Abstract

In the present study, WC-10Co with TiC, VC and (Ta, Nb)C as the inhibitors to the grain growth was prepared using high energy ball milling and the subsequent HIP process at various temperatures. Phase evolution and microstructural studies were performed for the milled and sintered samples by x-ray diffraction, vibrating sample magnetometry, field emission scanning electron microscopy and transmission electron microscopy. Also, the density and microhardness of the sintered samples were measured. It was found that densification and grain-growth rate were sensitive to the sintering temperature, type and overall content of the additives. The samples sintered at the higher temperature showed better densification and hardness, with lower porosities. The additives were found to have significant influence on the microstructure and properties of the sintered products. Sintered samples containing additives had considerably improved microhardness, but densification was lowered up to 4.8%. However, the highest microhardness was 1920 HV for the sample with the three types of additives sintered at 1480 °C.

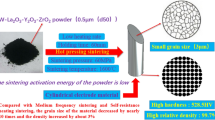

Graphical Abstract

Similar content being viewed by others

References

J.M. Marshall and A. Kusoffsky, Binder Phase Structure in Fine and Coarse WC-Co Hard Metals with Cr and v Carbide Additions, Int. J. Refract. Met. Hard Mater., 2013, 40, p 27–35. https://doi.org/10.1016/j.ijrmhm.2013.04.001

B. Yu, Y. Li, Q. Lei and Y. Nie, Microstructures and Mechanical Properties of WC-Co-XCr-Mo Cement Carbides, J. Alloys Compd., 2019, 771, p 636–642. https://doi.org/10.1016/j.jallcom.2018.08.255

J. García, V. Collado Ciprés, A. Blomqvist and B. Kaplan, Cemented Carbide Microstructures: A Review, Int. J. Refract. Met. Hard Mater., 2019, 80, p 40–68. https://doi.org/10.1016/j.ijrmhm.2018.12.004

M. Bacia, E. Pauty, S. Lay, C.H. Allibert and A. Delano, Cr-Rich Layer at the WC/Co Interface in Cr-Doped WC-Co Cermets: Segregation or Metastable Carbide?, J. Crystal Growth, 2004, 270, p 219–227.

E. Ghasali, T. Ebadzadeh, M. Alizadeh and M. Razavi, Mechanical and Microstructural Properties of WC-Based Cermets: A Comparative Study on the Effect of Ni and Mo Binder Phases, Ceram. Int., 2018, 44(2), p 2283–2291.

Z. Lin, J. Xiong, Z. Guo, W. Zhou, W. Wan and L. Yang, Effect of Mo2C Addition on the Microstructure and Fracture Behavior of (W, Ti)C-Based Cemented Carbides, Ceram. Int., 2014, 40(PB), p 16421–16428. https://doi.org/10.1016/j.ceramint.2014.07.150

M. Mohammadpour, P. Abachi, N. Parvin and K. Pourazrang, Study of Cemented Carbonitrides with Nickel as Binder: Experimental Investigations and Computer Calculations, Int. J. Refract. Met. Hard Mater., 2012, 31, p 164–170. https://doi.org/10.1016/j.ijrmhm.2011.10.011

W. Liu, X. Song, J. Zhang, F. Yin and G. Zhang, A Novel Route to Prepare Ultrafine-Grained WC-Co Cemented Carbides, J. Alloys Compd., 2008, 458(1–2), p 366–371.

X. Li, Y. Liu, W. Wei, M. Du, K. Li, J. Zhou and K. Fu, Influence of NbC and VC on Microstructures and Mechanical Properties of WC-Co Functionally Graded Cemented Carbides, Mater. Des., 2016, 90, p 562–567. https://doi.org/10.1016/j.matdes.2015.10.156

P.K. Katiyar and N.S. Randhawa, Corrosion Behavior of WC-Co Tool Bits in Simulated (Concrete, Soil, and Mine) Solutions with and without Chloride Additions, Int. J. Refract. Met. Hard Mater., 2019, 85(July), p 105062. https://doi.org/10.1016/j.ijrmhm.2019.105062

Z.S. Park, S.J. Lee, T. Lee, J.H. Kim and Y.H. Moon, Fabrication of Long Tubular Parts Made of Tungsten-Heavy Alloys by Inductive Bonding of Multiple Tubes, Int. J. Refract. Met. Hard Mater., 2019, 85(August), p 105058. https://doi.org/10.1016/j.ijrmhm.2019.105058

T.A. Fabijanić, Ž Alar and D. Ćorić, Influence of Consolidation Process and Sintering Temperature on Microstructure and Mechanical Properties of near Nano- and Nano-Structured WC-Co Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2016, 54, p 82–89.

K. Liu, Z. Wang, Z. Yin, L. Cao and J. Yuan, Effect of Co Content on Microstructure and Mechanical Properties of Ultrafine Grained WC-Co Cemented Carbide Sintered by Spark Plasma Sintering, Ceram. Int., 2018, 44(15), p 18711–18718. https://doi.org/10.1016/j.ceramint.2018.07.100

D.D. Phuong, P. Van Trinh, L. Van Duong and L.D. Chung, Influence of Sintering Temperature on Microstructure and Mechanical Properties of WC-8Ni Cemented Carbide Produced by Vacuum Sintering, Ceram. Int., 2016, 42(13), p 14937–14943. https://doi.org/10.1016/j.ceramint.2016.06.134

A. Saboori, C. Novara, M. Pavese, C. Badini, F. Giorgis and P. Fino, An Investigation on the Sinterability and the Compaction Behavior of Aluminum/Graphene Nanoplatelets (GNPs) Prepared by Powder Metallurgy, J. Mater. Eng. Perform., 2017, 26(3), p 993–999.

W. Wang, H. Zhou, Q. Wang, Y. Gao and K. Wang, Influence of Mechanical Alloying and Sintering Temperature on the Microstructure and Mechanical Properties of a Ti-22Al-25Nb Alloy, J. Mater. Eng. Perform., 2020, 29(3), p 1686–1695. https://doi.org/10.1007/s11665-020-04610-6

D.H. Xiao, Y.H. He, W.H. Luo and M. Song, Effect of VC and NbC Additions on Microstructure and Properties of Ultrafine WC-10Co Cemented Carbides, Trans. Nonferrous Met. Soc. China (English Ed. The Nonferrous Metals Society of China, 2009, 19(6), p 1520–1525. https://doi.org/10.1016/S1003-6326(09)60063-7

W. Su, Y. Wen and Q. Zhang, Effects of Ni and Cu Additions on Microstructures, Mechanical Properties and Wear Resistances of Ultra-Coarse Grained WC–6Co Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2018, 70(September2017), p 176–183. https://doi.org/10.1016/j.ijrmhm.2017.10.009

J. Jia, H. Liu, Z. Yang, W. Peng, Y. Xu, Y. Yang and J. Luo, Microstructure, Densification and Mechanical Properties of Ti-22Al-25Nb Alloy Fabricated by Spark Plasma Sintering, J. Mater. Eng. Perform., 2020, 29(2), p 1101–1112. https://doi.org/10.1007/s11665-020-04622-2

A.M. Soleimanpour, P. Abachi and A. Simchi, Microstructure and Mechanical Properties of WC-10Co Cemented Carbide Containing VC or (Ta, Nb)C and Fracture Toughness Evaluation Using Different Models, Int. J. Refract. Met. Hard Mater., 2012, 31, p 141–146. https://doi.org/10.1016/j.ijrmhm.2011.10.004

M. Mahmoodan, H. Aliakbarzadeh and R. Gholamipour, Microstructural and Mechanical Characterization of High Energy Ball Milled and Sintered WC-10 Wt%Co-XTaC Nano Powders, Int. J. Refract. Met. Hard Mater., 2009, 27(4), p 801–805. https://doi.org/10.1016/j.ijrmhm.2009.02.001

D. Wang, C. Yu, X. Zhou, J. Ma, W. Liu, and Z. Shen, Dense Pure Tungsten Fabricated by Selective Laser Melting. Appl. Sci., 2017, 7(4), 1–13. https://doi.org/10.3390/app7040430

B. AlMangour, D. Grzesiak and J.M. Yang, Nanocrystalline TiC-Reinforced H13 Steel Matrix Nanocomposites Fabricated by Selective Laser Melting, Mater. Des., 2016, 96, p 150–161.

W. Zhou, J. Xiong, W. Wan, Z. Guo, Z. Lin, S. Huang, L. Tang and H. Zhong, The Effect of NbC on Mechanical Properties and Fracture Behavior of WC-10Co Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2015, 50, p 72–78. https://doi.org/10.1016/j.ijrmhm.2014.11.006

N.A.N. Balbino, E.O. Correa, L. de Carvalho Valeriano and D.A. Amâncio, Microstructure and Mechanical Properties of 90WC-8Ni-2Mo2C Cemented Carbide Developed by Conventional Powder Metallurgy, Int. J. Refract. Met. Hard Mater., 2017, 68(June), p 49–53. https://doi.org/10.1016/j.ijrmhm.2017.06.009

W. Zeng, X. Gan, Z. Li and K. Zhou, Effect of TiC Addition on the Microstructure and Mechanical Properties of TiN-Based Cermets, Ceram. Int., 2017, 43(1), p 1092–1097. https://doi.org/10.1016/j.ceramint.2016.10.046

K. Choi, N.M. Hwang and D.Y. Kim, Effect of VC Addition on Microstructural Evolution of WC-Co Alloy: Mechanism of Grain Growth Inhibition, Powder Metall., 2000, 43(2), p 168–172.

S. Dehlouz, A. Alhussein, F. Lacroix, C. Fradet, S. Seghar and S. Azem, Self-Combustion of Ti-C and Ti-Al Powder Mixture in a Nitrogen Atmosphere: Product Application as Reinforcement in Metal Matrix Composites, J. Mater. Eng. Perform., 2020, 29(3), p 1984–1994.

A.S. Kurlov and A.A. Rempel, Effect of Sintering Temperature on the Phase Composition and Microhardness of WC-8 Wt% Co Cemented Carbide, Inorg. Mater., 2007, 43(6), p 602–607.

Z. Huang, X. Ren, M. Liu, C. Xu, X. Zhang, S. Guo and H. Chen, Effect of Cu on the Microstructures and Properties of WC-6Co Cemented Carbides Fabricated by SPS, Int. J. Refract. Met. Hard Mater., 2017, 62, p 155–160. https://doi.org/10.1016/j.ijrmhm.2016.06.007

G.H. Ha and B.K. Kim, Synthesis of Ultrafine WC/Co Powder by Mechanochemical Process, Powder Metall., 2002, 45(1), p 29–32.

V. Bonache, M.D. Salvador, D. Busquets and E.F. Segovia, Fabrication of Ultrafine and Nanocrystalline WC-Co Mixtures by Planetary Milling and Subsequent Consolidations, Powder Metall., 2011, 54(3), p 214–221.

G.H. Lee and S. Kang, Sintering of Nano-Sized WC-Co Powders Produced by a Gas Reduction-Carburization Process, J. Alloys Compd., 2006, 419(1–2), p 281–289.

J.R. Groza, Chapter 13 Powder Consolidation, Pergamon Mater. Ser., 1999, 2(C), p 347–372.

Z. Xiao, S. Yu, Y. Li, S. Ruan, L.B. Kong, Q. Huang, Z. Huang, K. Zhou, H. Su, Z. Yao, W. Que, Y. Liu, T. Zhang, J. Wang, P. Liu, D. Shen, M. Allix, J. Zhang and D. Tang, Materials Development and Potential Applications of Transparent Ceramics: A Review, Mater. Sci. Eng. R Rep., 2020, 139(May), p 100518. https://doi.org/10.1016/j.mser.2019.100518

D.A. Sandoval, J.J. Roa, O. Ther, E. Tarrés and L. Llanes, Micromechanical Properties of WC-(W, Ti, Ta, Nb)C-Co Composites, J. Alloys Compd., 2019, 777, p 593–601.

A. Kulmburg and F. Zeman, Influence of Carbon Content on Wc–Tic–(Tanb)c Cemented Carbides, Powder Metall., 1981, 24(4), p 181–184.

M.N. Rahaman, Kinetics and Mechanisms of Densification. Sinter. Adv. Mater., 2010, p 33–64. https://doi.org/10.1533/9781845699949.1.33

O. Seo, S. Kang and E.J. Lavernia, Growth Inhibition of Nano WC Particles in WC-Co Alloys during Liquid-Phase Sintering, Mater. Trans., 2003, 44(11), p 2339–2345.

J. Kim and Y.J. Suh, Temperature Dependent Elastic and Thermal Expansion Properties of W3Co3C, W6Co6C and W4Co2C Ternary Carbides, J. Alloys Compd., 2016, 666, p 262–269. https://doi.org/10.1016/j.jallcom.2016.01.061

M.R. Mahundla, W.R. Matizamhuka, and M.B. Shongwe, The Effect of Densification on Hardness of Ti, Ti-6Al-4V, Ti-34Nb-25Zr Alloy Produced by Spark Plasma Sintering. Mater. Today Proc., Elsevier Ltd, 2020, (xxxx), p 4–7, doi:https://doi.org/10.1016/j.matpr.2020.03.468.

A.O. Adegbenjo, B.A. Obadele and P.A. Olubambi, Densification, Hardness and Tribological Characteristics of MWCNTs Reinforced Ti6Al4V Compacts Consolidated by Spark Plasma Sintering, J. Alloys Compd., 2018, 749, p 818–833. https://doi.org/10.1016/j.jallcom.2018.03.373

A. Babapoor, M.S. Asl, Z. Ahmadi and A.S. Namini, Effects of Spark Plasma Sintering Temperature on Densification, Hardness and Thermal Conductivity of Titanium Carbide, Ceram. Int., 2018, 44(12), p 14541–14546. https://doi.org/10.1016/j.ceramint.2018.05.071

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Koroghli, M., Alimirzaloo, V., Mohammadzadeh, H. et al. Sintering Behavior of WC-Co with Additives of TiC, VC, and (Ta, Nb)C: Microstructural and Mechanical Features. J. of Materi Eng and Perform 31, 814–824 (2022). https://doi.org/10.1007/s11665-021-06209-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06209-x