Abstract

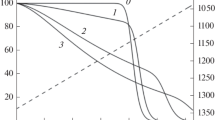

Issues of the formation of dust particles in high-temperature technological reactors are considered with an emphasis on the processes occurring in electrothermal ore-reduction furnaces of phosphorus production, when dust serves as a source of sludge that contaminates the product. A model of dust formation is proposed based on the hydrodynamic interaction of gas bubbles with liquid when they exit at the interface, when the destruction of bubbles leads to the appearance of drops carried away by the gas flow. Consideration of the stability positions for maximum perturbations in cylindrical liquid jets makes it possible to estimate the droplet sizes above the liquid surface and obtain qualitative and quantitative estimates for droplets carried away by the gas flow. Analytical dependencies for dust formation in a phosphoric furnace make it possible to relate the dust content to the operating parameters characterizing the operation of the furnaces (the temperature in the reaction zone) and the properties of the melt and control parameters (the voltage on the electrodes and the dosage of coke). Calculations based on the ratios show a satisfactory correlation with experimental data on the formation of dust in phosphoric, open-hearth furnaces, as well as bubbling heat and mass transfer installations. A model of thermophysical processes in an electrothermal reduction reactor is presented in the approximation of lumped-distributed parameters, which takes into account the interaction of zones of different phase compositions, making it possible to analyze the operating modes of the reactor from the main control parameters—voltage on the electrodes and the proportion of reducing coke. The results can be used to optimize the operating modes of the equipment within the limits of permissible dust emissions.

Similar content being viewed by others

REFERENCES

Guézennec, A.G., Huber, J.Ch., Patisson, F., et al., Dust formation in electric arc furnace: birth of the particles, Powder Technol., 2005, vol. 157, p. 2.

Nedar, L., Dust formation in BOF converter, Steel Res., 1996, no. 8, p. 320.

Gritzan, A. and Neuschütz, D., Rates and mechanisms of dust generation in oxygen steelmaking, Steel Res., 2001, no. 9, p. 324.

Doronin, I.E. and Svyazhin, A.G., Experimental study of steel smelting dust component evaporation, Metallurgist, 2015, vol. 58, nos. 9–10, p. 866.

Zhang, X., Guo, K., Qi, W., Zhang, T., and Liu, C., Gas holdup, bubble behavior, and mass transfer characteristics in a two-stage internal loop airlift reactor with different screens, Can. J. Chem. Eng., 2017, vol. 95, no. 6, p. 1202.

Ershov, V.A. and Pimenov, S.D., Elektrotermiya fosfora (Electrothermy of Phosphorus), St. Petersburg: Khimiya, 1996.

Meshalkin, V.P., Panchenko, S.V., Dli, M.I., Bobkov, V.I., and Chernovalova, M.V., Mechanism of the intensification of a heterogeneous reduction reaction with the liberation of gas bubbles, Theor. Found. Chem. Eng., 2020, vol. 54, no. 2, p. 304.

Svyazhin, A.G., Dusting during steel production, Stal’, 1999, no. 12, p. 78.

Baptizmanskii, V.I., Fiziko-khimicheskie osnovy kislorodno-konverternogo protsessa (Physicochemical Principles of the Oxygen-Converter Process), Baptizmanskii, V.I. and Okhotskii, V.B., Eds., Donetsk: Vishcha Shkola, 1981.

Kutateladze, S.S. and Styrikovich, M.A., Gidrodinamika gazozhidkostnykh sistem (Hydrodynamics of Gas-Liquid Systems), Moscow: Energiya, 1967.

Zhang, M., Li, J., Zeng, Q., Mou, Q., et al., An experimental study on the reduction behavior of dust generated from electric arc furnace, Appl. Sci., 2019, vol. 9, no. 17, p. 3604.

Surin, V.A. and Nazarov, Yu.N., Masso- i teploobmen, gidrogazodinamika metallurgicheskoi vanny (Heat and Mass Transfer and Fluid Dynamics in a Metallurgical Bath), Moscow: Metallurgiya, 1993.

Meshalkin, V.P., Panchenko, S.V., Bobkov, V.I., and Dli, M.I., Analysis of the thermophysical and chemical-technological properties of mining and processing waste materials, Theor. Found. Chem. Eng., 2020, vol. 54, no. 1, p. 157.

Levich, V.G., Fiziko-khimicheskaya gidrodinamika (Physicochemical Hydrodynamics), Moscow: Fizmatgiz, 1959.

Nigmatulin, R.I., Dinamika mnogofaznykh sred (Dynamics of Multiphase Media), Moscow: Nauka, 1987.

Dityakin, Yu.F., Klyachko, L.A., Novikov, B.V., and Yagodkin, V.I., Raspylivanie zhidkostei (Spraying of Liquids), Moscow: Mashinostroenie, 1977.

Zaitsev, A.I. and Bytev, D.O., Udarnye protsessy v dispersno-plenochnykh sistemakh (Shock Processes in Dispersed Film Systems), Moscow: Khimiya, 1994.

Ermakov, V.F., Kharlamova, I.N., and Vil’k, Yu.N., The dust formation during the electric sublimation of phosphorus from phosphate-siliceous minerals in the Karatau basin, in Issledovaniya v oblasti elektrotermii (Studies in Electrothermy), Leningrad: Leningr. Gos. Nauchno-Issled. Proekt. Inst. Osnovnoi Khim. Prom., 1972, p. 49.

Belov, V.N., Ermakov, V.F., and Ershov, V.A., Characteristics of dust losses during electrothermal processing of phosphorites, in Fosfatnoe syr’e i ego termicheskaya podgotovka dlya elektrovozgonki zheltogo fosfora (Phosphate Raw Materials and Its Thermal Preparation for the Electric Sublimation of Yellow Phosphorus), Leningrad: Leningr. Gos. Nauchno-Issled. Proekt. Inst. Osnovnoi Khim. Prom., 1982, p. 60.

Al’perovich, I.G., The forecast of sludge yield in phosphorus production (methodological aspects), in Sovershenstvovanie protsessov i apparatov proizvodstv karbida kal’tsiya, fosfora i fosfornykh solei (Improvement of Processes and Devices for the Production of Calcium Carbide, Phosphorus, and Phosphorus Salts), Leningrad: Leningr. Gos. Nauchno-Issled. Proekt. Inst. Osnovnoi Khim. Prom., 1988, p. 23.

Belov, V.N., Beskin, M.D., Zhikhova, A.N., et al., Testing of sinter in an industrial phosphoric furnace, in Fosfornaya promyshlennost’ (Phosphorus Industry), Moscow: Nauchno-Issled. Inst. Tekh.-Ekon. Issled. Khim. Kompl., 1978, no. 2, p. 42.

Merker, E.E., Gazodinamicheskaya zashchita zony produvki v staleplavil’nykh agregatakh (Gas-Dynamic Protection of the Blowing Zone in Steel Smelting Units), Moscow: Metallurgiya, 1994.

Markov, B.L., Produvka martenovskoi vanny (Blowing of the Open-Hearth Bath), Moscow: Metallurgiya, 1987.

Taubman, E.I., Gornev, V.A., Mel’tser, V.L., et al., Kontaktnye teploobmenniki (Contact Heat Exchangers), Moscow: Khimiya, 1987.

Panchenko, S.V., Dli, M.I., Borisov, V.V., and Panchenko, D.S., Analysis of thermophysical processes in near-electrode zone of electrothermal reactor, Non-Ferrous Met., 2016, no. 2, p. 57.

Utikar, R.P. and Ranade, V.V., Intensifying multiphase reactions and reactors: strategies and examples, ACS Sustainable Chem. Eng., 2017, vol. 5, no. 5, p. 3607.

Panchenko, S.V. and Panchenko, D.S., Simulation of the thermal state of an ore-thermal phosphoric furnace, in Problemy rudnoi elektrotermii (Ore Electrothermy), St. Petersburg: S.-Peterb. Gos. Tekhnol. Inst., 1996, p. 12.

Burlyaeva, E.V., Razlivinskaya, S.V., and Tregubov, A.V., Development and application of a generalized functional model of one-stage chemical production, Prikl. Inf., 2016, vol. 11, no. 1 (61), p. 64.

Meshalkin, V.P., Panchenko, S.V., Dli, M.I., and Panchenko, D.S., Analysis of the thermophysical processes and operating modes of electrothermic reactor using a computer model, Theor. Found. Chem. Eng., 2018, vol. 52, no. 2, p. 166.

Strakhov, A.F. and Strakhov, O.A., Implementation of information technologies at the stages of the life cycle of complex technical systems, Prikl. Inf., 2017, vol. 12, no. 3 (69), p. 80.

Styrikovich, M.A., Petukhov, V.I., and Kolokol’tsev, V.A., Influence of the density of the gas phase on the drop entrainment, Teploenergetika, 1964, no. 11, p. 78.

Rozen, A.M., Golub, S.I., and Davydov, I.F., Moisture entrainment from the evaporation mirror at small distances, Teor. Osn. Khim. Tekhnol., 1972, vol. 6, no. 3, p. 57.

Funding

This research was carried out with financial support from the Russian Foundation for Basic Research as part of scientific project no. 18-29-24094 and the Ministry of Science and Higher Education of the Russian Federation as part of State Task no. FSWF-2020-0019.

Author information

Authors and Affiliations

Corresponding author

Additional information

Special Issue Dedicated to the Jubilee of Academician of the RAS Valery P. Meshalkin.

Rights and permissions

About this article

Cite this article

Meshalkin, V.P., Panchenko, S.V., Dli, M. et al. Formation of Dust Particles in Process Multiphase Reactors. Theor Found Chem Eng 55, 628–637 (2021). https://doi.org/10.1134/S0040579521040291

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579521040291