Abstract

Currently, in order to ensure the safety of industrial facilities, diagnostics and monitoring of the condition of potentially dangerous equipment and the risks of its operation are being actively developed. At the same time, the risk assessment during the operation of various technical devices (TD) is carried out on the basis of the available damage statistics, which has accumulated over the past period of the TD operation, i.e., a probabilistic approach is used. This approach is imperfect and insufficiently objective since the risk assessment is done for the future period of time when the state of technical conditions can change significantly and fatigue damage to individual equipment units can occur in those zones that, as a rule, do not coincide with the calculated ones. The article proposes to carry out a risk assessment based on early diagnosis of the most damaged elements of TPP equipment. To implement this task, it is necessary to use more extensive methods of nondestructive testing of the actual stress-strain state in order to identify stress concentration zones (SCZ): the main sources of damage and modern methods of early diagnostics—acoustic emission, metal magnetic memory (MMM), and thermal control. An example of early diagnostics of developing damage from the practice of using the MMM method when monitoring the bend of a steam line is considered. It is shown that the difference in economic damage in risk assessment for TPPs with cross-links can be significant in case of damage to the steam line and damage to the boiler pipe.

Similar content being viewed by others

REFERENCES

V. T. Vlasov and A. A. Dubov, Physical Bases of the Metal Magnetic Memory Method (Tisso, Moscow, 2004) [in Russian].

A. A. Dubov, Diagnostics of Boiler Pipes Using the Metal Magnetic Memory Method (Energoatomizdat, Moscow, 1995) [in Russian].

A. A. Dubov, Diagnostics of Turbine Equipment Using the Metal Magnetic Memory (Tisso, Moscow, 2009) [in Russian].

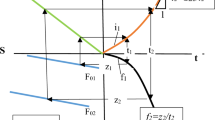

A. A. Dubov, “A technique for monitoring the bends of boiler and steam-line tubes using the magnetic memory of metal,” Therm. Eng. 48, 289–295 (2001).

Federal Norms and Rules in the Field of Industrial Safety “Rules of Examination of Industrial Safety”, Approved by Order of Rostekhnadzor No. 420 of October 20, 2020.

GOST R 58177-2018. Thermal Power Plants. Thermal-Mechanical Equipment of Thermal Power Plants. Control of Condition of Metal. Norms and Requirements.

A. A. Dubov, “Control of the stress-strain state of technical devices,” TekhNADZOR, No. 6 (127), 16–18 (2017).

I. N. Antonenko, “Risk-based approach to technical condition management of the assets in power industry,” Mire Nerazrushayushchego Kontrolya 23 (1), 18–22 (2020). https://doi.org/10.12737/1609-3178-2020-10-14

SO 153-34.17.470. Instructions on the Procedure for Inspection and Extension of the Service Life of Steam Pipelines Beyond the Park Resource (TsNTI ORGRES, Moscow, 2004).

A. A. Dubov, Al. A. Dubov, and S. M. Kolokol’nikov, The Metal Magnetic Memory Method and Control Devices: A Tutorial, 5th ed. (Tisso, Moscow, 2012) [in Russian].

A. A. Dubov, “Metrological aspects in the metal magnetic memory method,” Mir Izmer., No. 3, 42–45 (2018);

A. A. Dubov, “Metrological aspects in the metal magnetic memory method (ending),” Mir Izmer., No. 4, 41–43 (2018).

N. A. Makhutov and M. M. Gadenin, “Technogenic safety. Diagnostics and monitoring of the condition of potentially dangerous equipment and the risks of its operation,” in Federal Handbook: Informational-Analytical Publication (Tsentr Strategicheskogo Partnerstva, Moscow, 2012), Vol. 26, pp. 307–314 [in Russian].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dubov, A.A. Risk Monitoring Based on Early Diagnosis of Potential Damage to Power Equipment. Therm. Eng. 68, 730–734 (2021). https://doi.org/10.1134/S0040601521080024

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601521080024