The structure and mechanical properties of tough-pitch copper are studied after alternating elastoplastic deformation (bending). It is shown that alternating bending of a 3-mm-thick strip of tough-pitch copper raises the microhardness and produces a gradient of its values, i.e., the microhardness is minimum in the middle (with respect to the thickness) part of the strip and maximum near its surfaces. After the first pass of alternating bending the conventional yield strength of the strip increases by a factor of 1.5 without degradation of the elongation. The structural factors affecting the variation of mechanical properties of tough-pitch copper under alternating bending are determined.

Similar content being viewed by others

References

E. A. Maksimov and R. L. Shatalov, “Method for computing the parameters of straightening and the power of the main drive of a roller leveler,” Stal’, No. 6, 52 – 55 (2017).

R. L. Shatalov, A. S. Lukash, and V. L. Zisel’man, “Determination of mechanical properties of copper and brass strips from the parameters of hardness in cold rolling,” Tsvetn. Met., No. 5, 61 – 65 (2014).

Yu. A. Alyushin, S. V. Samusev, and G. P. Zhigulev, “Bending of sheet billets for longitudinal-welded tubes,” Chern. Met., No. 5, 40 – 46 (2016).

S. V. Samusev, G. P. Zhigulev, V. A. Fadeev, and K. S. Manakhov, “Shaping of pipe blanks on specialized bending equipment,” Steel in Trans., 46(3), 169 – 172 (2016).

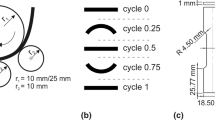

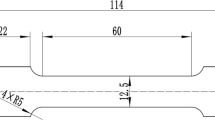

A. E. Shelest, V. S. Yusupov, M. M. Perkas, et al., “Special features of formation of mechanical properties of copper strips under alternating elastoplastic bending,” Metally, No. 3, 88 – 95 (2018).

E. V. Bobruk, I. P. Semenova, and R. Z. Valiev, Recent Methods of Deformation-Thermal Treatment: from Traditional Materials to Nanostructured Ones [in Russian], Ufimsk. Gos. Aviats. Tekh. Univ., Ufa (2015), 112 p.

A. E. Shelest, V. S. Yusupov, M. M. Perkas, et al., “Development of methods for determination of geometric and deformation parameters for straightening metallic sheets in roller levelers,” Proizvod. Prokata, No. 7, 3 – 8 (2016).

A. E. Shelest, V. S. Yusupov, M. M. Perkas, et al., “Advancement of methods for plotting metal flow curves for predicting its hardening under alternating cold plastic deformation,” Metally, No. 5, 89 – 95 (2017).

N. I. Matrosov, V. V. Chishko, E. A. Medvedskaya, et al., “Dependence of mechanical properties of metallic materials on the scheme of deformation,” Fiz. Tekh. Vysok. Davl., 15(4), 54 – 58 (2005).

A. G. Ksenofontov, M. Yu. Sidel’nikova, M. Yu. Krylov, and V. K. Fadeev, “High-temperature thermoplastic hardening of steels St3sp and 09G2S,” Metalloved. Term. Obrab. Met., No. 7, 18 – 19 (1991).

Y. Perlovich, M. Isaenkova, and V. Fesenko, “Modern methods of experimental construction of texture complete direct pole figures by using x-ray data,” IOP Conf. Ser., Mater. Sci. Eng., 130, 012055 (2016).

K. Pawlik, “Determination of the orientation distribution function from pole figures in arbitrarily defined cells,” Phys. Status Solidi B, 134, 477 – 483 (1986).

V. M. Matykhin, A. Yu. Marchenkov, A. E. Shelest, et al., “Variation of mechanical properties in tough-pitch copper under the action of alternating elastoplastic deformation,” Deform. Razrush. Mater., No. 5, 39 – 45 (2019).

M. G. Isaenkova, Yu. A. Perkovich, A. E. Rubanov, and A. V. Yudin, “Anisotropy of the mechanical properties of austenitic steel products obtained by selective laser melting,” CIS Iron Steel Rev., 18, 64 – 68 (2019).

F. A. Calnan and C. J. B. Clews, “Deformation textures in face-centred cubic metals,” The London, Edinburgh, and Dublin Philos. Mag. J. Sci., 41(322), 1085 – 1100 (1950).

M. A. Shtremel, Strength of Alloys. Part II. Deformation [in Russian], MISiS, Moscow (1997), 527 p.

V. S. Zolotarevskii, Mechanical Properties of Metals [in Russian], MISiS, Moscow (1998), 400 p.

R. N. Kyutt and A. A. Dyshekov, “Effect of microstructure of epitaxial layers on the shape of x-ray diffraction peaks,” Pis’ma Zh. Tekh. Fiz., 37(7), 31 – 37 (2011).

S. O. Rogachev, R. V. Sundeev, D. A. Kozlov, and D. V. Khalidova, “Structure and hardening of a layered steel/copper/steel material after joint torsional deformation at high pressure,” Fiz. Met. Metalloved., 120(2), 205 – 211 (2019).

The work has been performed within state assignment to IMET RAN No. 075-00328-21-00.

Author information

Authors and Affiliations

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 38 – 43, November, 2021.

Rights and permissions

About this article

Cite this article

Rogachev, S.O., Andreev, V.A., Perkas, M.M. et al. Effect of Alternating Bending on the Structure and Mechanical Properties of Tough-Pitch Copper. Met Sci Heat Treat 63, 612–617 (2022). https://doi.org/10.1007/s11041-022-00737-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-022-00737-6