1. Introduction

At the close of the ‘Rules and Articles to be observed by the Journeymen Paper Makers throughout England,’ the workers turned to verse. They spoke of peace and collaboration between masters and men, as well as sharing the wealth produced by their trade.

May masters with their men unite

Each other ne'er oppress;

And their assistance freely give

When men are in distress.

We covet not our master's wealth,

Nor crave for nothing more,

But to support our families

As our fathers have before.

Then may the God that rules above

Look on our mean endeavour,

And masters with men unite

In hand and hand for ever.Footnote 1

But everywhere paper was made by hand in Old Regime and Revolutionary Europe, unity between masters and men was scarce, bargaining intense, and victories hard won. Paper manufacturers and workers haggled relentlessly about wages, hiring, training, and the custom of the trade. Despite the mutuality of the English journeymen's doggerel, their trade union, the Original Society of Papermakers, reserved the symbol of clasped hands for itself, not the whole industry.

To starve their workers into accepting a wage cut, the paper producers of Kent shuttered their mills in 1803. The manufacturers’ triumph was fleeting. Soon an anonymous letter arrived at the tavern favoured by the Kentish masters. The journeymen proclaimed their ‘unalterable determination … not to submit by any means to [the manufacturers’] Arbitrary and Unjustifiable Articles and Resolutions.’ They also signaled their willingness to return ‘at your Notice upon the same Wages and Customs which they enjoyed before you discharged them.’ The workers concluded cheekily by reminding their betters that the Combination Act of 1800 ‘expresses that Masters shall not combine to reduce Wages or lengthen the time of labour.’Footnote 2 In fact, the nominal wages of England's paperworkers rose substantially during the Revolutionary and Napoleonic Era. Small wonder that earlier, French paperworkers sang out,

Long live the journeymen paperworkers

Who make the white sheets

Long live the journeymen paperworkers who make the Tour de France.

If the King knew

The life that we lead

He would quit his palace

And become a journeyman.Footnote 3

He would have landed in the paperworkers’ ‘Republic,’ the phrase favoured by the Crown's officials to depict the journeymen's feisty, independent association.

This essay examines the themes of industriousness and Enlightened production through the lens of hand papermaking and the mechanisation of the trade. As the paperworker poets suggested, the shopfloors of Europe's paper mills were contested terrain. Like other sites of concentrated production, such as shipyards, glassworks, pot-banks, and breweries, paper mills housed large workshops, extensive divisions of labour, and managerial coordination of production, which encompassed bookkeeping, the search for raw materials, and often the building of roads and wharves. These substantial mills and yards were constructed for greater space, access to sources of power, security against the theft of unique trade secrets and valuable wood or pulp, as well as to isolate these sites and their noxious odours, constant noise, and turbulent crowds of tramping men seeking work. Much of the labour in these workplaces involved skill, since the hands of journeymen and apprentices, rather than machines, turned out reams, ships, and porter. Above all, it was this skill that empowered the workers’ numerous and diverse challenges to their patrons.

2. The industrious revolution and the industrial enlightenment

Despite the manufacturers’ reliance on skilled men and their mastery, hand papermaking was a capitalist industry cloaked in a corporate idiom. Whether papermakers, paper merchants, public authorities, or printers owned the mills, they faced intense international competition for markets and profits. Every producer endured cold-eyed judgments about the price and quality of his reams, as well as the virtues and flaws of the sheets furnished by his country's paper manufacturers. Moreover, the manufacturers grumbled about their counterparts’ protected markets while seeking to shelter their own, shifts in the tints of fashionable paper, and teamsters and watermen who hijacked their reams. Making paper was a bruising business, as the frequency of insolvency and mills changing hands attested. But there was money to be made in the industry, if only the manufacturer could secure control of his markets and workshops.

Journeymen paperworkers had always fashioned reams for markets near and far rather than for their own use, and invariably did so under the watchful gaze of a millmaster. Equally, they had always relied on monetary wages as well as the masters’ provision of food, although they often paid rent for mill housing. Their wives and children also sweated for wages in the mills, especially in the production of the pulp, the carting of materials around the mills, and the finishing process. Nevertheless, paperworkers across Europe still spoke of masters, journeymen, and apprentices, recognised standards for proper entry into each rank, and celebrated their brothers’ climb up the craft ladder. These practices persisted despite the absence of formal production guilds in French papermaking and the English industry's freedom from the Statute of Artificers (1563).Footnote 4 The journeymen and their employers had fashioned distinctive identities, motives, and powers within the broad spectrum of Old Regime Europe's concentrated industries. Neither E. P. Thompson's depiction of the moral economy of the marketplace nor Jan de Vries's account of a new market orientation in worker households captures the trade's social relations of production.Footnote 5 After all, hand papermaking's journeymen and their wives and children had always inhabited a capitalist labour market and had not suddenly embraced a new orientation to that market.

The advanced nature of hand papermaking's capitalism blended costly raw materials and sophisticated instruments; an intricate, mature labour process; established hours and precise output schedules; and the pursuit of advantage within all this by masters and men alike. My discussion centres on hand papermaking's wage system, a set of arrangements, prescriptions, and understandings largely shared from Fabriano to Kent and Annonay to Krakow. These wage formats reflected and expressed the material demands and constraints of paper production. They linked the skilled and fatiguing work of turning out six reams of paper in a day's labour and the routine disruption of this work by fires, floods, freezes and shortages of discarded linen, the raw material of stationery and printing paper. If Enlightened optimism moved producers and tinkerers to dream of mechanised papermaking, so did the frustrations of shops honeycombed with struggles over wages and customs and despair over the fits and starts of hand production. As a result, in the early nineteenth century, risk-averse manufacturers of ten or twenty reams of paper per day dared to invest in large-scale capital equipment, the papermaking machine.

Recent study of how early modern European technology was learned and invented has given rise to a forest of eloquent concepts, including ‘expertise and experience,’ ‘learning by doing,’ ‘the mindful hand,’ and ‘trading zones.’Footnote 6 (The last two phrases refer less to an actual appendage or physical sites and more to exchanges between natural philosophers and artisans). Certainly, these terms rest on numerous, finely etched studies of past production. But these comprehensive distillations tend to sacrifice the diversity of technological practice and change that enlivened this production. The grittiness and grime that marked every Old Regime trade (and tradesperson) also melt away. Equally, the joys and cruelties of time on the road and the self-esteem and rage generated by every craft's exactions lose their bite. Only by examining hand papermaking as a whole, with its own terms of work, custom, mastery, and survival, can we assess how mechanised papermaking emerged from this art.

The transformation of papermaking serves as an ideal vantage from which to consider the enduring debate about the interplay of technological change, economic growth, and labour practice in early modern Europe. Currently, this discussion emphasises two concepts: the ‘industrious revolution’ and the ‘industrial Enlightenment.’ Jan de Vries, who developed the phrase industrious revolution, claimed that worker families during the period 1650–1800 chose to spend more days and longer hours at work, often at greater intensity, in order to consume ever more imported commodities and manufactured goods.Footnote 7 As a result, producers pursued machines and intensified the divisions of labour in their trades to satisfy the spiraling demand for a wide range of goods, such as furnishings, razors, and famously, mirrors.

My explorations of the hours and efforts of journeymen paperworkers tell a different tale. These skilled hands already sweated through exhausting days at the outset of de Vries's era of newfound industriousness. Everywhere paper was made in early modern Europe, masters and men haggled over the margins of daily production quotas, not their core. Moreover, these largely settled levels were accompanied by downtime compensation (if the master was responsible for the disruption) and overtime premiums. These standards reassured manufacturers in search of regular productivity and workers fearful of exploitation that the familiar day's work remained the order of the day in their trade. They also reflected the delicate nature of the product: masters and journeymen alike knew they had to both ‘speed up’ and ‘take their time’ to turn out quality paper at the expected rate.Footnote 8 So time-discipline, exhausting workdays, and deeply held expectations about the duration and yield of a proper workday neither awaited an industrious revolution nor the mechanical rhythm of the papermaking machine.

According to Joel Mokyr, the ‘industrial Enlightenment’ was at once a set of institutional transformations and a cultural campaign that exposed ‘tacit artisanal savoir-faire’ and its supposedly inflexible nature to the sunlight of scientific inspection. Yet Mokyr conceded that ‘the bulk of innovation in manufacturing and agriculture before 1800 advanced without science providing indispensable inputs.’ Instead, he ascribed these changes to ‘experience-driven insights, trial and error,’ and good fortune. The inventor of the papermaking machine would have added the trials of governing the toil of skilled, willful hands as the mainspring of his work.Footnote 9 In sum, papermaking's capitalist practices, which included the light touch (at most) of the industrial Enlightenment but lacked an industrious revolution, drove the search for a papermaking machine.

3. Making paper and its discontents

To understand how paper was made, we must first journey inside a paper mill. (See Figure 1.) Hand paper mills generally consisted of two buildings, with an upper storey in at least one structure. On the ground level, discarded linen, unravelling ropes, and stained, torn sails were sorted, paper was made, and newly minted sheets were glazed; the elevated workshop served as a drying loft. The creaking of carts loaded down with baskets of these dusty or sodden materials signaled the beginning of the papermaking season. The rag merchants who brought the cast-off linen to the mills knew they had a valuable commodity. In 1784–85, James Whatman II, England's premier papermaker, observed that rags accounted for 47.5 percent of his production costs. At the same time, the wages Whatman paid added up to 14 percent of his expenses.Footnote 10 Before large-scale mechanisation, materials were inevitably more expensive than men, even those who had hard-won skills. Rising wages alone, then, did not prompt the coming of the papermaking machine.Footnote 11

The division of labour and basic manipulations of hand papermaking were shared in mills across Europe. Effectively, production consisted of three stages: the rotting and mechanical reduction of discarded linen into pulp, the creation of the paper, and the preparation of the infant sheets for ink and transport. Female hands divided white rags from grey, removed caked dirt, and cut away matted patches. If their work was hasty or indifferent, the women could damage the pulp, so the master papermakers of Bern prescribed the maximum weight of rags they should ‘cut’ each day.Footnote 12 An experienced man watched over rows of stamping mallets that separated the linen, already weakened by a customary period of fermentation, into cellulose filaments. He knew that the fermentation had proceeded long enough when he could feel the proper degree of heat in a handful of pulp. By the close of the eighteenth century, Dutch, English, many Scandinavian, and some French manufacturers had dispensed with slow decomposition and turned to a machine, the Hollander beater, that macerated old linen quickly. This device cut the losses of fermentation and sped up the preparation of the pulp, but the journeymen who used this material still turned out the usual six reams of paper each day.

The vatman, who actually created the sheets, first evaluated the colour and consistency of the pulp, the surest guide to the final weight of the ream. Then he dipped his mould, a rectangular, wire mesh bounded by a wooden frame, into a tub partially filled with the warm, watery material. He lifted the mould quickly and shook it in a time-honoured pattern so that the fibres of the infant sheet ‘shut.’ Depending on the scale of the mould and its stringing (and hence the size and weight of the paper), he generally performed this task about 3000 times per day. After fashioning each sheet, the vatman passed the mould, with the fresh paper clinging to its wires, to the coucher, whose primary tool was a stack of hairy felts. He needed steady hands and good timing, since he transferred six or seven sheets of paper per minute from wire to felt. Once his pile of woollen felts, each now bearing a moist sheet of paper, reached a certain height, it was known as a post. Then it was pressed.

The layman separated the paper from the felts, a delicate task that resulted in many ruined sheets. More pressing followed and the paper was draped over cords to dry. The sizerman collected the still moist sheets and immersed them in an emulsion of hides, hoofs, tripe, and alum. This gelatine bath filled the paper's pores, thereby preventing ink blots. The sizerman tested his work with his tongue: if it left a balanced impression on the sheet that resembled a fan or a butterfly's wing, the glaze was good. Finally, women sorted and smoothed the paper, excised stained and clotted swatches, and assisted the loftsman in wrapping the reams. Though rich in custom and lore, papermaking was always a precise industry. The romantic image of the languid, self-directed pace of the independent artisan misses much of the activity in pre-mechanised paper mills. Here journeymen and women workers laboured at closely integrated tasks. Although certain hands still exercised some control over the rhythm of their toil, the lowly apprentice who failed to stir the pulp at the base of the vat at regular intervals put the quality of the paper at risk. If the supervisor of the stamping mallets failed to rouse himself from sleep during heavy rains, turbulent, muddy water flooded the troughs and discoloured the pulp. Exacting time-discipline had always been a feature of papermaking; its presence showed in every sheet. Moments mattered. There was little available production time for the intensified hours of labour that de Vries maintains newly industrious workers increasingly chose.

How, then, did youngsters learn the art of making paper by hand? In a word: slowly. Very young children gathered the scraps of rags and ropes that slipped out of the sorters’ bin, and they crossed shopfloors littered with flawed, crumpled sheets and puddled with spilled finish. Above all, they were members of papermaking families. To control the labour market and the rewards for their work (to the extent they could), journeymen paperworkers toiled tirelessly to keep their ranks thin, familial, and initiated in the workers’ custom, known in France as their modes. The men engaged in the trade in Angoumois reserved apprenticeships for their sons and brothers, and ‘formed a race distinct from the population in the midst of which they lived.’Footnote 13 Veteran hands evidently refused to labour without additional compensation beside skilled men who had not been born into the trade. Even millmasters, said the journeymen, had to possess the proper pedigree, or pay the company of workers for its absence. No doubt the journeymen squeezed their bosses for every possible sou, but this custom also ensured that the master knew his trade and the power of the workers’ self-styled ways.

In early modern France, apprenticeships in papermaking ranged from three to six years, with four years as the term specified by royal edict in 1739. According to one authority, German paperworkers endured indentures of ‘4 years and 14 days.’Footnote 14 Even after the legal basis for the prosecution of violators of apprenticeship law disappeared in England in 1814, the journeymen paperworkers mandated that ‘No one shall be entitled to the business unless he has served a legal apprenticeship of seven years and can produce his lawful indenture.’ The exception: ‘the eldest son of a paper-maker, who is deemed to be a worthy member at the age of twenty-one, provided that he is brought up to the trade.’Footnote 15 That said, every English paperworker was expected to carry his ‘card of freedom,’ the credential his trade union issued to acceptable journeymen, or else find work in another trade. Put simply, skill, family ties, and a firm grasp of his brothers’ custom earned a journeyman his welcome and keep. The paperworkers’ skill served as the cornerstone of their custom, this custom sheltered the journeymen's skill, and custom and skill together ensured the workers’ collective control of the labour market.

In time, a skilled apprentice might become a sort of bound journeyman. The veteran journeymen likely recognised these maturing novices as low-priced competition. Consequently, the master papermakers of the Auvergne conceded, in 1688, that apprentice vatmen, couchers, and laymen would enjoy the same perquisites as the journeymen who performed these tasks.Footnote 16 Meanwhile, the fully fledged journeymen taxed newcomers often, claiming these fees were compensation for the clumsiness of the youths and the hours spent instructing them in the tricks of the trade. There was always a trade-off between teaching and working, but one producer, doubtless echoing many others, lamented that these indemnities were ‘legitimately due to the master,’ since ‘no worker has ever taken the pain, even once, to demonstrate the craft to [an] apprentice.’ The manufacturer's bitterness aside, the journeymen were quick to demonstrate their elevated status to the indentured: a Parisian apprentice courted trouble when he refused to open the doors for the veterans, ‘as is customary.’Footnote 17

In 1801, the master papermakers of Kent and Surrey pledged to stand together against the ‘wanton unnecessary and extortionate demands’ of the journeymen.Footnote 18 They would oppose the workers’ ‘regular system of constant encroachment on the fair and established customs and usages of the trade.’Footnote 19 But the manufacturers’ resistance was hamstrung by their reliance on the journeymen's skills. Across Europe, every apprentice learned the value of this dependence before he became a layman or layboy, as this post was known in England.

Successful paper production depended on accessible markets, timely weather, a full storeroom of old linen, the absence of catastrophic disruptions, and a ready supply of capable journeymen. Few manufacturers could count on all of these assets for very long. While some paperworkers and their families took to the road to avoid tight-fisted or abusive masters, the manufacturers also turned them out quickly when production ceased. Whether a journeyman relied on his ‘card of freedom’ or his livret (an internal passport mandated by the state and signed by a recent French employer) to land his spot, he could not depend on the job lasting long. So, the French paperworker on the tramp made his way by ‘raising his rent.’ When he arrived at a mill, he generally received some combination of bread, wine or beer, a place to sleep, and a quire of broken sheets. If he was fortunate, he might get an audition for a place around the vats. Even if nothing came of this chance, an Auvergnat manufacturer complained that he had to let the itinerant ‘pass and pass and even pass again’ through his mill, or watch his own skilled hands depart en masse.Footnote 20 This was not the ‘propositional knowledge’ of Enlightened science, but it was the tacit knowledge that enabled vulnerable journeymen to survive the familiar passages of their trade.Footnote 21

The men, women, and children of hand papermaking retraced paths well-known to their ancestors as they roamed from mill to mill in search of a paid stint. Along the way, they shouldered their hardes, rolls of ratty clothing, a handful of personal items, and a bent tool or two fixed to the end of a stick. These papermaking families were neither the embodiment of a consumer revolution nor an industrious revolution. Instead, the journeymen struggled relentlessly to preserve their property in their skills and a second form of ‘capital,’ the rewards earned from the sweat and know-how of their wives and children. An industrious revolution had not changed this immemorial formula in artisanal papermaking.

Journeymen paperworkers were well aware that the end of the line came early and often suddenly. At the close of the seventeenth century, rag-collectors caught the eye of the Italian physician Bernardino Ramazzini. As they hauled their ‘filthy wares’ to the paper mills, he wrote, they were tormented by ‘coughs, asthma, nausea, and vertigo,’ the same afflictions known to plague paperworkers.Footnote 22 Red arms, missing fingernails, and rheumatism were the lot of every vatman and coucher. Stooped backs often hobbled these skilled men, who sometimes switched stations to ease their pain. Ramazzini prescribed vinegar and water for the rag-collectors’ ailments. Both the journeymen paperworkers and the millwomen, however, had little respite from the discomforts and toll of their work. In a rare mention of the distress of labour in a paper mill, the Encyclopaedia Britannica observed that the recent invention of the duster, a mechanical device that shook the debris from the rags before they were sorted, rendered this debilitating toil ‘less pernicious to the selectors.’Footnote 23 Battered by long hours in the mills and long hours on the road when mills went silent, only hardy journeymen fashioned paper once they turned forty; indeed, paperworkers above this age had to prove that they had a smooth and steady ‘vatman's shake.’

Proud of their art and gradually enfeebled by it, journeymen paperworkers did everything in their power to make sure that their mastery paid off. To regulate their ceaseless travels on forbidding roads as well as their routine journeys up the craft ladder, they forged local, regional, and national combinations everywhere in Europe. The French Crown deplored a kingdom-wide association that rendered journeymen paperworkers the ‘masters of the success or of the ruin of the entrepreneurs.’ As one official raged, ‘this republican corps’ remained ‘jealous of a self-styled, chimerical independence.’Footnote 24 In fact, countless commentators rightly fumed that the paperworkers had crafted their own, illicit civic bodies within the broader custom of the trade. Manufacturers who ignored the journeymen's claims found their mills ‘damned,’ that is, idled by the departing workers. Worse yet, the mills were surrounded by mountains of rags and stuffed with paper and chemicals: only the daring master did not bow to the threat of arson as well as a boycott. ‘Mindful hands’ learned more things by doing than technical expertise, which is why some masters dreamed of fully mechanised papermaking.

Neither master papermakers nor journeymen paperworkers considered themselves to be members of a unified craft community with a single set of interests. But they shared more than the manufacturers’ heated comments may suggest. For instance, French masters and men alike knew that wrinkles in the paper were ‘goat's feet’ and uneven swells of pulp were andouilles, ‘sausages,’ or perhaps turds. This colourful jargon also taught: if pulp puddled along the ‘mauvaise rue,’ the side of the mould that lay against the vatman's gut, an experienced coucher warned his companion that the infant sheet was ‘unrefined (revêche).’ Moreover, the masters and men who produced this flawed paper drew on common assumptions about the profitable use of worktime. In 1788, Nicolas Desmarest, a French inspector of manufactures, noted that ‘clever’ producers disdained overtime work.Footnote 25 Nevertheless, when orders backed up, enterprising manufacturers acted otherwise (as they always had) and paid the journeymen for ‘overwork’—and then hid the shoddy sheets fashioned by the fatigued workers in reams of fine paper. No doubt, the workers were also quite skilled at looking the other way, as they did when masters dumped quicklime into stained pulp to whiten the sheets.

As the arrangements between masters and men evolved, wages proved considerably less stable than output quotas. As a rule of thumb, the entrepreneurs and the workers remained well aware that the reward for a week's worth of a skilled man's toil equalled the price of a single ream of good paper. Consequently, both manufacturers and journeymen put a premium on the command of work, its time, and its compensation. The conceptualisation of time as money, at least in papermaking, took root long before the mechanisation of the art, not as a result of it.

Polish paperworkers and most of their French brothers sweated around the vats for twelve hours each day, six days a week.Footnote 26 At the Worblaufen and Zu Thal mills of Bern, where the journeymen evidently began their toil at 3:00 a.m., workdays stretched from twelve to fourteen hours, with some sort of ‘break’ for the vatmen and couchers.Footnote 27 Work around the vats in the Austrian Rannersdorf mill regularly lasted for an exhausting fourteen hours.Footnote 28 Such comparisons, it must be noted, are less exact than they appear. English paperworkers, for instance, sometimes took an hour-and-a-half break for meals, but they were also known to eat while sweating around the vats. At the Montgolfier mill in Annonay, France, however, the influential and calculating masters engineered particularly precise workdays punctuated by equally precise mealtimes. The governor of the beaters sounded the bell at 3:45 a.m. and work began at four. The day's labour was divided into four segments, each capped by a meal, and ended at 7:00 p.m. Étienne Montgolfier claimed that the ‘effective’ workday in the family's shops amounted to thirteen hours. Seasonal light mattered little in the mill, since the Montgolfiers joined their Auvergnat confrères and ignored the longer summer workdays prescribed by the state in 1739. Just to be sure, the Montgolfiers computed the precise hours of candlelight needed in their mill from mid-August to the end of April; December, for example, required six hours and forty-five minutes worth of candles.Footnote 29 They embraced a highly mathematised approach to secure regular diligence and output, but it was less audacious because their production quotas largely conformed to the trade's long-time standards.

If most paperworkers’ days were somewhat less mechanical than those endured by the Montgolfiers’ hands, their ‘day's work’ was every bit as exact. In Angoumois, Desmarest reported that the everyday workload ‘always’ amounted to twenty posts of paper.Footnote 30 This quota was so widely ingrained in the English trade that the Combination Act of 1796, which called into question much of the industry's contested custom, still specified that ‘twenty of which posts shall and do make a day's work.’ Over time, the seasoned vatman learned how often per minute he had to dip his mould in the pulp to build a proper post. This became an intense, familiar time-discipline. Thus the Combination Act mandated that ‘the time of working by journeymen at the vat … shall be half an hour about each post.’Footnote 31 The Montgolfiers’ hands even launched a complaint by indicating themselves precisely how much time it took to produce a post.Footnote 32 Perhaps masters once had to impose the ‘day's work’ of twenty posts on recalcitrant journeymen; but by the eighteenth century, paperworkers in England, France, and the German states had internalised this figure.

Across Europe, journeymen paperworkers had long expected premiums for exceeding their daily production quotas or putting in overtime hours. As early as 1557, the veteran hands of Krakow agreed that their masters could hire as many apprentices as they desired so long as they paid the journeymen for their overtime production.Footnote 33 Both sides knew what a full ‘day's work’ entailed: six reams of medium-size paper. In 1546, the King of Poland and Grand Duke of Lithuania, Sigismund I, had issued A Confirmation of the Regulations of the Papermaking Craft. This document affirmed the handiwork of ‘honest masters and [journeymen] of the papermaking craft,’ who had ‘submitted to Us articles regulating their craft approved and accepted by unanimous agreement, custom, and practice.’Footnote 34

Careful reckoning was inscribed in every reward for making paper. According to ‘The Paper-Maker & Stationers’ Assistant,’ which was published in London in 1794, ‘The over, or sheets made by odd felts in the year, pay the Maker for the Holydays.’Footnote 35 At the same time, the Montgolfiers’ vatmen and couchers produced posts of paper à deux when they sweated without the aid of a layman. To ensure the quality of their output, the ‘day's work’ was reduced substantially.Footnote 36 Whether during the Reformation or Revolutionary era, only a bold, determined, or foolhardy manufacturer – or perhaps a producer who could count on the rarely given, active backing of the state – dared to unwind this system of expectations and rewards.

There were few hours, little social space, and great risk for master and man alike if either spurned their trade's familiar production regimen. A rate-busting vatman gambled with his entire family's earnings, since his wife and daughters sorted stained linen and finished sheets, and his sons struggled with the layman's art, as they all always had. If his outraged brothers blackballed him, the whole family faced the road and pinched bellies. The everyday mathematisation of the killing work of hand papermaking and its interwoven tasks took shape as part of a fabric of customary formulas. It was the absence of an industrious revolution in papermaking and the modest contribution of Enlightened science to the trade that framed its mechanisation.

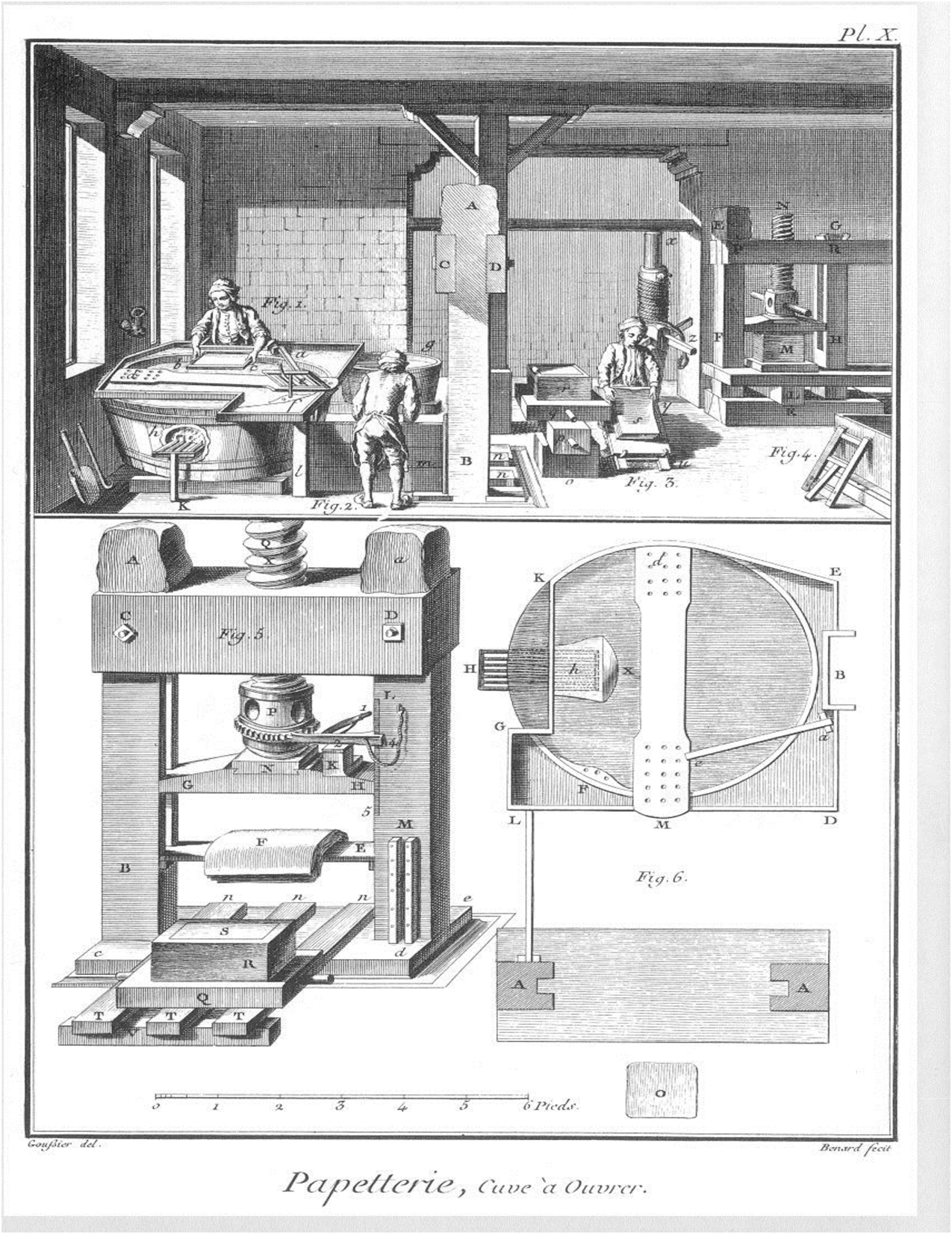

Papeterie, Plate X (Details of skills and tools of papermaking). In Denis Diderot and Jean le Rond d'Alembert, Encyclopédie, ou dictionnaire raisonné de sciences, des arts et des métiers, vol. 5, 1751–2.

4. Changes in the works

None of the eighteenth-century encyclopaedists called for the full mechanisation of papermaking. They were probably incapable of visualising such a transformation, although Joseph Montgolfier, the famed balloonist, experimented with wooden automata that mimicked the vat crew. His effort failed, and so enterprising manufacturers were left, at most, with Josiah Wedgwood's vision of making ‘such machines of the Men as cannot Err.’Footnote 37 But journeymen paperworkers resisted becoming automata. As one French official observed, these men bent ‘neither to threat nor to persuasion.’ And in 1786, an intendant cautioned that it was best ‘to use paths of gentleness’ when approaching the paperworkers.Footnote 38 Not surprisingly, a Royal decree conceded in 1777 that the paperworkers had rendered themselves the true masters of the mills.

The eighteenth century may have witnessed the birth of the fiscal-military state and its managerial attitude toward the economy, but in the realm of papermaking it was also a time of growing trust in the market. To ensure the operation of ‘natural,’ unencumbered labour markets, leading commentators on both sides of the English Channel counselled that governments must clear the clutter of custom, combination, and their own shop-worn mandates. Then master and man would negotiate freely, productivity would climb, capital would prosper, and revenues on heavily taxed paper would soar. But neither force nor statute produced these outcomes in Maidstone and Ambert. To use the language of Michel Foucault (while inverting his conjectures about shopfloor powers), the journeymen paperworkers’ skills, custom, and capacity to turn workshops into contested ground had survived the invasive, disciplinary gaze of their betters as well as the French and English states.Footnote 39

As a result, an improving Austrian papermaker, Ignaz Theodor von Pachner, tried a different strategy. To make the Empire ‘independent of the seemingly indispensable ‘foreign’ types and qualities’ of papers, he founded a large mill in Klein-Neusiedl in 1793. He furnished this enterprise with the best tools and machines of the day, including Hollander beaters. He expected his hands to turn out six reams of medium paper each day, the familiar rate throughout the European craft. But he concluded that the reams produced in early morning by the light of flickering candles or the burning of soot-laden woodchips were inferior. So he reduced the workday in Klein-Neusiedl. Previously, these hours had apparently matched one old Austrian formula of toil from 2:00 a.m. to 7:00 p.m., with a two-hour midday break. Under von Pachner, the mill's regimen lasted twelve hours, from 6:00 a.m. to 6:00 p.m. Now the daily schedule and quotas at Klein-Neusiedl matched the fatiguing expectations in paper mills elsewhere on the Continent. Put another way, von Pachner seemingly cut the slack out of the traditional Austrian production regimen, while bringing his mill in line with the already intensive practices of his foreign competitors. The Emperor found the elegant features of his paper convincing; he converted the working hours of the industry across his realm to 6:00 a.m. to 6:00 p.m.Footnote 40

There is no evidence that the self-assured von Pachner consulted the journeymen before he imposed the new regimen at Klein-Neusiedl. But he surely knew that if altering their hours posed a certain risk, reducing their earnings was downright dangerous. This was especially true because he wanted his skilled hands to avoid the rushed work that yielded too many ‘seconds’ among first-class sheets of writing paper. So, he accompanied his abbreviated time regimen with the end of daily quotas for the production of stationery. (He understood this shift, as an historian of Austrian papermaking put it, as ‘the dropping of piece-work.’) To compensate the vatmen and couchers for the loss of the piecework earnings that figured large in their trade's wage format, von Pachner provided them with a weekly ‘extra allowance.’Footnote 41 Since the fine rags necessary for the production of fine paper were more expensive than the cost of labour, he had made a set of considered choices. In effect, von Pachner embraced one facet of de Vries's industrious revolution – intensified work (in sunlight) – at the expense of another when he cut the journeymen's hours.

To contend with rapidly inflating wages, rag prices, and Excise duties, England's paper manufacturers began to forge regional and national cartels at the end of the eighteenth century. They fixed the prices of their reams and collectively ‘laid still’ their shops in order to cut the cost of cast-off linen and met with some success. (They seem to have been shocked, however, that the ‘Importers of Foreign Rags’ attempted to raise the price of discarded linen by ‘withholding the necessary Supplies.’Footnote 42) The manufacturers, especially in the papermaking centre of Kent, had more in mind when they silenced their mills; they also intended to reduce wages. They counted on draining the financial resources of the journeymen's union and pressing on the family responsibilities of individual workers. As we have noted, the short-term results of this strategy favoured the manufacturers, but their gains did not last. By 1804, the Kentish vatman creating first-class paper had a daily nominal wage of 4 s. 1 d., plus a weekly premium known as ‘beer money’ of 6 d., close to double his rate in 1792.Footnote 43

In a trade at once capital- and labour-intensive, the manufacturers’ willingness to suspend production was risky. Would a prolonged closure prove fatal to the cartel's interests or those of individual producers? Would the journeymen return and take up their moulds and felts? The manufacturers had embraced a weapon of the weak, a measure of their inability to bring the journeymen's ‘dangerous Combination’ to heel.Footnote 44 So the masters protected their lockout with a ‘blacklist’ and developed relief funds to mollify their hands. They would put an end to the formula of no more than one apprentice per vat that ‘the men have made the regulation.’Footnote 45 They would then hire and train youngsters in numbers that suited them, and thereby drown the workers’ custom and coalition in a deep pool of newly skilled hands. So long, however, as veteran hands sweated in familiar ways and closed mills of their choice in rolling strikes, the sort of control over remuneration and the terms of negotiation that the manufacturers pursued eluded them.

Just as they shuttered their shops to bring down the price of labour and rags, England's master papermakers quieted their mills to preserve their capital and solvency. State protection through high duties on foreign reams and collective price-fixing in their dealings with stationers also hedged their bets. At a time when Josiah Wedgwood was transforming the division of labour in pottery-making and Richard Arkwright's water frame and Samuel Crompton's mule had revolutionised cotton textile production, the master papermakers’ capitalism was that of the merchant-manufacturer rather than the growth-oriented industrial capitalist. Though producers, they trusted in Smithian commercial profits more than those of Schumpeterian growth fueled by technological change and the attendant debt. They took comfort in the craft's enduring, transnational wage formats, which were rooted in both a familiar production process and equally familiar standards for quality, productivity, and ‘overwork.’ Inevitably, these men were troubled by the journeymen's republics and customs, and by the challenge to their mastery and the unceasing unpredictability the paperworkers brought to the trade. Thus, the largely risk-averse manufacturers’ determination to break the journeymen's combinations at all costs, despite the danger.

Not every master papermaker, however, was determined to hold fast to his brothers’ cartel and its policies. Consider the appeal made by one producer to his uncertain English counterparts: ‘the only means that I think are left is a universal suspension of the Manufactory

… Do not let us be the dupes of the Men which I am persuaded we at present are … Nor let the private Interests of any prevail over the general good.’Footnote 46 Ironically, it was a Kentish master who made the strongest case against collective action by his confrères to fix the journeymen's wages at the lowest possible level. Wages in Kentish papermaking were the highest in England, and the producers there had profited from this bounty. As Finch Hollingsworth, a manufacturer in Maidstone, outlined to the lawmakers, ‘it has been usual with the Petitioner, and other Owners of Paper Mills and Works [in Kent], to give extraordinary Reward and Encouragement to such of their Workmen as are most skillful, sober, and industrious, from which Practice the Petitioner and others have reaped great Advantages.’ These enterprising producers did not wish to risk the ‘superior Quality’ of their reams; nor were they resigned to feeling ‘unsafe’ as a consequence of prompting ‘Emulation amongst the Workmen.’Footnote 47 In short, Hollingsworth and his allies were willing to pay premium wages for premium skills.

Evidently, the Kentish paper producers had secured, at least in part, the goal of the Combination Act of 1796: wage levels determined through bargaining by master and man. To protect this system, these influential masters had prevented the inclusion of wage prescription by the Justices of the Peace in the statute. Consequently, solidarity among the Kentish masters simultaneously produced silent mills in order to reduce wages and better work prompted by higher wages. In 1803, John Portal, a substantial paper manufacturer in Hampshire, pledged that his firm, Portal and Bridges, was ‘perfectly ready to lay our Mills still’ in support of his Kentish counterparts. But he continued, ‘we shall not think of discharging our Men, we shall keep them in pay, and I fear spoil them by paying them for not working.’ After all, he concluded, ‘where Men are working upon low wages [in Hampshire] comparatively speaking ought not those Men to be kept at work as an example for the unruly, instead of throwing them out of work?’Footnote 48 With tongue-in-cheek, Portal illuminated the often self-defeating practices of England's master papermakers.

For their part, England's journeymen paperworkers milked the labour market in their own favour. They boycotted stiff-necked producers, drew on their coalitions’ funds when they took to the road in defense of ‘wages or customs,’ and worked only for wages they and their brothers had agreed to.Footnote 49 While papermaking's enduring, trans-European labour process and wage formats served as sources of security and regular productivity for manufacturers and journeymen, they also bespoke inertia in an age of soaring demand for paper. As a result, Nicolas-Louis Robert, an ‘inspector of personnel’ at the Langlée mill in France, set out to create a papermaking machine. The prototype received a patent from the French state in 1799. But, as Robert's former employer, Saint-Léger Didot, explained, he had not crafted the device solely, or even primarily, to increase output. ‘Disgusted, like me, by the bad conduct of the corporation of paperworkers,’ Didot concluded, Robert had decided ‘to seek the means of fabricating paper without their aid.’Footnote 50 As French rag and paper prices tumbled and rose like Ministers, their policies, and the new paper currency, wage increases secured by the journeymen may have influenced his work; still, the paperworkers’ modes likely mattered more. In 1830, the paperworkers of the Vaucluse were sure his machine had been ‘invented with the aim of ruining the working class rather than the increase of the proprietors’ profits.’ They lamented that a ‘great number’ of paperworkers now traversed the Midi ‘without finding a single day's work there.’Footnote 51

Robert's invention turned on a ceaseless, rotating web of wire mesh slathered with pulp, and was yet another mechanical mimic of the journeymen's skills. Within a decade of Robert's patent, Bryan Donkin, an imaginative English engineer and tinkerer, had created a commercially viable papermaking machine. Robert had reversed Wedgwood's formula: he made a machine that embodied the actions of men. In doing so, he had also reconfigured the familiar balance of power in the industry. In 1837, an English producer testified that traditional paper manufacturers had been ‘very much at the mercy of the men.’Footnote 52 By 1853, a beleaguered English master papermaker, still clinging to his vat, observed that the contest of his day was no longer ‘Men versus Masters, but it is Men versus Machines.’Footnote 53

5. Conclusion

The lived terms of making paper by hand had been as tightly wrapped as the work of the vat crew and the trade's wage system. The papermaking machine drew on and unraveled this durable web of skilled toil, custom, compensation, worktime, and shopfloor relationships. In doing so, Robert imagined that his device would offer the manufacturers unfettered sway over their shops; indeed, he privileged this purpose above efficiency and productivity in his account of the inspiration for his machine. Certainly, it transformed the capitalism of hand papermaking into mechanised industrial capitalism and vastly strengthened the entrepreneurs’ hand in the labour market. But the manufacturers still required men who had mastered the trade's tacit knowledge about pulp, finish, and the proper weather for drying sheets, and who knew their way around the corners of the mills. With the legacy of his trade's conflicts and his need for such practiced workers in mind, William Joynson, a leading English producer of machine-made stationery, reported in 1865 that he had trained all of the approximately 630 hands in his employ.Footnote 54 They were, as he put it, ‘of his own breeding.’Footnote 55 He had reason to be wary. Even in 1865, several generations into the machine age of papermaking, the vatmen in Kent's surviving traditional mills enjoyed a ‘beer money’ bounty of 2s. per week.Footnote 56