Abstract

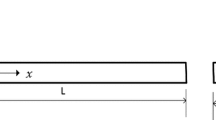

To consider the influence of the quality of the accelerometer and the installation position on the test frequency, a test scheme was designed to identify the first-order bending frequency with free and cantilever beams as well as the first-order torsion frequency with free plates. According to the energy method and mode shape, the correction relationship between the elastic modulus and the first-order bending frequency of free and cantilever beams is derived alongside the relationship between the shear modulus and first-order torsion frequency of a free plate. These relationships are suitable for informing the influence of the accelerometer mass and installation. The first-order bending frequency and the first-order torsion frequency of Sitka spruce beams, slabs, and oriented strand board have been measured along the length, which verifies the effectiveness of the derived relation in testing the elastic modulus and shear modulus of wood materials. Taking the ratio m/M between the mass of the accelerometer and the mass of the test specimen as a parameter, the scope of application of the modified relation is discussed.

Similar content being viewed by others

References

Lorenzo R, Mimendi L, Li HT, Dong Y (2020) Bimodulus bending model for bamboo poles. Constr Build Mater 262:120876. https://doi.org/10.1016/j.conbuildmat.2020.120876

Yang XJ, Ma L, Zhao Q, Yu YH (2018) Enduring performance of self-tapping screw connection in wood members and WPC members. Wood Res 63(5):833–842. https://doi.org/10.37763/wr.1336-4561/65.2.245256

Yang XJ, Zhao Q, Hao D et al (2020) Flexural behavior of OSB reinforced wood truss. Wood Res 65(2):245–256. https://doi.org/10.37763/wr.1336-4561/65.2.245256

Li HT, Qiu ZY, Wu G, Corbi O, Wei DD, Wang LB et al (2019) Slenderness ratio effect on eccentric compression properties of parallel bamboo strand lumber columns. J Struct Eng 145(8):04019077. https://doi.org/10.1061/(ASCE)ST.1943-541X.0002372

Yin SC (1996) Wood Science. China Forestry press, BeiJing

Hu YC, Wang FH, Liu YX (2001) Study on modulus of elasticity in bending of plywood by vibration method. China Wood Ind 02:3–5. https://doi.org/10.19455/j.mcgy.2001.02.001

Mei CT, Zhou XY, Jin JW (2005) Wood-based panels. China Forestry Press, Beijing

Liu HW, Lv RK (2017) Material mechanics experiment, 4th edn. Higher Education Press, Beijing

Wang Z, Xie WB, Wang ZH, Cao Y (2018) Strain method for synchronous dynamic measurement of elastic, shear modulus and Poisson’s ratio of wood and wood composites. Constr Build Mater 182:608–617. https://doi.org/10.1016/j.conbuildmat.2018.06.139

Wang Z, Li L, Gong M (2012) Measurement of dynamic modulus of elasticity and damping ratio of wood-based composites using the cantilever beam vibration technique. Constr Build Mater 28(1):831–834. https://doi.org/10.1016/j.conbuildmat.2011.09.001

Ventsel E, Krauthammer T (2001) Thin plates and shells: theory, analysis and applications. Marcel Dekker, New York

Ren J, Wang J, Bi SS (2017) Correction of transducers mass effects from the measured FRFs in Hammer impact testing. Shock Vib 2017(4):1–10. https://doi.org/10.1155/2017/6857326

Wang ZH, Wang YL, Cao Y, Wang Z (2016) Measurement shear modulus of materials based on torsional mode of cantilever plate. Constr Build Mater 124:1059–1071. https://doi.org/10.1016/j.conbuildmat.2016.08.104

Wang Z, Fu HY, Ding YW, Cao Y, Wang YL et al (2019) Dynamic testing of shear modulus and elastic modulus of oriented strand board. Sci Silvae Sin 55(08):136–146. https://doi.org/10.11707/j.1001-7488.20190815

Zhang WW, Cao HX, Hai LI et al (2014) Measurement of a metallic rod’s elastic modulus with the cantilever vibration monitored by a mini-accelerometer. Coll Phys 33(6):16–19. https://doi.org/10.16854/j.cnki.1000-0712.2014.06.015

Guan C, Zhang HJ, Zhou LJ, Wang XP (2015) Dynamic determination of modulus of elasticity of full-size wood composite panels using a vibration method. Constr Build Mater 100(DEC15):201–206. https://doi.org/10.1016/j.conbuildmat.2015.10.008

Zhang HJ, Shen SJ, Cui YY et al (2005) Measuring elastic modulus of wood using vibration method. J Beijing For Univ 27(6):91–94. https://doi.org/10.13332/j.1000-1522.2005.06.017

Ilic J (2003) Dynamic MOE of 55 species using small wood beams[J]. Holz als Roh- und Werkstoff 61(3):167–172. https://doi.org/10.1007/s00107-003-0367-8

Timoshenko (1965) Mechanical vibrational science. Mechanical Industry Press, Beijing, pp 316–333

Wang Z, Wang YL, Cao Y, Gao ZZ (2019) Measurements of the shear modulus of materials by the free-plate torsional mode shape method. J Test Eval 47(2):1163–1181. https://doi.org/10.1520/JTE20160471

Wang Z, Wang GG, Wang YL, Cao Y, Gao ZZ (2016) Determination of shear modulus of wood using free board torsional vibration method. J For Eng 1(04):10–17. https://doi.org/10.13360/j.issn.2096-1359.2016.04.002

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Zhu, H., Wang, Z. et al. Analysis of the Influence of Accelerometer Quality and Installation Position on the Test Value of Wood Material Constant. Exp Tech 46, 745–759 (2022). https://doi.org/10.1007/s40799-021-00512-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-021-00512-x