Abstract

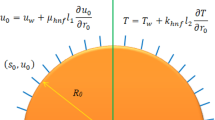

In this paper, a numerical model of elastohydrodynamic lubrication (EHL) in the line contact which happens on the surface of particle-reinforced composites is given. The influence of the particle size and burial depth on the EHL is studied. According to the influence of the structural parameters on the friction coefficient of the EHL contact, the structural parameters of the particles in the composites are optimized and the proper region of the parameters is obtained. The displacement and stress in elastic field caused by the uniform eigenstrains in the particles are described in terms of Galerkin vectors with the interactions between the particles are ignored. A coupling method of particle reinforced composites problem and EHL problem is presented, a new film thickness function is given considered the uneven elastic deformation caused by the presence of the particles. Finally, the presentation of film thickness and fluid pressure of the EHL explains that appropriate particle size, particle burial depth and particle distance can effectively reduce the friction coefficient. The lubrication behavior between the contacted surfaces can be improved under the heavy load.

Similar content being viewed by others

References

Krupka, I., Sperka, P., & Hartl, M. (2016). Effect of surface roughness on lubricant film breakdown and transition from EHL to mixed lubrication. Tribology International, 100, 116–125.

Wen, S., & Huang, P., (2012). Principles of tribology. John Wiley & Sons.

Masjedi, M., & Khonsari, M. M. (2015). On the effect of surface roughness in point-contact EHL: Formulas for film thickness and asperity load. Tribology International, 82, 228–244.

Van Emden, E., Venner, C. H., & Morales-Espejel, G. E. (2017). Investigation into the viscoelastic behaviour of a thin lubricant layer in an EHL contact. Tribology International, 111, 197–210.

Huang, K., Xiong, Y., Wang, T., et al. (2017). Research on the dynamic response of high-contact-ratio spur gears influenced by surface roughness under EHL condition. Applied Surface Science, 392, 8–18.

Masjedi, M., & Khonsari, M. M. (2014). Theoretical and experimental investigation of traction coefficient in line-contact EHL of rough surfaces. Tribology International, 70, 179–189.

Talekar, N., & Kumar, P. (2014). Steady state EHL line contact analysis with surface roughness and linear piezo-viscosity. Procedia Materials Science, 5, 898–907.

Ramesh, A., Akram, W., Mishra, S. P., et al. (2013). Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication. Tribology International, 57, 170–176.

Gachot, C., Rosenkranz, A., Hsu, S. M., & Costa, H. L. (2017). A critical assessment of surface texturing for friction and wear improvement, Wear, 372–373.

Max, M., Philipp, G., Andreas, R., Stephan, T., Frank, M., & Sandro, W. (2019). Designing surface textures for EHL point-contacts—Transient 3D simulations, meta-modeling and experimental validation. Tribology International, 137, 152–163.

Morris, N., Hart, G., Wong, Y. J., Simpson, M., & Howell, S. (2020) Laser surface texturing of Wankel engine apex seals. Surface Topography: Metrology Properties, 8, 034001.

Costa, H. L., & Hutchings, I. M. (2007). Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribology International, 40(8), 1227–1238.

Kovalchenko, A., Ajayi, O., Erdemir, A., & Fenske, G. (2011). Friction and wear behavior of laser textured surface under lubricated initial point contact. Wear, 271, 1719–1725.

Eshelby, J. D. (1957). The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences. The Royal Society, 241(1226), 376–396.

Mura, T. (2013). Micromechanics of defects in solids. Springer Science & Business Media.

Liu, S., Jin, X., Wang, Z., et al. (2012). Analytical solution for elastic fields caused by eigenstrains in a half-space and numerical implementation based on FFT. International Journal of Plasticity, 35, 135–154.

Liu, S., & Wang, Q. (2005). Elastic fields due to eigenstrains in a half-space. Journal of applied mechanics, 72(6), 871–878.

Zhou, K., Chen, W. W., Keer, L. M., et al. (2011). Multiple 3D inhomogeneous inclusions in a half space under contact loading. Mechanics of Materials, 43(8), 444–457.

Indraratna, B., Nimbalkar, S. S., Ngo, N. T., et al. (2016). Performance improvement of rail track substructure using artificial inclusions—Experimental and numerical studies. Transportation Geotechnics, 8, 69–85.

Wang, Z., Yu, H., & Wang, Q. (2016). Analytical solutions for elastic fields caused by eigenstrains in two joined and perfectly bonded half-spaces and related problems. International Journal of Plasticity, 76, 1–28.

Chiu, Y. P. (1978). On the stress field and surface deformation in a half space with a cuboidal zone in which initial strains are uniform. ASME Journal of Applied Mechanics, 45(2), 302–306.

Yu, H. Y., & Sanday, S. C. (1892). Elastic field in joined semi-infinite solids with an inclusion. Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences. The Royal Society, 1991(434), 521–530.

Chen, K., Zeng, L., Wu, Z., & Zheng, F. (2018). Elastohydrodynamic lubrication in point contact on the surfaces of particle-reinforced composite. AIP advances, 8, 045213.

Chen, K., Zeng, L., Zheng, F., Chen, J., & Ding, X. (2020). Effects of distribution density and location of subsurface particles on elastohydrodynamic lubrication. AIP Advances, 10(5), 055217.

Wen, S. Z., & Yang, P. R. (1992). Elastohydrodynamic lubrication. Tsinghua University Press.

Max, M., Stephan, T., & Sandro, W. (2018). Microtextured surfaces in higher loaded rolling-sliding EHL line-contacts. Tribology International, 127, 420–432.

Rosenkranz, A., Grützmacher, P. G., Gachot, C., & Costa, H. L. (2019). Surface texturing in machine elements. A critical discussion for rolling and sliding contacts. Advanced Engineering Materials, 1900194.

Acknowledgements

The project was supported in part by the National Natural Science Foundation of China under Grants No.51975425 and No. 51875417.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, J., Chen, K., Zeng, L. et al. Effects of Heterogeneous Particle Parameters on Micro-EHL Lubrication on Composite Surface in Line Contact. Int. J. Precis. Eng. Manuf. 22, 1989–1999 (2021). https://doi.org/10.1007/s12541-021-00588-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-021-00588-w