Abstract

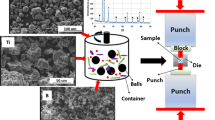

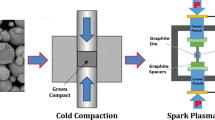

This study investigates the interface, microstructure, and mechanical properties of layered Ni/Ni-Ni3Al/Ni composite, fabricated by spark plasma sintering (SPS). Crack propagation behavior and joining mechanisms of particles in this layered composite were comprehensively studied and discussed. Ni3Al powders were first synthesized using mechanical alloying. Particulate Ni-Ni3Al composite was then produced by mixing 60 wt.% Synthesized Ni3Al and 40 wt.% Ni powders. The layered composite was then synthesized by SPS. Samples were held at 970°C for 10 minutes to do sintering. Results showed that a uniform interface has been formed between different layers of composite, without any obvious evidence of delamination, cracks, or flaws in-between layers. Moreover, there was hardly any sharp boundary/interface and necking between particles is discernible, inferring that applied sintering has resulted in rather complete densification. Based on the obtained results, interfaces were categorized into three different interface types: Ni-Ni, Ni3Al-Ni3Al, and Ni-Ni3Al. Results showed that intermetallic joints were less diffused and were less sintered, while metallic interfaces were much more diffused. Overall, complete sintering and diffusion for metal and kiss bonding or even cavities for intermetallic interfaces are more usual. The attribution of different interface structures to the mechanical properties and fracture behavior of the fabricated composite was thoroughly discussed. Results showed that a sample with a mixed Ni/Ni3Al mid-layer has an improved shear strength, when compared to the case where pure Ni3Al is used as the mid-layer.

Similar content being viewed by others

References

P. Mardiha, A. Bahrami and A. Mohammadnejad, Towards a High Strength Ductile Ni/Ni3Al/Ni Multilayer Composite Using Spark Plasma Sintering, Sci. Sinter., 2019, 51(4), p 401–408.

X. Yang, X. Peng and F. Wang, Size Effect of Al Particles on the Structure and Oxidation of Ni/Ni3Al Composites Transformed from Electrodeposited Ni–Al films, Scripta Mater., 2007, 56(6), p 509–512.

X.K. Meng, H. Shen, H. Vehoff, S. Mathur and A.H.W. Ngan, Fractography, Elastic Modulus And Oxidation Resistance of novel Metal-Intermetallic Ni/Ni3Al multilayer films, J. Mater. Research, 2002, 17(4), p 790–796.

A. Terzić, N. Obradović, V. Pouchly, J. Stojanović, K. Maca and V.B. Pavlović, Microstructure and Phase Composition of Steatite Ceramics Sintered by Traditional and Spark Plasma Sintering, Sci. Sinter., 2018, 50, p 299–312.

Y. Li, J. Zhao, G. Zeng, C. Guan and X. He, Ni/Ni3Al Microlaminate Composite Produced by EB-PVD and the Mechanical Properties, Mater. Lett., 2004, 58(10), p 1629–1633.

A. Mohammadnejad, A. Bahrami, M. Sajjadi, P. Karimi, H.R. Fozveh, M. Yazdan Mehr (2018) Microstructure and mechanical properties of spark plasma sintered nanocrystalline Ni3Al-xB (0.0< x< 1.5 at%) Alloy, Mater. Today Commun. 17, 161-168.

P. Dong, Z. Wang, W. Wang, S. Chen and J. Zhou, Understanding the Spark Plasma Sintering from the View of Materials Joining, Scripta Mater., 2016, 123, p 118–121.

W.R. Pinc, M. Di Prima, L.S. Walker, Z.N. Wing and E.L. Corral, Spark Plasma Joining of ZrB2–SiC Composites Using zirconium–Boron Reactive Filler Layers, J. Am Ceramic Soc., 2011, 94(11), p 3825–3832.

S. Grasso, P. Tatarko, S. Rizzo, H. Porwal, C. Hu, Y. Katoh, M. Salvo, M.J. Reece and M. Ferraris, Joining of β-SiC by Spark Plasma Sintering, J. European Ceramic Soc., 2014, 34(7), p 1681–1686.

S. Rizzo, S. Grasso, M. Salvo, V. Casalegno, M.J. Reece and M. Ferraris, Joining of C/SiC Composites by Spark Plasma Sintering Technique, J. European Ceramic Society, 2014, 34(4), p 903–913.

T. Okuni, Y. Miyamoto, H. Abe and M. Naito, Joining of Silicon Carbide and Graphite by Spark Plasma Sintering, Ceramics Int., 2014, 40(1), p 1359–1363.

K. Matsugi, Y. Wang, T. Hatayama, O. Yanagisawa and K. Syakagohri, Application of Electric Discharge Process in Joining Aluminum and Stainless Steel Sheets, J. Mater. Proc. Tech., 2003, 135(1), p 75–82.

C.R. Liu, J.F. Zhao, X.Y. Lu, Q.S. Meng, Y.P. Zhao and Z.A. Munir, Field-Assisted Diffusion Bonding and Bond Characterization of Glass to aluminum, J. Mater. Science, 2008, 43(15), p 5076–5082.

R. Bermejo, Y. Torres, A.J. Sanchez-Herencia, C. Baudín, M. Anglada and L. Llanes, Fracture Behaviour of an Al2O3–ZrO2 Multi-Layered Ceramic with Residual Stresses Due to Phase Transformations, Fatigue & Fracture of Eng Mater. & Structures, 2006, 29(1), p 71–78.

V.K. Krishnan and K. Sinnaeruvadi, Synthesis of Vanadium-Vanadium Carbide in-situ Nanocomposites by High Energy Ball Milling and Spark Plasma Sintering, Sci. Sinter., 2016, 48, p 325–332.

J. Yang, J. Trapp, Q. Guo and B. Kieback, Joining of 316L Stainless Steel by Using Spark Plasma Sintering Method, Mater. & Design, 2013, 52, p 179–189.

Y.W. Bao, J.X. Chen, X.H. Wang and Y.C. Zhou, Shear Strength and Shear Failure of Layered Machinable Ti3AlC2 Ceramics, J. European Ceramic Soc., 2004, 24(5), p 855–860.

M. Seyring and M. Rettenmayr, Impact of Crystallography at Ni/NiAl Interfaces on the Nucleation of Ni3Al, Acta Mater., 2021, 208, p 116713.

Z. Zhang, Q. Fu, J. Wang, P. Xiao, F. Ke and C. Lu, Hardening Ni3Al via complex stacking faults and twinning boundary, Comput Mater. Sci., 2021, 188, p 110201.

S. Zhao, Y, Osetsky, Structural and chemical disorder enhance point defect diffusion and atomic transport in Ni3Al-based γ′ phase, Acta Mater., 2021, 207, p 116704.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mardiha, P., Bahrami, A. & Mohammadnejad, A. An Investigation on the Microstructure, Interface, and Mechanical Properties of Spark Plasma Sintered Ni/Ni-Ni3Al/Ni Compound. J. of Materi Eng and Perform 31, 1163–1169 (2022). https://doi.org/10.1007/s11665-021-06227-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06227-9