Abstract

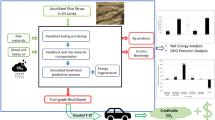

In Mexico, the possibility to exploit orange peels or sugarcane straw to generate heat has not been fully explored, even though they are major agronomic wastes generated in Mexico. Therefore, this paper aims to assess the heat generation’s environmental and economic performance from these feedstocks in a fruit-processing facility located in Veracruz, Mexico. The environmental performance was assessed through the life-cycle assessment methodology, while the economic performance was estimated through the total levelized cost of energy (TLCE) considering two scenarios: (1) a base scenario where orange peels are burnt to produce process steam, and (2) a second scenario where sugarcane straw is co-fired with it. Both scenarios assume to partially displace heavy-fuel–oil (HFO) for steam generation. Results indicate that the impacts of the use of residual biomass-based heat on the potential global warming, ozone layer depletion, marine aquatic ecotoxicity, and cumulative energy demand are 34–63% lower than when using HFO and decrease the TLCE by 18–21%. However, there is also an increase in other environmental impact categories such as human toxicity, photochemical oxidation, or eutrophication. The use of orange from organic farms improves the environmental results in some of these categories. The drying and combustion of the biomass, as well as the waste treatment, are the major contributors to the environmental impacts. On the other hand, capital and fuel costs are the major contributors to TLCE. Overall, the use of orange peels and sugarcane straw to generate heat is attractive from the environmental and economic point of views.

Similar content being viewed by others

Data Availability

The datasets generated are property of the institutions that generated them and may be made available on reasonable request through the Solid Biofuels Cluster.

Abbreviations

- ADP:

-

Abiotic depletion potential

- AP:

-

Acidification potential

- CAPEX:

-

Capital expenditures

- CED:

-

Cumulative energy demand

- EP:

-

Eutrophication potential

- FWAEP:

-

Freshwater aquatic ecotoxicity potential

- GWP:

-

Global-warming potential

- HFO:

-

Heavy-fuel oil

- HTP:

-

Human toxicity potential

- LCA:

-

Life cycle assessment

- MAEP:

-

Marine aquatic ecotoxicity potential

- NREC:

-

Non-renewable energy consumption

- ODP:

-

Ozone layer depletion potential

- OPEX:

-

Operational expenditures

- POP:

-

Photochemical oxidation potential

- REC:

-

Renewable energy consumption

- TEP:

-

Terrestrial ecotoxicity potential

- TLCE:

-

Total levelized cost of energy

- WC-ToT:

-

Total water consumption

References

De Pryck K (2021) Intergovernmental expert consensus in the making: the case of the summary for policy makers of the IPCC 2014 Synthesis Report. Glob Environ Polit 21:108–129

International Energy Agency (2019) World Energy Outlook 2019. In: World Energy Outlook 2019. https://www.iea.org/reports/world-energy-outlook-2019. Accessed 18 Jul 2021

Morseletto P (2020) Targets for a circular economy. Resour Conserv Recycl 153:104553. https://doi.org/10.1016/j.resconrec.2019.104553

Torreiro Y, Pérez L, Piñeiro G et al (2020) The role of energy valuation of agroforestry biomass on the circular economy. Energies 13:2516. https://doi.org/10.3390/en13102516

Sherwood J (2020) The significance of biomass in a circular economy. Bioresour Technol 300:122755. https://doi.org/10.1016/j.biortech.2020.122755

Rødsrud G, Lersch M, Sjöde A (2012) History and future of world’s most advanced biorefinery in operation. Int Conf Lignocellul ethanol 46:46–59. https://doi.org/10.1016/j.biombioe.2012.03.028

Kumar B, Verma P (2021) Biomass-based biorefineries: an important architype towards a circular economy. Fuel 288:119622. https://doi.org/10.1016/j.fuel.2020.119622

International Organization for Standardization (2006) Environmental management—life cycle assessment —principles and framework. Switzerland, Geneva

Hellweg S, Mila i Canals L, (2014) Emerging approaches, challenges and opportunities in life cycle assessment. Science (80-) 344:1109–1113. https://doi.org/10.1126/science.1248361

Jacquemin L, Pontalier P-Y, Sablayrolles C (2012) Life cycle assessment (LCA) applied to the process industry: a review. Int J Life Cycle Assess 17:1028–1041. https://doi.org/10.1007/s11367-012-0432-9

Short W, Packey DJ, Holt T (1995) A manual for the economic evaluation of energy efficiency and renewable energy technologies. National Renewable Energy Lab., Golden, CO (United States), Golden, CO

Doračić B, Pukšec T, Schneider DR, Duić N (2020) The effect of different parameters of the excess heat source on the levelized cost of excess heat. Energy 201:117686. https://doi.org/10.1016/j.energy.2020.117686

Hansen K (2019) Decision-making based on energy costs: comparing levelized cost of energy and energy system costs. Energy Strateg Rev 24:68–82. https://doi.org/10.1016/j.esr.2019.02.003

Doračić B, Novosel T, Pukšec T, Duić N (2018) Evaluation of excess heat utilization in district heating systems by implementing levelized cost of excess heat. Energies 11:575. https://doi.org/10.3390/en11030575

Stanytsina V, Artemchuk V, Bogoslavska O et al (2021) The influence of environmental tax rates on the Levelized cost of heat on the example of organic and biofuels boilers in Ukraine. E3S Web Conf 280:09012. https://doi.org/10.1051/e3sconf/202128009012

Gavaldà O, González A, Raya M et al (2021) Life cycle cost analysis for industrial bioenergy projects: development of a simulation tool and application to three demand sectors in Africa. SSRN Electron J. https://doi.org/10.2139/ssrn.3883139

Our World in Data (2018) Orange production. In: Orange Prod. https://ourworldindata.org/grapher/orange-production. Accessed 20 Apr 2021

FAO (2017) Citrus fruit-fresh and processed. Stat Bull 2016

SIAP (2021) Statistical yearbook of agricultural production. In: Serv. Inf. Agroaliment. y Pesq. https://nube.siap.gob.mx/cierreagricola/. Accessed 12 Aug 2021

SAGARPA (2017) National agricultural planning 2017–2030. Citrus: Mexican lemon, orange and grapefruit

Zema DA, Calabrò PS, Folino A et al (2018) Valorisation of citrus processing waste: a review. Waste Manag 80:252–273. https://doi.org/10.1016/j.wasman.2018.09.024

Rezzadori K, Benedetti S, Amante ER (2012) Proposals for the residues recovery: orange waste as raw material for new products. Food Bioprod Process 90:606–614. https://doi.org/10.1016/j.fbp.2012.06.002

Pourbafrani M, McKechnie J, MacLean HL, Saville BA (2013) Life cycle greenhouse gas impacts of ethanol, biomethane and limonene production from citrus waste. Environ Res Lett 8:015007. https://doi.org/10.1088/1748-9326/8/1/015007

Chavan P, Singh AK, Kaur G (2018) Recent progress in the utilization of industrial waste and by-products of citrus fruits: a review. J Food Process Eng 41:e12895. https://doi.org/10.1111/jfpe.12895

Chen Y, Barzee TJ, Zhang R, Pan Z (2019) Citrus. In: Pan Z, Zhang R, Zicari SBT-IPT for F and AB-P (eds) Integrated processing technologies for food and agricultural by-products. Academic Press, pp 217–242

Big Atlas (2020) World sugarcane production map. In: Ctries. by sugarcane Prod. https://www.atlasbig.com/en-us/countries-sugarcane-production. Accessed 20 Apr 2020

Carvalho DJ, Veiga JPS, Bizzo WA (2017) Analysis of energy consumption in three systems for collecting sugarcane straw for use in power generation. Energy 119:178–187. https://doi.org/10.1016/j.energy.2016.12.067

Leal MRLV, Galdos MV, Scarpare FV et al (2013) Sugarcane straw availability, quality, recovery and energy use: a literature review. Biomass Bioenergy 53:11–19. https://doi.org/10.1016/j.biombioe.2013.03.007

Salgado-García S, Aranda-Ibañez E, Castelán-Estrada M et al (2014) What to do with the straw from the mechanized harvest of sugarcane. Agroproductividad 7:3–9

Molina-Guerrero CE, Sanchez A, Vázquez-Núñez E (2020) Energy potential of agricultural residues generated in Mexico and their use for butanol and electricity production under a biorefinery configuration. Environ Sci Pollut Res 27:28607–28622. https://doi.org/10.1007/s11356-020-08430-y

Ciriminna R, Chavarría-Hernández N, Inés Rodríguez Hernández A, Pagliaro M (2015) Pectin: a new perspective from the biorefinery standpoint. Biofuels, Bioprod Biorefining 9:368–377. https://doi.org/10.1002/bbb.1551

Martínez-Guido SI, Betzabe González-Campos J, Ponce-Ortega JM et al (2016) Optimal reconfiguration of a sugar cane industry to yield an integrated biorefinery. Clean Technol Environ Policy 18:553–562. https://doi.org/10.1007/s10098-015-1039-1

Beltrán-Ramírez F, Orona-Tamayo D, Cornejo-Corona I et al (2019) Agro-industrial waste revalorization: the growing biorefinery. In: El-Fatah Abomohra A (ed) Biomass for bioenergy-recent trends and future challenges. IntechOpen, pp 83–102

Cervantes G, Torres LG, Ortega M (2020) Valorization of Agricultural Wastes and Biorefineries: a Way of Heading to Circular Economy. In: Salomone R, Cecchin A, Deutz P et al (eds) Industrial Symbiosis for the Circular Economy. Springer, pp 181–194

Cherubini F, Bird ND, Cowie A et al (2009) Energy- and greenhouse gas-based LCA of biofuel and bioenergy systems: key issues, ranges and recommendations. Resour Conserv Recycl 53:434–447. https://doi.org/10.1016/j.resconrec.2009.03.013

Mekonnen MM, Gerbens-Leenes PW, Hoekstra AY (2015) The consumptive water footprint of electricity and heat: a global assessment. Environ Sci Water Res Technol 1:285–297. https://doi.org/10.1039/C5EW00026B

Guest G, Bright RM, Cherubini F et al (2011) Life cycle assessment of biomass-based combined heat and power plants. J Ind Ecol 15:908–921. https://doi.org/10.1111/j.1530-9290.2011.00375.x

Patel M, Zhang X, Kumar A (2016) Techno-economic and life cycle assessment on lignocellulosic biomass thermochemical conversion technologies: a review. Renew Sustain Energy Rev 53:1486–1499. https://doi.org/10.1016/j.rser.2015.09.070

Jeswani HK, Whiting A, Azapagic A (2020) Environmental and economic sustainability of biomass heat in the UK. Energy Technol 8:1901044

Siles JA, Vargas F, Gutiérrez MC et al (2016) Integral valorisation of waste orange peel using combustion, biomethanisation and co-composting technologies. Bioresour Technol 211:173–182. https://doi.org/10.1016/j.biortech.2016.03.056

Negro V, Ruggeri B, Fino D, Tonini D (2017) Life cycle assessment of orange peel waste management. Resour Conserv Recycl 127:148–158. https://doi.org/10.1016/j.resconrec.2017.08.014

Ortiz DL, Batuecas E, Orrego CE et al (2020) Sustainable management of peel waste in the small-scale orange juice industries: a Colombian case study. J Clean Prod 265:121587. https://doi.org/10.1016/j.jclepro.2020.121587

Aguilar-Sánchez P, Navarro-Pineda FS, Sacramento-Rivero JC, Barahona-Pérez LF (2018) Life-cycle assessment of bioethanol production from sweet sorghum stalks cultivated in the state of Yucatan, Mexico. Clean Technol Environ Policy 20:1685–1696. https://doi.org/10.1007/s10098-017-1480-4

Navarro-Pineda FS, Handler R, Sacramento Rivero JC (2019) Conceptual design of a dedicated-crop biorefinery for Jatropha curcas using a systematic sustainability evaluation. Biofuels, Bioprod Biorefining 13:86–106. https://doi.org/10.1002/bbb.1940

White R, Navarro-Pineda FS, Cockerill T et al (2019) Techno-economic and life cycle impacts analysis of direct methanation of glycerol to bio-synthetic natural gas at a biodiesel refinery. Energies 12.https://doi.org/10.3390/en12040678

Lecksiwilai N, Gheewala SH, Sagisaka M, Yamaguchi K (2016) Net Energy Ratio and Life cycle greenhouse gases (GHG) assessment of bio-dimethyl ether (DME) produced from various agricultural residues in Thailand. J Clean Prod 134:523–531. https://doi.org/10.1016/j.jclepro.2015.10.085

Shonnard DR, Klemetsrud B, Sacramento-Rivero J et al (2015) A review of environmental life cycle assessments of liquid transportation biofuels in the Pan American Region. Environ Manag 56.https://doi.org/10.1007/s00267-015-0543-8

Aburto J, Martinez-Hernández E, Amezcua-Allieri MA (2021) Techno-economic feasibility of steam and electric power generation from the gasification of several biomass in a sugarcane mill. BioEnergy Res. https://doi.org/10.1007/s12155-021-10311-2

Global Combustion Systems (2021) Oil fuel properties. In: Oil fuel Prop. http://www.globalcombustion.com/oil-fuel-properties/. Accessed 16 Aug 2021

Ben SR, Combarnous M (2011) Study of orange peels dryings kinetics and development of a solar dryer by forced convection. Sol Energy 85:570–578. https://doi.org/10.1016/j.solener.2011.01.001

Welfle A, Gilbert P, Thornley P, Stephenson A (2017) Generating low-carbon heat from biomass: life cycle assessment of bioenergy scenarios. J Clean Prod 149:448–460. https://doi.org/10.1016/j.jclepro.2017.02.035

Gerssen-Gondelach SJ, Saygin D, Wicke B et al (2014) Competing uses of biomass: assessment and comparison of the performance of bio-based heat, power, fuels and materials. Renew Sustain Energy Rev 40:964–998. https://doi.org/10.1016/j.rser.2014.07.197

Tauro R, García CA, Skutsch M, Masera O (2018) The potential for sustainable biomass pellets in Mexico: an analysis of energy potential, logistic costs and market demand. Renew Sustain Energy Rev 82:380–389. https://doi.org/10.1016/j.rser.2017.09.036

US Department of Energy (2015) Steam turbine calculator. In: Steam Calc. https://www4.eere.energy.gov/manufacturing/tech_deployment/amo_steam_tool/equipTurbine. Accessed 9 Aug 2021

Lu HR, El Hanandeh A (2017) Assessment of bioenergy production from mid-rotation thinning of hardwood plantation: life cycle assessment and cost analysis. Clean Technol Environ Policy 19:2021–2040

Sua-Iam G, Makul N (2015) Utilization of coal-and biomass-fired ash in the production of self-consolidating concrete: a literature review. J Clean Prod 100:59–76

Silva FC, Cruz NC, Tarelho LAC, Rodrigues SM (2019) Use of biomass ash-based materials as soil fertilisers: critical review of the existing regulatory framework. J Clean Prod 214:112–124

Acknowledgements

We acknowledge the input of all participants in the Line 4 of the Solid Biofuels Cluster.

Funding

This work received support from the Mexican Council for Science and Technology (CONACYT) and the Mexican Secretariat of Energy (Fondo de Sustentabilidad Energética) through the project with Award Number 246911 “Clúster de biocombustibles sólidos para generación térmica y eléctrica.”

Author information

Authors and Affiliations

Contributions

All authors participated in the writing of this paper.

Corresponding author

Ethics declarations

Ethics Approval

There was no work with microorganisms, animal, or human subjects that require considering ethical issues.

Consent to Participate

Verbal informed consent was obtained from all individuals who participated in the study. Anonymity has been granted to all participants (and industries) who wished to stay anonymous.

Consent for Publication

Consent has been obtained from the management of the fruit processing plant for using process data and location names. All authors have given their consent for publication of this article. There is no need for consent from any other authors.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Navarro-Pineda, F.S., Equihua-Sánchez, M., Grande-Acosta, G.K. et al. Assessment of the Environmental and Economic Performance of Heat Generation from Orange Peels and Sugarcane Straw. Bioenerg. Res. 15, 1747–1763 (2022). https://doi.org/10.1007/s12155-021-10326-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10326-9