Abstract

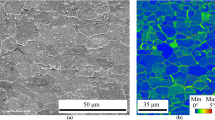

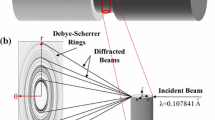

Microstructures and mechanical properties of tensile-strained 316L stainless steel are investigated using x-ray diffraction, electron backscatter diffraction, transmission electron microscopy, and mechanical tests to elucidate the underlying mechanisms for the evolved anisotropic mechanical properties. The straining facilitates the formation of dislocations, twins and martensite, and the yield strength increases with the strain while the elongation and the impact toughness exhibit the opposite trend. Under the same strain, the yield strength tested at angles of 0°, 45° and 90° and the impact toughness tested at angles of 0° and 90° to the straining direction are successively decreased, and this anisotropy will enhance with the strain extent. The yield strength is increased due to the higher dislocation and second-phase (martensite) hardening. The microstructure, the yield strength and the impact toughness are correlated, proving the linkage between the orientation dependence of the mechanical properties.

Similar content being viewed by others

References

G.B. Chitwood, L. Skogsberg, The SCC Resistance of 316L Expandable Pipe in Production Environments Containing H2S and Chloride, Corrosion, 2004, p 1–12.

F.K. Yan, G.Z. Liu, N.R. Tao and K. Lu, Strength and Ductility of 316L Austenitic Stainless Steel Strengthened by Nano-scale Twin Bundles, Acta Mater., 2012, 60, p 1059–1071.

M. Kulka, D. Mikolajczak, N. Makuch, P. Dziarski and A. Miklaszewski, Wear Resistance Improvement of Austenitic 316L Steel by Laser Alloying with Boron, Surf. Coat. Technol., 2016, 291, p 292–313.

T. Xi, M.B. Shahzad, D. Xu, Z. Sun, J. Zhao, C. Yang, M. Qi and K. Yang, Effect of Copper Addition on Mechanical Properties, Corrosion Resistance and Antibacterial Property of 316L Stainless Steel, Mater. Sci. Eng. C, 2017, 71, p 1079–1085.

B. AlMangour, D. Grzesiak and J.M. Yang, In-situ Formation of Novel TiC-Particle-Reinforced 316L Stainless Steel Bulk-form Composites by Selective Laser Melting, J. Alloys Compd., 2017, 706, p 409–418.

H. Pelletier, D. Müller, P. Mille, A. Cornet and J.J. Grob, Dose Effect on Mechanical Properties of High-energy Nitrogen Implanted 316L Stainless Steel, Surf. Coat. Technol., 2002, 151–152, p 377–382.

M. El-Tahawy, P.H.R. Pereira, Y. Huang, H. Park, H. Choe, T.G. Langdon and J. Gubicza, Exceptionally High Strength and Good Ductility in an Ultrafine-Grained 316L Steel Processed by Severe Plastic Deformation and Subsequent Annealing, Mater. Lett., 2018, 214, p 240–242.

X.H. Chen, J. Lu, L. Lu and K. Lu, Tensile Properties of a Nanocrystalline 316L Austenitic Stainless Steel, Scripta Mater., 2005, 52, p 1039–1044.

B. Ravi Kumar, S. Sharma and B. Mahato, Formation of Ultrafine Grained Microstructure in the Austenitic Stainless Steel and Its Impact on Tensile Properties, Mater. Sci. Eng. A, 2011, 528, p 2209–2216.

J. Peng, K. Li, J. Peng, J. Pei and C. Zhou, The Effect of Pre-strain on Tensile Behaviour of 316L Austenitic Stainless Steel, Mater. Sci. Tech., 2018, 34, p 547–560.

G. Marnier, C. Keller and L. Taleb, Fatigue of OFHC Pure Copper and 316L Stainless Steel Subjected to Prior Tensile and Cyclic Prestrains, Int. J. Fatigue, 2016, 91, p 204–219.

J. Peng, K. Li, Q. Dai, G. Gao, Y. Zhang and W. Cao, Estimation of Mechanical Strength for Pre-strained 316L Austenitic Stainless Steel by Small Punch Test, Vacuum, 2019, 160, p 37–53.

E. Galindo-Nava and P. Rivera-Díaz-del-Castillo, Understanding Martensite and Twin Formation in Austenitic Steels: a Model Describing TRIP and TWIP Effects, Acta Mater., 2017, 128, p 120–134.

S.B. Zaman, F. Barlat and J.H. Kim, Deformation-induced Anisotropy of Uniaxially Prestrained Steel Sheets, Int. J. Solids Struct., 2018, 134, p 20–29.

J. Li, Q. Mao, J. Nie, Z. Huang, S. Wang and Y. Li, Impact Property of High-strength 316L Stainless Steel with Heterostructures, Mater. Sci. Eng. A, 2019, 754, p 457–460.

A. Ben Rhouma, T. Amadou, H. Sidhom and C. Braham, Correlation between Microstructure and Intergranular Corrosion Behavior of Low Delta-ferrite Content AISI 316L Aged in the Range 550–700 °C, J. Alloys Compd., 2017, 708, p 871–886.

Y. Takagawa, Y. Tsujiuchi, C. Watanabe, R. Monzen and N. Tsuji, Improvement in Mechanical Properties of a Cu-2.0 Mass%Ni-0.5 Mass%Si-0.1 Mass%Zr Alloy by Combining Both Accumulative Roll-bonding and Cryo-rolling with Aging, Mater. Trans., 2013, 54, p 1–8.

M. El-Tahawy, J. Péter, K. Tamás, H. Gigap, P. Hyeji, C. Heeman and G. Jenő, Different Evolutions of the Microstructure, Texture, and Mechanical Performance During Tension and Compression of 316L Stainless Steel, Metall. Mater. Trans. A, 2020, 51, p 3447–3460.

J. Zhu, G. Lin, Z. Zhang and J. Xie, The Martensitic Crystallography and Strengthening Mechanisms of Ultra-high Strength Rare Earth H13 Steel, Mater. Sci. Eng. A, 2020, 797, p 140139.

C. Quitzke, C. Schröder, C. Ullrich, M. Mandel, L. Krüger, O. Volkova and M. Wendler, Evaluation of Strain-induced Martensite Formation and Mechanical Properties in N-alloyed Austenitic Stainless Steels by in situ Tensile Tests, Mater. Sci. Eng. A, 2021, 808, p 140930.

N. Guo, Z. Zhang, Q. Dong, H. Yu, B. Song, L. Chai, C. Liu, Z. Yao and M.R. Daymond, Strengthening and Toughening Austenitic Steel by Introducing Gradient Martensite via Cyclic Forward/Reverse Torsion, Mater. Des., 2018, 143, p 150–159.

M. Nezakat, H. Akhiani, M. Hoseini and J. Szpunar, Effect of Thermo-mechanical Processing on Texture Evolution in Austenitic Stainless Steel 316L, Mater. Charact., 2014, 98, p 10–17.

Y. Hong, C. Zhou, Y. Zheng, L. Zhang, J. Zheng, X. Chen and B. An, Formation of Strain-induced Martensite in Selective Laser Melting Austenitic Stainless Steel, Mater. Sci. Eng. A, 2019, 740–741, p 420–426.

V. Mazánová, M. Heczko, V. Škorík, A. Chlupová, J. Polák and T. Kruml, Microstructure and Martensitic Transformation in 316L Austenitic Steel During Multiaxial Low Cycle Fatigue at Room Temperature, Mater. Sci. Eng. A, 2019, 767, p 138407.

H.C. Shin, T.K. Ha and Y.W. Chang, Kinetics of Deformation Induced Martensitic Transformation in a 304 Stainless Steel, Scr. Mater., 2001, 45, p 823–829.

C. Zheng, H. Jiang, X. Hao, J. Ye, L. Li and D. Li, Tailoring Mechanical Behavior of a Fine-grained Metastable Austenitic Stainless Steel by Pre-straining, Mater. Sci. Eng. A, 2019, 746, p 332–340.

M. Naghizadeh and H. Mirzadeh, Modeling the Kinetics of Deformation-induced Martensitic Transformation in AISI 316 Metastable Austenitic Stainless Steel, Vacuum, 2018, 157, p 243–248.

G.K. Williamson and R.E. Smallman, Dislocation Densities in Some Annealed and Cold-worked Metals from Measurements on the X-ray Debye-Scherrer Spectrum, Philos. Mag., 1956, 1, p 34–46.

V. Tandon and A.P. Patil, On the Influence of Cold Working and Electrochemical Nitridation on the Corrosion Behaviour of 316L Austenitic Stainless Steel in Acidic Environment, Surf. Eng. Appl. Electrochem., 2020, 56, p 63–70.

N.N. Krishna, R. Tejas, K. Sivaprasad and K. Venkateswarlu, Study on Cryorolled Al–Cu Alloy Using X-ray Diffraction Line Profile Analysis and Evaluation of Strengthening Mechanisms, Mater. Des., 2013, 52, p 785–790.

R. Smallman and K. Westmacott, Stacking Faults in Face-Centred Cubic Metals and Alloys, Philos. Mag., 1957, 2, p 669–683.

M. El-Tahawy, Y. Huang, T. Um, H. Choe, J.L. Lábár, T.G. Langdon and J. Gubicza, Stored Energy in Ultrafine-Grained 316L Stainless Steel Processed by High-Pressure Torsion, J. Mater. Res. Technol, 2017, 6, p 339–347.

I.J. Park, J.G. Jung, S.Y. Jo, S.M. Lee and Y.K. Lee, The Effect of Pre-Strain on the Resistance to Hydrogen Embrittlement in 316L Austenitic Stainless Steel, Mater. Trans., 2014, 55, p 964–970.

L. Zhang, Z. Li, J. Zheng, Y. Zhao, P. Xu, C. Zhou and X. Li, Effect of Strain-induced Martensite on Hydrogen Embrittlement of Austenitic Stainless Steels Investigated by Combined Tension and Hydrogen Release Methods, Int. J. Hydrog. Energy, 2013, 38, p 8208–8214.

C. San Marchi, B.P. Somerday, X. Tang and G.H. Schiroky, Effects of Alloy Composition and Strain Hardening on Tensile Fracture of Hydrogen-precharged Type 316 Stainless Steels, Int. J. Hydrog. Energy, 2008, 33, p 889–904.

S.G. Chowdhury, S. Das and P.K. De, Cold Rolling Behaviour and Textural Evolution in AISI 316L Austenitic Stainless Steel, Acta Mater., 2005, 53, p 3951–3959.

J. Gubicza, M. El-Tahawy, Y. Huang, H. Choi, H. Choe, J.L. Lábár and T.G. Langdon, Microstructure, Phase Composition and Hardness Evolution in 316L Stainless Steel Processed by High-pressure Torsion, Mater. Sci. Eng. A, 2016, 657, p 215–223.

S. Kheiri, H. Mirzadeh and M. Naghizadeh, Tailoring the Microstructure and Mechanical Properties of AISI 316L Austenitic Stainless Steel Via Cold Rolling and Reversion Annealing, Mater. Sci. Eng. A, 2019, 759, p 90–96.

D.N. Wasnik, I.K. Gopalakrishnan, J.V. Yakhmi, V. Kain and I. Samajdar, Cold Rolled Texture and Microstructure in Types 304 and 316L Austenitic Stainless Steels, ISIJ Int., 2003, 43, p 1581–1589.

S.J. Huang, L.W. Chang and T.W. Shyr, Characterization of Microtexture of 316L Stainless Steel Fiber after Multi-pass Drawing by Electron Backscatter Diffraction, Mater. Charact., 2018, 141, p 338–347.

N. Nakada, H. Ito, Y. Matsuoka, T. Tsuchiyama and S. Takaki, Deformation-induced Martensitic Transformation Behavior in Cold-rolled and Cold-drawn Type 316 Stainless Steels, Acta Mater., 2010, 58, p 895–903.

A. Eres-Castellanos, F.G. Caballero and C. Garcia-Mateo, Stress or Strain Induced Martensitic and Bainitic Transformations During Ausforming Processes, Acta Mater., 2020, 189, p 60–72.

G.M. de Bellefon, J. Van Duysen and K. Sridharan, Composition-dependence of Stacking Fault Energy in Austenitic Stainless Steels Through Linear Regression with Random Intercepts, J. Nucl. Mater., 2017, 492, p 227–230.

ASM Handbook, Properties and Selection: Irons, Steels, and High-performance Alloys, ASM International, 1992.

R. Singh, S. Agrahari, S.D. Yadav and A. Kumar, Microstructural Evolution and Mechanical Properties of 316 Austenitic Stainless Steel by CGP, Mater. Sci. Eng. A, 2021, 812, p 141105.

H. Wen, T.D. Topping, D. Isheim, D.N. Seidman and E.J. Lavernia, Strengthening Mechanisms in a High-strength Bulk Nanostructured Cu–Zn–Al Alloy Processed via Cryomilling and Spark Plasma Sintering, Acta Mater., 2013, 61, p 2769–2782.

Y. Wu, J. Lu, S. Tan, F. Jiang and J. Sun, Accessing Enhanced Uniformity and Property in CuNiSiCr Alloy by High-temperature Recrystallization, Mater. Sci. Eng. A, 2019, 764, p 1–9.

Y. Wu, Y. Li, J. Lu, S. Tan, F. Jiang and J. Sun, Effects of Pre-deformation on Precipitation Behaviors and Properties in Cu-Ni-Si-Cr Alloy, Mater. Sci. Eng. A, 2019, 742, p 501–507.

P. Zhang, Y. Li, Q. Lei, H. Tan, R. Shi, J. She, S. Li, J. Zhu, X. Sheng, J. Zhang and Z. Li, Microstructure and Mechanical Properties of a CuNiTi Alloy with a Large Product of Strength and Elongation, J. Mater. Res. Technol, 2020, 9, p 2299–2307.

L. Jiang, H. Fu, C. Wang, W. Li and J. Xie, Enhanced Mechanical and Electrical Properties of a Cu-Ni-Si Alloy by Thermo-mechanical Processing, Metall. Mater. Trans. A, 2020, 51, p 331–341.

J. Li, G. Huang, X. Mi, L. Peng, H. Xie and Y. Kang, Microstructure Evolution and Properties of a Quaternary Cu–Ni–Co–Si Alloy with High Strength and Conductivity, Mater. Sci. Eng. A, 2019, 766, p 1–14.

Z. Zhao, Z. Xiao, Z. Li, W. Qiu, H. Jiang, Q. Lei, Z. Liu, Y. Jiang and S. Zhang, Microstructure and Properties of a Cu–Ni–Si–Co–Cr Alloy with High Strength and High Conductivity, Mater. Sci. Eng. A, 2019, 759, p 396–403.

Q. Lei, S. Li, J. Zhu, Z. Xiao, F. Zhang and Z. Li, Microstructural Evolution, Phase Transition, and Physics Properties of a High Strength Cu–Ni–Si–Al Alloy, Mater. Charact., 2019, 147, p 315–323.

B. Liu, X. Zhang, Z. Huang, J. Guo, S. Gong, G. Xie, L. Peng and Z. Li, Microstructure and Properties of a Novel Ultra-high Strength, High Elasticity and High Plasticity Cu–20Ni–20Mn-0.3Nb-0.3Cr-0.1Zr Alloy, J. Alloys Compd., 2021, 853, p 157402.

S. Mohd Yusuf, Y. Chen, S. Yang and N. Gao, Microstructural Evolution and Strengthening of Selective Laser Melted 316L Stainless Steel Processed by High-pressure Torsion, Mater. Charact., 2020, 159, p 110012.

Z.D. Wang, G.F. Sun, Y. Lu, M.Z. Chen, K.D. Bi and Z.H. Ni, Microstructural Characterization and Mechanical Behavior of Ultrasonic Impact Peened and Laser Shock Peened AISI 316L Stainless Steel, Surf. Coat. Technol., 2020, 385, p 125403.

W. Wang, T. Liu, X. Cao, Y. Lu and T. Shoji, In-situ Observation on Twin Boundary Evolution and Crack Initiation Behavior During Tensile Test on 316L Austenitic Stainless Steel, Mater. Charact., 2017, 132, p 169–174.

E. Hall, The Deformation and Ageing of Mild Steel: III Discussion of Results, Proc. Phys. Soc. B, 1951, 64, p 747–753.

N. Petch, The Cleavage Strength of Polycrystals, J. Iron Steel Inst., 1953, 174, p 25–28.

L. Balogh, T. Ungár, Y. Zhao, Y. Zhu, Z. Horita, C. Xu and T.G. Langdon, Influence of Stacking-fault Energy on Microstructural Characteristics of Ultrafine-grain Copper and Copper-Zinc Alloys, Acta Mater., 2008, 56, p 809–820.

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An and Z.P. Lu, A Precipitation-hardened High-entropy Alloy with Outstanding Tensile Properties, Acta Mater., 2016, 102, p 187–196.

T.H. Courtney, Mechanical Behavior of Materials, China Machine Press, Beijing, 2011.

J. Talonen, Effect of Strain-Induced α'-martensite Transformation on Mechanical Properties of Metastable Austenitic Stainless Steels, 2007.

T. Myeong, Y. Yamabayashi, M. Shimojo and Y. Higo, A New Life Extension Method for High Cycle Fatigue Using Micro-martensitic Transformation in an Austenitic Stainless Steel, Int. J. Fatigue, 1997, 19, p 69–73.

K. Spencer, J. Embury, K. Conlon, M. Véron and Y. Bréchet, Strengthening via the Formation of Strain-induced Martensite in Stainless Steels, Mater. Sci. Eng. A, 2004, 387, p 873–881.

I. Shakhova, A. Belyakov, Z. Yanushkevich, K. Tsuzaki and R. Kaibyshev, On Strengthening of Austenitic Stainless Steel by Large Strain Cold Working, ISIJ Int., 2016, 56, p 1289–1296.

M.N. Gussev, J.T. Busby, T.S. Byun and C.M. Parish, Twinning and Martensitic Transformations in Nickel-enriched 304 Austenitic Steel During Tensile and Indentation Deformations, Mater. Sci. Eng. A, 2013, 588, p 299–307.

A. Goodfellow, E. Galindo-Nava, C. Schwalbe and H. Stone, The Role of Composition on the Extent of Individual Strengthening Mechanisms in Polycrystalline Ni-based Superalloys, Mater. Des., 2019, 173, p 107760.

Y. Wu, J. Tian, W. Xiong, P. Zhang, F. Jiang, Z. Zhang and J. Sun, Correlation between Evolving Microstructures and Mechanical Properties of Served Inconel 783 Superalloys, J. Alloys Compd., 2021, 851, p 156921.

Z. Li, G. Winther and N. Hansen, Anisotropy in Rolled Metals Induced by Dislocation Structure, Acta Mater., 2006, 54, p 401–410.

K. Yvell, T. Grehk and G. Engberg, Microstructure Characterization of 316L Deformed at High Strain Rates Using EBSD, Mater. Charact., 2016, 122, p 14–21.

Z. You, H. Fu, S. Qu, W. Bao and L. Lu, Revisiting Anisotropy in the Tensile and Fracture Behavior of Cold-rolled 316L Stainless Steel with Heterogeneous Nano-lamellar Structures, Nano Mater. Sci., 2020, 2, p 72–79.

C. Gennari, L. Pezzato, E. Piva, R. Gobbo and I. Calliari, Influence of Small Amount and Different Morphology of Secondary Phases on Impact Toughness of UNS S32205 Duplex Stainless Steel, Mater. Sci. Eng. A, 2018, 729, p 149–156.

B. Sun, D. Palanisamy, D. Ponge, B. Gault, F. Fazeli, C. Scott, S. Yue and D. Raabe, Revealing Fracture Mechanisms of Medium Manganese Steels with and without Delta-ferrite, Acta Mater., 2019, 164, p 683–696.

H. Ding, Y. Wu, Q. Lu, P. Xu, J. Zheng and L. Wei, Tensile Properties and Impact Toughness of S30408 Stainless Steel and Its Welded Joints at Cryogenic Temperatures, Cryogenics, 2018, 92, p 50–59.

Acknowledgments

This work was supported by the China Postdoctoral Science Foundation under Grant No. 2020M683464.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, T., Li, N., Wu, Y. et al. Microstructural Evolution and Anisotropic Mechanical Properties of 316L Stainless Steel Induced by Tensile Straining. J. of Materi Eng and Perform 31, 1231–1240 (2022). https://doi.org/10.1007/s11665-021-06253-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06253-7