Abstract

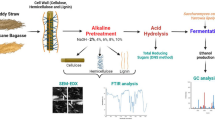

Biological pretreatment was investigated to increase ethanol production from lignocellulosic biomass, like sugarcane bagasse. Enzyme secretion, changes in substrate composition, enzymatic hydrolysis, and ethanol yield after pretreatment by different basidiomycetes were evaluated. Analysis by Fourier transform infrared spectroscopy showed that Pleurotus pulmonarius PS2001 and Trametes villosa 82I6 promoted more extensive selective modifications in the lignin content. Glucose release during enzymatic hydrolysis of samples pretreated with P. pulmonarius PS2001 for 35, 42, and 49 days and with T. villosa 82I6 for 21, 28, and 49 days were higher than the control (48.5 ± 2.38 mg/g), i.e., 68.4 ± 0.7, 76.3 ± 1.6, and 76.5 ± 2.1 mg/g and 70.9 ± 8.3, 77.8 ± 5.8, and 77.6 ± 4.2 mg/g, respectively. During the fermentation of hydrolysates of samples pretreated with T. villosa 82I6 for 14, 28, and 49 days, a maximum ethanol yield of 17.8 ± 1.9, 19.1 ± 2.8, and 20.2 ± 0.5 mg/g, respectively, was achieved. A positive effect of biological pretreatment on hydrolysis and fermentation was demonstrated.

Similar content being viewed by others

Data availability

Data available on request from the authors: the data that support the finding of this study are available from the corresponding author, on request.

References

Basso V, Machado JC, da Silva Lédo FJ et al (2014) Different elephant grass (Pennisetum purpureum) accessions as substrates for enzyme production for the hydrolysis of lignocellulosic materials. Biomass Bioenerg 71:155–161. https://doi.org/10.1016/j.biombioe.2014.10.011

Castoldi R, Bracht A, de Morais GR et al (2014) Biological pretreatment of Eucalyptus grandis sawdust with white-rot fungi: Study of degradation patterns and saccharification kinetics. Chem Eng J 258:240–246. https://doi.org/10.1016/j.cej.2014.07.090

Novello M, Vilasboa J, Schneider WDH et al (2014) Enzymes for second generation ethanol: Exploring new strategies for the use of xylose. RSC Adv 4:21361–21368. https://doi.org/10.1039/c4ra00909f

Akyol Ç, Ince O, Bozan M et al (2019) Biological pretreatment with Trametes versicolor to enhance methane production from lignocellulosic biomass: a metagenomic approach. Ind Crops Prod 140:111659. https://doi.org/10.1016/J.INDCROP.2019.111659

Scholl AL, Menegol D, Pitarelo AP et al (2015) Elephant grass (Pennisetum purpureum Schum.) pretreated via steam explosion as a carbon source for cellulases and xylanases in submerged cultivation. Ind Crops Prod 70:280–291. https://doi.org/10.1016/J.INDCROP.2015.03.056

Camassola M, Dillon AJP (2010) Cellulases and xylanases production by Penicillium echinulatum grown on sugar cane bagasse in solid-state fermentation. Appl Biochem Biotechnol 162:1889–1900. https://doi.org/10.1007/s12010-010-8967-3

Araújo M, Renata DA (2021) Production chain of first—generation sugarcane bioethanol : characterization and value-added application of wastes. BioEnergy Res. https://doi.org/10.1007/s12155-021-10301-4

Demirbaş A (2005) Estimating of structural composition of wood and non-wood biomass samples. Energ Sources 27:761–767. https://doi.org/10.1080/00908310490450971

Schneider WDH, Dillon AJP, Camassola M (2020) Lignin nanoparticles enter the scene: a promising versatile green tool for multiple applications. Biotechnol Adv 101676.https://doi.org/10.1016/j.biotechadv.2020.107685

Balat M, Balat H, Öz C (2008) Progress in bioethanol processing. Prog Energy Combust Sci 34:551–573. https://doi.org/10.1016/j.pecs.2007.11.001

Rajendran K, Drielak E, Sudarshan Varma V et al (2018) Updates on the pretreatment of lignocellulosic feedstocks for bioenergy production—a review. Biomass Convers Biorefinery 8:471–483. https://doi.org/10.1007/s13399-017-0269-3

Antonio F, Antunes F, Rajan K et al (2021) Sustainable second-generation ethanol production from switchgrass biomass via co-fermentation of pentoses and hexoses using novel wild yeasts. BioEnergy Res. https://doi.org/10.1007/s12155-021-10302-3

Yamakawa CK, Qin F, Mussatto SI (2018) Advances and opportunities in biomass conversion technologies and biorefineries for the development of a bio-based economy. Biomass Bioenerg 119:54–60. https://doi.org/10.1016/j.biombioe.2018.09.007

Camassola M, Dillon AJP (2009) Biological pretreatment of sugar cane bagasse for the production of cellulases and xylanases by Penicillium echinulatum. Ind Crops Prod 29:642–647. https://doi.org/10.1016/J.INDCROP.2008.09.008

Bezerra TL, Ragauskas AJ (2016) A review of sugarcane bagasse for second-generation bioethanol and biopower production. Biofuels, Bioprod Biorefining 10:634–647. https://doi.org/10.1002/bbb

Salvachúa D, Prieto A, López-Abelairas M et al (2011) Fungal pretreatment: an alternative in second-generation ethanol from wheat straw. Bioresour Technol 102:7500–7506. https://doi.org/10.1016/j.biortech.2011.05.027

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861. https://doi.org/10.1016/j.biortech.2009.11.093

Guo GN, Cai B, Li R et al (2019) Enhancement of saccharification and ethanol conversion from tobacco stalks by chemical pretreatment. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-019-00478-2

Gupta A, Verma JP (2015) Sustainable bio-ethanol production from agro-residues: a review. Renew Sustain Energy Rev 41:550–567. https://doi.org/10.1016/j.rser.2014.08.032

Singh P, Suman A, Tiwari P et al (2008) Biological pretreatment of sugarcane trash for its conversion to fermentable sugars. World J Microbiol Biotechnol 24:667–673. https://doi.org/10.1007/s11274-007-9522-4

Dal Picolli T, Regalin Aver K, Claudete Fontana R, Camassola M (2018) High-performance of Agaricus blazei fungus for the biological pretreatment of elephant grass. Biotechnol Prog 34:42–50. https://doi.org/10.1002/btpr.2529

Bugg TDH, Williamson JJ, Rashid GMM (2020) Bacterial enzymes for lignin depolymerisation: new biocatalysts for generation of renewable chemicals from biomass. Curr Opin Chem Biol 55:26–33. https://doi.org/10.1016/j.cbpa.2019.11.007

Schneider WDH, Fontana RC, Baudel HM et al (2020) Lignin degradation and detoxification of eucalyptus wastes by on-site manufacturing fungal enzymes to enhance second-generation ethanol yield. Appl Energ 262:114493. https://doi.org/10.1016/J.APENERGY.2020.114493

Sánchez C (2009) Lignocellulosic residues: biodegradation and bioconversion by fungi. Biotechnol Adv 27:185–194. https://doi.org/10.1016/j.biotechadv.2008.11.001

Gambato G, Todescato K, Pavão EM et al (2016) Evaluation of productivity and antioxidant profile of solid-state cultivated macrofungi Pleurotus albidus and Pycnoporus sanguineus. Bioresour Technol 207:46–51. https://doi.org/10.1016/J.BIORTECH.2016.01.121

Camassola M, da Rosa LO, Calloni R et al (2013) Secretion of laccase and manganese peroxidase by Pleurotus strains cultivate in solid-state using Pinus spp. sawdust. Braz J Microbiol 44:207–213. https://doi.org/10.1590/S1517-83822013005000006

Schneider WDH, Fontana RC, Mendonça S et al (2018) High level production of laccases and peroxidases from the newly isolated white-rot basidiomycete Marasmiellus palmivorus VE111 in a stirred-tank bioreactor in response to different carbon and nitrogen sources. Process Biochem 69:1–11. https://doi.org/10.1016/J.PROCBIO.2018.03.005

Heinzkill M, Bech L, Halkier T et al (1998) Characterization of laccases and peroxidases from wood-rotting fungi (family Coprinaceae). Appl Environ Microbiol 64:1601–1606. https://doi.org/10.1016/0038-0717(90)90187-5

Kuwahara M, Glenn JK, Morgan MA, Gold MH (1984) Separation and characterization of two extracelluar H2O2-dependent oxidases from ligninolytic cultures of Phanerochaete chrysosporium. FEBS Lett 169:247–250. https://doi.org/10.1016/0014-5793(84)80327-0

Bailey MJ, Biely P, Poutanen K (1992) Interlaboratory testing of methods for assay of xylanase activity. J Biotechnol 23:257–270. https://doi.org/10.1016/0168-1656(92)90074-J

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:695–702. https://doi.org/10.1351/pac198759050695

Camassola M, Dillon JPA (2012) Cellulase determination: modifications to make the filter paper assay easy, fast, practical and efficient. J Anal Bioanal Tech 01:10–13. https://doi.org/10.4172/scientificreports.125

Daroit D, Simonetti A, Hertz P, Brandelli A (2008) Purification and characterization of an extracellular beta-glucosidase from Monascus purpureus. J Microbiol Biotechnol 18:933–941

Scholl AL, Menegol D, Pitarelo AP et al (2015) Ethanol production from sugars obtained during enzymatic hydrolysis of elephant grass (Pennisetum purpureum, Schum.) pretreated by steam explosion. Bioresour Technol 192:228–237. https://doi.org/10.1016/j.biortech.2015.05.065

Menegol D, Fontana RC, Dillon AJP, Camassola M (2016) Second-generation ethanol production from elephant grass at high total solids. Bioresour Technol 211:280–290. https://doi.org/10.1016/j.biortech.2016.03.098

Scholl AL, Menegol D, Pitarelo AP et al (2015) Elephant grass pretreated by steam explosion for inducing secretion of cellulases and xylanases by Penicillium echinulatum S1M29 solid-state cultivation. Ind Crops Prod 77:97–107. https://doi.org/10.1016/j.indcrop.2015.08.051

Pérez V, de Troya MT, Martínez AT et al (1993) In vitro decay of Aextoxicon punctatum and Fagus sylvatica woods by white and brown-rot fungi. Wood Sci Technol 27:295–307. https://doi.org/10.1007/BF00195308

Gonçalves AR, Esposito E, Benar P (1998) Evaluation of Panus tigrinus in the delignification of sugarcane bagasse by FTIR-PCA and pulp properties. J Biotechnol 66:177–185. https://doi.org/10.1016/S0168-1656(98)00147-3

Dillon AJP, Camassola M, Henriques JAP et al (2008) Generation of recombinants strains to cellulases production by protoplast fusion between Penicillium echinulatum and Trichoderma harzianum. Enzyme Microb Technol 43:403–409. https://doi.org/10.1016/j.enzmictec.2008.07.009

Schneider WDH, dos Reis L, Fontana RC et al (2018) Exploring strategies for the use of glycerol in the production of cellulases and xylanases, and the use of these enzymes in the hydrolysis of lignocellulosic biomass. Ind Crops Prod 122:114–118. https://doi.org/10.1016/J.INDCROP.2018.05.067

Camassola M, Dillon AJP (2007) Effect of methylxanthines on production of cellulases by Penicillium echinulatum. J Appl Microbiol 102:478–485. https://doi.org/10.1111/j.1365-2672.2006.03098.x

Stoffel F, Santana WdeO, Gregolon JGN et al (2019) Production of edible mycoprotein using agroindustrial wastes: Influence on nutritional, chemical and biological properties. Innov Food Sci Emerg Technol 58:102227. https://doi.org/10.1016/J.IFSET.2019.102227

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass - An overview. Bioresour Technol 199:76–82. https://doi.org/10.1016/j.biortech.2015.08.030

Binod P, Janu KU, Sindhu R, Pandey A (2011) Hydrolysis of lignocellulosic biomass for bioethanol production, 1st ed. Elsevier Inc

Schneider WDH, BolanõLosada C, Moldes D et al (2019) A sustainable approach of enzymatic grafting on eucalyptus globulus wood by laccase from the newly isolated white-rot basidiomycete Marasmiellus palmivorus VE111. ACS Sustain Chem Eng 7:13418–13424. https://doi.org/10.1021/acssuschemeng.9b02770

Lynd LR, Laser MS, Bransby D et al (2008) How biotech can ransformation biofuels. Nat Biotechnol 26:169–172. https://doi.org/10.1038/nbt0208-169

Leisola M, Pastinen O, DDA (2012) Lignin—Designed Randomness Matti. Biocomplexity 1–11. https://doi.org/10.5048/BIO-C.2012.3

García-Torreiro M, López-Abelairas M, Lu-Chau TA, Lema JM (2016) Fungal pretreatment of agricultural residues for bioethanol production. Ind Crops Prod 89:486–492. https://doi.org/10.1016/j.indcrop.2016.05.036

Lee J-W, Gwak K-S, Park J-Y et al (2007) Biological pretreatment of softwood Pinus densiflora by three white rot fungi. J Microbiol 45:485–491

Acknowledgements

We would like to thank Dr. Luiz Humberto Gomes of Luiz de Queiroz College of Agriculture (ESALQ), University of São Paulo, Piracicaba, SP for the kind donation of Saccharomyces cerevisiae strain CAT-1 and Professor George Jackson de Moraes Rocha for the kind delivery of sugarcane bagasse.

Funding

This research was supported by grants from CAPES (3255/2013) and the National Council for Scientific and Technological Development (CNPq) (472153/2013–7). Marli Camassola is a recipient of a CNPq Research Fellowship.

Author information

Authors and Affiliations

Contributions

Conceptualization and design, MC; methodology, CH, RCF, and MC; investigation, CH and RCF; writing-original draft preparation, CH and MC; writing-review and editing, CH, FGS, and MC; administrative and technical support, and obtaining of funding: MC.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable for this study.

Consent for publication

Informed consent was obtained from all individual participants included in the study.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hartmann, C., Fontana, R.C., de Siqueira, F.G. et al. Fungal pretreatment of sugarcane bagasse: a green pathway to improve saccharification and ethanol production. Bioenerg. Res. 15, 1130–1143 (2022). https://doi.org/10.1007/s12155-021-10329-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-021-10329-6