Abstract

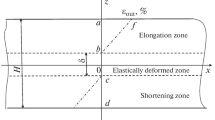

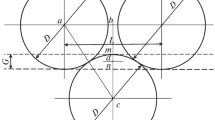

Using the developed model of alternating elastoplastic bending on processing metal strips on a roller straightening machine, we calculate the geometric and deformation parameters of the straightening process. The dependences of the bending radii, the relative and true strains on the strip surface, and the elastically deformed central region thickness on the strip thickness in the range 0.25–3.0 mm and the recommended gaps in a EcoMaster® 25 machine are constructed and analyzed. The straightening parameters that provide the maximum deformation effect on the strip material are determined.

Similar content being viewed by others

REFERENCES

http://stanko-group.net/katalog/stanki-dlya-obrabotki-lista/ustanovki-pravki-lista/precizionnyy-pravilny-stanok-ecomaster-2/(EcoMaster® precision straightening machines).

A. E. Shelest, V. S. Yusupov, M. M. Perkas, E. N. Sheftel’, V. V. Posvirnin, and K. E. Akopyan, “Development of a technique for determining the geometric and deformation parameters of metal sheet straightening on roller straightening machines,” Proizv. Prokata, No. 3, 3–8 (2016).

A. E. Shelest, V. S. Yusupov, M. M. Perkas, and E. N. Sheftel’, “Additional possibilities of the effect of alternating elastoplastic deformation on the properties of metallic materials,” Russ. Metall. (Metally), No. 1, 46–52 (2021).

V. Ya. Mezis, “Effect of changing the sign of cold plastic deformation on some properties of a metal,” Extended Abstract of Cand. Sci. (Eng.) Dissertation, Moscow, 1958.

G. A. Smirnov-Alyaev, Plastic Deformation Resistance of Materials, 3rd ed. (Mashinostroenie, Leningrad, 1978).

A. E. Shelest, V. S. Yusupov, M. M. Perkas, E. N. Sheftel’, K. E. Akopyan, and V. V. Prosvirnin, “Refinement of the technique of plotting the flow curves of a metal to predict its hardening in alternating cold plastic deformation,” Russ. Metall. (Metally), No. 9, 758–763 (2017).

A. A. Bogatov and S. S. Puzyrev, “Shaping and hardening of a metal during metal forming with alternating deformation,” Proizv. Prokata, No. 3, 2–8 (2013).

A. E. Shelest, V. S. Yusupov, M. M. Perkas, E. N. Sheftel’, K. E. Akopyan, and B. V. Prosvirnin, “Formation of the mechanical properties of copper strips during alternating elastoplastic bending,” Russ. Metall. (Metally), No. 5, 500–506 (2018).

GOST 11701–84. Metals. Methods of Tensile Tests of Thin Sheets and Strips (Izd. Standartov, Moscow, 1985).

S. V. Samusev and A. V. Lyuskin, “Procedure for calculating the geometric parameters of a pipe billet during shape change in various TESA lines,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 1, 10–12 (2009).

S. V. Samusev, G. P. Zhigulev, M. M. Skripalenko, and V. A. Fadeev, “Parameters of step forming of a billet in the production of large-diameter pipes on a TESA 1420 line,” Cher. Metally, No. 9, 73–77 (2017).

Funding

This work was performed according to state assignment 075-00328-21-00.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Shelest, A.E., Yusupov, V.S., Karelin, R.D. et al. Geometric and Deformation Parameters of Elastoplastic Alternating Bending of a Strip during Processing on a Roller Straightening Machine. Russ. Metall. 2022, 546–551 (2022). https://doi.org/10.1134/S0036029522050093

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029522050093