Abstract

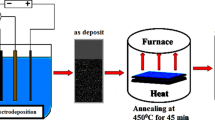

In recent years, the electrodeposition method had many advantages in large-area, low-cost preparation of thin-film solar cells. It was accelerating the commercialization of thin-film solar cells. In this work, electrochemical methods explored the electrodeposition mechanism of Cu2ZnSnS4(CZTS). The best sweep speed was 0.1 V s−1 by the cyclic voltammetry test. At the same time, it revealed that the deposition of CZTS film followed a chemical reaction preceding a reversible electron transfer (CE mechanism). The overall reaction rate was controlled by the slower chemical reaction. The electrode reaction product was not electrically active at the reduction potential. During the deposition, the Cu ions first deposited, then Zn ions and Sn ions deposited, and finally, S2O32− reduced to elemental S. Also, the addition of sodium citrate made the deposition potential of each element closer. Atomic force microscope and scanning electronic microscope showed that the heat-treated CZTS film was smooth and compact. UV–Vis spectra manifested that the CZTS film bandgap of 1.43 eV has a good match with solar radiation. The I–V curve offset was 35.23%. The short-circuit current density was 0.14 mA cm−2. The open-circuit voltage was 230 mV. The fill factor was 25%, and the cell efficiency was 1.56 × 10–3%.

Similar content being viewed by others

References

M.A. Basit, F. Raza, Sumayya, G. Karima, I. Ali, S. Butt, J. Mater. Sci. Mater. Electron. 31, 17563–17573(2020) https://doi.org/10.1007/s10854-020-04312-8.

S. Vallisree, A. Ghosh, R. Thangavel, T.R. Lenka, J. Mater. Sci. Mater. Electron. 29, 7273 (2018). https://doi.org/10.1007/s10854-018-8715-y

R.J. Deokate, R.S. Kate, S.C. Bulakhe, J. Mater. Sci. Mater. Electron. 30, 3530–3538 (2019). https://doi.org/10.1007/s10854-018-00630-0

E.M. Mkawi, K. Ibrahim, M.K.M. Ali, K.M.A. Saron, M.A. Farrukh, N.K. Allam, J. Mater. Sci. Mater. Electron. 26, 222–228 (2015). https://doi.org/10.1007/s10854-014-2387-z

M.A. Olgar, A. Seyhan, A.O. Sarp, R. Zan, J. Mater. Sci. Mater. Electron. 31, 20620–20631 (2020). https://doi.org/10.1007/s10854-020-04582-2

S.B. Patel, J.V. Gohel, J. Mater. Sci. Mater. Electron. 29, 18151–18158 (2018). https://doi.org/10.1007/s10854-018-9927-x

H. Zheng, Y. Liu, J. Mater. Sci. Mater. Electron. 32, 4125–4131 (2021). https://doi.org/10.1007/s10854-020-05153-1

P. Prabeesh, V.G. Sajeesh, I. Packia Selvam, S.N. Potty, J. Mater. Sci. Mater. Electron. 32, 4146–4156 (2021) https://doi.org/10.1007/s10854-020-05156-y

V.A. Madiraju, K. Taneja, M. Kumar, R. Seelaboyina, J. Mater. Sci. Mater. Electron. 27, 3152–3157 (2016). https://doi.org/10.1007/s10854-015-4137-2

A.V. Moholkar, S.S. Shinde, A.R. Babar, K.U. Sim, Y.B. Kwon, K.Y. Rajpure, P.S. Patil, C.H. Bhosale, J.H. Kim, Sol. Energy 85, 1354–1363 (2011). https://doi.org/10.1016/j.solener.2011.03.017

V.A. Moholkar, S.S. Shinde, L.G. Agawane, H.S. Jo, Y.K. Rajpure, J. Alloy. Compd. 544, 145–151 (2012). https://doi.org/10.1016/j.jallcom.2012.07.108

N.M. Shindea, C.D. Lokhande, J.H. Kim, J.H. Moon, J. Photoch. Photobio. A 235, 14–20 (2012). https://doi.org/10.1016/j.jphotochem.2012.02.006

M. Cao, L. Li, B.L. Zhang, J. Huang, L.J. Wang, Y. Shen, Y. Sun, J.C. Jiang, G.J. Hu, Sol. Energ. Mat. Sol. C 117, 81–86 (2013). https://doi.org/10.1016/j.solmat.2013.05.039

J. Lehner, M. Ganchev, M. Loorits, N. Revathi, T. Raadik, J. Raudoja, M. Grossberg, E. Mellikov, O. Volobujeva, J. Cryst. Growth. 380, 236–340 (2013). https://doi.org/10.1016/j.jcrysgro.2013.06.012

S. Ahmed, K.B. Reuter, O. Gunawan, L. Guo, L.T. Romankiw, H. Deligianni, Adv. Energy. Mater. 2, 253–259 (2012). https://doi.org/10.1002/aenm.201100526

E.M. Mkawi, K. Ibrahim, M.K.M. Ali, M.A. Farrukh, A.S. Mohamed, J. Mater. Sci. Mater. Electron. 25, 857–863 (2014). https://doi.org/10.1007/s10854-013-1657-5

Y. Li, T. Yuan, L. Jiang, F. Liu, Y. Liu, Y. Lai, J. Mater. Sci. Mater. 26, 204–210 (2015). https://doi.org/10.1007/s10854-014-2384-2

K. Zhang, J. Tao, J. He, W. Wang, L. Sun, P. Yang, J. Chu, J. Mater. Sci. Mater. 25, 2703–2709 (2014). https://doi.org/10.1007/s10854-014-1932-0

D. Seo, C. Kim, E. Oh, C.W. Hong, J.H. Kim, S. Lim, J. Mater. Sci. Mater. 25, 3420–3426 (2014). https://doi.org/10.1007/s10854-014-2034-8

D. Seo, S. Lim, J. Mater. Sci. Mater. 24, 3756–3763 (2013). https://doi.org/10.1007/s10854-013-1314-z

P. Termsaithong, R. Munprom, A. Shah, A. Rodchanaowan, Surf. Coat. Tech. 350, 807–812 (2018). https://doi.org/10.1016/j.surfcoat.2018.04.045

C. Malerba, F. Biccari, C.L.A. Ricardo, M. Valentini, R. Chierchia, M. Müller, A. Santoni, E. Esposito, P. Mangiapane, P. Scardi, A. Mittiga, J. Alloy. Compd. 582, 528–534 (2014). https://doi.org/10.1016/j.jallcom.2013.07.199

H. Katagiri, K. Jimbo, W.S. Maw, K. Oishi, M. Yamazaki, H. Araki, A. Takeuchi, Thin Solid Films 517, 2455–2460 (2009). https://doi.org/10.1016/j.tsf.2008.11.002

M. Zhou, Y. Gong, J. Xu, G. Fang, Q. Xu, J. Dong, J. ALLOY. COMPD. 574, 272–277 (2013). https://doi.org/10.1016/j.jallcom.2013.05.143

V.A. Akhavan, B.W. Goodfellow, M.G. Panthani, C. Steinhagen, T.B. Harvey, C. Jackson Stolle, B.A. Korgel, J. Solid. State. Chem. 189, 2–12(2012) https://doi.org/10.1016/j.jssc.2011.11.002.

T.S. Shyjua, S. Anandhi, R. Suriakarthick, R. Gopalakrishnan, P. Kuppusami, J. Solid. State. Chem. 227, 165–177 (2015). https://doi.org/10.1016/j.jssc.2015.03.033

V. Kheraj, K.K. Patel, S.J. Patel, D.V. Shah, J. CRYST. GROWTH. 362, 174–177 (2013). https://doi.org/10.1016/j.jcrysgro.2011.10.034

S.W. Shin, S.M. Pawar, C.Y. Park, J.H. Yun, J. Moon, J.H. Kim, J.Y. Lee, Sol. Energ. Mat. Sol. C 95, 12, 3202–3206(2011) https://doi.org/10.1016/j.solmat.2011.07.005.

S.B. Patel, A.H. Patel, J.V. Gohel, CrystEngComm 20(47), 7677–7687 (2018). https://doi.org/10.1039/C8CE01337C

Z.O. Elhmaidi, R. Pandiyan, M. Abd-Lefdil, E. Saucedo, M.A.E. Khakani, Appl. Surf. Sci. 507, 145003 (2020). https://doi.org/10.1016/j.apsusc.2019.145003

B. Ziti, H. Hartiti, S. Labrim, H.J.T. Fadili, A. Nkuissi, M. Ridah, P. Tahri, Thevenin. Appl. Phys. A-Mater. 125, 218 (2019). https://doi.org/10.1007/s00339-019-2513-0

H. Song, S. Son, S.K. Kim, G.Y. Jung, Nano. Res. 8, 3553–3561 (2015). https://doi.org/10.1007/s12274-015-0855-2

B. Gržeta, E. Tkalčec, C. Goebbert, M. Takeda, M. Takahashi, K. Nomura, M. Jakšić, J. Phys. Chem. Solids 63, 765–772 (2002). https://doi.org/10.1016/S0022-3697(01)00226-8

X. Zhang, Y. Zhang, Y. Song, Z. Wang, D. Yu, Physica E-Low-dimesional Systems and Nanostructures 28, 1–6 (2004). https://doi.org/10.1016/j.physe.2004.12.022

S. Iqbal, A. Bahadur, S. Anwer, S. Ali, R.M. Irfan, H. Li, M. Shoaib, M. Raheel, T.A. Anjum, M. Zulqarnain, Colloid. Surf. A 601, 124984 (2020). https://doi.org/10.1016/j.colsurfa.2020.124984

F. Jiang, H. Shen, W. Wang, J. Electron. Mater. 41. 2204–2209(2012) https://doi.org/10.1007/s11664-012-2112-8.

X. Gu, S. Zhang, Y. Qiang, Y. Zhao, L. Zhu, J. Electron. Mater. 43, 2709–2714 (2014). https://doi.org/10.1007/s11664-014-3200-8

A. Ziti, B. Hartiti, H. Labrim, S. Fadili, A. Batan, M. Tahri, A. Ridah, O. Mounkachi, A. Benyoussef, P. Thevenin, J. Mater. SCI-Mater. El. 30, 13134–13143 (2019). https://doi.org/10.1007/s10854-019-01676-4

H. Borate, A. Bhorde, A. Waghmare, S. Nair, S. Pandharkar, A. Punde, P. Shinde, P. Vairale, V. Jadkar, R. Waykar, S. Rondiya, Y. Hase, R. Aher, N. Patil, M. Prasad, S. Jadkar, ES Mater. Manuf. 11, 30–39(2021) https://dx.doi.org/https://doi.org/10.30919/esmm5f934.

B. Liu, J. Guo, R. Hao, L. Wang, K. Gu, S. Sun, Sol. Energy 201, 219–226 (2020). https://doi.org/10.1016/j.solener.2020.02.088

S. Varadharajaperumal, D. Alagarasan, R. Ganesan, M.N. Satyanarayan, G. Hegde, Mat. SCI. Semicon. Proc. 106, 104763 (2020). https://doi.org/10.1016/j.mssp.2019.104763

Acknowledgements

This work was supported financially by the National Natural Science Foundation of China [grant numbers 21706043].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cui, W., Li, L., Xu, Y. et al. Preparation of CZTS film by electro-deposition method: study on the principle of deposition and film performance. J Mater Sci: Mater Electron 32, 25188–25200 (2021). https://doi.org/10.1007/s10854-021-06975-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06975-3