Abstract

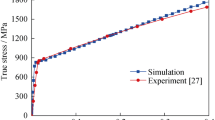

The main aim of this research is to simulate a compression test of semi-solid A380 aluminium alloy in numerical software. In order to achieve a more realistic model, 2D image-based modelling is used. The first step of this method is to obtain appropriate microstructural images. As the semi-solid material consists of non-dendritic solid phase and liquid channels, ECAP tool is used to apply a high plastic strain to casted samples. In order to observe desirable (non-dendritic) microstructure, microstructure image is taken from water quench ECAPed sample heated at semi-solid range. After the binarizing image data, the data are imported to appropriate software. A coupled Eulerian–Lagrangian (CEL) approach is used to obtain macro-scale mechanical behaviour. This approach is used to take advantages of both main formulations: Eulerian formulation and Lagrangian formulation. In CEL approach, material moves through an Eulerian mesh that is fixed in space while Lagrangian mesh is attached to the material points and is used to set boundary conditions. The simulations results show a strong dependence of mechanical behaviour on strain rate. This informations can be used for prediction of semi-solid forming, as well.

Similar content being viewed by others

References

A. Fabrizi, S. Capuzzi, A. De Mori, G. Timelli, Effect of T6 heat treatment on the microstructure and hardness of secondary AlSi9Cu3 (Fe) alloys produced by semi-solid SEED process. Metals 8, 750 (2018). https://doi.org/10.3390/met8100750

Y. Birol, Cooling slope casting and thixoforming of hypereutectic A390 alloy. J. Mater. Process. Technol. 207, 200–203 (2018). https://doi.org/10.1016/j.jmatprotec.2007.12.071

L.S. Rao, A.K. Jha, S.N. Ojha, Microstructure and tribological characteristics of strain-induced melt activation (SIMA)-processed Al–10Cu–Fe alloy. Int. J. Metalcast. 12(3), 523–542 (2018). https://doi.org/10.1007/s40962-017-0187-y

B. Zhou, S. Lu, K. Xu, C. Xu, Z. Wang, Microstructure and simulation of semisolid aluminum alloy castings in the process of stirring integrated transfer-heat (SIT) with water cooling. Int. J. Metalcast. (2019). https://doi.org/10.1007/s40962-019-00357-6

O.R.I.X. Bustos, S. Ordoñez, R. Colás, Rheological and microstructural study of A356 alloy solidified under magnetic stirring. Int. J. Metalcast. 7(1), 29–37 (2013). https://doi.org/10.1007/BF03355542

M.A. Abdelgnei, M.Z. Omar, M.J. Ghazali, M.N. Mohammed, Microstructure evaluation and mechanical properties of thixoformed Ai–5.7 Si–2Cu–0.3 Mg aluminum alloys. Int. J. Metalcast. (2021). https://doi.org/10.1007/s40962-021-00610-x

R. Koeune, J.P. Ponthot, iSemisolid metallic alloys constitutive modeling for the simulation of thixoforming processes, in Advanced Computational Materials Modeling: From Classical to Multi‐Scale Techniques, ed. By M. Vaz Júnior, E.A. de Souza Neto, P.A. Muñoz-Rojas (Wiley‐VCH Verlag GmbH & Co., 2011), p. 205. https://doi.org/10.1002/9783527632312

B. Cai, In situ synchrotron tomographic quantification of semi-solid properties of aluminum-copper alloys. A doctoral thesis (2015)

H.V. Atkinson, Modelling the semisolid processing of metallic alloys. Prog. Mater. Sci. 50(3), 341–412 (2005). https://doi.org/10.1016/j.pmatsci.2004.04.003

D. Fuloria, Characterisation of semi-solid deformation behaviour of aluminium-copper alloys via combined X-ray microtomography and finite element modelling. A doctoral thesis (2009)

F. Sheykh-jaberi, Exeprimental and numerical analysis of semi-solid constitutive behaviour of B206 and A356 foundry alloys. A doctoral thesis (2018)

J. Wang, A.B. Phillion, G. Lu, Development of a visco-plastic constitutive modeling for thixoforming of AA6061 in semi-solid state. J. Alloys Compd. 609, 290–295 (2014). https://doi.org/10.1016/j.jallcom.2014.04.140

Z. Ma, H. Zhang, W. Song, X. Wu, L. Jia, H. Zhang, Pressure-driven mold filling model of aluminum alloy melt/semi-solid slurry based on rheological behavior. J. Mater. Sci. Technol. 39, 14–21 (2020). https://doi.org/10.1016/j.jmst.2019.07.048

M. Modigell, A. Pola, M. Tocci, Rheological characterization of semi-solid metals: a review. Metals 8, 245 (2018). https://doi.org/10.3390/met8040245

M. Modigell, J. Koke, Time-dependent rheological properties of semi-solid metal alloys. Mech. Time Depend. Mater. 3, 15–30 (1999). https://doi.org/10.1023/A:1009856708511

A.N. Alexandrou, G. Georgiou, On the early breakdown of semisolid suspensions. J. Nonnewton Fluid Mech. 142, 199–206 (2007). https://doi.org/10.1016/j.jnnfm.2006.09.003

S. Simlandi, N. Barman, H. Chattopadhyay, Study on thixotropic property of A356 alloy in semi-solid state. Solid State Phenom. 192, 335–340 (2013). https://doi.org/10.4028/www.scientific.net/SSP.192-193.335

W.M. Van Haaften, W.H. Kool, L. Katgerman, Tensile behaviour of semi-solid industrial aluminium alloys AA3104 and AA5182. Mater. Sci. Eng. 336, 1–6 (2002). https://doi.org/10.1016/S0921-5093(01)01987-6

D. Larouche, J. Langlais, W. Wu, M. Bouchard, A constitutive model for the tensile deformation of a binary aluminum alloy at high fractions of solid. Metall. Mater. Trans. B 37, 431–443 (2006). https://doi.org/10.1007/s11663-006-0028-5

D. Fabrègue, A. Deschams, M. Suéry, J.M. Drezet, Non-isothermal tensile tests during solidification of Al–Mg–Si–Cu alloys: Mechanical properties in relation to the phenomenon of hot tearing. Acta Mater. 54, 5209–5220 (2006). https://doi.org/10.1016/j.actamat.2006.06.027

R. Takai, A. Matsushita, S. Yanagida, K. Nakamura, M. Yoshida, Development of an elasto-viscoplastic constitutive equation for an Al-Mg alloy undergoing a tensile test during partial solidification. Mater. Trans. 56, 1233–1241 (2015). https://doi.org/10.2320/matertrans.L-M2015815

K. Traidi, V. Favier, P. Lestriez, K. Debray, L. Langlois, T. Balan, Modelling semi-solid behaviour and brittle temperature range. Solid State Phenom. 285, 361–366 (2019). https://doi.org/10.4028/www.scientific.net/SSP.285.361

C.G. Kang, J.S. Choi, K. Kim, The effect of strain rate on macroscopic behavior in the compression forming of semi-solid aluminum alloy. J. Mater. Process. Technol. 88, 159–168 (1999). https://doi.org/10.1016/S0924-0136(98)00383-5

C.G. Kang, H.K. Jung, Finite element analysis with deformation behavior modeling of globular microstructure in forming process of semi-solid materials. Int. J. Mech. Sci. 41, 1423–1445 (1999). https://doi.org/10.1016/S0020-7403(98)00107-6

N.S. Kim, C.G. Kang, An investigation of flow characteristics considering the effect of viscosity variation in the thixoforming process. J. Mater. Process. Technol. 103, 237–246 (2000). https://doi.org/10.1016/S0924-0136(99)00441-0

A.N. Alexandrou, Y. Pan, D. Apelian, G. Georgiou, Semisolid material characterization using computational rheology, in Proceedings of the Seventh International Conference on Semi-Solid Processing of Alloys and Composites Tsukuba Japan, Vol. 417 (2002)

K.P. Sołek, Z. Mitura, R. Kuziak, P. Kapranos, The use of ADINA software to simulate thixocasting processes. Solid State Phenom. 116, 626–629 (2006). https://doi.org/10.4028/www.scientific.net/SSP.116-117.626

K.P. Sołek, R.M. Kuziak, M. Karbowniczek, The application of thermodynamic calculations for the semi-solid processing design. Arch. Metall. Mater. 52 (2007)

V. Favier, H.V. Atkinson, Micromechanical modelling of the elastic–viscoplastic response of metallic alloys under rapid compression in the semi-solid state. Acta Mater. 59, 1271–1280 (2011)

J. Wang, S. Shang, G. Lu, J. Yu, Viscosity estimation of semi-solid alloys based on thermal simulation compression tests. Int. J. Mater. Res. 104, 255–259 (2013). https://doi.org/10.3139/146.110858

J.J. Wang, G.M. Lu, J.G. Yu, Numerical analysis of semi-solid die-casting automobile part based on the thermo-visco-plastic constitutive relation. Adv Mat Res. 1096, 268–274 (2015). https://doi.org/10.4028/www.scientific.net/AMR.1096.268

M.H. Sheikh-Ansari, M. Aghaie-Khafri, Constitutive modeling of semisolid deformation for the assessment of dilatant shear bands. Appl. Math. Model. 70, 128–138 (2019). https://doi.org/10.1016/j.apm.2019.01.028

S. Gencalp, N. Saklakoglu, Semisolid microstructure evolution during cooling slope casting under vibration of A380 aluminum alloy. Mater. Manuf. Process. 25, 943–947 (2010). https://doi.org/10.1080/10426911003636944

G.R. HirtKopp, Kopp R (2009) Thixoforming: Semi-Solid Metal Processing (Wiley, Hoboken, 2009)

A. Matsushita, H. Mizuno, T. Okane, M. Yoshida, Image-based modeling of viscoelastic properties of solidifying Al alloys and model validation. J. Mater. Process. Technol. 263, 321–329 (2019). https://doi.org/10.1016/j.jmatprotec.2018.08.012

C.G. Kang, H.K. Jung, A study on solutions for avoiding liquid segregation phenomena in thixoforming process: Part I Constitutive modeling and finite element method simulations for die design. Metall. Mater. Trans. B 32, 119–127 (2001)

A. Neag, V. Favier, R. Bigot, T. Canta, D. Frunza, Experimental investigation and numerical simulation during backward extrusion of a semi-solid Al-Si hypoeutectic alloy. AIP Conf. Proc. 907, 620–628 (2007). https://doi.org/10.1063/1.2729582

V. Favier, H. Atikson, Analysis of semi-solid response under rapid comrpession tests using multi-scale modelling and epxperiments. Trans. Nonferrous Met. Soc. China 20, 1691–1695 (2010). https://doi.org/10.1016/S1003-6326(09)60359-9

F. Sheykh-jaberi, S.L. Cockcroft, D.M. Maijer, A.B. Phillion, Meso-scale modelling of semi-solid deformation in aluminum foundry alloys: Effects of feeding and microstructure on hot tearing susceptibility. J. Mater. Process. Technol. 279, 116551 (2020). https://doi.org/10.1016/j.jmatprotec.2019.116551

Z. Sun, M. Bernacki, R. Logé, G. Gu, Numerical simulation of mechanical deformation of semi-solid material using a level-set based finite element method. Model. Simul. Mater. Sci. Eng. 25, 065020 (2017). https://doi.org/10.1088/1361-651X/aa788e

A.B. Phillion, S.L. Cockcroft, P.D. Lee, A three-phase simulation of the effect of microstructural features on semi-solid tensile deformation. Acta Mater. 56, 4328–4338 (2008). https://doi.org/10.1016/j.actamat.2008.04.055

H. Sharifi, D. Larouche, An automatic granular structure generation and finite element analysis of heterogeneous semi-solid materials. Model. Simul. Mater. Sci. Eng. 23, 065013 (2015). https://doi.org/10.1088/0965-0393/23/6/065013

A. Matsushita, Measurement of the mechanical properties and construction of the visco-elastic constitutive equation of the partially solidified alloy for predicting hot tearing. A doctoral thesis (2017)

Abaqus Analysis User’s Manual; Dassault Systemes, Providence (RI, USA, 2013)

D.J. Benson, Computational methods in Lagrangian and Eulerian hydrocodes. Comput. Methods Appl. Mech. Eng. 99, 235–394 (1992). https://doi.org/10.1016/0045-7825(92)90042-I

M. Bakroon, R. Daryaei, D. Aubram, F. Rackwitz, Multi-material arbitrary Lagrangian–Eulerian and coupled Eulerian–Lagrangian methods for large deformation geotechnical problems. Numer. Method. Geotech. Eng. 8 (2018)

K.N. Campo, E.J. Zoqui, Thixoforming of an ECAPed aluminum A356 alloy: Microstructure evolution, rheological behavior, and mechanical properties. Metall. Mater. Trans. A, 47, 1792–1802. https://doi.org/10.1007/s11661-016-3339-4

L.V. Torres, L.F. Torres, E.J. Zoqui, Electromagnetic stirring versus ECAP: morphological comparison of Al-Si-Cu alloys to make the microstructural refinement for use in SSM processing. Adv. Mater. Sci. Eng. 2016 (2016). https://doi.org/10.1155/2016/9789061

C.T.W. Proni, L.V. Torres, R. Haghayeghi, E.J. Zoqui, ECAP: an alternative route for producing AlSiCu for use in SSM processing. Mater. Charact. 118, 252–262 (2016). https://doi.org/10.1016/j.matchar.2016.06.002

Y. Birol, Semisolid processing of near-eutectic and hypereutectic Al–Si–Cu alloys. J. Mater. Sci. 43, 3577–3581 (2008). https://doi.org/10.1007/s10853-008-2565-6

European Steel and Alloy Grades; Grade ENAC-AlSi10Mg(Fe)

T. Magnusson, L. Arnberg, Density and solidification shrinkage of hypoeutectic aluminum-silicon alloys. Metall. Mater. Trans. A 32, 2605–2613 (2001). https://doi.org/10.1007/s11661-001-0050-9

A. B. Phillion, Hot tearing and constitutive behaviour of semi-solid aluminum alloys. A doctoral thesis (2007)

D. Fuloria, P.D. Lee, An X-ray microtomographic and finite element modeling approach for the prediction of semi-solid deformation behaviour in Al–Cu alloys. Acta Mater. 57, 5554–5562. https://doi.org/10.1016/j.actamat.2009.07.051

M. Ferrante, E.R. De Freitas, Rheological behaviour and deformation characteristics of a commercial and a laboratory-cast Al-4% Cu alloy in the semi-solid state. Acta Mater. 49, 3839–3847 (2001). https://doi.org/10.1016/S1359-6454(01)00239-7

Acknowledgement

The authors would like to thank the company AD Plastik from Split, Croatia for providing them with numerical software.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

ID contributed to the study conception and design. Modelling in the software was performed by SJ, DB and ID. ID performed the simulations. The first draft of the manuscript was written by ID. All authors peer reviewed paper writing and editing. All authors reviewed the final manuscript.

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dumanić, I., Jozić, S. & Bajić, D. Simulation of Real Image Microstructural Model of Semi-solid Aluminium Alloy Using a Coupled Eulerian–Lagrangian Approach. Inter Metalcast 16, 1292–1302 (2022). https://doi.org/10.1007/s40962-021-00689-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-021-00689-2