Abstract

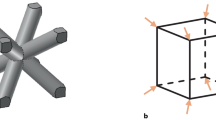

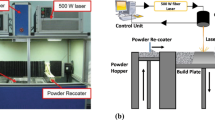

This study includes experimental research conducted to produce lattice structures and to examine their mechanical properties by taking advantage of the design freedom provided by additive manufacturing. Much of the existing literature involves mainly process parameters on mechanical behaviors. Thus, more lattice geometry studies are needed. In this study, different lattice structures designed according to the unit cell types selected through the SpaceClaim program were produced using AlSi10Mg powder material with the laser powder bed fusion (LPBF) method the metal additive manufacturing production methods. Cell sizes, Maxwell criterion, relative densities, and mechanical behaviors under semi-static compression force were investigated. It was concluded that with increasing relative density, the strength increased, and the structures with stress-dominating were more resistant than those with bending-dominating strength. It was determined that the mechanical properties of lattices depended on unit cell design and LPBF process parameters. The C1 and C2 coefficients of lattices produced by the LPBF process included in the Gibson and Ashby equation were determined.

Graphic Abstract

Similar content being viewed by others

References

M.F. Ashby, A. Evans, N.A. Fleck, J.W. Hutchinson, H.N.G. Wadley, Metals Foams: A Design Guide, 1st edn. (Elsevier Science, Amsterdam, 2000)

J.G. Kaufman, E.L. Rooy, Aluminum Alloy Castings: Properties, Processes, and Applications (ASM International, Russell Township, 2004), pp. 39–46

A.T. Erturk, I. Aydin, Acta Phys. Pol. A 131, 470 (2017)

A.T. Erturk, T. Sahin, Acta Phys. Pol. A 131, 39 (2017)

A.T. Erturk, Acta Phys. Pol. A 129, 592 (2016)

A. Nazir, K.M. Abate, A. Kumar, J.-Y. Jeng, Int. J. Adv. Manuf. Technol. 104, 3489 (2019)

M.G. Rashed, M. Ashraf, R.A.W. Mines, P.J. Hazell, Mater. Design 95, 518 (2016)

N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck, R. Hague, Prog. Mater. Sci. 106, 100578 (2019)

E.O. Olakanmi, R.F. Cochrane, K.W. Dalgarno, Prog. Mater. Sci. 74, 401 (2015)

R.R.J. Sélo, S. Catchpole-Smith, I. Maskery, I. Ashcroft, C. Tuck, Addit. Manuf. 34, 101214 (2020)

L.J. Gibson, Mater. Sci. Eng. A 110, 1 (1989)

C. Yan, L. Hao, A. Hussein, P. Young, J. Huang, W. Zhu, Mater. Sci. Eng. A 628, 238 (2015)

W. Li, F. Sun, P. Wang, H. Fan, D. Fang, Compos. Part A Appl. Sci. Manuf. 81, 313 (2016)

T. Wohlers, T. Gornet, Wohlers report 2014: 3D printing and additive manufacturing state of the industry annual worldwide progress report (Wohlers Associates, Colorado, 2014)

W. Brooks, C. Sutcliffe, W. Cantwell, P. Fox, J. Todd, R. Mines, Rapid design and manufacture of ultralight cellular materials, in Proceedings of the 2005 International Solid Freeform Fabrication Symposium, Austin, 2005, pp. 231–241

H. Zhou, M. Zhao, Z. Ma, D.Z. Zhang, G. Fu, Int. J. Mech. Sci. 175, 105480 (2020)

ASM handbook committee, Properties and selection: Nonferrous alloys and special-purpose materials, vol. 2 (ASM International, Russell Township, 1990)

K. Kempen, L. Thijs, J. Van Humbeeck, J.-P. Kruth, Phys. Proc. 39, 439 (2012)

L. Thijs, K. Kempen, J.-P. Kruth, J. Van Humbeeck, Acta Mater. 61, 1809 (2013)

X.X. Zhang, A. Lutz, H. Andrä, M. Lahres, W.M. Gan, E. Maawad, C. Emmelmann, Int. J. Plast. 139, 102946 (2021)

J. Samei, M. Amirmaleki, M.S. Dastgiri, C. Marinelli, D.E. Green, Mater. Lett. 255, 126512 (2019)

N.T. Aboulkhair, N.M. Everitt, I. Ashcroft, C. Tuck, Addit. Manuf. 1–4, 77 (2014)

M. Giovagnoli, G. Silvi, M. Merlin, M.T. Di Giovanni, Mater. Sci. Eng. A 802, 140613 (2021)

D. Manfredi, F. Calignano, M. Krishnan, R. Canali, E.P. Ambrosio, E. Atzeni, Materials 6, 856 (2013)

M. Krishnan, E. Atzeni, R. Canali, F. Calignano, D. Manfredi, E.P. Ambrosio, L. Iuliano, Rapid Prototyp. J. 20, 449 (2014)

M. Ghasri-Khouzani, H. Peng, R. Attardo, P. Ostiguy, J. Neidig, R. Billo, D. Hoelzle, M.R. Shankar, J. Manuf. Process. 37, 274 (2019)

A. Suzuki, K. Sekizawa, M. Liu, N. Takata, M. Kobashi, Adv. Eng. Mater. 21, 1900571 (2019)

X. Liu, K. Sekizawa, A. Suzuki, N. Takata, M. Kobashi, T. Yamada, Materials 13, 2902 (2020)

M.E. Bulduk, A.T. Ertürk, M. Coşkun, G. Tarakçı, U. Ergin, The microstructure and mechanical propertıes of porous structures produced from AlSi10Mg by direct metal laser sintering, in Proceedings of the Additive Manufacturing Conference (AMCTURKEY 2019), Istanbul, 17–18 October 2019, pp. 147–150

D. Herzog, V. Seyda, E. Wycisk, C. Emmelmann, Acta Mater. 117, 371 (2016)

R. Lumley, Technical data sheets for heat-treated aluminum high-pressure die castings. Die Casting Eng. 2008, 32

Z. Xiao, Y. Yang, R. Xiao, Y. Bai, C. Song, D. Wang, Mater. Design 143, 27 (2018)

V.S. Deshpande, N.A. Fleck, M.F. Ashby, J. Mech. Phys. Solids 49, 1747 (2001)

T. Maconachie, M. Leary, B. Lozanovski, X. Zhang, M. Qian, O. Faruque, M. Brandt, Mater. Design 183, 108137 (2019)

G. Özer, G. Tarakçı, M.S. Yılmaz, Z.C. Öter, Ö. Sürmen, Y. Akça, M. Coşkun, E. Koç, Mater. Corros. 71, 365 (2020)

G.M. Choi, D.G. Kim, B. Im, H.J. Chae, Met. Mater. Int. 25, 946 (2019)

G.M. Karthik, H.S. Kim, Met. Mater. Int. 27, 1 (2021)

G. Özer, A. Karaaslan, Steel Res. Int. 91, 2000195 (2020)

Acknowledgements

We would like to thank Dr. Ebubekir KOÇ and his team. The manager of Aluminum Testing Education and Research Center (ALUTEAM) for support for the study. We would like to express our gratitude to M.Sc. Eng. Mert COŞKUN for their assistance in production and analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Erturk, A.T., Bulduk, M.E., Tarakçi, G. et al. Investigation of the Microstructure and Mechanical Characteristics of Lattice Structures Produced by Laser Powder Bed Fusion Method. Met. Mater. Int. 28, 155–167 (2022). https://doi.org/10.1007/s12540-021-01038-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-021-01038-y