Abstract

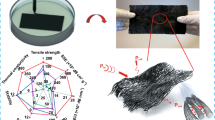

We develop a solution-processable, Ag-sandwiched carbon-nanotube-coated, durable (SAND) architecture that enables power-efficient and highly consistent cyclic heating up to 400 °C at 6 V with neither structural degradation nor substrate breakage. The Ag/CNT/Ag-stacked SAND structure, comprising an airbrushed carbon nanotube (CNT) network layer sandwiched by the Ag layers reduced with ionic Ag ink coatings, can be created by a facile and scalable all-solution-processable fabrication protocol without resorting to vacuum-assisted nanofabrication. Through a systematic comparison with Ag-only and CNT/Ag- or Ag/CNT-bilayered structures, we show that the SAND architecture can improve the joule-heating efficiency and uniformity, and more importantly, the anti-breaking durability to overcome the thermal expansion discrepancy against the underlying substrate. This is analytically interpreted through a thermal stress-induced substrate breaking mechanism, where the increasing difference in the thermal expansion between the substrate and coated layers upon heating can be effectively suppressed within the SAND architecture. Readily applicable to more scalable, diverse substrates ranging from brittle glass to large-area polymer films, the SAND architecture can be utilized in the flexible and reliable anti-failure heating devices required in such applications as machine and vehicle components, sensor systems, and safety and warm-up gears.

Similar content being viewed by others

References

Jung, J. H., Oh, H. C., Noh, H. S., Ji, J. H., & Kim, S. S. (2006). Metal nanoparticle generation using a small ceramic heater with a local heating area. Journal of Aerosol Science, 37, 1662–1670. https://doi.org/10.1016/j.jaerosci.2006.09.002

Sorel, S., Bellet, D., & Coleman, J. N. (2014). Relationship between Material Properties and Transparent Heater Performance for Both Bulk-like and Percolative Nanostructured Networks. ACS Nano, 8, 4805–4814. https://doi.org/10.1021/nn500692d

Zeng, P., Tian, B., Tian, Q. Y., Yao, W. J., Li, M. X., Wang, H. J., Feng, Y., Liu, L., & Wu, W. (2019). Screen-printed, low-cost, and patterned flexible heater based on Ag fractal dendrites for human wearable application. Advanced Materials Technologies, 4(3), 8. https://doi.org/10.1002/admt.201800453

Gupta, R., Rao, K. D. M., Kiruthika, S., & Kulkarni, G. U. (2016). Visibly transparent heaters. ACS Applied Materials & Interfaces, 8, 12559–12575. https://doi.org/10.1021/acsami.5b11026

Minnich, A. J., Dresselhaus, M. S., Ren, Z. F., & Chen, G. (2009). Bulk nanostructured thermoelectric materials: Current research and future prospects. Energy & Environmental Science, 2, 466–479. https://doi.org/10.1039/B822664B

Ko, E. H., Kim, H. J., Lee, S. J., Lee, J. H., & Kim, H. K. (2016). Nano-sized Ag inserted into ITO films prepared by continuous roll-to-roll sputtering for high-performance, flexible, transparent film heaters. Rsc Advances, 6, 46634–46642. https://doi.org/10.1039/C6RA08704C

Wang, Z., Li, J., Xu, J., Huang, J., Yang, Y., Tan, R., Chen, G., Fang, X., Zhao, Y., & Song, W. (2020). Robust ultrathin and transparent AZO/Ag-SnOx/AZO on polyimide substrate for flexible thin film heater with temperature over 400 °C. Journal of Materials Science & Technology, 48, 156–162. https://doi.org/10.1016/j.jmst.2020.01.058

Li, P., Ma, J. G., Xu, H. Y., Lin, D., Xue, X. D., Yan, X. Z., Xia, P., & Liu, Y. C. (2016). Flexible transparent heaters based on silver nanotrough meshes. Journal of Alloys and Compounds, 664, 764–769. https://doi.org/10.1016/j.jallcom.2015.12.216

Tigan, D., Genlik, S. P., Imer, B., & Unalan, H. E. (2019). Core/shell copper nanowire networks for transparent thin film heaters. Nanotechnology, 30, 11. https://doi.org/10.1088/1361-6528/ab19c6

Kim, Y., Lee, H. R., Saito, T., & Nishi, Y. (2017). Ultra-thin and high-response transparent and flexible heater based on carbon nanotube film. Applied Physics Letters, 110, 3. https://doi.org/10.1063/1.4978596

Sanchez-Vicente, C., Santos, J. P., Lozano, J., Sayago, I., Sanjurjo, J. L., Azabal, A., & Ruiz-Valdepenas, S. (2020). Graphene-Doped tin oxide nanofibers and nanoribbons as gas sensors to detect biomarkers of different diseases through the breath. Sensors, 20, 12. https://doi.org/10.3390/s20247223

Jiang, J. J., Shang, H. M., Shu, Y., Li, W. P., Zhang, H., Liu, W. J., Qu, M. Z., & Liu, S. (2020). Multi-walled carbon nanotube composite fiber formation in a water coagulation bath and application as wire heater. Diamond and Related Materials, 110, 7. https://doi.org/10.1016/j.diamond.2020.108109

Choi, S., Park, J., Hyun, W., Kim, J., Lee, Y. B., Song, C., Hwang, H. J., Kim, J. H., Hyeon, T., & Kim, D. H. (2015). Stretchable heater using ligand-exchanged silver nanowire nanocomposite for wearable articular thermotherapy. ACS Nano, 9, 6626–6633. https://doi.org/10.1021/acsnano.5b02790

Li, Y. A., Chen, Y. J., & Tai, N. H. (2014). Highly thermal conductivity and infrared emissivity of flexible transparent film heaters utilizing silver-decorated carbon nanomaterials as fillers. Materials Research Express, 1, 11. https://doi.org/10.1088/2053-1591/1/2/025605

Cheong, H. G., Song, D. W., & Park, J. W. (2015). Transparent film heaters with highly enhanced thermal efficiency using silver nanowires and metal/metal-oxide blankets. Microelectronic Engineering, 146, 11–18. https://doi.org/10.1016/j.mee.2015.02.029

Lin, S. Y., Zhang, T. Y., Lu, Q., Wang, D. Y., Yang, Y., Wu, X. M., & Ren, T. L. (2017). High-performance graphene-based flexible heater for wearable applications. Rsc Advances, 7, 27001–27006. https://doi.org/10.1039/C7RA03181E

Ishizaki, T., Miura, D., Kuno, A., Nagao, R., Aoki, S., Ohshima, Y., Kino, T., Usui, M., & Yamada, Y. (2016). Power cycle reliability of Cu nanoparticle joints with mismatched coefficients of thermal expansion. Microelectronics Reliability, 64, 287–293. https://doi.org/10.1016/j.microrel.2016.07.031

Yu, H. R., Jin, N., Wang, Z. G., Lin, J., Wei, J. F., Luo, Q., & Ma, C. Q. (2020). Use of solution-processed zinc oxide to prevent the breakdown in silver nanowire networks. Nanotechnology, 31, 7. https://doi.org/10.1088/1361-6528/ab6fe4

Ishizaki, T., Kuno, A., Tane, A., Yanase, M., Osawa, F., Satoh, T., & Yamada, Y. (2014). Reliability of Cu nanoparticle joint for high temperature power electronics. Microelectronics Reliability, 54, 1867–1871. https://doi.org/10.1016/j.microrel.2014.07.113

Yoon, K. B., & Jeong, D. G. (1999). Oxidation failure of radiant heater tubes. Engineering Failure Analysis, 6, 101–112. https://doi.org/10.1016/S1350-6307(98)00033-8

Bolelli, G., Bonferroni, B., Coletta, G., Lusvarghi, L., & Pitacco, F. (2011). Wear and corrosion behaviour of HVOF WC-CoCr/CVD DLC hybrid coating systems deposited onto aluminium substrate. Surface and Coatings Technology, 205, 4211–4220. https://doi.org/10.1016/j.surfcoat.2011.03.021

Fang, W. L., & Lo, C. Y. (2000). On the thermal expansion coefficients of thin films. Sensors and Actuators A: Physical, 84, 310–314. https://doi.org/10.1016/S0924-4247(00)00311-3

Cheacharoen, R., Boyd, C. C., Burkhard, G. F., Leijtens, T., Raiford, J. A., Bush, K. A., Bent, S. F., & McGehee, M. D. (2018). Encapsulating perovskite solar cells to withstand damp heat and thermal cycling. Sustainable Energy & Fuels, 2, 2398–2406. https://doi.org/10.1039/C8SE00250A

Koo, S., Lee, S. H., Kim, J. D., Hong, J. G., Baak, H. W., Kwak, M. K., & Ok, J. G. (2016). Controlled airbrush coating of polymer resists in Roll-to-Roll nanoimprinting with regimented residual layer thickness. International Journal of Precision Engineering and Manufacturing, 4, 5. https://doi.org/10.1007/s12541-016-0115-8

Lee, J. H., Na, M., Kim, J., Yoo, K., Park, J., Kim, J. D., Oh, D. K., Lee, S., Youn, H., Kwak, M. K., & Ok, J. G. (2017). Rapid and conformal coating of polymer resins by airbrushing for continuous and high-speed roll-to-roll nanopatterning: Parametric quality controls and extended applications. Nano Convergence, 2017(4), 5. https://doi.org/10.1186/s40580-017-0105-2

Yoo, K., Lee, W., Kang, K., Kim, I., Kang, D., Oh, D. K., Kim, M. C., Choi, H., Kim, K., Kim, M., Kim, J. D., Park, I., & Ok, J. G. (2020). Low-temperature large-area fabrication of ZnO nanowires on flexible plastic substrates by solution-processible metal-seeded hydrothermal growth. Nano Convergence, 7, 24. https://doi.org/10.1186/s40580-020-00235-6

Wi, J. S., Kim, J. D., Lee, W., Choi, H., Kwak, M., Song, J., Lee, T. G., & Ok, J. G. (2021). Inkjet-printable nanoporous Ag disk arrays enabling coffee-ring effect-driven analyte enrichment towards practical SERS applications. International Journal of Precision Engineering and Manufacturing-Green Technology. https://doi.org/10.1007/s40684-021-00351-6

Ahn, J. H., Na, M., Koo, S., Chun, H., Kim, I., Hur, J. W., Lee, J. H., & Ok, J. G. (2019). Development of a fully automated desktop chemical vapor deposition system for programmable and controlled carbon nanotube growth. Micro and Nano Systems Letters, 7, 1–8. https://doi.org/10.1186/s40486-019-0091-8

Wang, Y., Wu, J., & Wei, F. (2003). A treatment method to give separated multi-walled carbon nanotubes with high purity, high crystallization and a large aspect ratio. Carbon, 41, 2939–2948. https://doi.org/10.1016/S0008-6223(03)00390-7

Moraes, R. A., Matos, C. F., Castro, E. G., Schreiner, W. H., Oliveira, M. M., & Zarbin, A. J. G. (2011). The effect of different chemical treatments on the structure and stability of aqueous dispersion of iron- and iron oxide-filled multi-walled carbon nanotubes. Journal of the Brazilian Chemical Society, 22, 2191–2201. https://doi.org/10.1590/S0103-50532011001100024

Inktec Co. 2007 Korea Patent; 10–0727434

Chang, Y., Wang, D. Y., Tai, Y. L., & Yang, Z. G. (2012). Preparation, characterization and reaction mechanism of a novel silver-organic conductive ink. Journal of Materials Chemistry, 22, 25296–25301. https://doi.org/10.1039/c2jm34569b

J. D. Kim, H. Choi, K. Kim, H. Chae, H. Yi, M. H. Jeong, N. Lee, M. Lee, M. C. Kim, J. W. Suk, K.-T. Lee, H. E. Jeong, & J. G. Ok (2021). Solution-processable Ag nanostructuring (SPAN) with tunable optical and electrical properties and strong adhesion for graphene-incorporated transparent flexible devices and electronic textiles, In Preparation.

Lee, J. G., Lee, J. H., An, S., Kim, D. Y., Kim, T. G., Al-Deyab, S. S., Yarin, A. L., & Yoon, S. S. (2017). Highly flexible, stretchable, wearable, patternable and transparent heaters on complex 3D surfaces formed from supersonically sprayed silver nanowires. Journal of Materials Chemistry A, 5, 6677–6685. https://doi.org/10.1039/C6TA10997G

Wang, P. H., Chen, S. P., Su, C. H., & Liao, Y. C. (2015). Direct printed silver nanowire thin film patterns for flexible transparent heaters with temperature gradients. Rsc Advances, 5, 98412–98418. https://doi.org/10.1039/C5RA19804F

Shirasu, K., Yamamoto, G., Tamaki, I., Ogasawara, T., Shimamura, Y., Inoue, Y., & Hashida, T. (2015). Negative axial thermal expansion coefficient of carbon nanotubes: Experimental determination based on measurements of coefficient of thermal expansion for aligned carbon nanotube reinforced epoxy composites. Carbon, 95, 904–909. https://doi.org/10.1016/j.carbon.2015.09.026

Hwang, J. Y., Kim, H. S., Kim, J. H., Shin, U. S., & Lee, S. H. (2015). Carbon nanotube nanocomposites with highly enhanced strength and conductivity for flexible electric circuits. Langmuir, 31, 7844–7851. https://doi.org/10.1021/acs.langmuir.5b00845

Liu, L. Q., Ma, W. J., & Zhang, Z. (2011). Macroscopic carbon nanotube assemblies: preparation, properties, and potential applications. Small (Weinheim an der Bergstrasse, Germany), 7, 1504–1520. https://doi.org/10.1002/smll.201002198

Lee, J., Kim, J. Y., Choi, J. H., Ok, J. G., & Kwak, M. K. (2017). Scalable fabrication of flexible microstencils by using sequentially induced dewetting phenomenon. ACS Omega, 2, 1097–1103. https://doi.org/10.1021/acsomega.7b00070

Oh, D. K., Nguyen, D. T., Lee, S., Ko, P., Heo, G. S., Yun, C. H., Ha, T. W., Youn, H., & Ok, J. G. (2019). Facile and scalable fabrication of flexible reattachable lonomer nanopatterns by continuous multidimensional nanoinscribing and low-temperature roll imprinting. Acs Applied Materials & Interfaces, 11, 12070–12076. https://doi.org/10.1021/acsami.8b21915

Ok, J. G., Youn, H. S., Kwak, M. K., Lee, K. T., Shin, Y. J., Guo, L. J., Greenwald, A., & Liu, Y. S. (2012). Continuous and scalable fabrication of flexible metamaterial films via roll-to-roll nanoimprint process for broadband plasmonic infrared filters. Applied Physics Letters, 101, 4. https://doi.org/10.1063/1.4767995

Ok, J. G., Shin, Y. J., Park, H. J., & Guo, L. J. (2015). A step toward next-generation nanoimprint lithography: Extending productivity and applicability. Applied Physics a-Materials Science & Processing, 121, 343–356. https://doi.org/10.1007/s00339-015-9229-6

Wi, J. S., Lee, S., Lee, S. H., Oh, D. K., Lee, K. T., Park, I., Kwak, M. K., & Ok, J. G. (2017). Facile three-dimensional nanoarchitecturing of double-bent gold strips on roll-to-roll nanoimprinted transparent nanogratings for flexible and scalable plasmonic sensors. Nanoscale, 9, 1398–1402. https://doi.org/10.1039/C6NR08387K

Ok, J. G., Ahn, S. H., Kwak, M. K., & Guo, L. J. (2013). Continuous and high-throughput nanopatterning methodologies based on mechanical deformation. Journal of Materials Chemistry C, 1, 7681–7691. https://doi.org/10.1039/c3tc30908h

Ok, J. G., Kwak, M. K., Huard, C. M., Youn, H. S., & Guo, L. J. (2013). Photo-roll lithography (PRL) for continuous and scalable patterning with application in flexible electronics. Advanced Materials, 25, 6554–6561. https://doi.org/10.1002/adma.201303514

Ok, J. G., Panday, A., Lee, T., & Guo, L. J. (2014). Continuous fabrication of scalable 2-dimensional (2D) micro- and nanostructures by sequential 1D mechanical patterning processes. Nanoscale, 6, 14636–14642. https://doi.org/10.1039/C4NR05567E

Oh, D. K., Lee, S., Lee, S. H., Lee, W., Yeon, G., Lee, N., Han, K. S., Jung, S., Kim, D. H., Lee, D. Y., Park, H. J., & Ok, J. G. (2019). Tailored Nanopatterning by Controlled Continuous Nanoinscribing with Tunable Shape, Depth, and Dimension. ACS Nano, 13, 11194–11202. https://doi.org/10.1021/acsnano.9b04221

Acknowledgements

This research was supported by grants from the National Research Foundation of Korea (NRF) funded by the Korean Government (No. 2020R1F1A1073760 (Ministry of Science and ICT (MSIT)) and No. 2019R1A6A1A03032119 (Ministry of Education)).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, M., Kim, M., Kim, K. et al. Solution-Processable, Ag-Sandwiched Nanotube-Coated, Durable (SAND) Architecture Realizing Anti-breaking Cyclic Heating on Arbitrary Substrates. Int. J. of Precis. Eng. and Manuf.-Green Tech. 9, 1305–1315 (2022). https://doi.org/10.1007/s40684-021-00387-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-021-00387-8