Abstract

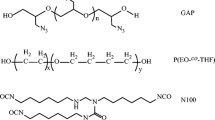

To improve the toughness of the semi-rigid chain of nitrocellulose (NC), and to avoid the phenomenon of small molecule gas generated by isocyanate polycondensation reaction in the curing of propellant, glycidyl azide polymer (GAP)-hexamethylene diisocyanate (HDI)-NC (GAP-HDI-NC) graft polymer and its click reaction elastomer were successfully fabricated by azide-alkyne cycloaddition click reaction in this contribution. In addition, the formulations of GAP-HDI-NC graft polymer and its elastomer were optimized on the basis of improving the mechanical properties, thermal stability and safety. With the increasing of GAP content, the peak value of α transition at high temperature increases, that is, mechanical loss increases and tensile strength decreases. When the mass ratio of GAP to NC is 45:55, the tensile strength (σm) and breaking elongation (εb) of GAP-HDI-NC graft polymer are 44.1 MPa and 58.7% respectively, and the Tg1 of GAP-HDI-NC click reaction curing elastomer reaches the minimum value of 105.7 °C, which is much lower than that of pristine NC. When R2 value is 1.0, the σm of GAP-HDI-NC click reaction curing elastomer reaches the maximum value of 47.6 MPa, while when R2 value is 0.9, its εb reaches the maximum value of 55.8%. In addition, the click reaction of azide group is beneficial to improve the thermal stability and safety performance of GAP-HDI-NC click reaction curing elastomer, which has good potential as solid propellant binder.

Graphical abstract

Similar content being viewed by others

References

Boopathi SK, Hadjichristidis N, Gnanou Y et al (2019) Direct access to poly (glycidyl azide) and its copolymers through anionic (co-)polymerization of glycidyl azide. Nat Commun 10:293. https://doi.org/10.1038/s41467-018-08251-1

Boulkadid MK, Lefebvre MH, Jeunieau L, Dejeaifve A (2019) Burning rate of artificially aged solid double-base gun propellants. J Energ Mater 38(2):1–19

Chai H, Duan Q, Jiang L et al (2019) Theoretical and experimental study on the effect of nitrogen content on the thermal characteristics of nitrocellulose under low heating rates. Cellulose 26:763–776

Daniel AW, James AF, Roan ASV, James DC (2021) Can 2-pyridyl-1,2,3-triazole “Click” ligands be used to develop Cu(I)/Cu(II) molecular switches. ACS Omega 6(44):30115–30129

Darryl AB, Jawad N, Jake F et al (2014) Facile fabrication of color tunable film and fiber nanocomposites via thiol click chemistry. Macromolecules 47(2):695–704

Ding HQ, Xiao LQ, Jian XX et al (2012) Research of blends of GAP-based polyurethane elastomer and NC. J Solid Rocket Technol 35(4):495–499

Gligorijević N, Živković S, Subotić S, Rodić V, Gligorijević I (2015) Effect of cumulative damage on rocket motor service life. J Energ Mater 33:229–259

Horne WS, Yadav MK, Stout CD, Ghadiri MR (2004) Heterocyclic peptide backbone modifications in an α-helical coiled coil. J Am Chem Soc 126(47):15366–15367

Hu YW, Zheng QL, Zhou WL et al (2016) Chin J Energ Mater 24(4):331–335

Hu JH, Liu YN, Cong K, He JY, Yang RJ (2020) Curing behaviors of alkynyl-terminated copolyether with glycidyl azide polymer in energetic plasticizers. Polymers 12:1199

Jawaid M, Abdul Khalil HPS, Hassan A, Dungani R, Hadiyane A (2013) Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos Part B-Eng 45:619–624

Kantheti S, Narayan R, Raju KVSN (2015) The impact of 1,2,3-triazoles in the design of functional coatings. RSC Adv 5:3687–3708

Kim SH, Im YT (2019) Experimental study of material behavior of AP-HTPB base composite solid propellant. J Mech Sci Technol 33(7):3355–3361

Luo YJ, Li SH, Li GP, Chai CP, Pang SP (2015) Novel engergetic materials. National Defense Industry Press, Beijing

Luo LQ, Jin B, Chai ZH, Huang Q, Chu SJ, Peng RF (2019) Interaction and mechanism of nitrocellulose and N-methyl-4-nitroaniline by isothermal decomposition method. Cellulose 26:9021–9033

Ma ZL, Qi L, He W, He LM (2019) A novel approach on the study of cure kinetics for rheological isothermal and non-isothermal methods. Compos Part B-Eng 162:242–249

Ma S, Fan HJ, Zhang N et al (2020) Investigation of a low-toxicity energetic binder for a solid propellant: curing, microstructures, and performance. ACS Omega 5(47):30538–30548

Max B, Konstantin K, Thomas MK (2021) A GAP replacement: Improved synthesis of 3-azidooxetane and its homopolymer based on sulfonic acid esters of oxetan-3-ol. J Org Chem 86(18):12607–12614

Michael N (2000) Compounding of glycidyl azide polymer with nitrocellulose and its influence on the properties of propellant. Propell Explos Pyrot 25:236–240

Min BS, Kim CK, Ryoo MS et al (2014) Azide-bearing polymer-based solid composite propellant prepared by a dual curing system consisting of a urethane-forming reaction and a dipolar addition reaction. Fuel 136:165–171

Ning B, Liu R, Yang ZQ, Hu RZ, Yu QS (1999) Numerical simulation of kinetic parameters of the first-order autocatalytic decomposition of NC. Chin J Energ Mater 7(4):162–165

Ou YP, Zhao Q, Zhang W, Zhang B, Yan S, Jiao QJ (2019) Fabrication of glycidyl azide polymer-hydroxyl terminated polyether semi-interpenetrating network via synchronous dual curing system. Mater Lett 237:152–155

Pan B, Yu LP, Yuan JY, Shen ZB, Tang GJ (2015) Determination of viscoelastic Poisson’s ratio of solid propellants using an accuracy-enhanced 2D digital image correlation technique. Propell Explos Pyrot 35:1–11

Pourmortazavi SM, Kohsari I, Zandavar H, Koudehi MF, Mirsadeghi S (2019) Electrospining and thermal characterization of nitrocellulose nanofibers containing a composite of diaminofurazan, aluminum nano-powder and iron oxide nanoparticles. Cellulose 26:4405–4415

Saba N, Jawaid M, Alothman OY, Paridah MT (2016) A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr Build Mater 106:149–159

Sharma S, Dhakate SR, Majumdar A, Singh BP (2019) Improved static and dynamic mechanical properties of multiscale bucky paper interleaved Kevlar fiber composites. Carbon 152:631–642

Sonawane S, Anniyappan M, Athar J et al (2016) Isocyanate-free curing of glycidyl azide polymer with bis-propargylhydroquinone. Propell Explos Pyrot 42(4):386–393

Wang ZJ, Qiang HF (2021) Mechanical properties of thermal aged HTPB composite solid propellant under confining pressure. Def Technol. https://doi.org/10.1016/j.dt.2021.06.014

Wang ZJ, Qiang HF, Wang G et al (2018) Strength criterion of composite solid propellants under dynamic loading. Def Technol 14(5):457–462

Wu YG, Luo YJ, Ge Z (2012) Mechanical properties of the binder for GAP based cross-linked modified double-base propellant. Chin J Explos Propellants 35(2):66–69

Wu YG, Ge Z, Luo YJ (2016) Properties and application of a novel type of glycidyl azide polymer modified double-base spherical powders. J Therm Anal Calorim 124:107–115

Wu YG, Chai K, Cai L, Yi ZC (2021) Preparation, characterization and molecular dynamics of novel pre-plasticized nitrocellulose composite microspheres containing burning rate catalysts. J Energ Mater 39(2):228–245

Wu YG (2018) A preparation method of elastomer based on azide-modified nitrocellulose microspheres. Chinese patent, ZL 201810628903.2

Zhang DQ (1995) Properties and preparation of raw materials for gunpowder. Beijing University of Technology Press, Beijing

Zhang L, Shen ZB, Li HY (2020a) Effects of superimposed pressure on the mechanical properties of HTPB propellant in a wide temperature range. Propell Explos Pyrot 45:1–12

Zhang PA, Yuan JM, Pang AM, Tang G, Deng JR (2020b) A novel UV-curing liner for NEPE propellant: insight from molecular simulations. Compos Part B-Eng 195:108087

Zou XB, Zhang WG, Zhang ZH et al (2021) Study on properties of energetic plasticizer modified double-base propellant. Propell Explos Pyrot 46:1662–1671

Acknowledgments

This work was supported by the Natural Science Foundation of Hubei Province (2020CFB649). The authors also appreciate the Natural National Science Foundation of China (51603156) and the Wuhan Institute of Technology Scientific Research Foundation of China (grant number k201704).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

This paper has no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Y., Li, C., Gao, J. et al. Preparation and properties of azide-modified nitrocellulose and its click reaction curing elastomer. Cellulose 29, 6009–6020 (2022). https://doi.org/10.1007/s10570-022-04637-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04637-z