Abstract

Super duplex stainless steel specimens were subjected to controlled (in a deformation simulator) thermal and thermal plus deformation treatments. The objective was to relate the corrosion performance with hot (1000-1300°C) deformed microstructures. The microstructural evolutions were quantified with extensive microtextural characterization and measurements of phase-specific micro-hardness. The corrosion behavior was investigated by anodic polarization and phase-specific selective dissolution methods. Though the thermal treatment imposed an increasing degradation in corrosion performance with holding temperature, the associated deformation at that temperature brought a non-monotonic behavior. The best corrosion performance (or the lowest passivation current density) was noted in the specimen deformed at ~1100°C. This superior corrosion behavior was attributed to the grain size refinement in the austenite phase. Finally, a combination of transmission Kikuchi diffraction (TKD) plus transmission electron microscopy (TEM) clearly related the grain size refinement to discontinuous dynamic recrystallization. The overall corrosion behavior was shown to be determined by a balance between decreasing austenite fraction and dynamic recrystallization-induced grain size refinement of the austenite phase.

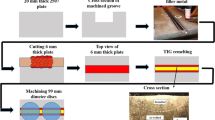

Graphical Abstract

Similar content being viewed by others

References

R. Gunn, Duplex Stainless Steels: Microstructure, Properties and Applications, Elsevier, England, Cambridge, 1997.

I.M. Association, Practical guidelines for the fabrication of duplex stainless steels, 2009, p 1-64, London, UK, https://www.imoa.info/download_files/stainlesssteel/Duplex_Stainless_Steel_3rd_Edition.pdf

J. Charles, Duplex stainless steels, a review after DSS’07 in Grado, Revue de Métallurgie– Int. J. Metall., 2008, 105(3), p 155–171.

J. Olsson and M. Snis, Duplex—a new generation of stainless steels for desalination plants, Desalination, 2007, 205(1–3), p 104–113.

J.O. Nilsson, Super duplex stainless steels, Mater. Sci. Technol., 1992, 8(8), p 685–700.

L. Jinlong, L. Tongxiang, W. Chen and D. Limin, Comparison of corrosion properties of passive films formed on coarse grained and ultrafine grained AISI 2205 duplex stainless steels, J. Electroanal. Chem., 2015, 757, p 263–269.

L. Jinlong, L. Tongxiang, W. Chen and D. Limin, Effect of ultrafine grain on tensile behaviour and corrosion resistance of the duplex stainless steel, Mater. Sci. Eng. C, 2016, 62, p 558–563.

R. Mondal, S.K. Bonagani, A. Lodh, T. Sharma, P. Sivaprasad, G. Chai, V. Kain and I. Samajdar, Relating general and phase specific corrosion in a super duplex stainless steel with phase specific microstructure evolution, Corrosion, 2019, 75(11), p 1315–1326.

R. Mondal, A. Rajagopal, S.K. Bonagani, A. Prakash, D. Fuloria, P. Sivaprasad, G. Chai, V. Kain and I. Samajdar, Solution annealing of super duplex stainless steel: correlating corrosion performance with grain size and phase-specific chemistry, Metall. Mater. Trans. A, 2020, 51, p 2480–2494.

I. Alvarez-Armas and S. Degallaix-Moreuil, Duplex Stainless Steels, Wiley, London, 2013.

J. Cabrera, A. Mateo, L. Llanes, J. Prado and M. Anglada, Hot deformation of duplex stainless steels, J. Mater. Process. Technol., 2003, 143, p 321–325.

T.A. Debold, Duplex stainless steel—microstructure and properties, JOM, 1989, 41(3), p 12–15.

H.D. Solomon, T. Devine Jr, Duplex stainless steels--a tale of two phases, in: Duplex stainless steels, 1982, pp. 693-756.

M. Rosso, I. Peter and D. Suani, About heat treatment and properties of duplex stainless steels, J. Achiev. Mater. Manuf. Eng., 2013, 59, p 26–36.

K. Takizawa, Y. Shimizu, Y. Higuchi and I. Tamura, Effect of cold work and volume fraction of ferrite on corrosion resistance of (α-γ) duplex stainless steel, Tetsu-to-Hagane, 1983, 69(11), p 1448–1455.

A. Elhoud, H. Ezuber and W. Deans, Influence of cold work and sigma phase on the pitting corrosion behavior of 25 chromium super duplex stainless steel in 3.5% sodium chloride solution, Mater. Corros., 2010, 61(3), p 199–204.

M. Breda, K. Brunelli, F. Grazzi, A. Scherillo and I. Calliari, Effects of cold rolling and strain-induced martensite formation in a SAF 2205 duplex stainless steel, Metall. Mater. Trans. A, 2015, 46(2), p 577–586.

A. Elhoud, N.C. Renton and W.F. Deans, The effect of manufacturing variables on the corrosion resistance of a super duplex stainless steel, Int. J. Adv. Manuf. Tech., 2011, 52(5–8), p 451–461.

R. Mondal, S.K. Bonagani, P. Raut, P. Sivaprasad, G. Chai, V. Kain and I. Samajdar, Role of recovery and recrystallization on the post cold work corrosion performance in a super duplex stainless steel, J. Electrochem. Soc., 2020, 167, p 101501.

K. Tsuzaki, H. Matsuyama, M. Nagao and T. Maki, High-strain rate superplasticity and role of dynamic recrystallization in a superplastic duplex stainless steel, Mater. Trans. JIM, 1990, 31(11), p 983–994.

J. Li, X. Ren and X. Gao, Effect of superplastic deformation on microstructure evolution of 3207 duplex stainless steel, Mater. Character., 2020, 164, p 110320.

K. Osada, S. Uekoh and K. Ebato, Superplasticity of as rolled duplex stainless steel, Tran. I. S. Ins. Japan/Tetsu-To-Hagane, 1987, 27(9), p 713–718.

S. Sasaki, T. Katsumura and J. Yanagimoto, Grain refinement technology for duplex stainless steel using rapid cooling immediately before hot working, J. Mater. Process. Technol., 2020, 281, p 116614.

H. Alinejad, B. Korojy, G. Ebrahimi and A. Momeni, Microstructure and flow behavior of cast 2304 duplex stainless steel at elevated temperatures, J. Mater. Res., 2016, 31, p 3939–3947.

Y. Han, D. Zou, Z. Chen, G. Fan and W. Zhang, Investigation on hot deformation behavior of 00Cr23Ni4N duplex stainless steel under medium–high strain rates, Mater. Charact., 2011, 62, p 198–203.

S. Spigarelli, M. El Mehtedi, P. Ricci and C. Mapelli, Constitutive equations for prediction of the flow behaviour of duplex stainless steels, Mater. Sci. Eng. A, 2010, 527(16–17), p 4218–4228.

G. Fargas, N. Akdut, M. Anglada and A. Mateo, Microstructural evolution during industrial rolling of a duplex stainless steel, ISIJ Int., 2008, 48(11), p 1596–1602.

A. Momeni and K. Dehghani, Hot working behavior of 2205 austenite–ferrite duplex stainless steel characterized by constitutive equations and processing maps, Mater. Sci. Eng. A, 2011, 528(3), p 1448–1454.

O. Balancin, W. Hoffmann and J. Jonas, Influence of microstructure on the flow behavior of duplex stainless steels at high temperatures, Metall. Mater. Trans. A, 2000, 31(5), p 1353–1364.

L. Chen, X. Ma, X. Liu and L. Wang, Processing map for hot working characteristics of a wrought 2205 duplex stainless steel, Mater. Des., 2011, 32(3), p 1292–1297.

D. Rajabi, A. Abedi and G. Ebrahimi, Study on static recrystallization process in duplex stainless steel, IJISSI, 2011, 8, p 20–23.

P. Cizek and B. Wynne, A mechanism of ferrite softening in a duplex stainless steel deformed in hot torsion, Mater. Sci. Eng. A, 1997, 230(1–10), p 88–94.

P. Cizek, The microstructure evolution and softening processes during high-temperature deformation of a 21Cr–10Ni–3Mo duplex stainless steel, Acta Mater., 2016, 106(1–2), p 129–143.

N. Haghdadi, P. Cizek, H. Beladi and P.D. Hodgson, The austenite microstructure evolution in a duplex stainless steel subjected to hot deformation, Philos. Mag., 2017, 97(15), p 1209–1237.

W. Chen, C. Zheng, C. Jia, B. Hu and D. Li, Strain-rate dependence of the dynamic softening in a duplex stainless steel, Mater. Character., 2020, 162, p 110219.

N. Haghdadi, P. Cizek, H. Beladi and P. Hodgson, A novel high-strain-rate ferrite dynamic softening mechanism facilitated by the interphase in the austenite/ferrite microstructure, Acta Mater., 2017, 126, p 44–57.

A. Dehghan-Manshadi and P. Hodgson, Effect of δ-ferrite co-existence on hot deformation and recrystallization of austenite, J. Mater. Sci., 2008, 43(18), p 6272–6277.

A. Iza-Mendia, A. Pinol-Juez, J. Urcola and I. Gutierrez, Microstructural and mechanical behavior of a duplex stainless steel under hot working conditions, Metall. Mater. Trans. A, 1998, 29(12), p 2975–2986.

S. Kingklang and V. Uthaisangsuk, Investigation of hot deformation behavior of duplex stainless steel grade 2507, Metall. Mater. Trans. A, 2017, 48(1), p 95–108.

G. Fargas, M. Anglada and A. Mateo, Effect of the annealing temperature on the mechanical properties, formability and corrosion resistance of hot-rolled duplex stainless steel, J. Mater. Process. Technol., 2009, 209(4), p 1770–1782.

M. Gholami, M. Hoseinpoor and M.H. Moayed, A statistical study on the effect of annealing temperature on pitting corrosion resistance of 2205 duplex stainless steel, Corr. Sci., 2015, 94, p 156–164.

X. Liu, C. Zhang, J. Li, W. Chen, Y. Zheng, H. Li and P. Han, Effect of solution annealing on microstructure evolution and pitting corrosion resistance of SAF2906 super duplex stainless steel, Steel Res. Int., 2017, 88(11), p 1700023.

Y.H. Yang and S.H. Li, High temperature deformation behavior and corrosion resistance of 2205 duplex stainless steel under strain rate of 0.5 s-1, Adv. Mater. Res. Trans. Tech. Publ., 2012, 581, p 1054–1057.

M. Dabala, I. Calliari and A. Variola, Corrosion behavior of a superduplex stainless steel in chloride aqueous solution, J. Mater. Eng. Perform., 2004, 13(2), p 237–240.

E. Paredes, A. Bautista, S.M. Álvarez and F. Velasco, Influence of the forming process of corrugated stainless steels on their corrosion behaviour in simulated pore solutions, Corr. Sci., 2012, 58, p 52–61.

A.F. Ciuffini, S. Barella, C. Di Cecca, A. Gruttadauria, S. Crugnola and C. Mapelli, Local pitting corrosion resistance evaluation in large forged UNS-S32760 super duplex stainless steel parts of a sphere valve for the oil & gas industry, Metall. Ital., 2017, 10, p 33–45.

S.I. Wright, M.M. Nowell, R. De Kloe and L. Chan, Orientation precision of electron backscatter diffraction measurements near grain boundaries, Microsc. Microanal., 2014, 20(3), p 852–863.

P.J. Goodhew and J. Humphreys, Electron Microscopy and Analysis, CRC Press, London, 2000.

S.I. Wright, A review of automated orientation imaging microscopy (OIM), J. Comput. Assist. Microscopy (USA), 1993, 5, p 207–221.

A. Prakash, T.N. Tak, A. Lodh, N. Nayan, S.N. Murty, P. Guruprasad and I. Samajdar, Composition gradient and particle deformed zone: an emerging correlation, Metall. Mater. Trans. A, 2019, 50(3), p 1250–1260.

B. Verlinden, J. Driver, I. Samajdar and R.D. Doherty, Electron Backscatter Diffraction in Materials Science, Springer, Berlin, 2009.

H. Hwang and Y. Park, Effects of heat treatment on the phase ratio and corrosion resistance of duplex stainless steel, Mater. Trans., 2009, 50, p 0905110767–0905110767.

W.T. Tsai and J.R. Chen, Galvanic corrosion between the constituent phases in duplex stainless steel, Corr. Sci., 2007, 49(9), p 3659–3668.

Y.H. Yau and M. Streicher, Galvanic corrosion of duplex FeCr-10% Ni alloys in reducing acids, Corrosion, 1987, 43(6), p 366–373.

E. Symniotis, Galvanic effects on the active dissolution of duplex stainless steels, Corrosion, 1990, 46(1), p 2–12.

M. Khan, H. Mehtani, A. Durgaprasad, G. Goyal, M. Prasad, S. Parida, T. Dasgupta, N. Birbilis and I. Samajdar, The defining role of interface crystallography in corrosion of a two-phase pearlitic steel, Phil. Mag., 2020, 100, p 1439–1453.

T. Chandra, D. Bendeich and D. Dunne, Dynamic Recovery and Recrystallization in a Duplex Stainless Steel, Strength of Metals and Alloys (ICSMA 6), Elsevier, London, 1982, p 505–510

L. Duprez, B. De Cooman and N. Akdut, Flow stress and ductility of duplex stainless steel during high-temperature torsion deformation, Metall. Mater. Trans. A, 2002, 33(7), p 1931–1938.

A.A. Salem, S.R. Kalidindi and R.D. Doherty, Strain hardening of titanium: role of deformation twinning, Acta Mater., 2003, 51(14), p 4225–4237.

F.J. Humphreys and M. Hatherly, Recrystallization and Related Annealing Phenomena, Elsevier, London, 2012.

H. McQueen, N. Ryan and E. Evangelista, Dynamic recrystallization in austenitic stainless steels, Mater. Sci. Forum, Trans. Tech. Publ., 1993, 113, p 435–440.

A. Dehghan-Manshadi and P.D. Hodgson, Dynamic recrystallization of austenitic stainless steel under multiple peak flow behaviours, ISIJ Inter., 2007, 47(12), p 1799–1803.

K. Thool, K.M. Krishna, D. Srivastava, A. Patra, R. Doherty and I. Samajdar, Confirmation of dynamically recrystallized grains in hexagonal zirconium through local internal friction measurements, Metall. Mater. Trans. A, 2019, 50(11), p 5000–5014.

P. Cizek, Microstructure evolution and softening processes in hot deformed austenitic and duplex stainless steels, Mater. Sci. Forum, Trans. Tech. Publ., 2013, 753, p 66–71.

A. Pinol-Juez, A. Iza-Mendia and I. Gutierrez, δ/γ Interface boundary sliding as a mechanism for strain accommodation during hot deformation in a duplex stainless steel, Metall. Mater. Trans. A, 2000, 31(6), p 1671–1677.

N. Haghdadi, P. Cizek, H. Beladi, P.D. Hodgson, Hot deformation and restoration mechanisms in duplex stainless steels: Effect of strain rate, ESSC and DUPLEX 2017, 9th European Stainless Steel Conference-Science and Market and the 5th European Duplex Stainless Steel Conference and Exhibition, 2017, Italian Association for Metallurgy, p 5-16.

J. Urcola and C. Sellars, Effect of changing strain rate on stress-strain behavior during high temperature deformation, Acta Metall., 1987, 35(11), p 2637–2647.

G. Fan, J. Liu, P. Han and G. Qiao, Hot ductility and microstructure in casted 2205 duplex stainless steels, Mater. Sci. Eng. A, 2009, 515(1–2), p 108–112.

E. Evangelista, H. McQueen, M. Niewczas and M. Cabibbo, Hot workability of 2304 and 2205 duplex stainless steels, Can. Metall. Q., 2004, 43(3), p 339–353.

N. Haghdadi, D. Martin and P. Hodgson, Physically-based constitutive modelling of hot deformation behavior in a LDX 2101 duplex stainless steel, Mater. Des., 2016, 106, p 420–427.

D. Mukherjee, U. Tewary, S. Kumar, S. Karagadde, R. Verma, M. Sambandam and I. Samajdar, Imposed thermal gradients and resultant residual stresses: physical and numerical simulations, Mater. Sci. Technol., 2020, 36, p 1020–1036.

D.C. Sicupira, R.F. Assumpção, D.B. Perasoli, D.S. Alves, A.O.V. Ferreira and D.B. Santos, Effect of warm rolling on the corrosion and mechanical properties of UNS S32205 duplex stainless steel, Mater. Res., 2019, 22, p 1–12.

M. Seshweni, A. Moloto, S. Aribo, S. Oke, O. Ige and P. Olubambi, Influence of cold and hot rolling on the corrosion behaviour of duplex stainless steels in mine water environment, Mater. Today Proc., 2020, 28, p 912–915.

Acknowledgment

The authors would like to acknowledge support from SandvikTM Materials Technology, Sweden and CoEST (center of excellence on steel technology, IIT Bombay). Support from the National Facility of Texture and OIM (IIT Bombay) is also appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Data Availability

The raw data required to reproduce the results of the present manuscript cannot be shared at this time as the data also form part of ongoing doctoral work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mondal, R., Bonagani, S.K., Raut, P. et al. Dynamic Recrystallization and Phase-Specific Corrosion Performance in a Super Duplex Stainless Steel. J. of Materi Eng and Perform 31, 1478–1492 (2022). https://doi.org/10.1007/s11665-021-06221-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06221-1