Abstract

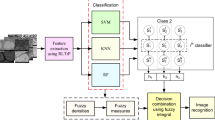

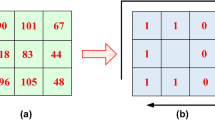

The hardness prediction model was established by support vector regression (SVR). In order to avoid exaggerating the contribution of very tiny alloying elements, a weighted fuzzy C-means (WFCM) algorithm was proposed for data clustering using improved Mahalanobis distance based on random forest importance values, which could play a full role of important features and avoid clustering center overlap. The samples were divided into two classes. The top 10 features of each class were selected to form two feature subsets for better performance of the model. The dimension and dispersion of features decreased in such feature subsets. Comparing four machine learning algorithms, SVR had the best performance and was chosen to modeling. The hyper-parameters of the SVR model were optimized by particle swarm optimization. The samples in validation set were classified according to minimum distance of sample to clustering centers, and then the SVR model trained by feature subset of corresponding class was used for prediction. Compared with the feature subset of original data set, the predicted values of model trained by feature subsets of classified samples by WFCM had higher correlation coefficient and lower root mean square error. It indicated that WFCM was an effective method to reduce the dispersion of features and improve the accuracy of model.

Similar content being viewed by others

References

S.Z. Wei, L.J. Xu, Acta Metall. Sin. 56 (2020) 523–538.

M. Jin, J.S. Lian, Z.H. Jiang, Acta Metall. Sin. 42 (2006) 405–410.

C.L. Hu, Y. Hu, Y.J. Zhang, Q.W. Deng, K.F. Quan, S.S. Li, Z. Zhao, Journal of Plasticity Engineering 27 (2020) No. 5, 7–11.

D.C. Wang, L.J. Wang, J.C. Guo, S.P. Ruan, S.L. Li, Heat Treatment of Metals 45 (2020) No. 8, 82–85.

J.H. Wang, S. Sun, Y.L. He, T.Y. Zhang, Sci. Sin. Technol. 49 (2019) 1148–1158.

X.Y. Chen, H.Z. Fang, Q. Wang, S.Y. Zhang, R.R. Chen, Y.Q. Su, China Foundry 17 (2020) 429–434.

D.M. Ji, Adv. Mater. Res. 616–618 (2013) 1787–1796.

N. Pillai, R. Karthikeyan, in: IOP Conf. Ser.: Mater. Sci. Eng. 346 (2018) 012067.

R. Slavkovic, Z. Jugovic, S. Dragicevic, A. Jovicic, V. Slavkovic, Comput. Ind. Eng. 64 (2013) 850–857.

S.F. Fang, M.P. Wang, W.H. Qi, F. Zheng, Comput. Mater. Sci. 44 (2008) 647–655.

G.Q. Wang, X. Chen, Y.X. Li, China Foundry 16 (2019) 190–197.

L.C. Yan, Y.P. Diao, K.W. Gao, Materials 13 (2020) 3266.

T. Shiraiwa, Y. Miyazawa, M. Enoki, Mater. Trans. 60 (2018) 189–198.

A. Agrawal, A. Choudhary, Int. J. Fatigue 113 (2018) 389–400.

G.M. Sun, H. Liu, C.F. He, Y. Li, Z.B. Li, X.C. Liu, R.H. Zhang, H.N. Lu, J. Beijing Univ. Technol. 45 (2019) 119–125.

J. Gola, J. Webel, D. Britz, A. Guitar, T. Staudt, M. Winter, F. Mücklich, Comput. Mater. Sci. 160 (2019) 186–196.

S. Datta, F. Pettersson, S. Ganguly, H. Saxén, N. Chakraborti, ISIJ Int. 47 (2007) 1195–1203.

J. Xiong, S.Q. Shi, T.Y. Zhang, Mater. Des. 187 (2020) 108378.

W. Yang, W.G. Li, Y.T. Zhao, B.K. Yan, W.B. Wang, Iron and Steel 53 (2018) No. 3, 44–49.

J. Xiong, T.Y. Zhang, S.Q. Shi, Sci. China Technol. Sci. 63 (2020) 1247–1255.

J.M. Zhou, W.H. Yin, T. You, F.L. Wang, Y. Liu, C. Chen, Machine Tool & Hydraulics 49 (2021) No. 1, 175–179.

J.B. Zhang, Z.H. Deng, S.T. Wang, Journal of Frontiers of Computer Science and Technology 9 (2015) 1513–1522.

H.H. Chen, J.D. Xing, W. Li, Application manual of wear resistant materials, 2nd ed., Machine Press, Beijing, China, 2012.

S. Wikaisuksakul, Appl. Soft Comp. 24 (2014) 679–691.

P. Kilham, C. Hartebrodt, G. Kändler, Forests 10 (2019) 20.

Z.H. Zhou, Machine learning, Tsinghua University Press, Beijing, China, 2018.

Z. Li, K. Luo, Journal of Computer Applications 31 (2011) 1355–1358.

Z.X. Zhao, Y.M. Gao, K.H. Zheng, Y.F. Li, S.Y. Zhao, Hot Working Technology 49 (2020) No. 2, 1–5.

J.P. Ning, K.H. Zheng, H.M. Zhou, H.Y. Wang, J. Long, Foundry 69 (2020) No. 2, 135–141.

H. Guo, Y. Liu, W. Li, Hot Working Technology 43 (2014) No. 10, 207–210.

Y.M. Dai, Y.Q. Ma, X.J. Zhang, L.T. Sun, P. Shi, Transactions of Materials and Heat Treatment 36 (2015) No. 1, 119–123.

B. Yu, X.Y. Li, J. Shi, Z.H. Li, H.F. Gao, J. Hu, Heat Treatment of Metals 40 (2015) No. 2, 176–179.

Acknowledgements

This work was financially supported by the National Research and Development Project of China (2020YFB2008400).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, Y., Wei, Sz. A weighted fuzzy C-means clustering method for hardness prediction. J. Iron Steel Res. Int. 30, 176–191 (2023). https://doi.org/10.1007/s42243-022-00786-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00786-4