Abstract

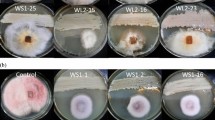

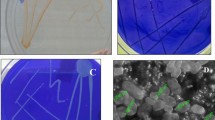

Fungi are accepted as novel sources of chitinous materials. The present study was performed to produce chitinous material from locally isolated Penicillium crustosum TZ18 (GenBank accesion number: OM095448) using molasses as substrate, prepare chitosan from chitinous material and investigate the antibacterial activity of the prepared chitosan. An initial pH of 6.0, a molasses concentration of 120 g/L, a temperature of 25 °C and an incubation time of 5 days were the most favourable parameters for the production of chitinous material. Under the optimized culture conditions, fungal biomass of 29.5 g/L and total chitinous material of 7.79 g/L (26.4%) could be produced. The chitin and chitosan concents of chitinous material were 97 (7.56 g/L) and 3% (0.23 g/L), respectively. Chitin fraction was converted into the chitosan (Penicillium chitosan, PC) by deacetylation process. FT-IR results revealed that the functional groups of PC and commercial chitosan (CC) were very similar to each other. Deacetylation degrees of PC and CC were found to be 78.3 and 76.9%, respectively. The viscosity-average molecular weights of PC and CC were determined as 122.7 and 298.3 kDa, respectively. When compared to CC, PC was found to have higher antibacterial efficiency against both Escherichia coli and Staphylococcus aureus. High antibacterial efficiency of the chitosan could be ascribed to its low molecular weight and high deacetylation degree. The chitosan may be useful for biomadical applications. The production of chitinous material from P. crustosum and the antibacterial efficiency of P. crustosum chitosan were investigated for the first time in the present study.

Graphical Abstract

Similar content being viewed by others

Data Availability

The data and materials that support the findings of this study are openly available on request.

References

Kurita K (1998) Chemistry and application of chitin and chitosan. Polym Degrad Stab 59:117–120. https://doi.org/10.1016/S0141-3910(97)00160-2

Wu T, Zivanovic S, Draughon FA, Conway WS, Sams CE (2005) Physicochemical properties and bioactivity of fungal chitin and chitosan. J Agric Food Chem 53:3888–3894. https://doi.org/10.1021/jf048202s

Croisier F, Jérôme C (2013) Chitosan-based biomaterials for tissue engineering. Eur Polym J 49:780–792. https://doi.org/10.1016/j.eurpolymj.2012.12.009

Casadidio C, Peregrina DV, Gigliobianco MR, Deng S, Censi R, Di Martino P (2019) Chitin and chitosans: characteristics, eco-friendly processes, and applications in cosmetic science. Mar Drugs 17:369. https://doi.org/10.3390/md17060369

Rinaudo M (2006) Chitin and chitosan: properties and applications. Prog Polym Sci 31:603–632. https://doi.org/10.1016/j.progpolymsci.2006.06.001

Kurita K (2006) Chitin and chitosan: functional biopolymers from marine crustaceans. Mar Biotechnol 8:203–226. https://doi.org/10.1007/s10126-005-0097-5

Akila R (2014) Fermentative production of fungal chitosan, a versatile biopolymer (perspectives and its applications). Adv Appl Sci Res 5:157–170

Younes I, Rinaudo M (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar Drugs 13:1133–1174. https://doi.org/10.3390/md13031133

Elsoud MMA, El Kady E (2019) Current trends in fungal biosynthesis of chitin and chitosan. Bull Natl Res Cent 43:59. https://doi.org/10.1186/s42269-019-0105-y

Pochanavanich P, Suntornsuk W (2002) Fungal chitosan production and its characterization. Lett Appl Microbiol 35:17–21. https://doi.org/10.1046/j.1472-765x.2002.01118.x

Di Mario F, Rapana P, Tomati U, Galli E (2008) Chitin and chitosan from Basidiomycetes. Int J Biol Macromol 43:8–12. https://doi.org/10.1016/j.ijbiomac.2007.10.005

Amer MS, Ibrahim HAH (2019) Chitosan from marine-derived Penicillum spinulosum MH2 cell wall with special emphasis on its antimicrobial and antifouling properties. Egypt J Aquat Res 45:359–365. https://doi.org/10.1016/j.ejar.2019.11.007

Ebrahimzadeh MA, Chabra A, Gharaei-Fathabad E, Pourmorad F (2013) Preparation of chitosan from Penicillium spp. and determination of their degree of deacetylation. Res Pharm Sci 7:477

Taskin M, Esim N, Ortucu S (2012) Efficient production of l-lactic acid from chicken feather protein hydrolysate and sugar beet molasses by the newly isolated Rhizopus oryzae TS-61. Food Bioprod Process 90:773–779. https://doi.org/10.1016/j.fbp.2012.05.003

Taskin M, Ortucu S, Aydogan MN, Arslan NP (2016) Lipid production from sugar beet molasses under non-aseptic culture conditions using the oleaginous yeast Rhodotorula glutinis TR29. Renew Energy 99:198–204. https://doi.org/10.1016/j.renene.2016.06.060

Arslan NP, Aydogan MN (2021) Evaluation of sheep wool protein hydrolysate and molasses as low-cost fermentation substrates for hyaluronic acid production by Streptococcus zooepidemicus ATCC 35246. Waste Biomass Valoriz 12:925–935. https://doi.org/10.1007/s12649-020-01062-w

Lakshmidevi R, Ramakrishnan B, Ratha SK, Bhaskar S, Chinnasamy S (2021) Valorisation of molasses by oleaginous yeasts for single cell oil (SCO) and carotenoids production. Environ Technol Innov 21:101281. https://doi.org/10.1016/j.eti.2020.101281

de Souza QS, Jofre FM, dos Santos HA, Hernández-Pérez AF, de Almeida Felipe MDG (2021) Xylitol and ethanol co-production from sugarcane bagasse and straw hemicellulosic hydrolysate supplemented with molasses. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-021-01493-y

Chatterjee S, Adhya M, Guha AK, Chatterjee BP (2005) Chitosan from Mucor rouxii: production and physico-chemical characterization. Process Biochem 40:395–400. https://doi.org/10.1016/j.procbio.2004.01.025

Berger LRR, Stamford TCM, Stamford-Arnaud TM et al (2014) Green conversion of agroindustrial wastes into chitin and chitosan by Rhizopus arrhizus and Cunninghamella elegans strains. Int J Mol Sci 15:9082–9102. https://doi.org/10.3390/ijms15059082

Tasar OC, Erdal S, Taskin M (2016) Chitosan production by psychrotolerant Rhizopus oryzae in non-sterile open fermentation conditions. Int J Biol Macromol 89:428–433. https://doi.org/10.1016/j.ijbiomac.2016.05.007

Álvarez SPO, Cadavid DAR, Sierra DME, Orozco CPO, Vahos DFR, Ocampo PZ, Atehortúa L (2014) Comparison of extraction methods of chitin from Ganoderma lucidum mushroom obtained in submerged culture. BioMed Res Int. https://doi.org/10.1155/2014/169071

Rasti H, Parivar K, Baharara J, Iranshahi M, Namvar F (2017) Chitin from the mollusc chiton: extraction, characterization and chitosan preparation. Iran J Pharm Res 16:366

Naghdi M, Zamani A, Karimi K (2014) A sulfuric–lactic acid process for efficient purification of fungal chitosan with intact molecular weight. Int J Biol Macromol 63:158–162. https://doi.org/10.1016/j.ijbiomac.2013.10.042

Pakizeh M, Moradi A, Ghassemi T (2021) Chemical extraction and modification of chitin and chitosan from shrimp shells. Eur Polym J 159:110709. https://doi.org/10.1016/j.eurpolymj.2021.110709

El-Far A, Shetaia YM, Ahmed MA, Amin RM, Abdou DAM (2021) Statistical optimization of chitosan production using marine-derived Penicillium chrysogenum MZ723110 in Egypt. Egypt J Aquat Biol Fish 25:799–819. https://doi.org/10.21608/ejabf.2021.206881

Edokpayi JN, Odiyo JO, Popoola EO, Alayande OS, Msagati TA (2015) Synthesis and characterization of biopolymeric chitosan derived from land snail shells and its potential for Pb2+ removal from aqueous solution. Materials 8:8630–8640. https://doi.org/10.3390/ma8125482

El Knidri H, Belaabed R, Addaou A, Laajeb A, Lahsini A (2018) Extraction, chemical modification and characterization of chitin and chitosan. Int J Biol Macromol 120:1181–1189. https://doi.org/10.1016/j.ijbiomac.2018.08.139

Rao DG (1993) Studies on viscosity–molecular weight relationship of chitosan solutions. J Food Sci Technol 30:66–67

Duduk N, Bekčić F, Žebeljan A, Vučković N, Vico I (2021) First report of blue mold caused by Penicillium crustosum on nectarine fruit in Serbia. Plant Dis 105:487. https://doi.org/10.1094/PDIS-07-20-1632-PDN

Karadayi YI, Aykutoglu G, Arslan NP, Baltaci MO, Adiguzel A, Taskin M (2021) Production of water-soluble sulfated exopolysaccharide with anticancer activity from Anoxybacillus gonensis YK25. J Chem Technol Biotechnol 96:1258–1266. https://doi.org/10.1002/jctb.6638

Scervino JM, Papinutti VL, Godoy MS et al (2011) Medium pH, carbon and nitrogen concentrations modulate the phosphate solubilization efficiency of Penicillium purpurogenum through organic acid production. J Appl Microbiol 110:1215–1223. https://doi.org/10.1111/j.1365-2672.2011.04972.x

Taskin M, Tasar GE, Incekara U (2013) Citric acid production from Aspergillus niger MT-4 using hydrolysate extract of the insect Locusta migratoria. Toxicol Ind Health 29:426–434. https://doi.org/10.1177/0748233712436646

Li Z, Bai T, Dai L et al (2016) A study of organic acid production in contrasts between two phosphate solubilizing fungi: Penicillium oxalicum and Aspergillus niger. Sci Rep 6:1–8. https://doi.org/10.1038/srep25313

Altun R, Esim N, Aykutoglu G, Baltaci MO, Adiguzel A, Taskin M (2020) Production of linoleic acid-rich lipids in molasses-based medium by oleaginous fungus Galactomyces geotrichum TS61. J Food Process Preserv 44:e14518. https://doi.org/10.1111/jfpp.14518

Aidynova R, Arslan NP, Aydoğan MN (2020) Use of mulberry pomace as substrate for citric acid production by Aspergillus niger MT-4. Trakya Univ J Nat Sci 21:159–65. https://doi.org/10.23902/trkjnat.670859

Manni L, Ghorbel-Bellaaj O, Jellouli K, Younes I, Nasri M (2010) Extraction and characterization of chitin, chitosan, and protein hydrolysates prepared from shrimp waste by treatment with crude protease from Bacillus cereus SV1. Appl Biochem Biotechnol 162:345–357. https://doi.org/10.1007/s12010-009-8846-y

Taser B, Ozkan H, Adiguzel A, Orak T, Baltaci MO, Taskin M (2021) Preparation of chitosan from waste shrimp shells fermented with Paenibacillus jamilae BAT1. Int J Biol Macromol 183:1191–1199. https://doi.org/10.1016/j.ijbiomac.2021.05.062

Sugiyanti D, Darmadji P, Santoso U, Pranoto Y, Anwar C, Anggrahini S (2018) Biological activity of native and low molecular weight chitosan obtained by steam explosion process. Pak J Biol Sci 21:441–447. https://doi.org/10.3923/pjbs.2018.441.447

Yadav M, Goswami P, Paritosh K, Kumar M, Pareek N, Vivekanand V (2019) Seafood waste: a source for preparation of commercially employable chitin/chitosan materials. Bioresour Bioprocess 6:1–20. https://doi.org/10.1186/s40643-019-0243-y

Guan Y, Liu X, Zhang Y, Yao K (1998) Study of phase behavior on chitosan/viscose rayon blend film. J Appl Polym Sci 67:1965–1972. https://doi.org/10.1002/(SICI)1097-4628(19980321)67:12%3C1965::AID-APP2%3E3.0.CO;2-L

El-Hefian EA, Nasef MM, Yahaya AH (2010) The preparation and characterization of chitosan/poly(vinyl alcohol) blended films. E J Chem 7:1212–1219. https://doi.org/10.1155/2010/626235

Odili C, Sekunowo O, Gbenebour PO, Adeosun OS (2020) Characterization and properties comparison of Nigerian crab-shell extracts. UUJES 3:1–12

Kong J, Yu S (2007) Fourier transform infrared spectroscopic analysis of protein secondary structures. Acta Biochim Biophys Sin 39:549–559. https://doi.org/10.1111/j.1745-7270.2007.00320.x

Aboul-Enein Y, Bunacıu A, Fleschın S (2014) Evaluation of the protein secondary structures using Fourier transform infrared spectroscopy. Gazi Univ J Sci 27:637–644

Tuysuz E, Ozkan H, Arslan NP, Adiguzel A, Baltaci MO, Taskin M (2021) Bioconversion of waste sheep wool to microbial peptone by Bacillus licheniformis EY2. Biofuel Bioprod Biorefin 15:1372–1384. https://doi.org/10.1002/bbb.2232

Brugnerotto J, Lizardi J, Goycoolea F, Argüelles-Monal W, Desbrieres J, Rinaudo M (2001) An infrared investigation in relation with chitin and chitosan characterization. Polymer 42:3569–3580. https://doi.org/10.1016/S0032-3861(00)00713-8

Abdou ES, Nagy KS, Elsabee MZ (2008) Extraction and characterization of chitin and chitosan from local sources. Bioresour Technol 99:1359–1367. https://doi.org/10.1016/j.biortech.2007.01.051

Povea MB, Monal WA, Cauich-Rodríguez JV, Pat AM, Rivero NB, Covas CP (2011) Interpenetrated chitosan-poly(acrylic acid-co-acrylamide) hydrogels. Synthesis, characterization and sustained protein release studies. Mater Sci Appl 2:509. https://doi.org/10.4236/msa.2011.26069

Liu S, Sun J, Yu L, Zhang C, Bi J, Zhu F, Qu M, Jiang C, Yang Q (2012) Extraction and characterization of chitin from the beetle Holotrichia parallela Motschulsky. Molecules 17:4604–4611. https://doi.org/10.3390/molecules17044604

Aiba SI (1992) Studies on chitosan: 4. Lysozymic hydrolysis of partially N-acetylated chitosans. Int J Biol Macromol 14:225–228. https://doi.org/10.1016/s0141-8130(05)80032-7

Khan TA, Peh KK, Ch’ng HS (2002) Reporting degree of deacetylation values of chitosan: the influence of analytical methods. J Pharm Pharm Sci 5:205–212

Zainol I, Akil HM, Mastor A (2009) Effect of γ-irradiation on the physical and mechanical properties of chitosan powder. Mater Sci Eng C 29:292–297. https://doi.org/10.1016/j.msec.2008.06.026

Fakhar M, Chabra A, Rahimi-Esboei B, Rezaei F (2015) In vitro protoscolicidal effects of fungal chitosan isolated from Penicillium waksmanii and Penicillium citrinum. J Parasit Dis 39:162–167. https://doi.org/10.1007/s12639-013-0300-y

Castro SPM, Paulín EGL (2012) Is chitosan a new panacea? Areas of application. In: Karunaratne DN (ed) The complex world of polysaccharides. IntechOpen, London, pp 3–46. https://doi.org/10.5772/51200

Liu N, Chen XG, Park HJ, Liu CG, Liu CS, Meng XH, Yu LJ (2006) Effect of MW and concentration of chitosan on antibacterial activity of Escherichia coli. Carbohydr Polym 64:60–65. https://doi.org/10.1016/j.carbpol.2005.10.028

Yuan Y, Chesnutt BM, Haggard WO, Bumgardner JD (2011) Deacetylation of chitosan: material characterization and in vitro evaluation via albumin adsorption and pre-osteoblastic cell cultures. Materials 4:1399–1416. https://doi.org/10.3390/ma4081399

Chang SH, Lin HTV, Wu GJ, Tsai GJ (2015) pH effects on solubility, zeta potential, and correlation between antibacterial activity and molecular weight of chitosan. Carbohydr Polym 134:74–81. https://doi.org/10.1016/j.carbpol.2015.07.072

Boudouaia N, Bengharez Z, Jellali S (2019) Preparation and characterization of chitosan extracted from shrimp shells waste and chitosan film: application for Eriochrome black T removal from aqueous solutions. Appl Water Sci 9:1–12. https://doi.org/10.1007/s13201-019-0967-z

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

FK: Methodology, conceptualization, data analysis and investigation. MD: Methodology, investigation and data analysis. HO: Methodology, investigation and writing-review & editing. NPA: Methodology and investigation. AA: Investigation and formal analysis. MT: Investigation, writing—review & editing, supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The author declares that there are no conflicts of interest.

Research Invovling Human and/or Animal Participants

This study does not contain any studies with human participants or animals performed by the author.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kayar, F., Doymus, M., Ozkan, H. et al. Preparation of Chitosan with High Antibacterial Efficiency from Penicillium crustosum TZ18. J Polym Environ 30, 3598–3608 (2022). https://doi.org/10.1007/s10924-022-02458-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02458-6