Abstract

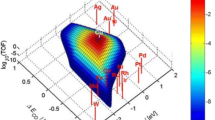

We demonstrate a new pathway for the synthesis of carbon nanohorns (CNHs) in a reactor by using inductively coupled plasma (ICP) and gaseous precursors. Thermal plasma synthesis allows the formation of different carbon allotropes such as carbon nanoflakes, hybrid forms of flakes and nanotubules, CNHs embryos, seed-like CNHs and onion-like polyhedral graphitic nanocapsules. In this study, pressure has the greatest impact on the selectivity of carbon nanostructures: pressure below 53.3 kPa favors the growth of carbon nanoflakes and higher pressures, 66.7 kPa and above, promotes the formation of CNHs. The ratio between methane and hydrogen as well as the global concentration of CH4 + H2 inside the plasma flame are also crucial to the reaction. CNHs are formed preferentially by injection of a 1:2 ratio of H2 to CH4 at 82.7 kPa with a production rate of 20 g/h. The synthesis pathway is easily scalable and could be made continuous, which offers an interesting alternative compared to methods based on laser-, arc- or induction-based vaporization of graphite rods.

Graphical Abstract

Similar content being viewed by others

References

Karousis N, Suarez-Martinez I, Ewels CP, Tagmatarchis N (2016) Structure, properties, functionalization, and applications of carbon nanohorns. Chem Rev 116(8):4850–4883. https://doi.org/10.1021/acs.chemrev.5b00611

Murakami T, Ajima K, Miyawaki J, Yudasaka M, Iijima S, Shiba K (2004) Drug-loaded carbon nanohorns: adsorption and release of dexamethasone in vitro. Mol Pharmaceutics 1(6):399–405. https://doi.org/10.1021/mp049928e

Ojeda I et al (2014) Carbon nanohorns as a scaffold for the construction of disposable electrochemical immunosensing platforms. application to the determination of fibrinogen in human plasma and urine. Anal Chem 86(15):7749–7756. https://doi.org/10.1021/ac501681n

Valentini F et al (2016) Sensor properties of pristine and functionalized carbon nanohorns. Electroanalysis 28(10):2489–2499. https://doi.org/10.1002/elan.201501171

Zhang Z, Han S, Wang C, Li J, Xu G (2015) Single-walled carbon nanohorns for energy applications. Nanomaterials. https://doi.org/10.3390/nano5041732

Tanaka A et al (2005) Friction and wear of carbon nanohorn-containing polyimide composites. Tribol Lett 19(2):135–142. https://doi.org/10.1007/s11249-005-5094-3

Miyawaki J, Yudasaka M, Azami T, Kubo Y, Iijima S (2008) Toxicity of single-walled carbon nanohorns. ACS Nano. https://doi.org/10.1021/nn700185t

He B et al (2018) Single-walled carbon-nanohorns improve biocompatibility over nanotubes by triggering less protein-initiated pyroptosis and apoptosis in macrophages. Nat Commun. https://doi.org/10.1038/s41467-018-04700-z

Iijima S et al (1999) Nano-aggregates of single-walled graphitic carbon nano-horns. Chem Phys Lett. https://doi.org/10.1016/S0009-2614(99)00642-9

Kasuya D, Yudasaka M, Takahashi K, Kokai F, Iijima S (2002) Selective production of single-wall carbon nanohorn aggregates and their formation mechanism. J Phys Chem B 106(19):4947–4951. https://doi.org/10.1021/jp020387n

Maser WK et al (1998) Production of high-density single-walled nanotube material by a simple laser-ablation method. Chem Phys Lett 292(4–6):587–593. https://doi.org/10.1016/S0009-2614(98)00776-3

Kokai F, Takahashi K, Kasuya D, Yudasaka M, Iijima S (2002) Growth dynamics of single-wall carbon nanotubes and nanohorn aggregates by CO2 laser vaporization at room temperature. Appl Surf Sci 197–198:650–655. https://doi.org/10.1016/S0169-4332(02)00434-8

Azami T et al (2008) Large-scale production of single-wall carbon nanohorns with high purity. J Phys Chem C 112(5):1330–1334. https://doi.org/10.1021/jp076365o

Yuge R, Yudasaka M, Toyama K, Yamaguchi T, Iijima S, Manako T (2012) Buffer gas optimization in CO2 laser ablation for structure control of single-wall carbon nanohorn aggregates. Carbon 50(5):1925–1933. https://doi.org/10.1016/j.carbon.2011.12.043

Wang H, Chhowalla M, Sano N, Jia S, Amaratunga GAJ (2004) Large-scale synthesis of single-walled carbon nanohorns by submerged arc. Nanotechnology 15(5):546–550. https://doi.org/10.1088/0957-4484/15/5/024

Sano N (2004) Low-cost synthesis of single-walled carbon nanohorns using the arc in water method with gas injection. J Phys D Appl Phys 37(8):L17–L20. https://doi.org/10.1088/0022-3727/37/8/L01

Yamaguchi T, Bandow S, Iijima S (2004) Synthesis of carbon nanohorn particles by simple pulsed arc discharge ignited between pre-heated carbon rods. Chem Phys Lett 389(1–3):181–185. https://doi.org/10.1016/j.cplett.2004.03.068

Gattia DM, Antisari MV, Marazzi R (2007) AC arc discharge synthesis of single-walled nanohorns and highly convoluted graphene sheets. Nanotechnology 18(25):255604. https://doi.org/10.1088/0957-4484/18/25/255604

Li N, Wang Z, Zhao K, Shi Z, Gu Z, Xu S (2010) Synthesis of single-wall carbon nanohorns by arc-discharge in air and their formation mechanism. Carbon 48(5):1580–1585. https://doi.org/10.1016/j.carbon.2009.12.055

Sun L, Wang C, Zhou Y, Zhang X, Cai B, Qiu J (2013) Flowing nitrogen assisted-arc discharge synthesis of nitrogen-doped single-walled carbon nanohorns. Appl Surf Sci 277:88–93. https://doi.org/10.1016/j.apsusc.2013.04.006

Zhang D et al (2019) Controllable synthesis of carbon nanomaterials by direct current arc discharge from the inner wall of the chamber. Carbon 142:278–284. https://doi.org/10.1016/j.carbon.2018.10.062

C. Pagura, S. Barison, S. Battiston, and M. Schiavon, “Synthesis and characterization of single wall carbon nanohorns produced by direct vaporization of graphite,” p. 3.

S. Mauro, “Device and method for production of carbon nanotubes, fullerene and their derivatives,” US7125525B2, Oct. 24, 2006 Accessed: Jun. 12, 2019. [Online]. Available: https://patents.google.com/patent/US7125525B2/en.

Boulos MI (1985) The inductively coupled R.F. (radio frequency) plasma. Pure Appl Chem 57(9):1321–1352. https://doi.org/10.1351/pac198557091321

M. I. Boulos and J. Jurewicz, “High performance induction plasma torch with a water-cooled ceramic confinement tube,” US5200595A, Apr. 06, 1993 Accessed: Apr. 22, 2020. [Online]. Available: https://patents.google.com/patent/US5200595A/en

Kim KS, Cota-Sanchez G, Kingston CT, Imris M, Simard B, Soucy G (2007) Large-scale production of single-walled carbon nanotubes by induction thermal plasma. J Phys D Appl Phys 40(8):2375–2387. https://doi.org/10.1088/0022-3727/40/8/S17

Pristavita R, Mendoza-Gonzalez N-Y, Meunier J-L, Berk D (2011) Carbon nanoparticle production by inductively coupled thermal plasmas: controlling the thermal history of particle nucleation. Plasma Chem Plasma Process 31(6):851–866. https://doi.org/10.1007/s11090-011-9319-y

Chen X, Wang C, Song M, Ma J, Ye T, Xia W (2019) The morphological transformation of carbon materials from nanospheres to graphene nanoflakes by thermal plasma. Carbon 155:521–530. https://doi.org/10.1016/j.carbon.2019.08.077

Aissou T, Braidy N, Veilleux J (2022) A new one-step deposition approach of graphene nanoflakes coating using a radio frequency plasma: Synthesis, characterization and tribological behaviour. Tribol Int 167:107406. https://doi.org/10.1016/j.triboint.2021.107406

Boulos MI (1991) Thermal plasma processing. IEEE Trans Plasma Sci 19(6):1078–1089. https://doi.org/10.1109/27.125032

Kim KS, Kingston CT, Ruth D, Barnes M, Simard B (2014) Synthesis of high quality single-walled carbon nanotubes with purity enhancement and diameter control by liquid precursor Ar–H2 plasma spraying. Chem Eng J 250:331–341. https://doi.org/10.1016/j.cej.2014.03.117

Pfender E (1989) Particle behavior in thermal plasmas. Plasma Chem Plasma Process. https://doi.org/10.1007/BF01015878

Ricolleau C et al (2013) Performances of an 80–200 kV microscope employing a cold-FEG and an aberration-corrected objective lens. Microscopy 62(2):283–293. https://doi.org/10.1093/jmicro/dfs072

Bandow S et al (2000) Evidence for anomalously small charge transfer in doped single-wall carbon nanohorn aggregates with Li, K and Br. Appl Phys A Mater Sci Process 71(5):561–564. https://doi.org/10.1007/s003390000681

Peña-Álvarez M, del Corro E, Langa F, Baonza VG, Taravillo M (2016) Morphological changes in carbon nanohorns under stress: a combined Raman spectroscopy and TEM study. RSC Adv 6(55):49543–49550. https://doi.org/10.1039/C5RA27162B

Peña-Álvarez M, del Corro E, Baonza VG, Taravillo M (2014) Probing the stress effect on the electronic structure of graphite by resonant raman spectroscopy. J Phys Chem C 118(43):25132–25140. https://doi.org/10.1021/jp505730v

Fujimori T, Radovic LR, Silva-Tapia AB, Endo M, Kaneko K (2012) Structural importance of Stone–Thrower–Wales defects in rolled and flat graphenes from surface-enhanced Raman scattering. Carbon 50(9):3274–3279. https://doi.org/10.1016/j.carbon.2011.12.010

Ertekin E, Chrzan DC, Daw MS (2009) Topological description of the Stone-Wales defect formation energy in carbon nanotubes and graphene. Phys Rev B 79(15):155421. https://doi.org/10.1103/PhysRevB.79.155421

Dresselhaus MS, Jorio A, Souza Filho AG, Saito R (2010) Defect characterization in graphene and carbon nanotubes using Raman spectroscopy. Phil Trans R Soc A 368:5355–5377

Yuge R, Yudasaka M, Toyama K, Yamaguchi T, Iijima S, Manako T (2012) Buffer gas optimization in CO2 laser ablation for structure control of single-wall carbon nanohorn aggregates. Carbon. https://doi.org/10.1016/j.carbon.2011.12.043

Irie M, Nakamura M, Zhang M, Yuge R, Iijima S, Yudasaka M (2010) Quantification of thin graphene sheets contained in spherical aggregates of single-walled carbon nanohorns. Chem Phys Lett 500(1):96–99. https://doi.org/10.1016/j.cplett.2010.10.018

Utsumi S et al (2005) Opening mechanism of internal nanoporosity of single-wall carbon nanohorn. J Phys Chem B. https://doi.org/10.1021/jp0512661

Perejón A, Sánchez-Jiménez PE, Criado JM, Pérez-Maqueda LA (2011) Kinetic analysis of complex solid-state reactions. A new deconvolution procedure. J Phys Chem B. https://doi.org/10.1021/jp110895z

Utsumi S et al (2007) Direct evidence on C−C single bonding in single-wall carbon nanohorn aggregates. J Phys Chem C. https://doi.org/10.1021/jp071273k

L.-T. Hsieh, W.-J. Lee, C.-Y. Chen, M.-B. Chang, and H.-C. Chang, “Converting methane by using an RF plasma reactor,” p. 25, 1998.

Vlassiouk I et al (2011) Role of hydrogen in chemical vapor deposition growth of large single-crystal graphene. ACS Nano 5(7):6069–6076. https://doi.org/10.1021/nn201978y

Fan J et al (2005) Micrometer-sized graphitic balls produced together with single-wall carbon nanohorns. J Phys Chem B. https://doi.org/10.1021/jp050548y

Bandow S, Kokai F, Takahashi K, Yudasaka M, Qin LC, Iijima S (2000) Interlayer spacing anomaly of single-wall carbon nanohorn aggregate. Chem Phys Lett. https://doi.org/10.1016/S0009-2614(00)00353-5

Tamura G, Yudasaka M, Iijima S (2009) Efficient separation of giant graphite balls from as-grown single-wall carbon nanohorns. Jpn J Appl Phys 48(1R):015003. https://doi.org/10.1143/JJAP.48.015003

Fauchais PL, Heberlein JVR, Boulos MI (2014) Thermal Spray Fundamentals: From Powder to Part. Springer Science & Business Media, US

Mohanta A, Lanfant B, Asfaha M, Leparoux M (2017) Methane dissociation process in inductively coupled Ar/H 2 /CH 4 plasma for graphene nano-flakes production. Appl Phys Lett 110(9):093109. https://doi.org/10.1063/1.4977568

Pristavita R, Meunier J-L, Berk D (2011) Carbon nano-flakes produced by an inductively coupled thermal plasma system for catalyst applications. Plasma Chem Plasma Process. https://doi.org/10.1007/s11090-011-9289-0

Gaufrès E et al (2014) Giant Raman scattering from J-aggregated dyes inside carbon nanotubes for multispectral imaging. Nat Photonics. https://doi.org/10.1038/nphoton.2013.309

Gaufrès E et al (2016) Aggregation control of α-Sexithiophene via isothermal encapsulation inside single-walled carbon nanotubes. ACS Nano. https://doi.org/10.1021/acsnano.6b05660

Meunier J-L, Mendoza-Gonzalez N-Y, Pristavita R, Binny D, Berk D (2014) Two-dimensional geometry control of graphene nanoflakes produced by thermal plasma for catalyst applications. Plasma Chem Plasma Process 34(3):505–521. https://doi.org/10.1007/s11090-014-9524-6

Acknowledgements

The Natural Sciences, Engineering Research Council, the Centre Québécois pour les Matériaux Fonctionnels (Fonds Nature et Technologie) and the Quebec Centre for Advanced Materials (QCAM) are acknowledged for funding this work. R.M. and N.B. acknowledge financial support from the Canada Research Chair programs. We thank Kossi Eyadéma Béré and André Bilodeau for their help during experiments. We would like to thank Charles Bertrand and Carl Saint-Louis from the Plateforme de Recherche et d’Analyse des Matériaux (PRAM) of Université de Sherbrooke for their help in the acquisition of data related to material characterization. We are very grateful to the MEANS team (Microscopie Electronique Avancée et Nano-Structures) of University of Paris, especially Guillaume Wang for helping us on the JEOL microscope.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Casteignau, F., Aissou, T., Allard, C. et al. Synthesis of Carbon Nanohorns by Inductively Coupled Plasma. Plasma Chem Plasma Process 42, 465–481 (2022). https://doi.org/10.1007/s11090-022-10240-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-022-10240-8