Abstract

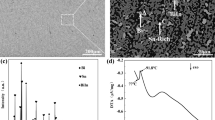

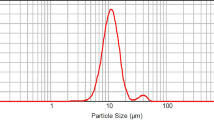

Due to the directions and environmental legislations from RoHS (Restrictions of Hazardous Substances), WEEE (World Electrical and Electronic Equipment) and from various countries, lead is banned from alloy making. Lead free solder alloys thus become very popular in electronic package industries. The research people around the globe started searching for new lead free solder alloys which can replace the Sn–Pb alloy. Many lead free solder alloys were identified. SAC alloys were very popular among this. The presence of 3 and 4% of Ag content adds the cost as well as threat were detected in the medical devices due to electrochemical migration. Sn–1Cu–1Ni–1Ag is a promising alloy with good mechanical properties. The corrosion behavior of the Sn–1Cu–1Ni–xAg (x = 0, 0.5, 1% by wt.) was studied in this paper using 3.5% by wt. NaCl solution. Microstructure analysis, EDAX analysis was also done. The results show that the corrosion rates were decreased with the addition of Ag. The corrosion rates for 7 days and 14 days were almost same. Combining the mechanical properties and corrosion resistance, Sn–1Cu–1Ni–1Ag is a promising lead free solder alloy.

Similar content being viewed by others

REFERENCES

Schwartz, M.M., Soldering: Understanding the Basics, Materials Park, OH: ASM Int., 2014.

NCMS Lead-Free Solder Project Final Report 0401RE96, Ann Arbor, MI: National Center for Manufacturing Sciences, 1997.

Mccormack, M. and Jin, S., J. Electron. Mater., 1994, vol. 23, no. 8, p. 715. https://doi.org/10.1007/BF02651364

Glazer, J., J. Electron. Mater.,1994, vol. 23, no. 8, p. 693. https://doi.org/10.1007/BF02651361

Management Methods for Restriction of the Use of Hazardous Substances in Electrical and Electronic Products. http://www.chinarohs.com. Accessed July 1, 2019.

J-Moss (Japanese RoHS). http://home.jeita.or.jp/eps/ jmoss_en.htm. Accessed July 1, 2019.

Act for Resource Recycling of Electrical and Electronic Equipment and Vehicles. http://www.rsjtechnical.com/ images/Documents/Korea_RoHS_ELV_April_2007_ EcoFrontier.pdf. Accessed July 1, 2019.

Turkey Announces RoHS Legislation. http://www.intertek.com/news/2008/10-28-turkeyannounces-rohs-legislation/. Accessed July 1, 2019.

Restrictions on the Use of Certain Hazardous Substances (RoHS) in Electronic Devices. https://www.dtsc.ca. gov/HazardousWaste/RoHS.cfm. Accessed July 1, 2019.

Tu, K.N., Gusak, A.M., and Li, M., J. Appl. Phys., 2003, vol. 93, pp. 1335–1353.

Ma, H.T. and Suhling, J.C., J. Mater. Sci., 2009, vol. 44, pp. 1141–1158.

Wang, M., Wang, J., Feng, H., and Ke, W., J. Mater. Sci.: Mater. Electron., 2012, vol. 23, pp. 148–155.

Jayesh, S. and Elias, J., Met. Mater. Int., 2019. https://doi.org/10.1007/s12540-019-00305-3

Jayesh, S. and Elias, J., Lett. Mater., 2019, vol. 9, no. 2, pp. 239–242. https://doi.org/10.22226/2410-3535-2019-2-239-242

Jayesh, S. and Elias, J., Int. J. Simul. Multidiscip. Des. Optim.,=IJSMDO 2019, vol. 10, p. A11. https://doi.org/10.1051/smdo/2019013

Tsao, L.C., in Corrosion Resistance, Shanghai: In Tech, 2012, pp. 107–132.

Yu, D.Q., Jillek, W., and Schmitt, E., J. Mater. Sci.: Mater. Electron., 2006, vol. 17, pp. 219–227.

Chuin Wern See, et al., Procedia Chem., 2016, vol. 19, pp. 847–854.

Nurwahida, M.Z., et al., IOP Conf. Ser.: Mater. Sci. Eng., 2018, vol. 318, p. 12004.

Sarveswaran, C., et al., AIP Conf. Proc., 2017, vol. 1838, p. 020003. https://doi.org/10.1063/1.4982175

Li, D., Conway, P.P., and Liu, C., Corros. Sci., 2008, vol. 50, pp. 995–1004.

Kireev, S.Yu., Prot. Met. Phys. Chem. Surf., 2016, vol. 52, p. 1134. https://doi.org/10.1134/S2070205116070091

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jayesh, S., Jacob Elias Investigations on the Corrosion Properties of Sn–1Cu–1Ni–xAg Lead Free Solders in 3.5% NaCl Solution. Prot Met Phys Chem Surf 57, 858–865 (2021). https://doi.org/10.1134/S2070205121040110

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205121040110