Abstract

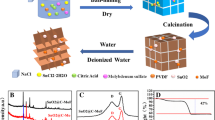

TiO2 has been considered as a promising anode material for lithium-ion batteries (LIBs) due to its low cost and high stability, but its low conductivity has greatly limited its application. In this study, the nitrogen-doped TiO2 (N-TiO2) with a uniform carbon coating was prepared by the solvothermal method. According the XPS results, the nitrogen was successfully doped in the TiO2. The N-doped TiO2 electrode exhibited obviously higher lithium-ion storage performance, of which the discharge capacity was 420 mAh g−1 under the current density 0.1 A g−1. Additionally, the superior long-term cycling stability was also observed with a reversible capacity of 148 mAh g−1 after 3000 cycles under 3 A g−1 current density. The result showed that after the nitrogen doped, the replacing of lattice oxygen with nitrogen can decrease the band-gap width and improve the conductivity of titanium oxide. Meanwhile, the oxygen vacancies on the surface of the material can adsorb a large number of lithium ions and produce significant pseudo-capacitance, thus, effectively increasing the specific capacity of the material. Therefore, the N-doped TiO2 electrode can present obviously higher lithium-ion storage performance.

Similar content being viewed by others

References

K. Mizushima, P.C. Jones, P.J. Wiseman et al., Mater. Res. Bull. 15, 783–789 (1980)

A.S. Nagelberg, W.L. Worrell, J. Solid State Chem. 29, 345–354 (1979)

C. Senthil, T. Kesavan, A. Bhaumik, et al., Electrochim. Acta. 255, 417–427 (2017)

(2017)

J. Li, J. Huang, J. Li, L. Cao, H. Dang, J. Alloys Compd. 727, 998–1005 (2017)

Y.Y. Zhang, Y.X. Tang, W.L. Li, X.D. Chen, ChemNanoMat. 8, 764–775 (2016)

A.S. Lee, W. Eom, H. Park, T.H. Han, ACS Appl. Mater. Interf. 9, 25332–25338 (2017)

A. Kashale, K.P. Gattu, K. Ghule, V.H. Ingole et al., Compos. B. Eng. 99, 297–304 (2016)

H. Han, T. Song, E.K. Lee, A. Devadoss, Y. Jeon, J. Ha et al., ACS Nano 6, 8308–8315 (2012)

Y.J. Hong, J.W. Yoon, J.H. Lee, Y.C. Kang, Chemistry 21, 371–376 (2015)

L. Wu, H. Lu, L. Xiao, X. Ai, H. Yang, Y. Cao, J. Mater. Chem. A. 3, 5708–5713 (2015)

J. Chen, Y. Zhang, G. Zou et al., Small 12, 5554–5563 (2016)

A.I. Hochbaum, P. Yang, Chem. Rev. 110, 527–546 (2010)

N.N. Wang, Z.C. Bai, Y.T. Qian, J. Yang, Adv. Mater. 28, 4126–4133 (2016)

J.Y. Liao, B.D. Luna, A. Manthiram, J. Mater. Chem. A 4, 801–806 (2015)

X.M. Yang, W. Chao, Y.C. Yang et al., J. Mater. Chem. A 3, 8800–8807 (2015)

K. Lan, L. Yao, Z. Wei et al., J. Am. Chem. Soc. 140, 4135–4143 (2018)

J. Chen, W.X. Song, H.S. Hou et al., Adv. Funct. Mater. 25, 6793–6801 (2015)

L. Wu, D. Buchholz, D. Bresser et al., J. Power Sources 251, 379–385 (2014)

F.H. Yang, Z.A. Zhang, H. Yu et al., Electrochim. Acta. 178, 871–876 (2015)

Y. Yang, Q. Fu, H. Zhao et al., J. Alloys Compd. 769, 257–263 (2018)

H. He, Q. Gan, H. Wang et al., Nano Energy 44, 217–227 (2018)

T. Lan, W. Zhang, N.L. Wu et al., Chemistry 23, 5059–5065 (2017)

A. Kashale, A.S. Rasal, G.P. Kamble et al., Composites 167, 44–50 (2019)

Y. Zhang, C. Wang, H. Hou et al., Adv. Energy Mater. 7(1600173), 1–12 (2017)

H. Yin, T. Lin, C. Yang et al., Chem. Eur. J. 19, 13313–13316 (2013)

M. Wei, T. Lin, W. Zhang et al., Chem. Eur. J. 23, 5059–5065 (2017)

M. Boniecki et al., Ceram. Int. 43, 10066–10070 (2017)

R. Vinodkumar, I. Navas, K. Porsezian et al., SPECTROCHIM ACTA A 118, 724–732 (2014)

S. Shang, X. Jiao, D. Chen, A.C.S. Appl, Mater. Interfaces 4, 860–865 (2012)

J. Li, J. Huang, J. Li et al., J. Alloys Compd. 784, 165–172 (2019)

N.C. Saha, H.G. Tompkins, J. Appl. Phys. 72, 3072–3079 (1992)

Y. Wu, X.W. Liu et al., Small 12, 3474–3474 (2016)

H. Cui, Z. Wei, C. Yang et al., J. Mater. Chem. A 2, 8612–8616 (2014)

W. Zhang, D. Liu, Electrochim. Acta 156, 53–59 (2015)

Q.M. Gan, H.N. He, Y.H. Zhu et al., ACS Nano 13, 9247–9258 (2019)

C. Chen, Y. Wen, X. Hu et al., Nat. Commun. 6, 6929 (2015)

Y. Qiao, X. Hu, Y. Liu et al., J. Mater. Chem. A 1, 10375–10381 (2013)

X. Bai, T. Li et al., Electrochim. Acta 187, 20–33 (2016)

J. Lee, Y.M. Chen et al., RSC Adv. 5, 99329–99338 (2015)

L. Tan, L. Pan, C.C. Cao et al., J. Power Sources 253, 193–200 (2014)

I. Takahashi, D.J. Payne, R.G. Pali, et al., Chem. Phys. Lett, 454, 314–317 (2008)

C. Savory, A. Ganose, W. Travis et al., J. Mater. Chem. A 4, 12648–12657 (2016)

Z. Jiang, W. Wei, D. Mao et al., Nanoscale 7, 784–797 (2015)

X. Wang, K. Zhang, X. Guo et al., New J. Chem. 38, 6139–6146 (2014)

J.C. Chang, T.C. Chiu, J.H. Chao et al., J. Mater. Chem. 21, 4605–4614 (2011)

Y.C. Yang, X.B. Ji et al., J. Mater. Chem. A 3, 5648–5655 (2015)

X. Chen, C. Burda et al., J. Am. Chem. Soc. 140, 4135–4143 (2018)

W. Jiao, N. Li, L. Wang, L, et al., Chem. Commun. 49, 3461–3463 (2013)

R.T. Asahi, T. Morikawa et al., Science 293, 269–271 (2001)

X. Wang, Z. Li, J. Shi et al., Chem. Rev. 114, 9346–9384 (2014)

L. Zhao, T, Tang, W, Chen, et al., Green Energy Environ. 3, 277–285 (2018)

Y.L. Xing, S.B. Wang et al., Power Sourc 385, 10–17 (2018)

Z. Lu, C.T. Yip et al., ChemPlusChem 77, 991–1000 (2012)

Y. Hu, Y. Li et al., ACS Appl. Mater. Interf 12, 21709–21719 (2020)

X. Yang, C. Wang, Y. Yang et al., J. Mater. Chem. A 3, 8800–8807 (2015)

Y. Li, M.S. Chen, J. Cheng et al., Langmuir 36, 2255–2263 (2020)

J. Han, A. Hirata, J. Du et al., Nano Energy 49, 354–362 (2018)

V. Augustyn, J. Come, M.A. Lowe et al., Nat. Mater. 12, 518–522 (2013)

Acknowledgements

This work was supported by Open fund of Fujian Provincial Key Laboratory of Functional Materials and Applications (Xiamen University of Technology Fma 2018009), Fujian Provincial Education Department Fundamental (No. JT180421, JT180423, JT180424), and Natural Science Foundation of Fujian Province (2019J01871)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sun, JJ., Lei, CX., Li, ZY. et al. Nitrogen-doped/carbon-coated 2D TiO2 Scaly clusters as high-performance anode for Lithium-ion batteries. J Mater Sci: Mater Electron 32, 23798–23810 (2021). https://doi.org/10.1007/s10854-021-06708-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06708-6