Abstract

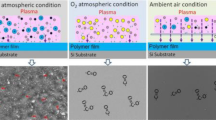

Atmospheric pressure cold plasma has the advantages of high reactive species content, free from the limitation of vacuum environment and low cost in polymer films pattern etching. However, due to the extension phenomenon of the jet, there are problems in the pattern etching, such as low processing accuracy and difficulty in process precise control. In this paper, an atmospheric pressure cold plasma jet diffusion limited etching model is established to simulate the etching process and surface etching morphology under different conditions, and a plasma jet processing platform is built for experimental confirmation. The effect of diffusion coefficient and move probability on the etching results is studied by numerical simulation. The experiment observes the extension phenomenon of the plasma jet hitting the glass slide under the influence of working voltage or nitrogen flow, and the color reaction of Starch-KI test paper. The results show that the simulated etching results are consistent with the extension phenomenon of the jet impinging on the glass slide. The greater the probability of the active particles moving downward, the greater the contact line width and the etching depth, which is the same as the experimental result of increasing the working voltage. The shielding gas can isolate the air, reduce the diffusion coefficient, and reduce the loss of particles, which is beneficial to plasma etching. It is hoped that the research results in this paper can provide a certain reference for realizing high-precision and controllable etching and process optimization of atmospheric pressure cold plasma jet.

Similar content being viewed by others

References

Gotoha K, Shohbukeb E, Kobayashic Y, Yamada H (2018) Wettability control of PET surface by plasma-induced polymer film deposition and plasma/UV oxidation in ambient air. Colloids Surf A 556:1–10

Chen F-Z, Xu W-J, Yao L, Song J-L, Huang S, Wang L, Parkin IP, Liu X (2015) Hydrophilic patterning of superhydrophobic surfaces by atmospheric pressure-pressure plasma jet. Micro Nano Lett 10(2):105–108

Ghosh A, Ganguly R, Schutzius TM, Megaridis CM (2014) Wettability patterning for high-rate, pumpless fluid transport on open, non-planar microfluidic platforms. Lab Chip 14:1538–1550

Lee C, Cho H, Kim D, Hwang W (2014) Fabrication of patterned surfaces that exhibit variable wettability ranging from superhydrophobicity to high hydrophilicity. Appl Surf Sci 288:619–624

Elsharkawy M, Schutzius TM, Megaridis CM (2014) Inkjet patterned superhydrophobic paper for open-air surface microfluidic devices. Lab Chip 14:1168–1175

Auad P, Ueda E, Levkin PA (2013) Facile and multiple replication of superhydrophilic-superhydrophobic patterns using adhesive tape. ACS Appl Mater Interfaces 5:8053–8057

Wang X-W, Song Y-X, Wang H (2012) Observation of nucleate boiling on a fine copper wire with superhydrophobic micropatterns. Chin Phys Lett 29(11):114702.1-114702.3

Koval NN, Ivanov YF, Lopatin IV, Akhmadeev YH, Shugurov VV, Krysina OV, Denisov VV (2015) Generation of low-temperature gas discharge plasma in large vacuum volumes for plasma chemical processes. Russ J Gen Chem 85(5):1326–1338

Tian J, Liu W-Z, Cui W-S, Gao Y-J (2018) Generation characteristics of a metal ion plasma jet in vacuum discharge. Plasma Sci Technol 20(8):35–41

Zhang M, Dai Y-C, Wen L, Wang H, Chu J (2018) Maskless surface modification of polyurethane films by an atmospheric pressure He/O2 plasma microjet for gelatin immobilization. Micromachines 9(195):1–13

Yang S-J, Hong Y (2007) Two atmospheric-pressure plasma sources for polymer surface modification. Plasma Chem Plasma Process 27(1):23–33

Wang T, Yang B, Chen X, Wang X-L, Yang C-S, Liu J-Q (2017) Distinct modes in the evolution of interaction between polymer film and atmospheric pressure plasma jet. Plasma Process Polym 14(7):e1600067.1-e1600067.9

Akishev YS, Balakirev AA, Medvedev MA, Petryakov AV, Trushkin NI (2020) Effect of the speed of the flat substrate movement on the air plasma jet transversal spreading at its impinging the surface. J Phys Conf Ser 1588(1):012042.1-012042.5

Onyshchenko I, Geyter ND, Morent R (2017) Improvement of the plasma treatment effect on PET with a newly designed atmospheric pressure plasma jet. Plasma Process Polym 14(8):1–15

Schmidt-Bleker A, Winter J, Bösel A, Reuter S, Weltmann KD (2016) On the plasma chemistry of a cold atmospheric pressure argon plasma jet with shielding gas device. Plasma Sources Sci Technol 25(1):015005.1-015005.24

Kapaldo J, Han X, Ptasinska S (2019) Shielding-gas-controlled atmospheric pressure plasma jets: optical emission, reactive oxygen species, and the effect on cancer cells. Plasma Process Polym. https://doi.org/10.1002/ppap.201800169

Ogawa K, Yajima H, Oh JS, Furuta H, Hatta A (2019) Effects of sheath gas flow on He atmospheric pressure plasma jet. Appl Phys Express 12(3):036001.1-036001.5

Nguyen DB, Trinh QH, Mok YS, Lee WG (2020) Generation of cold atmospheric pressure plasma jet by a coaxial double dielectric barrier reactor. Plasma Sources Sci Technol 29(3):035014

Nakajima A, Uchida G, Kawasaki T, Koga K, Sarinont T, Amano T, Takenaka K, Shiratani M, Setsuhara Y (2015) Effects of gas flow on oxidation reaction in liquid induced by He/O2 plasma-jet irradiation. J Appl Phys 118(4):043301-1-043301–9

Li Q, Li J-T, Zhu W-C, Zhu X-M, Pu Y-K (2009) Effects of gas flow rate on the length of atmospheric pressure nonequilibrium plasma jets. Appl Phys Lett 95:141502.1-141502.3

Xiong Q, Lu X, Ostrikov K, Xiong Z, Xian Y, Zhou F, Zou C, Hu J, Gong W, Jiang Z (2009) Length control of He atmospheric pressure plasma jet plumes: effects of discharge parameters and ambient air. Phys Plasma 16:043505.1-043505.6

Pan W-X, Zhang W-H, Zhang W-H, Wu C-K (2000) Generation of long, laminar plasma jets at atmospheric pressure and effects of flow turbulence. Plasma Chem Plasma Process 21(1):23–35

Meiners A, Leck M, Abel B (2015) Compact high-velocity atmospheric pressure dielectric barrier plasma jet in ambient air. Plasma Sci Technol 17(1):14–19

Deynse AV, Cools P, Leys C, Morent R, Geyter ND (2015) Surface modification of polyethylene in an argon atmospheric pressure plasma jet. Surf Coat Technol 276:384–390

Stoffels E, Flikweert AJ, Stoffels WW, Kroesen GMW (2002) Plasma needle: a non-destructive atmospheric pressure plasma source for fine surface treatment of (bio)materials. Plasma Sources Sci Technol 11:383–388

Lu X-P, Laroussi M (2006) Dynamics of an atmospheric pressure plasma plume generated by submicrosecond voltage pulses. J Appl Phys 100(6):063302.1-063302.6

Ishchuk V, Volland BE, Hauguth M, Cooke M, Rangelow IW (2012) Charging effect simulation model used in simulations of plasma etching of silicon. J Appl Phys 112(8):084308.1-084308.9

Ishchuk V, Olynick DL, Liu Z-W, Rangelow IW (2015) Profile simulation model for sub-50 nm cryogenic etching of silicon using SF6/O2 inductively coupled plasma. J Appl Phys 118(5):053302.1-053302.13

Ning W-J, Dai D, Zhang Y-H, Li L-C (2018) Effects of trace of nitrogen on the helium atmospheric pressure plasma jet interacting with a dielectric substrate. J Phys D 51(12):1–13

Liu X-Y, He M-B, Liu D-W (2015) The effect of working gas impurities on plasma jets. Phys Plasmas 22(4):043513.1-043513.4

Jin Y, Ren C-S, Yang L, Zhang J-L, Wang D-Z (2013) Atmospheric pressure plasma jet in Ar and O2/Ar mixtures: properties and high performance for surface cleaning. Plasma Sci Technol 15(12):1203–1208

Shirafuji T, Sawada Y (2018) Effects of ambient air on the characteristics of an atmospheric-pressure plasma jet of a gas mixture of highly N2-diluted O2 on a sliding substrate. Jpn J Appl Phys 57:01AA06.1-01AA06.10

Pinchuk M, Stepanova O, Kurakina N, Spodobin V (2017) Propagation of atmospheric pressure helium plasma jet into ambient air at laminar gas flow. J Phys Conf Ser 830(1):012060.1-012060.6

Prkash GV, Patel K, Behera N, Kumar A (2020) Expansion dynamics of atmospheric pressure helium plasma jet in ambient air. Phys Lett A 384(19):126497.1-126497.4

Kawasaki T, Sato A, Kusumegi S, Kudo A, Sakanoshita T, Tsurumaru T, Uchida G, Koga K, Shiratani M (2016) Two-dimensional concentration distribution of reactive oxygen species transported through a tissue phantom by atmospheric-pressure plasma-jet irradiation. Appl Phys Express 9(7):076202

Mitsugi F, Kusumegi S, Kawasaki T (2018) Visualization of ROS distribution generated by atmospheric plasma jet. IEEE Trans Plasma Sci 2:1–6

Jing L, Guo H, Zhang XF, Li HP (2018) Numerical and experimental studies on the interactions between the radio-frequency glow discharge plasma jet and the shielding gas at atmosphere. IEEE Trans Plasma Sci 8:1–10

Nakajima A, Uchida G, Kawasaki T, Koga K, Sarinont T, Amano T, Takenaka K, Shiratani M, Setsuhara Y (2015) Effects of gas flow on oxidation reaction in liquid induced by He/O2 plasma-jet irradiation. J Appl Phys 118(4):503

Wang H-X, Chen X, Pan W-X (2008) Effects of the length of a cylindrical solid shield on the entrainment of ambient air into turbulent and laminar impinging argon plasma jets. Plasma Chem Plasma Proces 28(1):85–105

Funding

Project supported by the National Natural Science Foundation of China (Grant No. 51905002), Anhui Provincial Natural Science Foundation (Grant No. 2008085QE230), Open project of Key Laboratory of Green Fabrication and Surface Technology of Advanced Metal Materials (Grant No. GFST2021KF06), Open Project of AnHui Province Key Laboratory of Special and Heavy Load Robot (Grant Nos. TZJQR003-2021, TZJQR003-2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lv, L., Wang, T., Wang, JH. et al. Numerical Simulation and Experimental Investigation on Etching Process of Atmospheric Pressure Cold Plasma Jet with Shielding Gas. Plasma Chem Plasma Process 42, 321–337 (2022). https://doi.org/10.1007/s11090-021-10226-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-021-10226-y