Abstract

Platinum (Pt) has found wide use as an electrocatalyst for sustainable energy conversion systems1,2,3. The activity of Pt is controlled by its electronic structure (typically, the d-band centre), which depends sensitively on lattice strain4,5. This dependence can be exploited for catalyst design4,6,7,8, and the use of core–shell structures and elastic substrates has resulted in strain-engineered Pt catalysts with drastically improved electrocatalytic performances7,9,10,11,12,13. However, it is challenging to map in detail the strain–activity correlations in Pt-catalysed conversions, which can involve a number of distinct processes, and to identify the optimal strain modification for specific reactions. Here we show that when ultrathin Pt shells are deposited on palladium-based nanocubes, expansion and shrinkage of the nanocubes through phosphorization and dephosphorization induces strain in the Pt(100) lattice that can be adjusted from −5.1 per cent to 5.9 per cent. We use this strain control to tune the electrocatalytic activity of the Pt shells over a wide range, finding that the strain–activity correlation for the methanol oxidation reaction and hydrogen evolution reaction follows an M-shaped curve and a volcano-shaped curve, respectively. We anticipate that our approach can be used to screen out lattice strain that will optimize the performance of Pt catalysts—and potentially other metal catalysts—for a wide range of reactions.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

Code availability

The Vienna ab initio Simulation Package (VASP) for the density functional theory calculations is available at https://www.vasp.at.

References

Luo, M. et al. PdMo bimetallene for oxygen reduction catalysis. Nature 574, 81–85 (2019).

Li, M. et al. Single-atom tailoring of platinum nanocatalysts for high-performance multifunctional electrocatalysis. Nat. Catal. 2, 495–503 (2019).

Zhang, L. et al. Platinum-based nanocages with subnanometer-thick walls and well-defined, controllable facets. Science 349, 412–416 (2015).

Mavrikakis, M., Hammer, B. & Nørskov, J. K. Effect of strain on the reactivity of metal surfaces. Phys. Rev. Lett. 81, 2819–2822 (1998).

Hammer, B. & Nørskov, J. K. Theoretical surface science and catalysis-calculations and concepts. Adv. Catal. 45, 71–129 (2000).

Beckord, S., Brimaud, S. & Behm, R. J. Stability and ORR performance of a well-defined bimetallic Ag70Pt30/Pt(111) monolayer surface alloy electrode-probing the de-alloying at an atomic scale. Electrochim. Acta 259, 762–771 (2018).

Strasser, P. et al. Lattice-strain control of the activity in dealloyed core–shell fuel cell catalysts. Nat. Chem. 2, 454–460 (2010).

Wu, J. et al. Surface lattice-engineered bimetallic nanoparticles and their catalytic properties. Chem. Soc. Rev. 41, 8066–8074 (2012).

Bu, L. et al. Biaxially strained PtPb/Pt core/shell nanoplate boosts oxygen reduction catalysis. Science 354, 1410–1414 (2016).

Wang, X. et al. Palladium-platinum core–shell icosahedra with substantially enhanced activity and durability towards oxygen reduction. Nat. Commun. 6, 7594 (2015).

Wang, H. et al. Direct and continuous strain control of catalysts with tunable battery electrode materials. Science 354, 1031–1036 (2016).

Xie, S. et al. Atomic layer-by-layer deposition of Pt on Pd nanocubes for catalysts with enhanced activity and durability toward oxygen reduction. Nano Lett. 14, 3570–3576 (2014).

Koh, S. & Strasser, P. Electrocatalysis on bimetallic surfaces: modifying catalytic reactivity for oxygen reduction by voltammetric surface dealloying. J. Am. Chem. Soc. 129, 12624–12625 (2007).

He, T. et al. Inflating hollow nanocrystals through a repeated Kirkendall cavitation process. Nat. Commun. 8, 1261 (2017).

Li, X. et al. Coordination effect assisted synthesis of ultrathin Pt layers on second metal nanocrystals as efficient oxygen reduction electrocatalysts. J. Mater. Chem. A 4, 13033–13039 (2016).

Li, J. et al. Hard-magnet L1O-CoPt nanoparticles advance fuel cell catalysis. Joule 3, 124–135 (2019).

Wang, W., Li, X., He, T., Liu, Y. & Jin, M. Engineering surface structure of Pt nanoshells on Pd nanocubes to preferentially expose active surfaces for ORR by manipulating the growth kinetics. Nano Lett. 19, 1743–1748 (2019).

Jin, M. et al. Synthesis of Pd nanocrystals enclosed by {100} facets and with sizes < 10 nm for application in CO oxidation. Nano Res. 4, 83–91 (2011).

Henkes, A. E., Vasquez, Y. & Schaak, R. E. Converting metals into phosphides: a general strategy for the synthesis of metal phosphide nanocrystals. J. Am. Chem. Soc. 129, 1896–1897 (2007).

Kitchin, J. R., Nørskov, J. K., Barteau, M. A. & Chen, J. Role of strain and ligand effects in the modification of the electronic and chemical properties of bimetallic surfaces. Phys. Rev. Lett. 93, 156801 (2004).

Wang, L. et al. Tunable intrinsic strain in two-dimensional transition metal electrocatalysts. Science 363, 870–874 (2019).

Feng, Q. et al. Strain engineering to enhance the electrooxidation performance of atomic-layer Pt on intermetallic Pt3Ga. J. Am. Chem. Soc. 140, 2773–2776 (2018).

Danilovic, N., Subbaraman, R., Strmcnik, D., Stamenkovic, V. R. & Markovic, N. M. Electrocatalysis of the HER in acid and alkaline media. J. Serb. Chem. Soc.78, 2007–2015 (2013).

Kang, Y., Yang, P., Markovic, N. M. & Stamenkovic, V. R. Shaping electrocatalysis through tailored nanomaterials. Nano Today 11, 587–600 (2016).

Ferrin, P. & Mavrikakis, M. Structure sensitivity of methanol electrooxidation on transition metals. J. Am. Chem. Soc. 131, 14381–14389 (2009).

Chang, S. C. & Weaver, M. J. Influence of coadsorbed bismuth and copper on carbon monoxide adlayer structures at ordered low-index platinum-aqueous interfaces. Surf. Sci.241, 11–24 (1991).

Subbaraman, R. et al. Enhancing hydrogen evolution activity in water splitting by tailoring Li+-Ni(OH)2-Pt interfaces. Science 334, 1256–1260 (2011).

Subbaraman, R. et al. Trends in activity for the water electrolyser reactions on 3d M (Ni, Co, Fe, Mn) hydr(oxy)oxide catalysts. Nat. Mater. 11, 550–557 (2012).

Strmcnik, D. et al. Improving the hydrogen oxidation reaction rate by promotion of hydroxyl adsorption. Nat. Chem. 5, 300–306 (2013).

Gu, G. H. et al. Autobifunctional mechanism of jagged Pt nanowires for hydrogen evolution kinetics via end-to-end simulation. J. Am. Chem. Soc. 143, 5355–5363 (2021).

Hÿtch, M. J., Snoeck, E. & Kilaas, R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 74, 131–146 (1998).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Kresse, G. & Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comp. Mater. Sci. 6, 15–50 (1996).

Nørskov, J. K., Rossmeisl, J., Logadottir, A. & Lindqvist, L. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Rossmeisl, J., Qu, Z.-W., Zhu, H., Kroes, G.-J. & Nørskov, J. K. Electrolysis of water on oxide surfaces. J. Electroanal. Chem. 607, 83–89 (2007).

Ceperley, D. M. & Alder, B. J. Ground state of the electron gas by a stochastic method. Phys. Rev. Lett. 45, 566-569 (1980).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953 (1994).

Pearson, W. B. A Handbook of Lattice Spacings and Structures of Metals and Alloys (Pergamon Press, 1958).

Yoo, J. S., Abild-Pedersen, F., Nørskov, J. K. & Studt, F. Theoretical analysis of transition-metal catalysts for formic acid decomposition. ACS Catal. 4, 1226–1233 (2014).

Bu, L. et al. Surface engineering of hierarchical platinum-cobalt nanowires for efficient electrocatalysis. Nat. Commun. 7, 11850 (2016).

Ding, J. et al. Morphology and phase controlled construction of Pt–Ni nanostructures for efficient electrocatalysis. Nano Lett. 16, 2762–2767 (2016).

Ma, S. Y. et al. Synthesis of low Pt-based quaternary PtPdRuTe nanotubes with optimized incorporation of Pd for enhanced electrocatalytic activity. J. Am. Chem. Soc. 139, 5890–5895 (2017).

Li, J. et al. Ternary CoPtAu nanoparticles as a general catalyst for highly efficient electro-oxidation of liquid fuels. Angew. Chem. Int. Ed. 131, 11651–11657 (2019).

Zhao, W. Y. et al. Highly active and durable Pt72Ru28 porous nanoalloy assembled with sub-4.0 nm particles for methanol oxidation. Adv. Energy Mater. 7, 1601593 (2017).

Zhang, W. et al. Ultrathin PtNiM (M= Rh, Os, and Ir) nanowires as efficient fuel oxidation electrocatalytic materials. Adv. Mater. 31, 1805833 (2019).

Liu, H. et al. Ultrathin Pt–Ag alloy nanotubes with regular nanopores for enhanced electrocatalytic activity. Chem. Mater. 30, 7744–7751 (2018).

Li, H. H. et al. Highly crystalline PtCu nanotubes with three dimensional molecular accessible and restructured surface for efficient catalysis. Energy Environ. Sci. 10, 1751–1756 (2017).

Luo, S. & Shen, P. K. Concave platinum–copper octopod nanoframes bounded with multiple high-index facets for efficient electrooxidation catalysis. ACS Nano 11, 11946–11953 (2017).

Yin, H. et al. Ultrathin platinum nanowires grown on single-layered nickel hydroxide with high hydrogen evolution activity. Nat. Commun. 6, 6430 (2015).

Wang, P. et al. Precise tuning in platinum-nickel/nickel sulfide interface nanowires for synergistic hydrogen evolution catalysis. Nat. Commun. 8, 14580 (2017).

Alinezhad, A. et al. Direct growth of highly strained Pt islands on branched Ni nanoparticles for improved hydrogen evolution reaction activity. J. Am. Chem. Soc. 141, 16202–16207 (2019).

Liu, Z. et al. Aqueous synthesis of ultrathin platinum/non-noble metal alloy nanowires for enhanced hydrogen evolution activity. Angew. Chem. Int. Ed. 57, 11678–11682 (2018).

Fang, C. et al. Engineering of hollow PdPt nanocrystals via reduction kinetic control for their Superior electrocatalytic performances. ACS Appl. Mater. Interfaces 10, 29543–29551 (2018).

Zhang, J. et al. PdPt bimetallic nanoparticles enabled by shape control with halide ions and their enhanced catalytic activities. Nanoscale 8, 3962–3972 (2016).

Liu, Y. et al. Composition-controlled synthesis of bimetallic PdPt nanoparticles and their electro-oxidation of methanol. Chem. Mater.23, 4199–4203 (2011).

Kakade, B. A. et al. Highly active bimetallic PdPt and CoPt nanocrystals for methonal electro-oxidation. J. Phys. Chem. C 116, 7464–7470 (2012).

Stull, D. R. & Propher, H. JANAF Thermochemical Tables (US National Bureau of Standards, 1971).

Acknowledgements

We thank J. Li, C. Li, J. Liu and G. Zhou at the Instrument Analysis Center in Xi’an Jiaotong University for assistance with HRTEM, XPS and ICP-MS analyses. We acknowledge the support from the Shanghai Institute of Microsystem and Information Technology for HAADF-STEM characterizations. The work is sponsored by the National Natural Science Foundation of China (NSFC, numbers 51888103, 21773180, 21875137, 51521004 and 5140105009), the State Key Laboratory for Mechanical Behavior of Materials from Xi’an Jiaotong University, the National Key R&D Program of China (number 2017YFB0406000) and the Center of Hydrogen Science and Joint Research Center for Clean Energy Materials from Shanghai Jiao Tong University. Y.Y. acknowledges the support from UC Riverside and Korea Institute of Materials Science through the UC-KIMS Center for Innovation Materials for Energy and Environment and the Hydrogen Energy Innovation Technology Development Program of the National Research Foundation of Korea (NRF) funded by the Korean government (Ministry of Science and ICT (MSIT); grant NRF-2019M3E6A1064020).

Author information

Authors and Affiliations

Contributions

M.J. and Y.Y. conceived and designed the experiments. T.H. and W.W. performed the catalyst preparation, catalytic testing, characterization and wrote the manuscript. F.S. and J.W. contributed to the geometric phase analysis and HAADF-STEM analysis. X.Y. carried out theoretical calculations for this work. X.L. participated in the data analysis on electrocatalysis. The manuscript was written through the contributions of all authors.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks Sylvain Brimaud and Harry Hoster for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

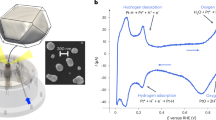

Extended Data Fig. 1 Key characteristics of the synthesis.

a–f, TEM images of Pd nanocubes phosphorized for 0 min (a), 2.5 min (b), 5 min (c), 7.5 min (d), 10 min (e) and 20 min (f). The interfaces between inner Pd cores and outer Pd-P phase are marked with white boxes for better comparison among all samples. The magnifications of inset images are the same as other particles. g, h, Representative STEM images of the uniform PtC-2.5 (g) and PtT-2.8 (h) core-shell nanocubes. i, Atomic ratio of Pt:Pd calculated from the ICP-MS data and the number of Pt atomic layers, suggesting an average thickness of ~7 atomic layers for all Pt shells. j–m, Representative HRTEM image (j, k), HAADF-STEM (l) image, and lattice profile (m) of Pt shell grown on Pd@Pd-P seed. The Pd/Pd-P interphase and Pd-P/Pt interface are marked with white boxes for better observation.

Extended Data Fig. 2 Characterization of the lattice strain in Pt shells.

a–c, Lattice profiles measured at different regions in PtT-1.3 (a), PtT-2.8 (b) and PtT-5.9 (c), showing the uniform strain distributions. d, Average lattice strains of tensile strained samples calculated from the value collected from the edge sites. e, f, HAADF-STEM images of overly phosphorized Pd-P@Pt nanocubes, showing the significant rupture of the Pt shell. g–i, HRTEM images of Pd@Pt nanocubes (g) and Pd-P@Pt nanocubes (h), and their XRD patterns showing negative shifts for the diffraction peaks of Pd-P@Pt relative to those of Pd@Pt nanocubes (i). j–l, Lattice profiles measured at different regions in PtC-1.2 (j), PtC-2.5 (k) and PtC-5.1 (l). m, Average lattice strains of compressive strained samples calculated from the value collected from the shell regions. n, o, XPS spectrum of tensile strained Pt shells (n) and compressive strained Pt shells (o), showing that the Pt binding energy shifts negatively with the lattice expanding and positively with the lattice contracting. p, ICP-MS-determined content of Pd and P for different samples (C-xP represents Pd-P@Pt prior to the dephosphorization), verifying the complete removal of P during the dephosphorization process.

Extended Data Fig. 3 Characterization of the surface compositions of PtC-2.5.

a–f, Layer-by-layer EDX line scan analysis for a single particle. g–m, Representative STEM image of Pt0 (g) and layer-by-layer EDX line scans for particles in the recorded region (h–m). These data demonstrate the low-level Pd/Pt intermixing on the surface of compressive strained Pt (100) shells.

Extended Data Fig. 4 Characterization of the surface compositions of Pt0.

a–f, Layer-by-layer EDX line scan analysis for a single particle. g–o, Representative STEM image of PtC-2.5 (g) and layer-by-layer EDX line scans for particles in the recorded region (h–o). These data demonstrate the low-level Pd/Pt intermixing on the surface of non-strained Pt (100) shells.

Extended Data Fig. 5 Characterization of the surface compositions of PtT-2.8.

a–f, Layer-by-layer EDX line scan analysis for a single particle. g–n, Representative STEM image of PtT-2.8 (g, k) and layer-by-layer EDX line scans for particles in the recorded region (h–j, l–n). These data demonstrate the low-level Pd/Pt intermixing on the surface of tensile-strained Pt (100) shells.

Extended Data Fig. 6 Structural analyses of Pt shells before and after electrocatalysis.

a–c, TEM images, HAADF-STEM images, and lattice profiles of PtC-5.1 (a), Pt0 (b) and PtT-5.9 (c), showing negligible restructuring of the core-shell catalysts after MOR catalysis. d, Proportions of different types of surface defects (Pt (111) sites and step sites) calculated by counting the atomic numbers of different sites on all Pt surfaces before (d2) MOR catalysis and proportions of different types of surface defects of PtC-5.1, Pt0, PtT-5.9 (from left to right) after (d3) MOR catalysis, showing the identically minor fractions of defects on all Pt shells and negligible accumulation of these defects during electrocatalysis. e–m, CV curves of the strain-modified Pt shells before and after MOR catalysis, showing no obvious restructuring of Pt (100) surfaces. n, CV curve of Pt/C catalyst. o, ECSAs of all catalysts. The error bars in d2, d3 and o represent the standard deviations of five independent measurements of the same sample.

Extended Data Fig. 7 Electrocatalytic properties of all catalysts.

MOR specific and mass activities at 0.65 V (a, b) and i-t curves recorded at 0.65 V (c) and 0.3 V (d), all measured vs. Ag/AgCl in a solution containing 0.5 M H2SO4 and 1 M CH3OH. The initial specific MOR activities of all catalysts at 0.65 V vs. Ag/AgCl (e) and 0.3 V vs. Ag/AgCl (f); and the corresponding steady specific activities of all catalysts at the end of the i-t recording at 0.65 V vs. Ag/AgCl 0(g) and 0.3 V vs. Ag/AgCl (h). CO stripping tests (i, j) show that CO can be oxidized at a lower potential on compressive strained Pt while at a higher potential on tensile strained Pt. HER polarization curves (k–n) and HER specific and mass catalytic activities at −0.07 V vs. RHE (o, p) for all catalysts measured in 1 M KOH. Fitting of the HER polarization curves based on Butler-Volmer equation (q, r) gives Tafel slope values and exchange current densities of all catalysts toward HER (s). The error bars in a, b, e–h, o and p represent the standard deviations of five independent measurements of the same sample.

Extended Data Fig. 8 DFT calculations.

a, Atomic models showing the different adsorption sites on Pt (100) surface. b, c, Strain-dependent reaction free energies of water dissociation in alkaline (b) and acidic (c) solutions. d–f, Strain-dependent adsorption energies of OH* (d), H* (e) and CO* (f) on different sites.

Extended Data Fig. 9 Comparisons of catalytic performances.

a, MOR catalytic activities (at ~0.65 V vs. Ag/AgCl) achieved by some typical Pt-based catalysts developed in recent years. b, HER catalytic activities (at −0.07 V vs. Ag/AgCl) achieved by some typical Pt-based catalysts developed in recent years. c, MOR catalytic activities (at ~0.65 V versus Ag/AgCl) achieved by some typical PdPt bimetallic catalysts developed in recent years. d, Representative TEM image of Pd@Pt core-shell nanocubes synthesized using ~6 nm Pd nanocubes instead of ~17.3 nm Pd nanocubes as substrates.

Extended Data Fig. 10 Characterization of catalytic stabilities.

a–d, MOR CV evolutions (a), MOR mass activity evolutions (b), HER LSV evolutions (c), and HER mass activity evolutions (d) for Pt/C, PtT-2.8 and PtT-2.8-6 nm. The accelerated durability tests show 6% activity loss for PtT-2.8 toward MOR after 20,000 potential cycles and 12% activity loss for PtT-4.7 toward HER after 10,000 potential cycles, both surpassing Pt/C. e, Atomic ratio of Pt:Pd before and after the durability tests for PtT-2.8 and PtT-4.7, showing negligible compositional changes. f, g, TEM images, HAADF-STEM images, and lattice profiles of PtT-2.8 (f) and PtT-4.7 (g) after the durability tests, showing negligible structural changes.

Supplementary information

Rights and permissions

About this article

Cite this article

He, T., Wang, W., Shi, F. et al. Mastering the surface strain of platinum catalysts for efficient electrocatalysis. Nature 598, 76–81 (2021). https://doi.org/10.1038/s41586-021-03870-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-021-03870-z

This article is cited by

-

Site-specific reactivity of stepped Pt surfaces driven by stress release

Nature (2024)

-

Improving hydrogen evolution reaction efficiency through lattice tuning

Nano Research (2024)

-

Strain engineering in electrocatalysis: Strategies, characterization, and insights

Nano Research (2024)

-

Ultra-Efficient and Cost-Effective Platinum Nanomembrane Electrocatalyst for Sustainable Hydrogen Production

Nano-Micro Letters (2024)

-

Phosphorus Doping in PtRu Nanoalloys to Boost Alkaline Hydrogen Evolution Reaction

Journal of Electronic Materials (2024)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.