Abstract

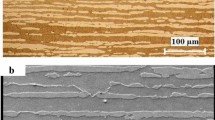

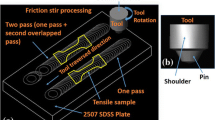

Microstructure evolution of friction stir processed 2507 duplex stainless steel was investigated at rotational speed of 400 rpm and traverse speed of 100 mm/min. The microstructural evolution in processed zone was studied by optical microscopy and electron backscattered diffraction. Regions in the stir zone and the thermo-mechanically affected zone experienced different microstructure evolution due to different thermo-mechanical processes. The results showed that static recrystallization, dynamic recrystallization, and dynamic recovery occurred in the processed zone. And the ferrite was occurred the recrystallization prior to the austenite.

Similar content being viewed by others

References

Sathiya P, Aravindan S, Soundararajan R, Haq AN (2009) Effect of shielding gases on mechanical and metallurgical properties of duplex stainless-steel welds. J Mater Sci 44:1

Ureña A, Otero E, Utrilla MV, Múnez CJ (2007) Weldability of a 2205 duplex stainless steel using plasma arc welding. J Mater Process Technol 182:1–3

Zhang ZQ, Jing HY, Xu LY et al (2016) Investigation on microstructure evolution and properties of duplex stainless steel joint multi-pass welded by using different methods[J]. Mater Des 109:670–685

Rui L, Yan C, Yue W et al (2016) Influence of absorbed nitrogen on microstructure and corrosion resistance of 2205 duplex stainless steel joint processed by fiber laser welding[J]. J Mater Process Technol 231:397–405

Meng X, Huang Y, Cao J (2020) Recent progress on control strategies for inherent issues in friction stir welding. Prog Mater Sci 115:100706

Ma ZY (2008) Friction stir processing technology: a review. Metall Mater Trans A 39:642–658

Zhou L, Li GH, Zhang RX, Zhou WL, He WX, Huang YX, Song XG (2019) Microstructure evolution and mechanical properties of friction stir spot welded dissimilar aluminum-copper joint. J Alloy Compd 775:372–382

Saeid T, Abdollah-Zadeh A, Shibayanagi T, Ikeuchi K, Assadi H (2010) On the formation of grain structure during friction stir welding of duplex stainless steel. Mater Sci Eng A-Struct Mater Prop Microstruct Process 527:24–25

Hu J, Ding L, Guo B, Fang W (2010) Technical research of friction stir welding repair in aeroplane aluminium alloy damage. Adv Mater Res 154–155:1262–1265

Gunter C, Miles M, Liu F, Nelson T (2017) Solid state crack repair by friction stir processing in 304L stainless steel. J Mater Sci Technol 34:1

Ma CY et al (2020) Enhancement in mechanical properties and corrosion resistance of 2507 duplex stainless steel via friction stir processing. J Market Res 9(4):8296–8305

Zhao YQ et al (2021) Microstructure characteristics and corrosion resistance of friction stir welded 2205 duplex stainless steel. Adv Mater Sci Eng 3:1–11

Sato YS, Nelson TW, Sterling CJ, Steel RJ, Pettersson CO (2005) Microstructure and mechanical properties of friction stir welded SAF 2507 super duplex stainless steel. Mater Sci Eng A-Struct Mater Prop Microstruct Process 397:1–2

Santos TFA, Idagawa HS, Ramirez AJ (2014) Thermal history in UNS S32205 duplex stainless steel friction stir welds. Sci Technol Weld Join 19:2

Emami S, Saeid T, Khosroshahi RA (2018) Microstructural evolution of friction stir welded SAF 2205 duplex stainless steel. J Alloy Compd 739:678–689

Mishra MK, Gunasekaran G, Rao AG, Kashyap BP, Prabhu N (2017) Friction stir processing of 2507 super duplex stainless steel: microstructure and corrosion behaviour. Springer International Publishing, New York, pp 289–296

Santos TFA, Marinho RR, Paes MTP, Ramirez AJ (2013) Microstructure evaluation of UNS S32205 duplex stainless steel friction stir welds. Metall Mater 66:2

Zhang Z, Zhang H, Hu J et al (2018) Microstructure evolution and mechanical properties of briefly heat-treated SAF 2507 super duplex stainless steel welds[J]. Constr Build Mater 168:338–345

Mishra RS, Ma ZY (2005) Friction stir welding and processing II. Mater Sci Eng R 50:1

Cizek P, Wynne BP (1997) A mechanism of ferrite softening in a duplex stainless steel deformed in hot torsion. Mater Sci Eng A-Struct Mater Prop Microstruct Process 230:1–2

Fargas G, Akdut N, Mateo A (2008) Microstructural evolution during industrial rolling of a duplex stainless steel. ISIJ Int 48:11

Jorge AM, Reis GS, Balancin O (2011) Influence of the microstructure on the plastic behaviour of duplex stainless steels. Mater Sci Eng A-Struct Mater Prop Microstruct Process 528:6

Momeni A, Dehghani K, Zhang XX (2012) Mechanical and microstructural analysis of 2205 duplex stainless steel under hot working condition. J Mater Sci 47:6

Xie GM, Ma ZY, Geng L, Chen RS (2007) Microstructural evolution and mechanical properties of friction stir welded Mg–Zn–Y–Zr alloy. Sci Eng A-Struct Mater Prop Microstruct Process 471:1–2

Santos TFA, Torres EA, Lippold JC, Ramirez AJ (2016) Detailed microstructural characterization and restoration mechanisms of duplex and superduplex stainless steel friction-stir-welded joints. J Mater Eng Perform 25:12

Cho JH, Boyce DE, Dawson PR (2005) Modeling strain hardening and texture evolution in friction stir welding of stainless steel. Mater Sci Eng A-Struct Mater Prop Microstruct Process 398:1–2

Park SHC, Sato YS, Kokawa H (2003) Microstructural evolution and its effect on Hall-Petch relationship in friction stir welding of thixomolded Mg alloy AZ91D. J Mater Sci 38:21

Funding

The research was sponsored by the Key Research and Development Program in Shandong Province (No. 2017CXGC0811) and the Science and Technology Plan Project of Guangzhou City (201704030038).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Gao, S., Zhao, H., Zhang, R. et al. Microstructure evolution of friction stir processed 2507 duplex stainless steel. Weld World 65, 2349–2358 (2021). https://doi.org/10.1007/s40194-021-01175-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-021-01175-3