Abstract

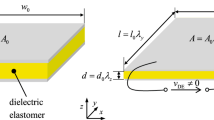

Dielectric elastomers (DEs) deform and change shape when an electric field is applied across them. They are flexible, resilient, lightweight, and durable and as such are suitable for use as soft actuators. In this paper a physics-based and control-oriented model is developed for a DE tubular actuator using a physics-lumped parameter modeling approach. The model derives from the nonlinear partial differential equations (PDE) which govern the nonlinear elasticity of the DE actuator and the ordinary differential equation (ODE) that governs the electrical dynamics of the DE actuator. With the boundary conditions for the tubular actuator, the nonlinear PDEs are numerically solved and a quasi-static nonlinear model is obtained and validated by experiments. The full nonlinear model is then linearized around an operating point with an analytically derived Hessian matrix. The analytically linearized model is validated by experiments. Proportional–Integral–Derivative (PID) and \(H_{\infty }\) control are developed and implemented to perform position reference tracking of the DEA and the controllers’ performances are evaluated according to control energy and tracking error.

Similar content being viewed by others

References

Brochu, P., Pei, Q.: Advances in dielectric elastomers for actuators and artificial muscles. Macromol. Rapid Commun. 31, 10–36 (2010). (01)

Carpi, F., Bauer, S., de Rossi, D.: Stretching dielectric elastomer performance. Science (New York, N.Y.) 330, 1759–61 (2010). (12)

Chakraborti, P., Toprakci, H.K., Yang, P., Spigna, N.D., Franzon, P., Ghosh, T.: A compact dielectric elastomer tubular actuator for refreshable braille displays. Sens. Actuators A Phys. 179, 151–157 (2012)

Documentation, S.: Simulation and model-based design, 2020. [Online]. https://www.mathworks.com/products/simulink.html (2020). Accessed 14 June 2021

dspace.: [Online]. https://www.dspace.com/en/inc/home.cfm (2021). Accessed 14 June 2021

Gu, G.-Y., Gupta, U., Zhu, J., Zhu, L.-M., Zhu, X.: Modeling of viscoelastic electromechanical behavior in a soft dielectric elastomer actuator. IEEE Trans. Robot. 33(5), 1263–1271 (2017)

He, T., Cui, L., Chen, C., Suo, Z.: Nonlinear deformation analysis of a dielectric elastomer membrane-spring system. Smart Mater. Struct. 19(8), 085017 (2010). (07)

Hoffstadt, T., Maas, J.: Adaptive sliding-mode position control for dielectric elastomer actuators. IEEE/ASME Trans. Mechatron. 22(5), 2241–2251 (2017)

Huang, P., Wu, J., Zhang, P., Wang, Y., Su, C.-Y.: Dynamic modeling and tracking control for dielectric elastomer actuator with model predictive controller. IEEE Trans. Ind. Electron. 1–1 (2021)

Jordi, C., Michel, S., Fink, E.: Fish-like propulsion of an airship with planar membrane dielectric elastomer actuators. Bioinspir. Biomimet. 5, 026007 (2010). (06)

Katzschmann, R.K., DelPreto, J., MacCurdy, R., Rus, D.: Exploration of underwater life with an acoustically controlled soft robotic fish. Sci. Robot. 3(16) (2018)

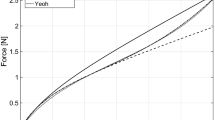

Kim, B., Lee, S.B., Lee, J., Cho, S., Park, H., Yeom, S., Park, S.: A comparison among neo-Hookean model, Mooney-Rivlin model, and Ogden model for chloroprene rubber. Int. J. Precis. Eng. Manuf. 13, 05 (2012)

Kovacs, G., Lochmatter, P., Wissler, M.: An arm wrestling robot driven by dielectric elastomer actuators. Smart Mater. Struct. 16, 306 (2007). (04)

Kovacs, G., Düring, L., Michel, S., Terrasi, G.: Stacked dielectric elastomer actuator for tensile force transmission. Sens. Actuators A Phys. 155(2), 299–307 (2009)

Lau, G.-K., Lim, H.-T., Teo, J.-Y., Chin, Y.-W.: Lightweight mechanical amplifiers for rolled dielectric elastomer actuators and their integration with bio-inspired wing flappers. Smart Mater. Struct. 23(2), 025021 (2014)

Lu, T., Huang, J., Jordi, C., Kovacs, G., Huang, R., Clarke, D.R., Suo, Z.: Dielectric elastomer actuators under equal-biaxial forces, uniaxial forces, and uniaxial constraint of stiff fibers. Soft Matter 8(22), 6167–6173 (2012)

Marchese, A., Onal, C., Rus, D.: Autonomous soft robotic fish capable of escape maneuvers using fluidic elastomer actuators. Soft Robot. 1, 75–87 (2014). (03)

Massa, B., Roccella, S., Carrozza, M.C., Dario, P.: Design and development of an underactuated prosthetic hand. In: Proceedings ICRA ’02, IEEE International Conference on Robotics and Automation, vol. 4, 01, pp. 3374–3379 (2002)

MATLAB.: 9.7.0.1216025 (R2019b). Natick, Massachusetts: The MathWorks Inc., (2019)

Nise, N.S.: Control Systems Engineering, (With CD). Wiley, Hoboken (2007)

Ogden, R.W.: Large deformation isotropic elasticity—on the correlation of theory and experiment for incompressible rubberlike solids. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 326(1567), 565–584 (1972)

Pelrine, R., Kornbluh, R.D., Eckerle, J., Jeuck, P., Oh, S., Pei, Q., Stanford, S.: Dielectric elastomers: generator mode fundamentals and applications. In: Smart Structures and Materials,: Electroactive Polymer Actuators and Devices, Y. Bar-Cohen, Ed., vol. 4329, International Society for Optics and Photonics. SPIE, 2001, 148–156 (2001a)

Pelrine, R., Sommer-Larsen, P., Kornbluh, R.D., Heydt, R., Kofod, G., Pei, Q., Gravesen, P.: Applications of dielectric elastomer actuators. In: Smart Structures and Materials: Electroactive Polymer Actuators and Devices, Y. Bar-Cohen, Ed., vol. 4329, International Society for Optics and Photonics. SPIE, 2001, 335–349 (2001b)

Pelrine, R., Kornbluh, R., Pei, Q., Stanford, S., Oh, S., Eckerle, J., Meijer, K.: Dielectric elastomer artificial muscle actuators: toward biomimetic motion. Proc. SPIE 4695, 126–137 (2002). (07)

Pid tuner app. [Online]. https://www.mathworks.com/help/slcontrol/gs/automated-tuning-of-simulink-pid-controller-block.html (2021). Accessed 14 June 2021

Plante, J.-S., Dubowsky, S.: Large-scale failure modes of dielectric elastomer actuators. Int. J. Solids Struct. 43, 04 (2006)

Rizzello, G., Naso, D., York, A., Seelecke, S.: Closed loop control of dielectric elastomer actuators based on self-sensing displacement feedback. Smart Mater. Struct. 25(3), 035034 (2016)

Romasanta, L., Lopez-Manchado, M., Verdejo, R.: Increasing the performance of dielectric elastomer actuators A review from the materials perspective. Progress Polym. Sci., 51, pp. 188–211 (2015), environmentally Relevant and Hybrid Polymer Materials. [Online]. https://www.sciencedirect.com/science/article/pii/S0079670015000921. Accessed 20 July 2021

Sarban, R., Jones, R.W.: Physical model-based active vibration control using a dielectric elastomer actuator. J. Intell. Mater. Syst. Struct. 23(4), 473–483 (2012)

Sarban, R., Jones, R., Mace, B., Rustighi, E.: A tubular dielectric elastomer actuator: fabrication, characterization and active vibration isolation. Mech. Syst. Signal Process. 25(8), 2879–2891 (2011)

Sarban, R., Lassen, B., Willatzen, M.: Dynamic electromechanical modeling of dielectric elastomer actuators with metallic electrodes. IEEE/ASME Trans. Mechatron. 17(5), 960–967 (2012)

Son, S., Goulbourne, N.: Dynamic response of tubular dielectric elastomer transducers. Int. J. Solids Struct. 47(20), 2672–2679 (2010)

Stoyanov, H., Brochu, P., Niu, X., Lai, C., Yun, S., Pei, Q.: Long lifetime, fault-tolerant freestanding actuators based on a silicone dielectric elastomer and self-clearing carbon nanotube compliant electrodes. RSC Adv. 3, 2272–2278 (2013). https://doi.org/10.1039/C2RA22380E. (Online)

Tryson, M., Kiil, H.-E., Benslimane, M.: Powerful tubular core free dielectric electro activate polymer (DEAP) push actuator. In: Bar-Cohen, Y., Wallmersperger, T. (eds.) Electroactive Polymer Actuators and Devices (EAPAD), Online, vol. 7287, pp. 447–457. International Society for Optics and Photonics, SPIE (2009). https://doi.org/10.1117/12.815740

van Kessel, R., Bauer, P., Ferreira, J.A.: Electrical modeling of cylindrical dielectric elastomer transducers. Smart Mater. Struct. 30(3), 035021 (2021). https://doi.org/10.1088/1361-665x/abde4f. (Online)

Wang, S., Kaaya, T., Chen, Z.: Self-sensing of dielectric elastomer tubular actuator with feedback control validation. Smart Mater. Struct. 7, 075037 (2020)

Xie, S., Ramson, P., Graaf, D., Calius, E., Anderson, I.: An adaptive control system for dielectric elastomers. In: IEEE International Conference on Industrial Technology, 2005, pp. 335–340 (2005)

Ye, Z., Chen, Z.: Modeling and control of 2-dof dielectric elastomer diaphragm actuator. IEEE/ASME Trans. Mechatron. 24, 1 (2019). (01)

Ye, Z., Chen, Z., Asmatulu, R., Chan, H.: Robust control of dielectric elastomer diaphragm actuator for human pulse signal tracking. Smart Mater. Struct. 26(8), 085043 (2017). https://doi.org/10.1088/1361-665x/aa75f7. (Online)

Yeoh, O.H.: Characterization of elastic properties of carbon-black-filled rubber vulcanizates. Rubber Chem. Technol. 63(5), 792–805 (1990)

Acknowledgements

This work was supported by the National Science Foundation under Grant CMMI #1747855.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Appendix 1: derivation of equations of state

Starting with Eq. 10,

Here,

A small change in \(\lambda _1\) is given by

and from Eq. 2, taking a small change in dl

Substituting Eq. 1 into this result gives

Finally Eq. 47 is written as

Also a small change in \(\lambda _2\) is given by

Finally, from Eq. 5, a small change in \({\bar{D}}\) is given by

With these, Eq. 46 becomes

Integrating by parts gives

By comparing the left hand side with the right hand side of the equation, the following is observed from the \(\delta z\) term inside the integral

Since there is no \(\delta z\) on the right hand side, physically this means that the vertical longitudinal stress component is fixed for a given applied load. This is the expected condition for the membrane in static equilibrium since the vertical force components must cancel out each other. Evaluating the boundaries gives

The boundary conditions for the tubular actuator require that \(\delta r_B=\delta r_A=\delta z_A=0\). Therefore

This corresponds to Eq. 15. Moving back into the integral is Eq. 14 directly from

This result is from the fact that there are no external forces acting on the surface of the membrane radially as would be the case if the actuator were to be under compression or tension by an applied pressure on the membrane (Son and Goulbourne 2010). Finally,

Taking the actuator as a cylindrical capacitor, \({\bar{E}}\) does not vary along the longitudinal direction and hence is a constant with respect to the X-direction. This gives

And from Eq. 6

therefore

1.2 Appendix 2: derivation of the governing differential equations

This is the extended derivation of Eqs. 21–23: Divide Eq. 1 by dX to get

But \(\frac{dl}{dX}=\lambda _1\). This gives Eq. 21 which is

Using Eqs. 14 and 51 one can get Eq. 22. Solving Eq. 14 gives

and solving Eq. 51 gives

Dividing Eq. 57 by Eq. 56 gives

Solving for \(\frac{d\theta }{dX}\) gives

Expanding \(\tan \theta\) gives

and using the trigonometric identity \(\sin ^2\theta + \cos ^2\theta = 1\) and multiplying through by \(\frac{\cos \theta }{s_1}\) gives us Eq. 22 as

Now the algebraic equation 23 can be derived by solving for \(s_1\) in Eqs. 15 and 18 and setting the two equations equal to each other. From Eq. 15

Using the normalized load \(F^*\) gives

and with Eq. 18

From Eq. 20, \({\bar{D}}=\epsilon \lambda _1^2\lambda _2^2{\bar{E}}\) so,

From Eq. 16, \({\bar{E}}^2= \frac{\Phi ^2}{H^2}\). Substituting this in the above expression gives

Using the normalized applied voltage on the membrane gives the algebraic equation

1.3 Appendix 3: Jacobian elements

and

Rights and permissions

About this article

Cite this article

Kaaya, T., Wang, S., Cescon, M. et al. Physics-lumped parameter based control oriented model of dielectric tubular actuator. Int J Intell Robot Appl 6, 397–413 (2022). https://doi.org/10.1007/s41315-021-00211-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s41315-021-00211-1