Abstract

This study proposed a rapid and low-cost fabrication method for open-channel hydrogel-based microfluidic devices using CO2 laser ablation. The agarose hydrogel substrate was prepared with agarose gelation in DI water upon microwave heating, then a commercial CO2 laser system was used for the direct laser ablation of microchannels on the surface of agarose hydrogel substrate, the hydrophilic nature of the microchannels fabricated on hydrogel substrate enables the self-driven of the liquid inside the microchannels with capillary force. The profiles of the laser ablated microchannels on agarose hydrogel substrate with various laser power and scan speed were studied in detail. Due to the loss of water when exposed to the atmosphere, significant deformation of the fabricated microchannels was observed, and the profile change was recorded for 48 h for comparison. An easy-to-access storage method of hydrogel-based microfluidic device in DI water was also proposed in this study. Unlike compact silicon or polymer-based microfluidic devices, the hydrogel is formed by cross-linked polymer chains filled with water, for a better understanding of the diffusion of small molecules into the bulk hydrogel material during fluid propagation inside the microchannel, the Nile red fluorescent was added into the liquid and the diffusion across the hydrogel-based microchannels with time was measured and discussed in this study. Several open-channel agarose hydrogel-based microfluidic devices were fabricated in this study for the demonstration of the proposed fabrication method. The CO2 laser ablation approach for agarose hydrogel-based microfluidic devices has the advantages of rapid processing time, low-cost, highly biocompatible, and self-driven without pumps and could have wide application potentials in biological and medical fields.

Similar content being viewed by others

References

P. Gravesen, J. Branebjerg, O.S. Jensen, Microfluidics-a review. J. Micromech. Microeng. 3(4), 168 (1993)

H. Becker, L.E. Locascio, Polymer microfluidic devices. Talanta 56(2), 267–287 (2002)

J.S. Jeon, S. Chung, R.D. Kamm, J.L. Charest, Hot embossing for fabrication of a microfluidic 3D cell culture platform. Biomed. Microdevice 13(2), 325–333 (2011)

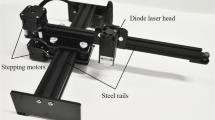

K. Gao, J. Liu, Y. Fan, Y. Zhang, Ultra-low-cost fabrication of polymer-based microfluidic devices with diode laser ablation. Biomed. Microdevice 21(4), 1–7 (2019)

D. Sticker, M. Rothbauer, S. Lechner, M.T. Hehenberger, P. Ertl, Multi-layered, membrane-integrated microfluidics based on replica molding of a thiol–ene epoxy thermoset for organ-on-a-chip applications. Lab Chip 15(24), 4542–4554 (2015)

X. Ma, R. Li, Z. Jin, Y. Fan, X. Zhou, Y. Zhang, Injection molding and characterization of PMMA-based microfluidic devices. Microsyst. Technol. 26(4), 1317–1324 (2020)

S. Zeinali, B. Cetin, S.N.B. Oliaei, Y. Karpat, Fabrication of continuous flow microfluidics device with 3D electrode structures for high throughput DEP applications using mechanical machining. Electrophoresis 36(13), 1432–1442 (2015)

N. Bhattacharjee, A. Urrios, S. Kang, A. Folch, The upcoming 3D-printing revolution in microfluidics. Lab Chip 16(10), 1720–1742 (2016)

X. Chen, J. Shen, M. Zhou, Rapid fabrication of a four-layer PMMA-based microfluidic chip using CO2-laser micromachining and thermal bonding. J Micromech Microeng 26(10), 107001 (2016)

S. Liu, Y. Fan, K. Gao, Y. Zhang, Fabrication of Cyclo-olefin polymer-based microfluidic devices using CO2 laser ablation. Materials Research Express 5(9), 095305 (2018)

M.P. Cuchiara, A.C. Allen, T.M. Chen, J.S. Miller, J.L. West, Multilayer microfluidic PEGDA hydrogels. Biomaterials 31(21), 5491–5497 (2010)

J. Nie et al., Vessel-on-a-chip with Hydrogel-based Microfluidics. Small 14(45), 1802368 (2018)

J. Nie, J. Fu, Y. J. S. He, Hydrogels: The next generation body materials for microfluidic chips? 16(46), 2003797 (2020)

T. Hu, Q. Li, H. Dong, W. Xiao, L. Li, X. Cao, Patterning electrospun nanofibers via agarose hydrogel stamps to spatially coordinate cell orientation in microfluidic device. Small 13(3) (2017)

S. Lv et al, Micro/nanofabrication of brittle hydrogels using 3D printed soft ultrafine fiber molds for damage-free demolding. 12(2), 025015 (2020)

J. Nie et al, Vessel‐on‐a‐chip with hydrogel‐based microfluidics. 14(45), 1802368 (2018)

J. Berthier, K. A. Brakke, E. Berthier, Open microfluidics. John Wiley & Sons (2016)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51804014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 2351 KB)

Supplementary file2 (MP4 4007 KB)

Rights and permissions

About this article

Cite this article

Yao, Y., Fan, Y. CO2 laser fabrication of hydrogel-based open-channel microfluidic devices. Biomed Microdevices 23, 47 (2021). https://doi.org/10.1007/s10544-021-00584-x

Accepted:

Published:

DOI: https://doi.org/10.1007/s10544-021-00584-x