Abstract

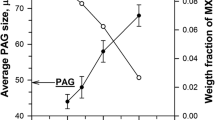

The creep resistance of the 9% Cr–1% W–1% Mo steel subjected to quenching from the temperatures of 1050 and 1150°C, cooling in the air, and further tempering at a temperature of 750°C for 3 h has been studied at a temperature of 650°C and applied stresses of 160, 140, and 120 MPa. An increase in the quenching temperature from 1050 to 1150°C leads to a growth in the average size of prior austenite grains from 25 to 93 µm due to the dissolution of MX carbonitride particles enriched in niobium under exposure in the austenite region. An increase in the size of the prior austenite grains is accompanied by a decrease in the average size of blocks and martensite laths by 17 and 43%, respectively. Moreover, an increased temperature of heating for quenching provides favorable conditions (fraction of boundaries, density of dislocations, and content of doping elements in a solid solution) for the precipitation of carbide М23С6 and carbonitride МХ particles of smaller size under tempering. The improvement of structural hardening due to a decreased size of blocks and martensite laths and dispersion hardening due to nanosized VX particles has a positive effect on the creep resistance by decreasing the minimum creep rate and the duration of the transient creep stage to increase the time until rupture by several times.

Similar content being viewed by others

REFERENCES

F. Abe, T. U. Kern, and R. Viswanathan, Creep-Resistant Steels (Woodhead, Cambridge, 2008).

R. O. Kaibyshev, V. N. Skorobogatykh, and I. A. Shchen-kova, “New martensitic steels for thermal power plant: Creep resistence,” Phys. Met. Metallogr. 109, 186–200 (2010).

R. Viswanathan and W. Bakker, “Materials for ultrasupercritical coal power plants – boiler materials: Part 1,” J. Mater. Eng. Perform. 10, 81–95 (2001).

V. M. Gundyrev, V. I. Zel’dovich, and V. M. Schastlivtsev, “Crystallographic analysis and the mechanism of martensitic transformation in iron alloys,” Fiz. Met. Metalloved. 121, 1142–1161 (2020).

V. S. Sagaradze, T. N. Kochetkova, N. V. Kataeva, K. A. Kozlov, V. A. Zavalishin, N. F. Vil’danova, V. S. Ageev, M. V. Leont’eva-Smirnova, and A. A. Nikitina, “Structure and creep of russian reactor steels with a bcc structure,” Phys. Met. Metallogr. 118, 494–506 (2017).

I. Nikitin, A. Fedoseeva, and R. Kaibyshev, “Strengthening mechanisms of creep-resistant 12% Cr–3% Co steel with low N and high B contents,” J. Mater. Sci. 55, 7530–7545 (2020).

A. E. Fedoseeva, I. S. Nikitin, N. R. Dudova, and R. O. Kaibyshev, “The effect of creep and long annealing conditions on the formation of the Z-phase particles,” Phys. Met. Metallogr. 121, 561–567 (2020).

F. Abe, “Precipitate design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants,” Sci. Tech. Adv. Mater. 9, No. 013002 (2008).

K. Suzuki, S. Kumai, Y. Toda, H. Kushima, and K. Kimura, “Two-phase separation of primary MX Carbonitride during tempering in creep resistant 9Cr1MoVNb steel,” ISIJ Int. 43, 104312 (2003).

K. Maruyama, N. Sekido, and K. Yoshimi, “Changes in strengthening mechanisms in creep of 9Cr–1.8W–0.5Mo–VNb steel tested over wide ranges of creep conditions,” ISIJ Int. 190, No. 1089–1094 (2021).

A. Kostka, K-G. Tak, R. J. Hellmig, Y. Estrin, and G. Eggeler, “On the contribution of carbides and micrograin boundaries to the creep strength of tempered martensite ferritic steels,” Acta Mater. 55, 539–550 (2007).

K. Kimura, N. Ohi, K. Shimazu, T. Matsuo, R. Tanaka, and M. Kikuchi, “Effect of prior austenite grain size on high temperature creep properties of Cr–Mo–V rotor steel,” Scr. Metall. 21, 19–22 (1987).

A. Fedoseeva, I. Nikitin, E. Tkachev, R. Mishnev, N. Dudova, and R. Kaibyshev, “Effect of alloying on the nucleation and growth of Laves phase in the 9–10% Cr–3% Co martensitic steels during creep,” Metals 11, No. 60 (2021).

A. Zhilyaev, S. Sergeev, and T. Langdon, “Electron backscatter diffraction (EBSD) microstructure evolution in HPT copper annealed at a low temperature,” J. Mater. Res. Technol. 3, 338–343 (2014).

A. Fedoseeva, N. Dudova, and R. Kaibyshev, “Creep strength breakdown and microstructure evolution in a 3% Co modified P92 steel,” Mater. Sci. Eng., A 654, 1–12 (2016).

Q. Li, “Modeling the microstructure-mechanical property relationship for a 12% Cr–2W–V–Mo–Ni power plant steel,” Mater. Sci. Eng., A. 361, 385–391 (2003).

V. Dudko, A. Belyakov, and R. Kaibyshev, “Origin of threshold stresses in a P92-type steel,” Trans. Ind. Inst. Met. 69, 223–227 (2016).

ACKNOWLEDGMENTS

This study was performed on the equipment of the Shared Facilities Center “Technologies and Materials” of the National Research University “Belgorod National Research University.”

Funding

The results of studying the microstructure and mechanical properties were obtained under support from the Russian Foundation for Basic Research (grant no. 20-33-90117). The results of modeling the phase compositions were obtained under support of a grant from the President of the Russian Federation for the State Support of Young Russian Scientists—Candidates of Sciences (agreement no. 075-15-2021-336).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Glushachenkova

Rights and permissions

About this article

Cite this article

Fedoseeva, A.E., Nikitin, I.S. & Kaibyshev, R.O. Effect of the Quenching Temperature on the Creep Resistance of 9% Cr–1% W–1% Mo–V–Nb Martensite Steel. Phys. Metals Metallogr. 123, 92–98 (2022). https://doi.org/10.1134/S0031918X22010033

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X22010033