y\right)\) is given as

Substituting \({y}^{^{\prime}}\) for \({y}^{^{\prime}}=y-d\mathrm{tan}\theta \mathrm{sin}\phi\), \(\Gamma \left(x,y\right)\) is given as

By the approximation that the numerical aperture of the telecentric optical system is small (\(\left|\theta \right|\ll 1\)) and the angular distribution \({g}_{0}\left(\uptheta ,\upphi \right)\) of rays is sufficiently close to constant within the integration interval, \(\Gamma \left(x,y\right)\) is given as

Rights and permissions

About this article

Cite this article

Onishi, Y., Seo, Y., Matsuoka, M. et al. Theoretical and experimental guideline of optimum design of defect-inspection apparatus for transparent material using phase-shift illumination approach. Opt Rev 29, 409–419 (2022). https://doi.org/10.1007/s10043-022-00745-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10043-022-00745-0