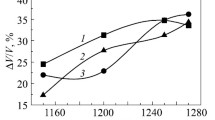

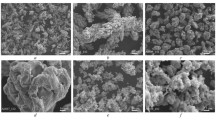

The influence of sintering temperature and content of high-carbon ferrochrome on the phase composition, structure, and mechanical properties of chromium carbide powder steels was studied. When sintering temperature changed from 1100 to 1250°C, the bulk shrinkage, density, porosity, hardness, and bending strength of the iron-based composites with high-carbon ferrochrome FKh800 varying from 25 to 40 wt.% increased nonmonotonically and their porosity decreased. The optimal sintering conditions were established for the Fe–(25–40 wt.%) FKh800 composites, and FKh800 content in the composition range under study was found to hardly influence the optimal sintering temperature of the composites. A vertical section was constructed by analytical/graphical method and demonstrated wide regions of two-phase (γ-Fe) + (Cr, Fe)7C3 and (α-Fe) + (Cr, Fe)7C3 equilibria. The constructed vertical section allowed the eutectic composition and eutectic formation temperature to be determined for the iron-based composites with FKh800, which were 73.7 wt.% Fe–26.3 wt.% FKh800 and 1285°C, and a tentative optimal sintering range to be found, which varied from 1100 to 1250°C. Electron microscopy studies of the carbide steels showed that their microstructure was heterogeneous and consisted of metallic and carbide phases and a number of pores. According to electron microprobe analysis and X-ray diffraction of the carbide steel, its metallic phase was close in composition to chromium steel Kh17 and its carbide phase corresponded to (Cr, Fe)7C3. The effect of 25–40 wt.% high-carbon ferrochrome on the mechanical properties of the composites was examined. When FKh800 content changed from 25 to 35 wt.%, the hardness and bending strength increased and fracture toughness decreased. The optimal combination of these mechanical properties was shown by the 65 wt.% Fe–35 wt.% FKh800 carbide steel.

Similar content being viewed by others

References

M.E. Garber, Wear-Resistant White Cast Irons [in Russian], Mashinostroenie, Moscow (2010), p. 279.

Y.F. Zhou, G.K. Qin, P.J. Jiang, S.F. Wang, X.W. Qi, X.L. Xing, and Q.X. Yang, “Dry sliding wear behavior of (Cr, Fe)7C3–γ(Cr, Fe) metal matrix composite (MMC) coatings: The influence of high volume fraction (Cr, Fe)7C3 carbide,” Tribol. Lett., 66, No. 3, 108 (2018).

H. Sabet, S. Mirdamadi, S. Kheirandish, and M. Goodarz, “Effect of volume fraction of (Cr, Fe)7C3 carbides on corrosion resistance of the Fe–Cr–C hardfacing alloys at Cr/C = 6,” Metall. Mater. Eng., 19, No. 2, 108–114 (2013).

O. Yilmaz, M. Aksoy, and S. Yildirim, “Wear behavior of Fe/M7C3 metal matrix composites with various microstructures during dry sliding,” Mater. Sci. Technol., 19, No. 5, 661–668 (2013).

V. Jankauskas, E. Katinas, A. Laskauskas, M. Antonov, V. Varnauskas, I. Gedzevičius, and V. Alekneviciene, “Effect of electrode covering composition on the microstructure, wear, and economic feasibility of Fe–C–Cr manual arc-welded hardfacings,” Coatings, 10, No. 3, 294 (2020).

A. Bondar, V. Ivanchenko, A. Kozlov, and I.-C. Tedenac, “Carbon–Chromium–Iron,” in: Landolt–Börnstein, Numerical Data and Functional Relationships in Science and Technology, W. Martienssen (ed.), New Series, Group IV: Physical Chemistry, Ternary Alloy Systems, Phase Diagrams, Crystallographic and Thermodynamic Data Critically Evaluated by MSIT, Vol. 11D2, Springer–Verlag, Berlin, Heidelberg (2007), pp. 1–55.

S. Liu, Y. Zhou, X. Xing, J. Wang, X. Ren, and Q. Yang, “Growth characteristics of primary M7C3 carbide in hypereutectic Fe–Cr–C alloy,” Sci. Rep., 6, No. 1, 1–8 (2016).

S. Liu, Y. Zhou, X. Xing, J. Wang, Y. Yang, and Q. Yang, “Agglomeration model of (Fe, Cr)7C3 carbide in hypereutectic Fe–Cr–C alloy”, Mater. Lett., 183, 272–276 (2016).

S. Ma, J. Xing, Y. He, Y. Li, Z. Huang, G. Liu, and Q. Geng, “Microstructure and crystallography of M7C3 carbide in chromium cast iron,” Mater. Chem. Phys., 161, 65–73 (2015).

I.D. Radomyselskii, G.G. Serdyuk, and N.I. Shcherban, Structural Powder Materials [in Russian], Tekhnika, Kyiv (1985), p. 152.

V.A. Maslyuk, A.A. Bondar, V.B. Kuras, M.I. Podoprygora, and V.M. Varchenko, “Structure and properties of iron–high-carbon ferrochrome powder composites,” Powder Metall. Met. Ceram., 52, No. 5–6, 291–297 (2013).

O.M. Shevchenko, “Structural bases for developing eutectic chromium carbide steel with increased wear resistance,” Dop. Nats. Akad. Nauk Ukrainy, No. 5, 104–110 (2013).

O.M. Shevchenko, G.O. Maksimova, M.I. Danilenko, V.V. Kovylyaev, and S.O. Firstov, “Carbide transformations in the production of eutectic chromium carbide steel,” Dop. Nats. Akad. Nauk Ukrainy, No. 6, 83–91 (2015).

V. Maslyuk, E. Karaimchuk, O. Gripachevsky, G. Bagliuk, and I. Sytnyk, “Peculiarities of the interaction of a highly carbonized ferrochrome with iron during sintering of 65% Fe–35% FH800 composite,” Mach. Technol. Mater., 13, Issue 8, 370–372 (2019).

V.A. Maslyuk, E.S. Karaimchuk, M.I. Podoprygora, V.T. Varchenko, and Ya.I. Sytnik, “Structure and mechanical and tribotechnical properties of iron–high-carbon ferrochrome doped with Ni3B additions,” Powder Metall. Met. Ceram., 57, No. 3–4, 175–181 (2018).

V.A. Maslyuk, Ya. A. Sytnik, M.I. Podoprygora, and R.V. Yakovenko, “The effect of chromium steels and nickel boride additives on the structure and properties of iron–high-carbon ferrochrome FKh800 powder composites,” Powder Metall. Met. Ceram., 54, No. 5–6, 292–297 (2015).

ISO 4498-1-:1990, Sintered Metal Materials, Excluding Hardmetals—Determination of Apparent Hardness, Part 1: Materials of Essentially Uniform Section Hardness, Ed. 1990-08-2, ISO (1990).

ISO 3327:2009, Hardmetals—Determination of Transverse Rupture Strength, Ed. 2009-05-15, ISO (2009).

V.G. Rivlin, “Phase equilibria in iron ternary alloys. 14. Critical review of constitution of carbon–chromium–iron and carbon–iron–manganese systems,” Int. Met. Rev., 29, No. 4, 299–327 (1984).

G.V. Raynor and V.G. Rivlin, “C–Cr–Fe,” in: Phase Equilibria in Iron Ternary Alloys, Institute of Metals, London, 143–156 (1988).

J.-O. Andersson, “A thermodynamic evaluation of the Fe–Cr–C system,” Metall. Mater. Trans. A, 19A, 627–636 (1988).

M. Hillert and C. Qui, “A thermodynamic assessment of the C–Cr–Fe–Ni system,” Metall. Trans. A, 22A, No. 10, 2187–2198 (1991).

M. Hino, K.-I. Higuchi, T. Nagasaka, and S. Ban-Ya, “Thermodynamic estimation on the reduction behavior of iron-chromium ore with carbon,” Metall. Mater. Trans. B, 29B, 351–360 (1998).

A.A. Mitin (ed.), Powder Metallurgy and Sprayed Coatings: University Textbook [in Russian], Metallurgiya, Moscow (1987), p. 792.

R.A. Andrievskii, Introduction to Powder Metallurgy [in Russian], Izd. ILIM, Frunze (1988), p. 173.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 3–4 (538), pp. 58–68, 2021.

Rights and permissions

About this article

Cite this article

Maslyuk, V., Kyryliuk, Y., Bondar, A. et al. The Influence of Sintering Temperature and Content of High-Carbon Ferrochrome on the Structure and Properties of Iron–FKh800 Powder Composites. Powder Metall Met Ceram 60, 174–182 (2021). https://doi.org/10.1007/s11106-021-00225-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00225-1