Abstract

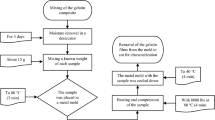

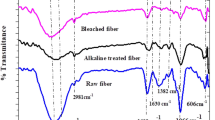

Cellulosic nanofibrils from cocoa shells were used in this study to produce biodegradable films from a residue naturally rich in bioactive compounds, while reserving these compounds. The nanofibrils were obtained by mechanical defibrillation without chemical or enzymatic pretreatment. The nanofibril gel was evaluated in biodegradable films, for the first time, with the addition of glycerol as a plasticizer in the proportions of 0, 1, 3, 5, and 7% (w/w). The morphological characteristics, thermal analysis, mechanical properties (rupture tensile, maximum rupture elongation, and Young’s modulus), water vapor permeability, and water solubility of the films were investigated. In addition, the residue was analyzed and compared to the films by the FTIR technique to prove the maintenance of functional groups characteristic of antioxidant activity. The use of 3% and 5% glycerol as a plasticizer showed the best mechanical characteristics—reduced water vapor permeation and increased degradation in water. The pure nanofibril film demonstrated greater thermal stability. It was possible to identify the maintenance of aromatic groups and phenols in the residue from all cocoa shell nanofibril films. This study contributes to the future application of cocoa shell nanofibers in the production of edible films, coatings, and packaging materials. It recommends their application in cocoa and chocolate products due to the compatibility of smell and color.

Graphic abstract

Similar content being viewed by others

References

Phanthong, P, Reubroycharoen, P, Hao, X, Xu, G, Abudula, A, Guan, G, “Nanocellulose: Extraction and application.” Carbon Resour. Convers., 1 (1) 32–43. https://doi.org/10.1016/j.crcon.2018.05.004 (2018)

Pfaltzgraff, LA, Debruyn, M, Cooper, EC, Budarin, V, Clark, JH, “Food waste biomass: A resource for high-value chemicals.” Green Chem., 15 (2) 307–314. https://doi.org/10.1039/C2GC36978H (2013)

Cherubini, F, “The biorefinery concept: Using biomass instead of oil for producing energy and chemicals.” Energy Convers. Manag., 51 (7) 1412–1421. https://doi.org/10.1016/j.enconman.2010.01.015 (2010)

Tharanathan, RN, “Biodegradable films and composite coatings: Past, present and future.” Trends Food Sci. Technol., 14 (3) 71–78. https://doi.org/10.1016/S0924-2244(02)00280-7 (2003)

Portes, E, Gardrat, C, Castellan, A, Coma, V, “Enviromentally friendly films based on chitosan and tetrahydrocurcuminoid derivatives exhibiting antibacterial and antioxidative properties.” Carbohydr. Polym., 76 (4) 578–584. https://doi.org/10.1016/j.carbpol.2008.11.031 (2009)

Siró, I, Plackett, D, “Microfibrillated cellulose and new nanocomposite materials: A review.” Cellulose, 17 459–494. https://doi.org/10.1007/s10570-010-9405-y (2010)

Mishra, RK, Sabu, A, Tiwari, SK, “Materials chemistry and the futurist eco-friendly applications of nanocellulose: Status and prospect.” J. Saudi Chem. Soc., 22 (8) 949–978. https://doi.org/10.1016/j.jscs.2018.02.005 (2018)

Abitbol, T, Rivkin, A, Cao, Y, Nevo, Y, Abraham, E, Ben-Shalom, T, Lapidot, S, Shoseyov, O, “Nanocellulose, a tiny fiber with huge applications.” Shoseyov Curr. Opin. Biotechnol., 39 76–88. https://doi.org/10.1016/j.copbio.2016.01.002 (2016)

Bagde, P, Nadanathangam, V, “Mechanical, antibacterial and biodegradable properties of starch film containing bacteriocin immobilized crystalline nanocellulose.” Carbohydr. Polym., 222 115021. https://doi.org/10.1016/j.carbpol.2019.115021 (2019)

Guimarães, IC, Reis, KC, Menezes, EGT, Rodrigues, AC, Silva, TF, Oliveira, IRN, Vilas Boas, EVB, “Cellulose microfibrillated suspension of carrots obtained by mechanical defibrillation and their application in edible starch films.” Ind. Crops Prod., 70 (89) 285–294. https://doi.org/10.1016/j.indcrop.2015.03.014 (2015)

Tao, P, Zhang, Y, Wu, Z, Liao, X, Nie, S, “Enzymatic pretreatment for cellulose nanofibrils isolation from bagasse pulp: Transition of cellulose crystal structure.” Carbohydr. Polym., 214 1–7. https://doi.org/10.1016/j.carbpol.2019.03.012 (2019)

Wang, Y, Zhang, L, Liu, W, Cui, C, Hou, Q, “Fabrication of optically transparent and strong nanopaper from cellulose nanofibril based on corncob residues.” Carbohydr. Polym., 214 159–166. https://doi.org/10.1016/j.carbpol.2019.03.035 (2019)

Haslam, E, Practical Polyphenolics: From structure to molecular recognition and physiological action. Cambridge University Press, New York (2005)

Rahimi, M, Behrooz, R, “Effect of cellulose characteristic and hydrolyze conditions on morphology and size of nanocrystal cellulose extracted from wheat straw.” Int. J. Polym. Mate, 60 (8) 529–541. https://doi.org/10.1080/00914037.2010.531820 (2011)

Santos, RMD, Flauzino, NWP, Silvério, HA, Martins, DF, Dantas, NO, Pasquini, D, “Cellulose nanocrystals from pineapple leaf, a new approach for the reuse of this agro-waste.” Ind. Crops Prod., 50 707–714. https://doi.org/10.1016/j.indcrop.2013.08.049 (2013)

Lessa, OA, Reis, NS, Leite, SGF, Gutarra, MLE, Souza, AO, Gualberto, SA, Oliveira, JR, Aguiar-Oliveira, E, Franco, M, “Effect of the solid-state fermentation of cocoa shell on the secondary metabolites, antioxidant activity, and fatty acids.” Food Sci. Biotechnol., 27 107–113. https://doi.org/10.1007/s10068-017-0196-x (2018)

Okiyama, DCG, Navarro, SLB, Rodrigues, CEC, “Cocoa shell and its compounds: Applications in the food industry.” Trends Food Sci. Technol., 63 103–112. https://doi.org/10.1016/j.tifs.2017.03.007 (2017)

Bruna, C, Eichholz, I, Rohn, S, Kroh, LW, Huyskens-Keil, S, “Bioactive compounds and antioxidant activity of cocoa hulls (Theobroma cacao L.) from different origins.” J. Appl. Bot. Food Qual., 83 (1) 9–13 (2009)

Hoyos, CG, Márquez, PM, Vélez, LP, Guerra, AS, Eceiza, A, Urbina, L, Velásquez-Cock, J, Rojo, PG, Acosta, LV, Zuluaga, R, “Cocoa shell: An industrial by-product for the preparation of suspensions of holocellulose nanofibers and fat.” Cellulose, 27 10873–10884. https://doi.org/10.1007/s10570-020-03222-6 (2020)

Souza, LO, Lessa, OA, Dias, MC, Tonoli, GHD, Rezende, DVB, Martins, MA, Neves, ICO, Resende, JV, Carvalho, EEN, Vilas Boas, EVB, Oliveira, JR, Franco, M, “Study of morphological properties and rheological parameters of cellulose nanofibrils of cocoa shell (Theobroma cacao L.).” Carbohydr. Polym., 214 152–158. https://doi.org/10.1016/j.carbpol.2019.03.037 (2019)

Souza, VGL, Fernando, AL, Pires, JRA, Rodrigues, PF, Lopes, AAS, Fernandes, FMB, “Physical properties of chitosan films incorporated with natural antioxidants.” Ind. Crops Prod., 107 565–572. https://doi.org/10.1016/j.indcrop.2017.04.056 (2017)

Barbosa-Pereiram, L, Ângulo, I, Lagarón, JM, Paseiro-Losada, P, Cruz, JM, “Development of new active packaging films containing bioactive nanocomposites.” Innov. Food Sci. Emerg. Technol., 26 310–318. https://doi.org/10.1016/j.ifset.2014.06.002 (2014)

Miranda, MC, Castelo, PAR, “Avaliações Anatômicas das Fibras da Madeira de Parkia gigantocarpa Ducke.” Braz. J. Wood Sci., 3 (2) 01–09. https://doi.org/10.15210/cmad.v3i2.4039 (2012)

French, AD, “Idealized powder diffraction patterns for cellulose polymorphs.” Cellulose, 21 885–896. https://doi.org/10.1007/s10570-013-0030-4 (2014)

ASTM-American Society for Testing and Materials, Standard test methods for tensile properties of thin plastic sheeting. ASTM d882-00, Philadelphia, 2000.

ASTM-American Society for Testing and Materials, Standard test methods for water vapor transmission of materials. ASTM e96-00, Philadelphia, 2000.

Bourtoom, T, Chinnan, MS, “Preparation and properties of rice starch–chitosan blend biodegradable film.” LWT-Food Sci. Technol., 41 (9) 1633–1641. https://doi.org/10.1016/j.lwt.2007.10.014 (2008)

Tetens, VO, Uber einige meteorologische, vol 6. Zeitschrift Geophysic, Wurzburg (1930)

Gontard, N, Duchez, C, Jean-Louis, C, Guilbert, S, “Edible composite films of wheat gluten and lipids: Water vapor permeability and other physical properties.” Int. J. Food Sci. Techonol., 29 (1) 39–50. https://doi.org/10.1111/j.1365-2621.1994.tb02045.x (1994)

Chacón, ES, Rodríguez, OA, Arrieta, AR, Alpízar, LG, “Micromorfología de los foliolos de pejibaye Bactris gasipaes (Arecaceae) var. Diamantes-10.” Rev. Biol. Trop., 64 (3) 1273–1285. https://doi.org/10.15517/rbt.v64i3.19718 (2016)

Ifuku, S, Ikuta, A, HironoriIzawa, H, Morimoto, M, Saimoto, H, “Control of mechanical properties of chitin nanofiber film using glycerol without losing its characteristics.” Carbohydr. Polym., 101 714–717. https://doi.org/10.1016/j.carbpol.2013.09.076 (2014)

Kiziltas, EE, Kiziltas, A, Nazari, B, Gardner, DJ, Bousfield, DW, “Glycerine treated nanofibrillated cellulose composites.” J. Nanomater., 2016 7851308. https://doi.org/10.1155/2016/7851308 (2016)

Batista, NN, Andrade, DP, Ramos, CL, Dias, DR, Schwan, RF, “Antioxidant capacity of cocoa beans and chocolate assessed by FTIR.” Food Res. Int., 90 313–319. https://doi.org/10.1016/j.foodres.2016.10.028 (2016)

Rosa, MF, Medeiros, ES, Malmonge, JA, Gregorski, KS, Wood, DF, Mattoso, LHC, Glenn, G, Orts, WJ, Imam, SH, “Cellulose nanowhiskers from coconut husk fibers: effect of preparation conditions on their thermal and morphological behaviour.” Carbohydr. Polym., 81 (1) 83–92. https://doi.org/10.1016/j.carbpol.2010.01.059 (2010)

Alemdar, A, Sain, M, “Biocomposites from wheat straw nanofibers: Morphology, thermal and mechanical properties.” Compos. Sci. Technol., 68 (2) 557–565. https://doi.org/10.1016/j.compscitech.2007.05.044 (2008)

Hoeger, IC, Nair, SS, Ragauskas, AJ, Deng, Y, Rojas, OJ, Zhu, JY, “Mechanical deconstruction of lignocellulose cell walls and their enzymatic saccharification.” Cellulose, 20 807–818. https://doi.org/10.1007/s10570-013-9867-9 (2013)

Chandra, JCS, George, N, Narayanankutty, SK, “Isolation and characterization of cellulose nanofibrils from areca nut husk fibre.” Carbohydr. Polym., 142 158–166. https://doi.org/10.1016/j.carbpol.2016.01.015 (2016)

Rosa, SML, Rehman, N, Miranda, MIG, Nachtigal, SMB, Bica, CID, “Chlorine-free extraction of cellulose from rice husk and whisker isolation.” Carbohydr. Polym., 8 (2) 1131–1138. https://doi.org/10.1016/j.carbpol.2011.08.084 (2012)

Costa, LAS, Assis, DJ, Gomes, GVP, Da Silva, JBA, Fonsêca, AF, Druzian, JI, “Extraction and characterization of nanocellulose from corn stover.” Mater. Today, 2 (1) 287–294. https://doi.org/10.1016/j.matpr.2015.04.045 (2015)

Yang, X, Han, F, Xu, C, Jiang, S, Huang, L, Liu, L, Xia, Z, “Effects of preparation methods on the morphology and properties of nanocellulose (NC) extracted from corn husk.” Ind. Crops Prod., 109 241–247. https://doi.org/10.1016/j.indcrop.2017.08.032 (2017)

Li, M, Tian, X, Ruifa, J, Li, D, “Preparation and characterization of nanocomposite films containing starch and cellulose nanofibers.” Ind. Crops Prod., 123 654–660. https://doi.org/10.1016/j.indcrop.2018.07.043 (2018)

Flauzino Neto, WP, Silvério, HA, Dantas, NO, Pasquini, D, “Extraction and characterization of cellulose nanocrystals from agro-industrial residue – Soy hulls.” Ind. Crops Prod., 42 480–488. https://doi.org/10.1016/j.indcrop.2012.06.041 (2013)

Lee, SY, Mohan, DJ, Kang, IA, Doh, GH, Lee, S, Han, SO, “Nanocellulose reinforced PVA composite films: Effects of acid treatment and filler loading.” Fiber and Polym., 10 77–82. https://doi.org/10.1007/s12221-009-0077-x (2009)

Franco, TS, Potulski, DC, Viana, LC, Forville, E, de Andrade, AS, de Muniz, GIB, “Nanocellulose obtained from residues of peach palm extraction (Bactris gasipaes).” Carbohydr. Polym., 218 8–19. https://doi.org/10.1016/j.carbpol.2019.04.035 (2019)

Xu, C, Zhu, S, Xing, C, Li, D, Zhu, N, Zhou, H, “Isolation and properties of cellulose nanofibrils from coconut palm petioles by different mechanical process.” PloS One, 10 (4) e0122123. https://doi.org/10.1371/journal.pone.0122123 (2015)

Alemdar, A, Sain, M, “Isolation and characterization of nanofibers from agricultural residues – Wheat straw and soy hulls.” Bioresour. Technol., 99 (6) 1664–1671. https://doi.org/10.1016/j.biortech.2007.04.029 (2008)

Guimarães, M, Botaro, VR, Novack, KM, Teixeira, FG, Tonoli, GHD, “Starch/PVA-based nanocomposites reinforced with bamboo nanofibrils.” Ind. Crops Prod., 70 72–83. https://doi.org/10.1016/j.indcrop.2016.05.024 (2015)

Lago, RC, Oliveira, ALM, Dias, MC, Carvalho, EEN, Tonoli, GHD, Vilas-Boas, EVB, “Obtaining cellulosic nanofibrils from oat straw for biocomposite reinforcement: Mechanical and barrier properties.” Ind. Crops Prod., 148 112264. https://doi.org/10.1016/j.indcrop.2020.112264 (2020)

Machado, BAS, Reis, JHO, Cruz, LS, Leal, IL, Barbosa, JDV, Azevedo, JB, Druzian, JI, “Characterization of cassava starch films plasticized with glycerol and strengthened with nanocellulose from green coconut fibers.” Afr. J. Biotechnol., 16 (28) 1567–1578. https://doi.org/10.5897/AJB2017.1594 (2017)

Boonsuk, P, Sukolrat, A, Kaewtatip, K, Chantarak, S, Kelarakis, A, Chaibundit, C, “Modified cassava starch/poly (vinyl alcohol) blend films plasticized by glycerol: Structure and properties.” J. Appl. Polym. Sci., 137 (48848) 1–13. https://doi.org/10.1002/APP.48848 (2020)

Munthoub, DI, Rahman, WA, “Tensile and water absorption properties of biodegradable composites derived from cassava skin/polyvinyl alcohol with glycerol as plasticizer.” Sains Malays., 40 (7) 713–718 (2011)

Faradilla, RHF, Lee, G, Roberts, J, Martens, P, Stenzel, M, Arcot, J, “Effect of glycerol, nanoclay and graphene oxide on physicochemical properties of biodegradable nanocellulose plastic sourced from banana pseudo-stem.” Cellulose, 25 399–416. https://doi.org/10.1007/s10570-017-1537-x (2018)

Dufresne, A, “Nanocellulose: A new ageless bionanomaterial.” Mater. Today, 16 (6) 220–227. https://doi.org/10.1016/j.mattod.2013.06.004 (2013)

Azeredo, HMC, Mattoso, LHC, Wood, D, Williams, TG, Avena-Bustillos, RJ, Mchugh, TH, “Nanocomposite edible films from mango puree reinforced with cellulose nanofibers.” J. Food. Sci., 74 (5) 31–35. https://doi.org/10.1111/j.1750-3841.2009.01186.x (2009)

Miao, X, Lin, J, Tian, F, Li, X, Bian, F, Wang, J, “Cellulose nanofibrils extracted from the byproduct of cotton plant.” Carbohydr. Polym., 136 841–850. https://doi.org/10.1016/j.carbpol.2015.09.056 (2016)

Kaushik, A, Singh, M, Verma, G, “Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw.” Carbohydr. Polym., 82 (2) 337–345. https://doi.org/10.1016/j.carbpol.2010.04.063 (2010)

Singh, B, Sharma, N, “Mechanistic implications of plastic degradation.” Polym. Degrad. Stabil., 93 (3) 561–584. https://doi.org/10.1016/j.polymdegradstab.2007.11.008 (2008)

Acknowledgments

The authors would like to thank Banco do Nordeste do Brasil (BNB, Brazil), the Coordination for the Improvement of Higher Education Personne (CAPES, Procad 88881.068456/2014-01), the National Council for Scientific and Technological Development (Productivity in Research Grants 302259/2018-0, 302699/2019-8, CNPq, Brazil), the Research Support Foundation of the State of Minas Gerais (PPM-00458-15, FAPEMIG, Brazil), and the Research Support Foundation of the State of Bahia (FAPESB, Brazil) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lessa, O.A., de Carvalho Tavares, I.M., Souza, L.O. et al. New biodegradable film produced from cocoa shell nanofibrils containing bioactive compounds. J Coat Technol Res 18, 1613–1624 (2021). https://doi.org/10.1007/s11998-021-00519-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-021-00519-4