Abstract

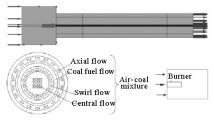

The production process of direct reduced iron from titanomagnetite by coal reduction in air in rotary kiln is a key step in the extraction of titanium and iron. This process is conducive to alleviating the stocking problem of a large amount of Ti-bearing blast furnace slag. The relationships between particle movement and pulverized coal injection combustion in rotary kiln were studied by the particle motion simulation and the pulverized coal injection combustion simulation. In particle motion simulation, the repose angle of ore particles was calculated to be 28.06°, and the reaction zone was roughly determined by the reaction temperature isothermal surface and the repose angle; the axial discrete distribution of ore particles would further cause the axial energy fluctuation due to the endothermic nature of the reduction. In pulverized coal injection combustion simulation, the rebound effect of coal injection under gravity would cause local overheating in the rebound region due to the benefits of heat and mass transfer processes, while this could strengthen the reduction reaction of ore particles and cause agglomerate by melting. Two suggestions on weakening the energy fluctuation and agglomerate were proposed based on the characteristics of particle motion and external carbon reaction.

Similar content being viewed by others

References

S.Y. Chen, M.S. Chu, Int. J. Miner. Metall. Mater. 21 (2014) 225–233.

G.B. Sadykhov, I.A. Karyazin, Russ. Metall. 2007 (2007) 447–454.

X. Zhu, W. Li, X. Guan, Int. J. Miner. Process. 157 (2016) 55–59.

T. Hu, X.W. Lü, C.G. Bai, G.B. Qiu, Int. J. Miner. Metall. Mater. 21 (2014) 131–137.

D. Chen, H. Zhao, G. Hu, T. Qi, H. Yu, G. Zhang, L. Wang, W. Wang, J. Hazard. Mater. 294 (2015) 35–40.

J.L. Zhang, X.D. Xing, M.M. Cao, K.X. Jiao, C.L. Wang, S. Ren, J. Iron Steel Res. Int. 20 (2013) 1–7.

B.C. Jena, W. Dresler, I.G. Reilly, Miner. Eng. 8 (1995) 159–168.

Y.F. Feng, Study on solid reduction strengthening and comprehensive utilization of titanomagnetite, Central South University, Changsha, China, 2007.

P. Liu, L.B. Zhang, B.G. Liu, G.J. He, J.H. Peng, M.Y. Huang, Int. J. Miner. Metall. Mater. 28 (2021) 88–97.

Y.Z. Wang, J.L. Zhang, Z.J. Liu, C.B. Du, JOM 69 (2017) 2397–2403.

S. Wang, Y. Guo, T. Jiang, F. Chen, F. Zheng, L. Yang, M. Tang, JOM 71 (2019) 329–335.

S. Wang, Y. Guo, T. Jiang, F. Chen, F. Zheng, L. Yang, JOM 71 (2019) 1858–1865.

W. Zhao, H.T. Wang, Z.G. Liu, M.S. Chu, Z.W. Ying, J. Tang, JOM 69 (2017) 1737–1744.

S. Wang, Y. Guo, T. Jiang, L. Yang, F. Chen, F. Zheng, X. Xie, M. Tang, JOM 69 (2017) 1646–1653.

Q. Li, S. Ji, Q. He, S. Zheng, Trans. Ind. Inst. Met. 72 (2019) 635–644.

Y.J. Wang, Y.Z. Xue, M. Pan, S.M. Wen, J. Cent. South Univ. (Sci. Technol.) 50 (2019) 497–505.

H.Y. Sun, Q.S. Zhu, H.Z. Li, Chin. J. Process Eng. 18 (2018) 1146–1159.

T.A.I. Lasheen, Hydrometallurgy 76 (2005) 123–129.

D. Wang, J. Chu, Y. Liu, J. Li, T. Xue, W. Wang, T. Qi, Ind. Eng. Chem. Res. 52 (2013) 15756–15762.

X.X. Zhou, Study on the relationship between environmental regulation and fossil energy consumption path in China, China University of Mining and Technology, Xuzhou, China, 2016.

L.X. Dou, L. Feng, S. Zhang, Shanxi Coking Coal Science & Technology 35 (2011) No. 12, 36–39.

Q. Du, H. Mo, L. Tian, L. Yuan, in: 2010 International Conference on Measuring Technology and Mechatronics Automation, IEEE, Changsha, China, 2010, pp. 286–290.

A. Atmaca, R. Yumrutas, Appl. Therm. Eng. 66 (2014) 435–444.

J. Mu, F. Leder, W.C. Park, R.A. Hard, J. Megy, H. Reiss, Metall. Trans. B 17 (1986) 861–868.

A.A. Boateng, Rotary kilns—transport phenomena and transport processes, 2nd Ed., Elsevier, 2016.

M. Wang, W. Zhu, Q. Sun, X. Zhang, Powder Technol. 267 (2014) 221–233.

M. Fang, K. Luo, S. Yang, K. Zhang, J. Fan, Ind. Eng. Chem. Res. 52 (2013) 7556–7568.

S. Zhao, X. Zhou, W. Liu, Granular Matter 17 (2015) 793–806.

B. Nassauer, M. Kuna, Granular Matter 15 (2013) 349–355.

H. Mikulčić, E. von Berg, M. Vujanović, X. Wang, H. Tan, N. Duić, Appl. Energy 184 (2016) 1292–1305.

M. Hossain, S.Z. Islam, P. Pollard, Renewable Energy 51 (2013) 404–418.

V. Yakhot, S.A. Orszag, J. Sci. Comput. 1 (1986) 3–51.

S. Wang, J. Lu, W. Li, J. Li, Z. Hu, Energy Fuels 20 (2006) 2350–2356.

J. Blumm, E. Kaisersberger, J. Therm. Anal. Calorim. 64 (2001) 385–391.

R. Zeng, W. Li, N. Wang, G. Fu, M. Chu, M. Zhu, Powder Technol. 376 (2020) 342–350.

D. Chen, B. Song, L. Wang, T. Qi, Y. Wang, W. Wang, Miner. Eng. 24 (2011) 864–869.

A.A. Adetoro, H. Sun, S. He, Q. Zhu, H. Li, Metall. Mater. Trans. B 19 (2018) 846–857.

J. Chen, W. Chen, L. Mi, Y. Jiao, X. Wang, Metals 9 (2019) 95.

J. Dang, G.H. Zhang, X.J. Hu, K.C. Chou, Int. J. Miner. Metall. Mater. 20 (2013) 1134–1140.

C. Geng, T.C. Sun, Y.W. Ma, C.Y. Xu, H.F. Yang, J. Iron Steel Res. Int. 24 (2017) 156–164.

T. Hu, X. Lv, C. Bai, Z. Lun, G. Qiu, Metall. Mater. Trans. B 44 (2013) 252–260.

T. Hu, X. Lv, C. Bai, Steel Res. Int. 87 (2016) 494–500.

Y.G. Ding, J.S. Wang, X.F. She, G. Wang, Q.G. Xue, J. Iron Steel Res. Int. 20 (2012) No. 5, 28–33.

Acknowledgements

This work was supported by the National Key R&D Program of China (2018YFC1900500) and National Natural Science Foundation of China (No. 51961020).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Liu, P., Liu, Bg., Zhang, Lb. et al. Particle motion simulation and pulverized coal injection combustion simulation of titanomagnetite pellets in rotary kiln for reduction process with coal. J. Iron Steel Res. Int. 29, 891–906 (2022). https://doi.org/10.1007/s42243-021-00741-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00741-9