Abstract

Grip strength is an important indicator of health conditions and needs to be monitored for health management. However, different populations (e.g., babies and rehabilitation patients) have different hand sizes and different levels of grip strengths, requiring a personalized sensor to monitor grip strength. In this paper, we developed a smart ball sensor by laser kirigami of graphene for personalized grip strength monitoring. To realize the rational utilization of space, a transparent pill shell embedding all electronic accessories is installed in the center of the ball sensor with a spiral-sensing unit fabricated by laser kirigami of graphene on the surface. Furthermore, we assessed the influence of contact area between hand and ball on grip strength using finite-element analysis (FEA), which was then considered in our results readout. The grip strength can be continuously read by a mobile phone in a wireless manner. The smart ball sensor demonstrated a high performance in vitro against gold-standard method in diseased and healthy subjects. It would be a powerful tool for personalized long-term monitoring of grip strength, especially suitable for specific populations such as babies and sensitive enough for samll grip strength.

Similar content being viewed by others

Introduction

Grip strength, referred to muscular strength, is an important indicator of health conditions associated with aging, diseases, nutrition, and degree of training or rehabilitation1,2,3,4. For instance, poliomyelitis caused by poliovirus has clinical symptoms of bodily pain and muscular atrophy, mainly occurring in children under five years old, especially babies5. Clinical pediatricians generally recommend handgrip tests to predict incident disability or even early diagnose muscular weakness/atrophy-related diseases such as poliomyelitis6,7. Furthermore, many rehabilitation patients suffer from myasthenia caused by hand injury or paraplegia due to spinal cord injury, which results in significantly reduced grip strength8. It is necessary to detect the grip strength during the rehabilitation process for better monitoring the state of illness to direct the treatments9,10. Therefore, personalized grip strength detection in a simple, fast, inexpensive and painless manner is an appealing need for effective long-term monitoring of human health, especially important for reducing the risk of cardiovascular morbidity or even mortality11,12,13,14,15,16.

There exist various hospital grip instruments and commercial hand dynamometers for measuring grip strength. However, they are generally designed for adults and are not small enough or sensitive enough for special populations (e.g., babies and rehabilitation patients). Besides, clinical detection of grip strength relies on large and complex grip instruments, limiting its access for special populations who need personalized handgrip monitoring. Therefore, there is still an unmet need for the small size and the high sensitivity grip monitor to conduct an effective, inexpensive and portable grip monitoring suitable for specific populations such as tiny enough for babies and sensitive enough for people with small grip strength.

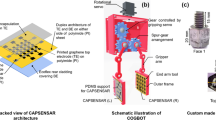

In this work, as inspired by the rationally structural design of a 3D spherical ball base combined with laser reduction17,18,19,20,21 and kirigami techniques22,23,24,25,26,27, we developed a smart ball sensor fabricated by laser kirigami of graphene with the small size and the high sensitivity for small grip monitoring (Fig. 1). The smart ball sensor includes four parts, i.e., an elastic ball base, two graphene-based spiral sensors, a transparent pill shell filled with all electronic accessories, and a sealing layer. The soft elastic ball was designed for users’ comfort and convenience, and its 3D contact surface enables a 3D spiral sensor landed onto the ball base. All the electrical accessories were placed in the center of the ball for signal processing. The continuous readout can be acquired in a wireless way with a cellphone for personalized health management in daily life. Furthermore, the contact area between hand and ball was calculated through FEA and the result was used to revise the equation of grip strength. Finally, we compared the on-body validation tests in adults and children’s grip detection with hospital and household grip detections, and evaluated its potential for personalized long-term monitoring of grip strength.

Results and discussions

Rational design of the smart ball sensor

In this paper, we developed a smart ball sensor (Fig. 1a) for long-term monitoring of the grip strength, especially beneficial for specific populations, such as tiny enough for babies and sensitive enough for people with samll grip strength (Fig. 1b). The smart ball sensor mainly includes four units, i.e., a soft elastic ball base made of PDMS, a spiral sensor fabricated by laser kirigami, a transparent pill shell installed all electronic accessories inside, and a thin sealing layer (Supplementary Fig. 1).

Compared to the existed smart ball sensors28,29,30,31, our device exhibits significant advantages for long-term health monitoring, in terms of portability, 3D theory support, innovative structure design and powerful functions (Fig. 1c). Firstly, it has a unique 3D soft elastic ball-based design and the 3D spiral sensing units spread onto the entire surface of the ball, accurately capturing the deformations of the ball during grasping. It is sensitive enough to a slight deformation by a tiny grasping. In addition, our smart ball sensor can realize the small size and the high sensitivity of small grip detection, showing significant advantages over the representive commercial grip instruments (e.g., hospital grip instruments by the film-based pressure sensing, and the household dynamometer by the spring-based sensing). To realize the rational utilization of space, and inspired from the core-sheath structure of materials32,33,34, all electronic accessories are installed in a transparent pill shell in the center of the ball with a charging port retained (Supplementary Figs. 2–4). Considering the users’ demands of comfortable, convenient, inexpensive and household experiences, we designed this fully integrated, portable and miniaturized smart ball sensor with wireless transmission, enabling the constant results readout of grip strength by a cellphone. Such a design just needs a simple molding process, which provides a new template for the fast mass production of flexible sensors in situ (Supplementary Fig. 5). In addition, laser kirigami successfully achieves an approach of 3D spiral sensing unit from 2D film, allowing scalable manufacture for wearable devices because of rapid and precise patterning in ambient conditions.

Laser kirigami of a 3D graphene-based spiral-sensing unit

The spiral-sensing unit is crucial to the smart ball sensor, which is prepared by direct laser patterning of graphene-based piezoresistive material on the polyimide film and landing on the 3D terraced fields of the soft elastic ball base. It is perfectly attached to the surface of the ball to make an integration of the 3D strain-sensing unit. The sensing material of graphene has superiorities of fast electron mobility, large specific surface area, ultrahigh current carries, intriguing optical properties and excellent electrical conductivity35,36,37,38,39. These unique properties enable graphene to be an appropriate candidate for high-performance piezoresistive sensing unit to monitor weak signals such as tiny grip strength from babies or rehabilitation patients40,41,42,43. The mechanism is that it can respond to the mechanical deformations as induced by grasping the smart ball, which leads to resistance changes (Fig. 2a).

a Mechanism of graphene-based piezoresistive strain sensing. b A cock pattern obtained from laser reduction on PI. c SEM cross-section and surface images of the graphene-based strain sensor. d I–V curves of the graphene-based strain sensor (20*5*0.075 mm) with different laser speeds. e Strain–stress curves. f Cyclic test of the strain-resistance curve (laser speed 1%, power 0.3%, PPI 400).

Structural designs of material morphology and layout are critical for realizing the sensing effect. The fine pattern design (Fig. 2b) and flower-like appearance with porous structure (Fig. 2c), are resulted from the optimized laser parameters (lower laser speed 1%, power 0.3%, PPI 400). It achieves a much lower electrical resistance of 4.59 kΩ cm−1, compared with 8.09 kΩ cm−1 by the medium speed of 1.2% and 10.07 kΩ cm−1 by the higher speed of 1.4% (Fig. 2d). Relative lower laser speed yields more graphene production on the surface of PI film. Here, a thin protective layer of PDMS is coated onto the surface of the graphene sensing unit to avoid graphene loss. In addition, the 3D spiral sensor is designed for the grip monitoring. The laser kirigami enables the spreading of 2D films into the 3D architecture to be suitable for a 3D soft elastic ball. Leveraging the unique structures and 3D spiral layout, the graphene-based 3D spiral-sensing unit can accurately respond to the mechanical deformations of the ball during grasping. It is sensitive enough to a tiny deformation and stable enough to achieve reliable monitoring. The graphene-based sensing unit fabricated by higher laser speed can withstand a larger tensile strength due to the lower laser-engraved depth, leading to a relatively more robust PI substrate with a maximum strain of 29% (Fig. 2e, Supplementary Fig. 6). However, it produces the least sensing material of graphene under higher laser speed, which is not favorable for sensing applications. So lower laser speed of 1% is further used in this research, and its significant strain response and high stability are suitable for accurate detection of grip strength (Fig. 2f).

Furthermore, based on the tests of a graphene-enabled strain sensor, a spiral sensing unit (Supplementary Fig. 7) is designed for the grip monitoring. The spiral sensing unit from 2D film to 3D architecture, via stretching the spiral sensor fabricated by laser kirigami, gives a resistance change rate of 76.19 kΩ cm−1 up to 2 MΩ at a maximum stretching height of 21 cm (Fig. 3). The smart ball sensor with a mechanical strength of 32.97 kPa, embedded with the super sensitive graphene-based spiral-sensing units fabricated by laser kirigami, is suitable for accurately monitoring the grip strength.

It shows that the 3D graphene-based spiral sensor prepared by stretching the 2D graphene-based spiral sensor fabricated by laser kirigami. The resistance changes with the time of a continuous stretching test in a stretching cycle. The maximum stretching height reaches 21 cm. Laser speed 1%, power 0.3%, PPI 400.

Performance and mechanism of the grip strength monitoring

Structural deformations of the graphene-based spiral sensor result in resistance change, which is the piezoresistive sensing mechanism. When compressed, the spiral sensor is deformed, leading to the change of resistance. Thus, the smart ball sensor responds to the grip strength in terms of resistance change rate. To determine the relationship between the grip strength and resistance change rate, an indentation test of the smart ball sensor was conducted (Fig. 4a). Then the relationship between grip strength and resistance change rate was obtained as

where \(\Delta R/R_0\) and F are the resistance change rate and grip strength respectively, and \(a = 1.03 \times 10^{ - 2}\,{{{\mathrm{N}}}}^{ - 2}\) is the fitting parameter. Meanwhile, the smart ball sensor exhibits highly cyclic (Fig. 4b) and stable (Fig. 4c) performances.

a Resistance changes versus different forces of the smart ball sensor. b Cyclic performance (1 Hz, 17.7 N) and c stability under various levels of force. Under a contact area of 490.87 mm2, d the 2D loading model and e FEA results of the strains of the spiral sensor versus different compressing forces. Under a compressing force of 18 N, f the 3D loading model and g FEA results of the strains of the spiral sensor versus different 3D contact areas. The spiral sensor (diameter 45 mm × width 2 mm × thickness 0.075 mm, 4 circles, 1% laser speed, 0.3% power, 400 PPI), the egg-shaped ball model (width 3.8 cm × height 5.8 cm), and the indenter (diameter 25 mm × height 3 mm) were used here.

However, the actual handgrip is not only related to the compressing force onto the ball, but also related to the contact area between hand and ball. Since the strains of the spiral sensor could be different even with the same grip force when the contact areas are different, further leading to the different resistance change rates of the spiral sensor. To explore the influence of the contact area, FEA was introduced. First, a compressing FEA model (Fig. 4d) was established based on the actual indentation test in Fig. 4a, which was experimentally verified under a 10 mm compressing process using a cylindrical indenter (25 mm in diameter and 3 mm in height) (Supplementary Fig. 8). From the displacement fields of the ball as obtained by simulation, we found that the horizontal deformation of the ball increases during the vertical compression with the same contact area (Video 1). Based on the horizontal displacement fields of the ball, we calculated the strains of the spiral-sensing unit with various compressing forces (Fig. 4e, Supplementary Fig. 9). Therefore, by using this cylindrical indenter, the linear equation between the strain of the spiral-sensing unit and the compressing force under the same contact area could be obtained as

where ε is the strain of the spiral sensing unit, S is the contact area, which is equal to \(S_{{indenter}}(490.87\,{{{\mathrm{mm}}}}^2)\) corresponding to the bottom area of the cylindrical indenter in the indentation test, and \(k = 1.89 \times 10^{ - 3}\,{{{\mathrm{N}}}}^{ - 1}\) is the linear fitting parameter.

Furthermore, unlike 2D plane loading with a 2D contact area, the actual handgrip is a 3D loading onto a 3D curved surface. So FEA was used to simulate the 3D loading process, which gave the displacement fields of the ball with various 3D contact areas in the same compressing force of 18 N (Fig. 4f, Supplementary Fig. 9). The horizontal deformation of the ball becomes increasingly concentrated in the center of the ball with increasing contact area (Video 2). Then based on the horizontal displacement fields of the ball with various 3D contact areas under the same compressing force, we calculated the strains of the spiral-sensing unit (Fig. 4g). Under a compressing force of 18 N, the fitted exponential equation about the relationship between the strain of the spiral sensing unit and the 3D contact area is

where \(b = - 4.8 \times 10^{ - 4}\,{{{\mathrm{mm}}}}^{ - 2}\) is the fitting parameter, and ε0 is equal to the ideal strain when contact area S = 0. According to Eq. (3), we obtain

Substituting Eq. (4) into Eq. (2), we rewrite Eq. (4) as

Based on Fig. 2e, we can obtain \(\Delta R/R_0 = C\varepsilon ^2\), where C is a constant to be determined. Combining this equation and Eq. (5), the relationship of resistance change rate, grip strength and contact area could be converted to the following equation:

Substituting Eq. (1) and \(S = S_{{{indenter}}}\) into Eq. (6), we obtain \(Ck^2 = a = 1.03 \times 10^{ - 2}\,{{{\mathrm{N}}}}^{ - 2}\). Then we get \(\Delta R/R_0 = \Delta R/R_0(F,S)\).

However, in the actual handgrip monitoring, the 3D contact area is difficult to measure. To address this, we proposed to measure the arc length when grasping the ball to determine the 3D contact area between hand and ball. The relationship between 3D contact area and arc length could be obtained by the following equation:

where r is the radius of the lower part of the ball and l is measured arc length. Details about the arc length method can be found in Supplementary Figs. 10 and 11.

Overall, substituting Eq. (7) into Eq. (6), the final equation of the grip strength in the way of \(F = F\left( {\Delta R/R_0,\,l} \right)\), is

where \(a = 1.03 \times 10^{ - 2}\,{{{\mathrm{N}}}}^{ - 2}\) and \(b = - 4.8 \times 10^{ - 4}\,{{{\mathrm{mm}}}}^{ - 2}\) are the fitting parameters from Eqs. (1) and (3). \(S_{{{indenter}}}\) is a constant of \(490.87\,{{{\mathrm{mm}}}}^{{{\mathrm{2}}}}\) in Fig. 4, but other mini-ball sensors may have a different \(S_{{\mathrm {indenter}}}\) when a smaller or larger indenter is used to compress the ball. In actual grip strength detection, it needs to measure the arc length under grasping, and then a cellphone could calculate the grip strength according to Eq. (8). This smart ball sensor thus achieves highly sensitivity grip strength monitoring.

In addition, other directions of compression, such as 45° and 90° loading, should also be considered in the actual applications. Therefore, we have made a mechanical analysis from both experiments and simulations about other loading conditions. From the aspect of experiments, we found that only compression along the vertical axis (Supplementary Fig. 12) of the smart ball sensor could get the consistent, repeatable, effective, stable and continuous signals of the spiral sensor. Other directional loading may generate loose stage of the circles of the spiral sensor, which could further produce irresponsive or jumping signals of the ball sensor. Therefore, from the aspect of experiments, only vertical compression is reliable for the grip study. From the aspect of simulation, besides the vertical compression (Supplementary Fig. 13), we also established a 3D FEA model of the egg-shaped ball, and studied the effects of different 3D loading forces (Supplementary Fig. 14) and areas (Supplementary Fig. 15) on the deformations of the ball under 90° compression. However, it is challenging to calculate the strains of the spiral sensor under 90° loading, due to the non-uniform deformations around the circles of the spiral sensor. The egg-shaped design of the ball sensor, and the uneven deformation of the landing positions, both increased the difficulty in the selection of boundary conditions and in the calculation of the strains of the spiral sensor under 90° compression. Moreover, the random deformations of the spiral sensor under 45°or other directional (except vertical) compressions could not derive stable and reliable strains of the spiral sensor. Therefore, we chose the vertical compression to study the final expression of the grip strength. In the grip monitoring, we usually recommended the users to compress the ball sensor along the vertical axis of the device to get the most accurate data. That is why we designed the ball sensor in the shape of an egg instead of a simple sphere, which can easily recognize the hold position.

In vitro system validation

In section “Performance and mechanism of the grip strength monitoring”, we proposed a new measurement mechanism model of the grip strength monitoring that considers both the grip strength and the 3D contact area, namely Eq. (8), which revises the original measurement mechanism as shown in Eq. (1). Then we made an accuracy comparison test by evaluating the accuracy of the grip strength without or with considering the 3D contact area, as shown in Eqs. (1) and Eq. (8). The accuracy in this test is defined as

where Fmon is the grip strength derived from the resistance change rate of the sensor in the actual grip strength measurement. Freal is the actual grip strength, which cannot be directly measured in the process of measuring human grip strength but can be obtained in the indentation tests directly. We chose an indenter with a different area (\(S = 1219.2\,{{{\mathrm{mm}}}}^2\)) from that in the section “Performance and mechanism of the grip strength monitoring” for indentation experiments. Then the force directly obtained during the indentation experiment can be taken as Freal. Fmon can be derived by substituting the resistance change rates of the coil sensor into Eqs. (1) and (8), corresponding to the grip strength without or with considering the 3D contact area. Therefore, from Eq. (9), the accuracy of considering 3D contact area was 83.12%, 98.76%, 93.66%, while without considering 3D contact area was 69.79%, 82.92%, 89.29%, when the Freal was 6, 12, 18 N, respectively. That is to say, the accuracy of considering 3D contact area was about 80.67%, while without considering 3D contact area was about 91.85%. These results show that when considering the 3D contact area, the accuracy of grip strength calculated from Eq. (8) is higher than that of not considering the 3D contact area from Eq. (1) (Fig. 5). The accuracy improves 11.18% after considering the 3D contact area in the actual grip strength monitoring. Details data in Supplementary Fig. 16 in the supporting information.

When considering the 3D contact area, Fmon (Eq. (8)), the accuracy of the grip strength calculated from Eq. (8), is higher than that of not considering the 3D contact area from Eq. (1), namely Fmon (Eq. (1)). Accuracy improves 11.18% after considering 3D contact area. Details in Fig. S12 in supporting information.

Grip strength is vital to reflect the health conditions of the heart and brain. An early study published a 4-year investigation on grip strength in 1.4 million people aged 35–70 from 17 different countries. It indicates that as grip strength decreases 5 kg, cardiovascular mortality increases 17%, death risk of non-cardiovascular increases 17%, while the risk of heart attack and stroke increases 7% and 9%44. Besides, the enhancement of grip strength can help to prolong life for cardiovascular patients. The grip strength is such an important health indicator that the hospital rehabilitation departments generally assess the physical rehabilitation by monitoring grip strength. To better demonstrate the powerful functions of our smart ball sensor, we have made a comparison with the hospital grip instruments. For example, a stroke man (aged 57, from the Department of Rehabilitation Medicine in First Affiliated Hospital of Xi’an Jiaotong University) was invited to do the on-body validation tests. The grip strengths of hands and each finger as measured by our ball sensor display accurate and stable results (Fig. 6a–d), as validated by hospital grip instruments with a correlation coefficient of 0.92 (Fig. 6e). A Bland–Altman method45 refers to the combining quantitative and qualitative approaches for analysis of variances between two devices, showing no significant deviation (Fig. 6f). The on-body validation for adults have verified that our smart ball sensor can achieve similar accuracy and sensitivity with the bulky hospital grip instruments. However, the hospital grip instruments are still not sensitive enough for some serious patients, for the reason that the cylindrical handlebar is too hard and can only do the grip sensing by a commercial film-based pressure sensor inside. Just vertically directional forces can be detected by pressure sensor, and other directional forces are not available for the final grip strength. Since the actual grip strength is from all directional forces, such measurement may cause low sensitivity and fail to detect small grip strength. Furthermore, the bulky hospital grip instruments make them less accessible for patients to visit hospital frequently for grip measurement. Although a few hospital grip instruments could achieve small grip detection for rehabilitation patients, there is no miniaturized design for convenient and accurate grip strength measurement for children. While our smart ball sensor with all the electronic accessories embedded in the center of the soft elastic ball (Fig. 6g), can realize continuous monitoring, wireless transmission and readout with a cellphone (Fig. 6h). It is especially suitable for children’s grip monitoring. Compared with the commercial dynamometer in the household usage, our smart ball sensor is small and lightweight enough for better grasping by children’s small hands, which enables accurate and sensitive measurement of children’s grip strength (Fig. 7a). In the aspect of personalized customization, we designed an additional function of color change on the outside of the ball sensor. The temperature sensitive layer of the ball can respond to thermal stimulus in color changes, which can appeal to children for entertainment or strength training (Fig. 7b, Supplementary Fig. 17). After comparing the performances between our proposed device and the household dynamometer in children’s grip measurement, we demonstrate that our smart ball sensor is powerful for a wide range of grip monitoring. It can detect both big grip strength of children over 7 years old and even recognize the small grip strength of infants under 3 years old (Fig. 7c).

a Schematic of a hand dynamometer (hospital grip instrument) read with a computer and the smart ball sensor read with a cellphone. b Finger strength measurement using hospital grip instrument and our smart ball sensor. Comparison between a hospital grip instrument and the proposed smart ball sensor in grip strength of c palm and d four fingers of a stroke patient. e Relationship between the smart ball sensor and hospital grip instrument. The correlation coefficient of the results acquired by the two devices is 0.92. f A Bland–Altman plot of the smart ball sensor and hospital grip instrument. Here all the grip strength means the maximum value. g A digital photo of a pill shell filled with all the electronic accessories. h Photos of the maximum grip strength of a healthy man monitored by the smart ball sensor and read with a cellphone.

a Comparison of volume and weight between commercial grip instrument and our ball sensor. Our ball sensor is small and lightweight enough for better grasping by children’s small hands. b Additional function of the smart ball sensor. The temperature sensitive layer of the ball can respond to thermal stimulus in color change, which can appeal to children for entertainment or strength training. c Comparison of the monitoring performances. There is rarely miniaturized customization of commercial grip instruments for children under 7 years old that can hardly grasp the big and heavy dynamometer by their small hands, so the adult design of the commercial grip instrument cannot get these children’s grip data (S1 stage) or only get inaccurate results (S2 stage). In comparison, our smart ball sensor is powerful for a wide range of grip monitoring. It can not only detect big grip strength of children over 7 years old (S3 stage), same with commercial grip instruments, but also recognize the small grip strength of infants under 7 years old.

In summary, we proposed a smart ball sensor fabricated by laser kirigami of graphene for personalized long-term monitoring of the grip strength. As inspired by the structural composition of an egg, the smart ball sensor has a transparent pill shell with all electronic accessories embedded in the central of the ball and two graphene-based spiral-sensing units landed onto a soft elastic ball base, which realizes a fully integrated design. It is an inexpensive, portable and miniaturized grip device, enabling long-term monitoring of the grip strength in wireless transmission and readout with a cellphone for personalized health management. More importantly, the influence of the contact area between hand and ball on the grip strength was considered for the first time. Finally, a validation between the smart ball sensor and the gold standard method in diseased and healthy subjects was carried out for evaluating its potential for personalized long-term monitoring of grip strength. The smart ball sensor is inexpensive, portable and miniaturized for personalized grip strength monitoring, especially for specific populations such as tiny enough for babies and sensitive enough for samll grip populations.

Methods

Fabrication of the graphene-based spiral sensor

Direct laser writing of the symmetrical spiral coil (45 mm in diameter) on a polyimide film (DuPont, 0.075 mm) is used to make a spiral sensor in a 50-W CO2 laser cutter (Universal laser system). For the sensing spiral coil patterning, the optimized laser parameters were speed 1%, power 0.3%, PPI 400, vector mode. For the cutting spiral coil patterning, the optimized laser parameters were: speed 1%, power 0.6%, PPI 400, raster mode. For better exploring the reduction properties of the laser method, we named 1%, 1.2%, 1.4% as laser lower speed, medium speed, and higher speed. To avoid graphene falling, we coated a thin layer PDMS (1:10) on the symmetrical spiral coil to encapsulate the spiral sensor for better conductive performance.

Fabrication of the smart ball sensor

Firstly, all the electronic accessories (including power system, Bluetooth, and control system) are installed into a transparent pill shell, and a connecting wire stretched out from a small spot at the top of the pill shell. Then the pill shell hung in the middle of an eggshell from a hole at the top. The soft elastic precursor solution of PDMS (1:10) was added into the eggshell (Supplementary Fig. 2b), and dried at 60 °C in an oven. After decladding the eggshell, a soft elastic ball base was obtained. Furthermore, we used an electric welder to construct the terraced fields with the same size and shape as that of the spiral sensor onto the surface of the soft elastic ball. Then we landed the spiral sensor onto the terraced fields to integrate a smart ball sensor. Finally, a thermos-sensitive layer made of PDMS and temperature-sensitive power was coated onto the surface of the ball sensor for encapsulation and better visualization.

When installing the spiral sensor onto the surface of the ball base, precisely controlling the landing effect is important to enable the ball sensor with consistent performance. Because too tight landing to recover its original shape will result in non-consistent performances or even reducing the service life of the spiral sensor, while too loose landing cannot sensitively respond to the external forces. Thus, we did three steps to prevent the random deformations of the spiral sensor. The first is through the rational design of the size and shape of the spiral sensor and the terraced fields to match with each other. Then the fixed landing sites in each circle of the spiral sensor and each orbit of the terraced field were marked to ensure the consistent installation. The second step is that the pre-compressing tests to scrupulously check out the imperfections, such as the wave-shape or the cracked spiral sensors. The third step is to experimentally assess the uniform landing of the spiral sensor. Only after the three steps to achieve the uniform landing effect, we can use the integrated ball sensor for further uses.

Structural, mechanical, and conductivity tests

The morphologies of the spiral sensor were observed by an FE-SEM (Zeiss GeminiSEM 500). I–V curves were measured with an electricity meter (KEYB1GHT, B2901A). Mechanical tests of the spiral sensor and the ball sensor were taken with a force instrument (ElectroForce 3200 Series III, Bose, USA). Resistance changes of the spiral sensor caused by mechanical deformations when grasped were recorded with a digital multimeter (KEYSIGHT, 34465A) or an oscilloscope (UTD2102CM, UNI-T, China).

Signal acquisition, processing, Bluetooth transmission, and power supply

The core of the circuit system is a STM32F103C8tT6 ultralow-power ARM Cortex-M4 32-bit microprocessor (25 mm diameter) with a 12-bit ADC. The ST-Link/V3 in-circuit debugger and programmer can program the microprocessor. The amplified resistance through the circuit system can respond to the external grip strength when compressing the smart ball sensor. A voltage divider converted the resistance value into a voltage signal to eliminate the circuit noise and electromagnetic interference via a filter circuit. Finally, the signal amplification circuit and the reference circuit of the on-chip ADC adjusted the amplitude of the voltage signal. The acquired data was transmitted via a Bluetooth transceiver from the microprocessor to the user interface, which can be further analyzed or displayed via an upper computer. The power system includes a 3.7–4.2 V Li-ion battery (18 × 7 mm), a TP4056 battery management chip (25 × 17 mm) for battery charge and protection, and a TLV62568P chip (16 × 13 mm) converting the battery voltage to 3.3 V for a stable and reliable signal processing. It just needs ~12 mA during working.

Finite-element analysis on strain distribution of the smart ball sensor

Finite-element model of the smart ball sensor in the indentation test was conducted using commercially available software (Abaqus 6.14, Dassault Systèmes, France). The model included an axisymmetric egg-shaped ball (Young’s modulus 200 kPa, Poisson ratio 0.49, a \(30.67\,{{{\mathrm{mm}}}} \times 25\,{{{\mathrm{mm}}}}\) semi-ellipsoid as the upper part and a \(25\,{{{\mathrm{mm}}}}\) radius of hemisphere as the lower part) and a cylindrical indenter (analytical rigid, diameter × height was 25 × 3 mm). Using this indenter to do a 10 mm vertical compression, the strain distribution of the ball could be obtained. According to the displacement field of the ball, the strain of spiral sensor was further calculated (Supplementary Fig. 12) using a commercially available software (MATLAB R2020b, MathWorks, USA).

Finite-element analysis on the 3D contact area

Finite-element analysis on the 3D contact area was conducted using a commercially available software (Abaqus 6.14, Dassault Systèmes, France). The model was an axisymmetric egg-shaped ball (Young’s modulus 200 kPa, Poisson ratio 0.49, a \(30.67\,{{{\mathrm{mm}}}} \times 25\,{{{\mathrm{mm}}}}\) semi-ellipsoid as the upper part and a 25 mm radius of the hemisphere as the lower part). Applying 9 different heights (h, 2, 4, 6, 8, 10, 12, 14, 16, 18 mm) to match 9 different 3D contact areas (S, 0.31, 0.63, 0.94, 1.26, 1.57, 1.88, 2.20, 2.51, 2.83 × 103 mm2), the strain distributions of the ball in terms of various 3D contact areas could be obtained (Supplementary Fig. 10). According to the strain distribution of the ball, strains of the spiral sensor in terms of various 3D contact areas were further calculated (Supplementary Fig. 9) in a commercially available software (MATLAB R2020b, MathWorks, USA). The final grip strength was calculated by an equation in terms of \(F = F(\Delta R/R_{\mathrm {o}},l)\). So before monitoring, l was determined by measuring the arc length when grasping the smart ball sensor.

Accuracy test

Two indentation tests of the smart ball sensor were conducted with two indenters with different areas (\(S_1 = 490.63\,{{{\mathrm{mm}}}}^2\), \(S_2 = 1219.2\,{{{\mathrm{mm}}}}^2\)) as shown in Fig. 5a. Here, a force instrument (ElectroForce 3200 Series III, Bose, USA) recorded the compressing forces, and a digital multimeter (KEYSIGHT, 34465A) recorded the resistance changes of the ball sensor. In the Eq. (1),\(\Delta R/R_0(F) = aF^2\), where \(a = 1.03 \times 10^{ - 2}\,{{{\mathrm{N}}}}^{ - 2}\) is the parameter when the contact area is \(S_{{{indenter}}} = S_1\). Then we used the forces from the indentation test with a indenter with a contact area of S2 as Freal, and substituted the resistance change rates of coil sensor into Eqs. (1) and (8) to obtain Fmon. Finally, according to Eq. (9), the accuracy of the grip strength without or with considering the 3D contact area can be calculated, and data details in Supplementary Fig. 16.

On-body verification

Human experiments were conducted under approval from 32 human subjects. One is a stroke patient (57 years old, man) from the department of rehabilitation medicine in First Affiliated Hospital of Xi’an Jiaotong University. The other human subject is students (20–35 years old, 13 female and 18 man) in the school of life science and technology of Xi’an Jiaotong University. The children subjects are ages of 1, 3, 5, 7, 9 in the affiliated school of Xi’an Jiaotong University. All experiments involved informed consent from human subjects. All the grip strength measurements are carried out with a hospital grip instrument reading with a computer or an electronic hand dynamometer reading with its own screen. The smart ball sensor reads with a cellphone by wireless transmission (Bluetooth). In the practical applications, both the hospital grip instruments and the commercial grip dynamometer use kg (kilogram-force) to be unit of the grip strength. So here in Figs. 6 and 7, we chose kg (kilogram-force) to be unit of the grip strength for the consistency of data. Based on the equation of 1 kg (kilogram-force) ≈ 9.8 N, the grip strength in the unit of N was divided by 9.8 to be the unit of kg (kilogram-force).

Data availability

All data needed to evaluate the conclusions in the paper are present in the paper and/or the Supplementary Materials. Additional data related to this paper may be requested from the authors.

References

Leong, D. P. et al. Prognostic value of grip strength: findings from the Prospective Urban Rural Epidemiology (PURE) study. Lancet 386, 266–273 (2015).

Rantanen, T. et al. Muscle strength and body mass index as long-term predictors of mortality in initially healthy men. J. Gerontol. A Biol. Sci. Med. Sci. 55, 168 (2000).

Nunez, J., Nunez, E., Bodi, V., Bayes-Genis, A. & Sanchis, J. Optimal decongestive therapy in acute decompensated heart failure syndromes: far from being solved. Int. J. Cardiol. 174, 457–458 (2014).

Ortega, F. B., Silventoinen, K., Tynelius, P. & Rasmussen, F. Muscular strength in male adolescents and premature death: cohort study of one million participants. BMJ 345, e7279 (2012).

Kodama, S. et al. Cardiorespiratory fitness as a quantitative predictor of all-cause mortality and cardiovascular events in healthy men and women. JMMA 301, 2024 (2009).

Ruiz, J. R. et al. Association between muscular strength and mortality in men: prospective cohort study. BMJ 337, a439 (2008).

Gale, C. R., Martyn, C. N., Cooper, C. & Sayer, A. A. Grip strength, body composition, and mortality. Int. J. Epidemiol. 36, 228–235 (2007).

Sasaki, H., Kasagi, F., Yamada, M. & Fujita, S. Grip strength predicts cause-specific mortality in middle-aged and elderly persons. Am. J. Med. 120, 337–342 (2007).

Newman, A. B. et al. Strength, but not muscle mass, is associated with mortality in the health, aging and body composition study cohort. J. Gerontol. A Biol. Sci. Med. Sci. 61, 72 (2006).

Shin, J. et al. Sensitive wearable temperature sensor with seamless monolithic integration. Adv. Mater. 32, e1905527 (2020).

Yang, Y. et al. A laser-engraved wearable sensor for sensitive detection of uric acid and tyrosine in sweat. Nat. Biotechnol. 38, 217–224 (2020).

Zheng, X., Jia, B., Chen, X. & Gu, M. In situ third-order non-linear responses during laser reduction of graphene oxide thin films towards on-chip non-linear photonic devices. Adv. Mater. 26, 2699–2703 (2014).

Choi, G. P. T., Dudte, L. H. & Mahadevan, L. Programming shape using kirigami tessellations. Nat. Mater. 18, 999–1004 (2019).

Rafsanjani, A., Zhang, Y., Liu, B., Rubinstein, S. M. & Bertoldi, K. Kirigami skins make a simple soft actuator crawl. Sci. Robot 3, 1 (2018).

Babaee, S. et al. Bioinspired kirigami metasurfaces as assistive shoe grips. Nat. Biomed. Eng. 4, 778–786 (2020).

Yang, C. et al. Kirigami-inspired deformable 3D structures conformable to curved biological surface. Adv. Sci. 5, 1801070 (2018).

Lamoureux, A., Lee, K., Shlian, M., Forrest, S. R. & Shtein, M. Dynamic kirigami structures for integrated solar tracking. Nat. Commun. 6, 8092 (2015).

Chen, S., Choi, G. P. T. & Mahadevan, L. Deterministic and stochastic control of kirigami topology. Proc. Natl Acad. Sci. USA 117, 4511–4517 (2020).

Jayanty, S. & Radhakrishnan, T. P. Core and sheath’ structure of a TTF complex forming a square grid. J. Mater. Chem. 9, 1707 (1999).

Wang, X., Qiu, Y., Cao, W. & Hu, P. Highly stretchable and conductive core–sheath chemical vapor deposition graphene fibers and their applications in safe strain sensors. Chem. Mater. 27, 6969–6975 (2015).

Yang, Z. et al. Direct spinning of high-performance graphene fiber supercapacitor with a three-ply core-sheath structure. Carbon 132, 241–248 (2018).

Sundaram, S. et al. Learning the signatures of the human grasp using a scalable tactile glove. Nature 569, 698–702 (2019).

Blees, M. K. et al. Graphene kirigami. Nature 524, 204–207 (2020).

Zhang, F., Liu, F. & Zhang, Y. Analyses of mechanically-assembled 3D spiral mesostructures with applications as tunable inductors. Sci. China Technol. Sc. 62, 243–251 (2018).

Evke, E. E., Meli, D. & Shtein, M. Developable rotationally symmetric Kirigami‐based structures as sensor platforms. Adv. Mater. Technol. 4, 1900563 (2019).

Schaap, L. A. et al. Grip strength measurement: towards a standardized approach in sarcopenia research and practice. Eur. Geriatr. Med. 7, 247–255 (2016).

Roberts, H. C. et al. A review of the measurement of grip strength in clinical and epidemiological studies: towards a standardised approach. Age Ageing 40, 423–429 (2011).

Jaber, R., Hewson, D. J. & Duchêne, J. Design and validation of the grip-ball for measurement of hand grip strength. Med. Eng. Phys. 34, 1356–1361 (2012).

Jang, T. M. et al. Expandable and implantable bioelectronic complex for analyzing and regulating real-time activity of the urinary bladder. Sci. Adv. 6, eabc9675 (2020).

Lunardini, F. et al. Validity and usability of a smart ball–driven serious game to monitor grip strength in independent elderlies. Health Inform. J. 26, 1952–1968 (2020).

Stone, T. et al. On smart soccer ball as a head impact sensor. IEEE Trans. Instrum. Meas. 68, 2979–2987 (2019).

Snib, S. A., Markides, K. S., Ray, L., Ostir, G. V. & Goodwin, J. S. Handgrip strength and mortality in older Mexican Americans. J. Am. Geriatr. Soc. 50, 1250 (2002).

Tricoli, A., Nasiri, N. & De, S. Wearable and miniaturized sensor technologies for personalized and preventive medicine. Adv. Funct. Mater. 27, 1605271 (2017).

Chen, L. Y. et al. Continuous wireless pressure monitoring and mapping with ultra-small passive sensors for health monitoring and critical care. Nat. Commun. 5, 5028 (2014).

Gao, Y., Yu, L., Yeo, J. C. & Lim, C. T. Flexible hybrid sensors for health monitoring: materials and mechanisms to render wearability. Adv. Mater. 32, e1902133 (2020).

Nair, R. R. et al. Fine structure constant defines visual transparency of graphene. Science 320, 1308 (2008).

Li, Y., Li, Z. & Shen, P. K. Simultaneous formation of ultrahigh surface area and three-dimensional hierarchical porous graphene-like networks for fast and highly stable supercapacitors. Adv. Mater. 25, 2474–2480 (2013).

Ning, G. et al. Gram-scale synthesis of nanomesh graphene with high surface area and its application in supercapacitor electrodes. Chem. Commun. 47, 5976–5978 (2011).

Loh, K. P., Bao, Q., Ang, P. K. & Yang, J. The chemistry of graphene. J. Mater. Chem. 20, 2277 (2010).

Yang, T., Xie, D., Li, Z. & Zhu, H. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R. 115, 1–37 (2017).

Chen, Z. et al. Flexible piezoelectric-induced pressure sensors for static measurements based on nanowires/graphene heterostructures. ACS Nano 11, 4507–4513 (2017).

Huang, T. et al. Phase-separation-induced PVDF/graphene coating on fabrics toward flexible piezoelectric sensors. ACS Appl. Mater. Interfaces 10, 30732–30740 (2018).

Amjadi, M., Kyung, K. -U., Park, I. & Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: a review. Adv. Funct. Mater. 26, 1678–1698 (2016).

Sayer, A. A. & Kirkwood, T. B. L. Grip strength and mortality: a biomarker of ageing. Lancet 386, 226–227 (2015).

Dogan, N. O. Bland–Altman analysis: a paradigm to understand correlation and agreement. Turkish. J. Emerg. Med. 18, 139–141 (2018).

Acknowledgements

This work was financially supported by the Fundamental Research Funds for the Central Universities (xzy022019014) and the National Key R&D Program of China (2018YFC1707700).

Author information

Authors and Affiliations

Contributions

H.Z. designed, prepared, and characterized the sensor. X.D. did the simulation tests. H.Z. and X.D. drafted the manuscript. X.Z. revised the manuscript. F.X. supervised the project. All authors discussed and wrote the paper.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zhang, H., Ding, X., Zhang, X. et al. A smart ball sensor fabricated by laser kirigami of graphene for personalized long-term grip strength monitoring. npj Flex Electron 6, 28 (2022). https://doi.org/10.1038/s41528-022-00156-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41528-022-00156-w