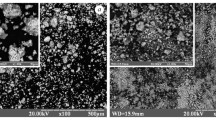

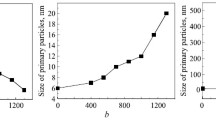

Alumina-based nanocrystalline powders with different ZrO2 amounts were produced for the first time by hydrothermal synthesis in an alkaline environment for designing zirconia toughened alumina (ZTA) composites. In ZTA composites, ZrO2 solid solution particles codoped with ceria and yttria are distributed in a rigid Al2O3 matrix. To examine the physicochemical properties, 90 wt.% Al2O3–10 wt.% ZrO2 (Y2O3, CeO2) and 58.5 wt.% Al2O3–42.5 wt.% ZrO2 (Y2O3, CeO2) powders were used. The ZrO2 solid solution had composition 90 mol.% ZrO2–2 mol.% Y2O3–8 mol.% CeO2. The hydrothermal powders were heat treated in the temperature range 400–1450°C and examined by X-ray diffraction, differential thermal analysis, and electron microscopy. The powder specific surface area was determined by the BET method. The sizes of primary particles were determined with the Scherrer equation. The AMIC software (Automatic Microstructure Analyzer) was employed to process the morphology analysis results. The phase transformations and active sintering of the ZTA powders determined the dependences showing the sizes of primary particles and the specific surface area of the powders versus the heat treatment temperature. With higher ZrO2 content, temperature of the F-ZrO2 → T-ZrO2 phase transformation decreased, the likelihood of M-ZrO2 to emerge increased, and the sequence of Al2O3 phase transformations changed after the boehmite had decomposed. The variation in the morphology and specific surface area of the powders in the heat treatment process indicated that their sintering activity increased. The dependence of the shape factor characterizing the nanocrystalline 90AZG and 58.5AZG powders on the heat treatment temperature was studied. The starting nanosized 90AZG and 58.5AZG powders had a similar distribution of agglomerates according to the shape factor. Round agglomerates and multifaceted regular agglomerates were predominant. The way in which the shape factor of the agglomerates varied with temperature was associated with a topochemical memory effect manifested by the 90AZG and 58.5AZG powders were examined. With increasing ZrO2 content, the microhardness of the ZTA composites decreased from 195 to 160 MPa, fracture toughness (KIc) increased from 6 to 8 MPa · m0.5, and Vickers hardness decreased from 8.3 to 5.6 GPa. The improvement in consolidation methods for ZTA composites will allow tool, structural, and functional ceramics with the required properties to be produced.

Similar content being viewed by others

References

S. Rezaee, Kh. Ranjbar, and A.R. Kiasat, “Characterization and strengthening of porous alumina-20 wt.% zirconia ceramic composites,” Ceram. Int., 46, No. 1, 893–902 (2020).

R.H.J. Hannink, P.M. Kelly, and B.C. Muddle, “Transformation toughening in zirconia-containing ceramics,” J. Am. Ceram. Soc., 83, No. 3, 461–487 (2000).

A.V. Shevchenko, A.K. Ruban, and E.V. Dudnik, “High-performance zirconium dioxide ceramics,” Ogneupory Tekh. Keram., No. 9, 2–8 (2000).

Yu.S. Karabasov (ed.), New Materials [in Russian], Mosk. Inst. Stali Splav., Moscow (2002), p. 736.

S.M. Olhero, Ib. Ganesh, P.M.C. Torres, F.J. Alves, and J.M.F. Ferreira, “Aqueous colloidal processing of ZTA composites,” J. Am. Ceram. Soc., 92, No. 1, 9–16 (2009).

S.R. Banik, I.M. Iqbal, R. Nath, L.J. Bora, B.K. Singh, N. Mandal, and M.R. Sankar, “State of the art on zirconia toughened alumina cutting tools,” Mater. Today: Proc., 18, 2632–2641 (2019).

M.M. Basha, S.M. Basha, B.K. Singh, N. Mandal, and M.R. Sankar, “A review on synthesis of zirconia toughened alumina (ZTA) for cutting tool applications,” Mater. Today: Proc., 26, Part 2, 534–541 (2020).

S. Huang, J. Binner, B. Vaidhyanathan, P. Brown, C. Hampson, and C. Spacie, “Development of nano zirconia toughened alumina for ceramic armor applications,” Adv. Ceram. Armor VII: Ceram. Eng. Sci. Proc., 32, Issue 5, 103–115 (2011).

J. Chevalier and L. Gremillard, “Zirconia as a biomaterial,” Compr. Biomater. II, 1, 122–144 (2017).

R. Benzaid, J. Chevalier, M. Saadaoui, G. Fantozzi, M. Nawa, and L.A. Diaz, “Fracture toughness, strength and slow crack growth in a ceria stabilized zirconia-alumina nanocomposite for medical applications,” Biomaterials, 29, 3636–3641 (2008).

S. Tanaka, M. Takaba, Y. Ishiura, E. Kamimura, and K. Baba, “A 3-year follow-up of ceria stabilized zirconia/alumina nanocomposite (Ce-TZP/A) frameworks for fixed dental prostheses,” J. Prosthodont. Res., 59, 55–61 (2015).

P. Sengupta, A. Bhattacharjee, and H.S. Maiti, “Zirconia: A unique multifunctional ceramic material,” Trans. Indian. Inst. Met., 72, No. 8, 1981–1998 (2019).

S. De Bernardi-Martin, B.M. Moshtaghioun, D.G. Garcia, and A. Dominguez-Rodriguez, “Grain-boundary cation diffusion in ceria tetragonal zirconia determined by constant strain-rate deformation tests,” J. Eur. Ceram. Soc., 34, 4469–4472 (2014).

Y. Hao, C-K. Yang, and S.M. Haile, “Ceria–zirconia solid solutions (Ce1–xZrxO2–δ, x ≤ 0.2) for solar thermochemical water splitting,” Thermodyn. Study, Chem. Mater., 26, 6073–6082 (2014).

M. Kuhn, S.R. Bishop, J.L.M. Rupp, and H.L. Tuller, “Structural characterization and oxygen nonstoichiometry of ceria–zirconia (Ce1–xZrxO2–δ) solid solutions,” Acta Mater., 61, 4277–4285 (2013).

J. Chen, Z. Xie, W. Zeng, and W. Wu, “Toughening mechanisms of ZTA ceramics at cryogenic temperature (77 K),” Ceram. Int., 43, No. 4, 3970–3974 (2017).

J.-H. Ouyang, Y.-H. Ma, and A. Henniche, “Synthesis, densification and characterization of nanosized oxide ceramic powders with eutectic compositions by heating of alcohol–aqueous salt solutions,” J. Ceram. Sci. Technol., 8, 81–90 (2017).

B.J. Oberste, J. Legouxu, and J. Gabriel, “Mechanical and thermal transport properties of suspension thermal sprayed alumina-zirconia composite coatings,” J. Therm. Spray Technol., 17, Issue 1, 91–104 (2008).

F. Tarasi, M. Medraj, and A. Dolatabadi, “Phase formation and transformation in alumina/YSZ nanocomposite coating deposited by suspension plasma spray process,” J. Therm. Spray Technol., 19, 787–795 (2010).

S.V. Veselov, N.S. Stukacheva, and R.I. Kuzmin, “Structure and mechanical properties of Al2O3–ZrO2 ceramic materials,” Nauch. Vest. NGTU, 65, No. 4 207–217 (2016).

N.V. Sharova, N.A. Popova, and E.S. Lukin, “Effect of eutectic addition in the Al2O3–ZrO2–Y2O3 system on the properties of corundum ceramics,” Usp. Khim. Khim. Tekhnol., XXXI, No. 3, 119–121 (2017).

V. Ponnilavan and S. Kannan, “Structural, morphological and mechanical characteristics on the role of excess ceria additions in zirconia toughened alumina systems,” J. Alloys Compd., 694, 1073–1082 (2017).

Z.D.I. Sktani, N.A. Rejab, A.F.Z. Rosli, A. Arab, and Z.A. Ahmad, “Effects of La2O3 addition on microstructure development and physical properties of harder ZTA-CeO2 composites with sustainable high fracture toughness,” J. Rare Earths (2020), DOI: https://doi.org/10.1016/j.jre.2020.06.005.

Ah.Z.Ah. Azhar, S.H.M. Shawal, H. Manshor, A.M. Ali, N.A. Rejab, E.Ch. Abdullah, and Z.A. Ahmad, “The effects of CeO2 addition on the physical and microstructural properties of ZTA-TiO2 ceramics composite,” J. Alloys. Compd., 773, 27–33 (2019).

P. Tana, Y. Yanga, Y. Suia, and Y. Jianga, “Influence of CeO2 addition on the microstructure and mechanical properties of zirconia-toughened alumina (ZTA) composite prepared by spark plasma sintering,” Ceram. Int., 46, Issue 6, 7510–7516 (2020).

N.K. Mitra, Supratim Das, S. Maitra, U. Sengupta, and A. Basumajumdar, “Effect of CeO2 on the sintering behavior of zirconia–alumina composite,” Ceram. Int., 28, 827–833 (2002).

M.Yu. Smyrnova-Zamkova and O.V. Dudnik, “Methods of producing starting nanocrystalline powders in the Al2O3–ZrO2(Y2O3, CeO) system,” in: Current Issues of Materials Science: Collected Papers [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2017), Issue 26, pp. 50–65.

M.Yu. Smyrnova-Zamkova, O.K. Ruban, O.I. Bykov, O.I. Khomenko, and O.V. Dudnik, “Synthesis and properties of a nanocrystalline eutectic powder in the Al2O3– ZrO2(Y2O3, CeO2) system,” Adhez. Raspl. Paika Mater., Issue 52, 35–44 (2019).

O.I. Khomenko and O.V. Khomenko, “Use of the AMIC software package for quantitative metallography,” in: Mathematical Models and Computer Experiments in Material Science: Collected Papers [in Ukrainian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2014), Issue 16, pp. 35–42.

K.S. Chernyavskii, Stereology in Metal Science [in Russian], Metallurgiya, Moscow (1977), p. 280.

Acknowledgement

The authors are grateful to V.M. Pavlikov for the differential thermal analysis and to T.E. Babutina for determining the specific surface area of the powders.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 3–4 (538), pp. 3–17, 2021.

Rights and permissions

About this article

Cite this article

Smyrnova-Zamkova, M., Ruban, O., Bykov, O. et al. The Influence of the ZrO2 Solid Solution Amount on the Physicochemical Properties of Al2O3–ZrO2–Y2O3–CeO2 Powders. Powder Metall Met Ceram 60, 129–141 (2021). https://doi.org/10.1007/s11106-021-00222-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00222-4