Abstract

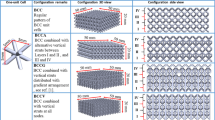

In this paper, the compression behavior of four lattice topologies with body-centered and face-centered structures was first analyzed numerically based on the material model of 3D printed polylactic acid (PLA). To enhance the interface bonding properties between the AZ31B Mg face sheets and the PLA lattice cores, the skin-core interface was preprocessed by 3D printing microgrooves on PLA pre-pregs. The interface parameters of the heterogeneous bonding layer were then obtained through DCB and ENF experiments. The impact simulation by using ABAQUS/Explicit with a self-written VUMAT subroutine for the enhanced interfacial layer was finally carried out for the hybrid Mg alloy skin and PLA lattice-core sandwich panels with high energy absorption characteristics under static compression. The results have shown that the BCCZ and F2CCZ lattice configurations with Z-direction pillars exhibit better quasi-static compression characteristics compared with the BCC and F2CC structures. Interlayer fracture toughness values GIC and GIIC of the skin-core interface can reach up to 0.63 and 7.02 kJ/m2, respectively. Under low-velocity impact, the hybrid sandwich panels with F2CCZ lattice cores exhibit better impact resistance and energy absorption capacity than those of the BCCZ lattice sandwich panels.

Similar content being viewed by others

References

S. Bhandari and R. Lopez-Anido, Finite Element Analysis of Thermoplastic Polymer Extrusion 3D Printed Material for Mechanical Property Prediction, Addit. Manuf., 2018, 22, p 187–196.

Y.K. Ming, S.Q. Zhang, W. Han et al., Investigation on Process Parameters of 3D Printed Continuous Carbon Fiber-Reinforced Thermosetting Epoxy Composites, Addit. Manuf., 2020, 33, p 101184.

T.A. Schaedler, C.J. Ro, A.E. Sorensen et al., Designing Metallic Microlattices for Energy Absorber Applications, Adv. Eng. Mater., 2014, 16, p 276–283.

T.A. Schaedler and W.B. Carter, Architected Cellular Materials, Annu. Rev. Mater. Res., 2016, 46, p 187–210.

H. Yazdani Sarvestani, A.H. Akbarzadeh, H. Niknama et al., 3D Printed Architected Polymeric Sandwich Panels: Energy Absorption and Structural Performance, Compos. Struct., 2018, 200, p 886–909.

T.Y. Yao, J. Ye, Z.C. Deng et al., Tensile Failure Strength and Separation Angle of FDM 3D Printing PLA Material: Experimental and Theoretical Analyses, Compos. Part B, 2020, 188, p 107894.

B. Han, Z.J. Zhang, Q.C. Zhang et al., Recent Advances in Hybrid Lattice-Cored Sandwiches for Enhanced Multifunctional Performance, Extreme Mech. Lett., 2017, 10, p 58–69.

P.P. Zhou, X. Wu, Y.C. Pan et al., Mechanical Properties of Carbon Fibre-Reinforced Polymer/Magnesium Alloy Hybrid Laminates, Mater. Res. Express, 2018, 5(4), p 046523.

Y.C. Pan, G.Q. Wu, X. Cheng et al., Mode I and Mode II Interlaminar Fracture Toughness of CFRP/Magnesium Alloys Hybrid Laminates, Compos. Interface, 2016, 23, p 453–465.

X. Zhou, K. Li, C.H. Chen and X.C. Chen, Low-Velocity Impact Response and Damage Simulation of Fiber/Magnesium Alloy Composite Laminates, J. Vib. Shock, 2018, 37(22), p 1–9. ((in Chinese))

D. De Cicco and F. Taheri, Performances of Magnesium- and Steel-Based 3D Fiber-Metal Laminates under Various Loading Conditions, Compos. Struct., 2019, 229, p 111390.

Z.B. Liu, H.T. Chen and S.Q. Xing, Mechanical Performances of Metal-Polymer Sandwich Structures with 3D-printed Lattice Cores Subjected to Bending Load, Arch. Civ. Mech. Eng., 2020, 20, p 89.

L. Chen, C. Alessandro, D.G. Michael and C. Philip, Mechanical Behaviour of Additively-Manufactured Polymeric Octet-truss Lattice Structures under Quasi-static and Dynamic Compressive Loading, Mater. Des., 2019, 162, p 106–118.

W.F. Liu, H.W. Song, Z. Wang, J.T. Wang and C.G. Huang, Improving Mechanical Performance of Fused Deposition Modeling Lattice Structures by a Snap-Fitting Method, Mater. Des., 2019, 181, p 108065.

A.J. Turner, M. Al Rifaie, A. Mian and R. Srinivasan, Low-Velocity Impact Behavior of Sandwich Structures with Additively Manufactured Polymer Lattice Cores, J. Mater. Eng. Perform., 2018, 27, p 2505–2512.

R. Falck, S.M. Goushegir, J.F. dos Santos and S.T. Amancio-Filho, AddJoining: A Novel Additive Manufacturing Approach for Layered Metal-Polymer Hybrid Structures, Mater. Lett., 2018, 217, p 211–214.

J. Butt and H. Shirvani, Experimental Analysis of Metal/Plastic Composites Made by a New Hybrid Method, Addit. Manuf., 2018, 22, p 216–222.

X. Zhou, Y.T. Zhao, X.C. Chen, Z.F. Liu, J.L. Li and Y.F. Fan, Fabrication and Mechanical Properties of Novel CFRP/Mg Alloy Hybrid Laminates with Enhanced Interface Adhesion, Mater. Des., 2021, 197, p 109251.

X. Zhou, J.L. Li, C. Qu, W.M. Bu, Z.F. Liu, Y.F. Fan and G. Bao, Bending Behavior of Hybrid Sandwich Composite Structures Containing 3D Printed PLA Lattice Cores and Magnesium Alloy Face Sheets, J. Adhes., 2021 https://doi.org/10.1080/00218464.2021.1939015

F. Feng, S. Huang, Z. Meng et al., A Constitutive and Fracture Model for AZ31B Magnesium Alloy in the Tensile State, Mat. Sci. Eng. A Struct., 2014, 594, p 334–343.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Zhou, X., Qu, C., Luo, Y. et al. Compression Behavior and Impact Energy Absorption Characteristics of 3D Printed Polymer Lattices and Their Hybrid Sandwich Structures. J. of Materi Eng and Perform 30, 8763–8770 (2021). https://doi.org/10.1007/s11665-021-06242-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06242-w