Abstract

As the output of solid-state lighting and light sources increases, the demand for transparent phosphor inorganic plates with excellent heat resistance is increasing. It is known that α-SiAlON, which has excellent heat resistance as engineering ceramics, shows photoluminescence by stabilized ions, but it is not possible to obtain α-SiAlON bulk single crystals. In this study, we fabricated transparent Y-α SiAlON:Ce3+ ceramics for use as wave conversion materials for high-power solid-state semiconductor light sources. For this purpose, gas pressure sintering, followed by hot isostatic pressing at lower temperatures, were carried out using homogeneous and dense green bodies. In particular, cyclic cold isostatic pressing increased the density and homogeneity of the green body, which promoted the densification at lower temperatures and the efficient disappearance of pores during sintering. As a result of the suppression of grain growth by low-temperature densification, Y-α SiAlON:Ce3+ ceramics with high in-line transmittance were successfully obtained. The transparent Y-α SiAlON:Ce3+ ceramics exhibited photoluminescence due to the 5d-4f transition of Ce3+. The peak wavelength of the emission intensity depended on the concentration of Ce3+, and the luminescence color was in the range of blue to blue-green.

Export citation and abstract BibTeX RIS

This is an open access article distributed under the terms of the Creative Commons Attribution 4.0 License (CC BY, http://creativecommons.org/licenses/by/4.0/), which permits unrestricted reuse of the work in any medium, provided the original work is properly cited.

In recent years, there has been a growing demand for high-power solid-state semiconductor light sources for illumination, medical devices, displays and so on. 1 Conventional white LEDs, which are typical solid-state semiconductor light sources, consist of a resin, various phosphor particles, and a blue or ultraviolet light source that excites the phosphors. However, because of the low heat resistance of the resin, it was difficult to use them for high power applications. For this reason, there was an urgent requirement to develop wavelength conversion materials with high heat resistance. Although inorganic single crystals are one of the candidates, 2–5 the single crystals obtained by the melting method are limited and thermal strain results in the problem. In previous study, transparent phosphor ceramics of yttrium aluminum garnet and other oxides have been developed, 6,7 but their luminescence color is limited. In particular, considering the color rendering property, a transparent ceramics with blue-color emission is required.

Silicon nitride (Si3N4) ceramics are thermally durable engineering materials because of their intrinsic thermal and mechanical properties. 8–11 α-SiAlON is a solid solution of α-Si3N4 in which Si4+ and N3+ are partially substituted for Al3+ and O2−, and cations such as Li+, Ca2+, Sr2+, and Y3+ are interstitially dissolved. 12,13 The general compositional formula for α-SiAlON is expressed as Mm/νSi12-(m+n)Alm+n On N16-n . In this formula, M is interstitial cation, ν is its valence. The m/ν, m, n are the quantities of M, Al and O in Si12N16 lattice, which means that the m and n correspond to the number of Al-N and Al-O bonds. α-SiAlON doped with rare earth ions such as Eu2+, Ce3+, Tb3+, Yb2+, Sm3+, and Dy3+ has attracted attention as promising phosphor materials. 14–22 For example, Ce-doped Y-α SiAlON (Y-α SiAlON:Ce3+) emits blue fluorescence when illuminated by ultraviolet light, and Eu-doped Ca-α SiAlON (Ca-α SiAlON:Eu2+) emits yellow fluorescence when activated by blue or UV light. 16–19 These emissions are caused by the 5d-4f transition of the activator ions. Therefore, the transparency of SiAlON ceramics with fluorescence properties is a useful method to solve the aforementioned problem. However, α-SiAlON ceramics have generally been opaque.

In order to make the ceramics transparent, scattering sources such as pores and coarser grains must be removed. Conventionally, since α-SiAlON is a difficult-to-sinter material, dense α-SiAlON ceramics are usually fabricated by liquid-phase sintering using a gas-pressure sintering (GPS) technique. 8 In this process, green bodies consisting of Si3N4 and sintering aids as raw materials are prepared taking into consideration of the composition of desired α-SiAlON. In the initial stage of liquid-phase sintering of SiAlON, SiO2 on the Si3N4 surface reacts with sintering aids such rare earth oxides to form the liquid phase, resulting in the grain rearrangement. After that, Si3N4 dissolves in the liquid phase and α-SiAlON precipitates. The mass transfer during this process promotes the disappearance of pores and densification. Finally, all raw materials react and dense α-SiAlON ceramics are obtained. Because the crystal structure of α-SiAlON is hexagonal, coarser grains are also a source of light scattering. In order to obtain a finer microstructure for transparency improvement, it is necessary to control both nucleation and grain growth of α-SiAlON. In general, densification at lower temperatures is more advantageous to obtain finer grains. In previous studies, transparent or translucent α-SiAlON ceramics have been obtained by hot pressing and spark plasma sintering at temperatures above 1800 °C. 20–22 Although these sintering techniques are effective for the preparation of dense ceramics in a short time at relatively low temperature, they have limitations on the size and shape of the products and are not very productive compared to the method of firing powder compacts.

Considering that larger pores are difficult to be removed during sintering, it is essential that the green body be homogeneous and have as high a starting density as possible in order to fabricate transparent α-SiAlON ceramics at lower temperatures. Cyclic cold isostatic pressing (C-CIP) has been reported to be an excellent molding technique to obtain denser and more homogeneous green bodies by repeated application of isostatic pressure. 23,24 Hot isostatic pressing (HIP), in which a high gas pressure of about 100 MPa is applied to a pre-sintered body, is also a well-known sintering process to increase the density of ceramics. 25–27 However, blue light emitting transparent Y-α SiAlON:Ce3+ ceramics have not been fabricated by GPS using C-CIPed green bodies, followed by HIP treatment. Such transparent ceramics could be used as the layered-phosphor structure and as phosphor wheel system. In this study, the transparent and fluorescent Y-α SiAlON:Ce3+ ceramics was fabricated by a combination of C-CIP, GPS and HIP. Furthermore, the effect of HIP temperature on transmittance and the effect of the amount of doped Ce3+ on luminescence properties were investigated.

Experimental

The composition of the Y-α SiAlON:Ce3+ ceramics fabricated in this study is (Y1-x Cex )1/3Si10.5Al1.5O0.5N15.5, which x is 0.1 and 0.5, respectively. The raw materials used were α-Si3N4 (SN-E10, Ube Industry Co., Ltd., Japan), AlN (H-grade, Tokuyama Co., Japan), Y2O3 (RU-P, Shin-Etsu Chemical Co., Ltd., Japan), and CeO2 (Shin-Etsu Chemical Co., Ltd., Japan). The molar ratio of α-Si3N4:AlN:Y2O3:CeO2 was 21:9:0.9:0.2 (x = 0.1) and 21:9:0.5:1 (x = 0.5). They were mixed with a dispersant (2 wt%, polyacrylic acid, Celuna E 503, Chukyo Yushi Co., Ltd., Japan) and ball-milled in ethanol for 48 h. Dioctyl phthalate (2 wt%, FUJIFILM Wako Pure Chemicals Co., Japan) and paraffin (4 wt%, melting point: 46°C–48 °C, Junsei Chemical Co. Ltd., Japan) were added as the lubricant and binder, respectively. The granules were prepared by forced sieving of the mixed powders through a nylon mesh of 250 μm opening. They were molded by uniaxial pressing at 50 MPa for 30 s, followed by cold isostatic pressing (CIP) at 200 MPa for 1 min to make pellet-like green bodies of ϕ15 × 3 mm. The number of CIP cycles ranged from 1 to 10. The green bodies dewaxed at 500 °C for 3 h in the air were gas-pressure sintered at 1600 °C for 2 h in 0.9 MPa N2. HIP treatment of the GPSed samples was carried out at 1600 °C or 1800 °C for 1 h in 100 MPa N2.

Cristalline phases present of the fabricated ceramics were identified by X-ray diffractometry (XRD, Multiflex, Rigaku Co., Japan). Green density was estimated by the weight and dimensions of the green body. Bulk density of the sintered body was measured using Archimedes' method. Relative density was calculated from the bulk density and the theoretical density estimated from the composition of the powder and the lattice constant reported by Smrčok. 28 Microstructure of the sintered body was observed by scanning electron microscopy (SEM, JSM-6390LV, JEOL Ltd., Japan) using fractured surface. Photoluminescence was evaluated using a fluorescence spectrophotometer (FP6300, Jasco Co., Japan). Emission spectra excited at 365 nm and excitation spectra emitted at 485 nm were obtained. In-line transmittance was evaluated in the range 300 to 800 nm using a UV/Vis/NIR spectrophotometer (UV-3100PC, Shimadzu Co., Japan) with with a ϕ 2 mm aperture on the sample. Total transmittance was measured using the same spectrometer with an integrating sphere with a diameter of 60 mm.

Results and Discussion

Density, phase present of Y-a SiAlON:Ce3+ ceramics

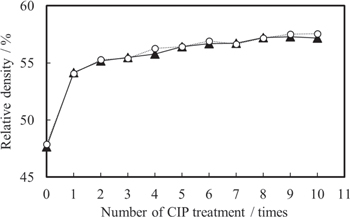

Figure 1 shows the relationship between the relative density and the number of CIP treatments. The relative densities of uniaxially pressed and once CIP-treated green bodies were about 47 and 54%, respectively. The relative density increased with an increase in the number of CIP treatments, and reached 57% by 10 times of CIP treatment. This tendency was similar to previous studies. 23,24 Since the green body consists of fine particles and pores, an increase in the green density implies a decrease in porosity and pore size. From this result, we decided to carry out 10 times of CIP treatment to obtain dense Y-α SiAlON ceramics in this study.

Figure 1. Relationship between the relative density of the green body and the number of CIP treatments (〇: x = 0.1, ▲: x = 0.5).

Download figure:

Standard image High-resolution imageFigure 2 shows the XRD profiles of the samples after HIP treatment at (a) 1600 and (b) 1800 °C. The main phase was Y-α SiAlON with small amount of β-SiAlON (Si5AlON7). Although no glassy phase was detected in the XRD analysis, it is assumed that there is some glassy phase in these samples as well as reported in previous studies. Since no crystalline phase containing Ce was identified, it is considered that Ce3+ is mostly dissolved in Y-α SiAlON and slightly present in the glassy phase as well. From the point of view of reducing the source of light scattering, the presence of β-SiAlON as the secondary phase is problem to be solved. However, the difference in refractive index between α- and β- SiAlONs is estimated to be not large, and the effect on transmittance is not so great compared to scattering in the pores. The dissolution of Y3+ and Ce4+ into β-SiAlON has not been reported. Furthermore, because the emission spectra described below (Fig. 6) did not show any luminescence specific to β-SiAlON:Ce3+, it is considered that β-SiAlON does not contain Y and Ce ions.

Figure 2. XRD profiles of Y-α SiAlON:Ce3+ ceramics HIP-treated at (a) 1600 and (b) 1800 °C.

Download figure:

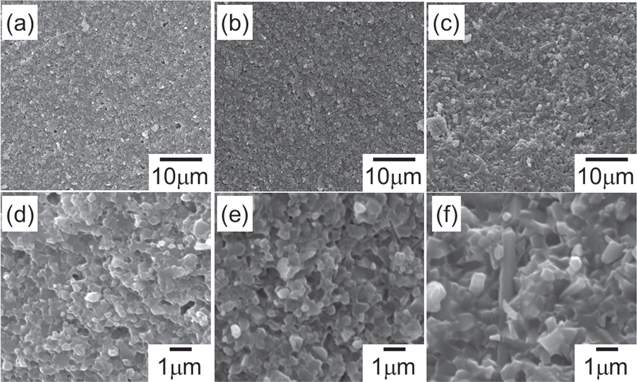

Standard image High-resolution imageThe relative densities of the sample after GPS and HIP treatments are shown in Table I. By combining C-CIP, GPS, and HIP treatment in this study, the sintered body with high density was successfully obtained regardless of composition and HIP treatment temperature. Figure 3 shows the SEM photographs of the fractured surface of the samples after GPS and HIP treatment. In the samples densified by GPS at 1600 °C, the grain size was small (several hundred nm) and the pores remained, whereas the porosity decreased after HIP treatment. The particle size of the Y-α SiAlON treated at 1600 °C did not change significantly and was only a few hundred nm, whereas the Y-α SiAlON of the sample treated at 1800 °C showed significant grain growth, with many particles larger than 1 μm. In contrast, the Y-α SiAlON sample treated by HIP at 1800 °C showed significant grain growth, with many particles larger than 1 μm. The microstructure was not significantly dependent on the amount of Ce doping.

Table I. Relative density of the sample after GPS and HIP treatment.

| Composition | After GPS at 1600 °C | After HIP at 1600 °C | After HIP at 1800 °C |

|---|---|---|---|

| x = 0.1 | 98.1 ± 0.6% | 99.2 ± 0.2% | 98.8 ± 0.0% |

| x = 0.5 | 97.5 ± 0.3% | 99.2 ± 0.2% | 98.7 ± 0.4% |

Figure 3. SEM photographs of fractured surface of the Y-α SiAlON:Ce3+ ceramics after (a) GPS at 1600 °C, (b) HIP at 1600 °C, and (c) HIP at 1800 °C. (d), (e) and (f) are enlarged views of (a), (b) and (c), respectively.

Download figure:

Standard image High-resolution imageTransparency of Y-a SiAlON:Ce3+ ceramics

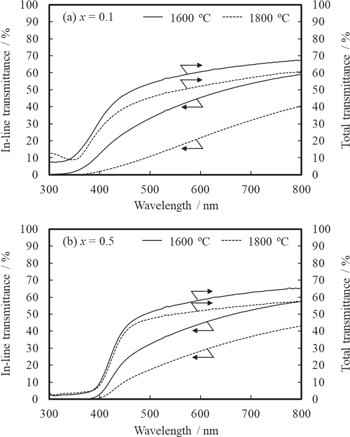

Figure 4 indicates the appearance of specimens of Y-α SiAlON:Ce3+ ceramics HIP-treated at 1600 °C with a thickness of 0.1 mm and its surface polished to a mirror finished. Figures 4a and 4b are the specimens observed under visible and UV light (365 nm), respectively. The pattern on the back is clearly visible, which confirms that the obtained Y-α SiAlON:Ce3+ ceramics are highly transparent. In addition, the Y-α SiAlON:Ce3+ ceramics were also observed to exhibit blue to blue-green fluorescent color under ultraviolet light depending on the Ce concentration. These fluorescent colors are similar to those observed in Y-α SiAlON:Ce3+ synthesized as powders in previous studies. 16,18 Figure 5 shows the in-line and total transmittance of the Y-α SiAlON:Ce3+ ceramics with a thickness of 0.1 mm. The transmittance in the visible light region was almost independent of the amount of Ce added, though the wavelength of the absorption edge of the x = 0.1 sample was lower than that of x = 0.5 sample because the excitation by Ce3+ depended on the amount of Ce added. Furthermore, the transmittance was strongly dependent on the HIP treatment temperature. When the same quantity of Ce was added, the samples HIP-treated at 1600 °C showed higher transmittance than those treated at 1800 °C. In particular, the difference was seen in the in-line transmittance, which reached about 60% at 800 nm in the sample HIP-treated at 1600 °C. Although the refractive index of Y-α SiAlON:Ce3+ has not been reported, the maximum value of transmittance is estimated to be about 76% by assuming it is compatible to that of Si3N4 (2.0634 at 500 nm 29 ). From these comparisons, it is noteworthy that Y-α SiAlON:Ce3+ ceramics with extremely high transparency, although not perfect, were obtained by fabricating homogenous and dense green bodies even when sintered at a temperature 200 °C lower than the conventional process. The high transmittance, especially the high in-line transmittance, can be attributed to the fact that the densification at lower temperature suppressed grain growth, resulting in Y-α SiAlON:Ce3+ consisting of particles smaller than visible light as shown in Fig. 4. On the other hand, when the HIP-treatment temperature was set to 1800 °C, which is the sintering temperature used to fabricate conventional high-density α-SiAlON ceramics, the transmittance became low. In particular, the in-line transmittance was greatly reduced. In general, for non-cubic crystals, the transmittance decreases as the grain size increases because the coarser grains resulting from the crystal growth at high temperatures become a source of light scattering. As shown in Fig. 4, grain growth progressed in the sample HIP-treated at 1800 °C, and many grains larger than 1 μm were present. Although the fabrication of translucent SiAlON ceramics has been reported using the hot pressing or other technique to accelerate sintering, the same temperature as previously reported was too high for high transparency because of the high density and homogeneity of the green bodies used in this study. CIP treatment at higher pressures, modification of the surface of the raw particles, and control of the particle size should be effective for making the compacts denser and more homogenous. It is expected that more transparent α-SiAlON ceramics can be fabricated by further improvement of the powder processing in the future.

Figure 4. Appearances of Y-α SiAlON:Ce3+ ceramics HIP-treated at 1600 °C observed under (a) room light and (b) UV light. The thickness of the samples is 0.1 mm.

Download figure:

Standard image High-resolution imageFigure 5. In-line and total transmittances of Y-α SiAlON:Ce3+ ceramics HIP-treated at 1600 °C. The thickness of the sample is 0.1 mm.

Download figure:

Standard image High-resolution imageFluorescence property of Y-a SiAlON:Ce3+ ceramics

Figure 6a shows the emission and excitation spectra of Y-α SiAlON:Ce3+ ceramics prepared by HIP treatment at 1600 °C. The excitation wavelengths of Y-α SiAlON:Ce3+ ceramics with x = 0.1 have peaks at 291 nm and 374 nm, and the peak emission wavelength is 476 nm. Although the values of m and n were different from the present study and the emission and excitation spectra were not published, it is reported that the peak excitation wavelength of Y-α SiAlON:Ce3+ with x = 0.1 is about 340 nm and its peak emission wavelength is 430–460 nm 16 The emission and excitation wavelength peaks obtained in this study were almost the same as or slightly larger than those in the previous study, though the values of m and n, i.e., compositions were different. The excitation wavelengths of the the Y-α SiAlON:Ce3+ ceramics with x = 0.5 were 289 and 396 nm, and the peak emission wavelength was 491 nm, which was red-shifted compared to that with x = 0.1. Figure 6b indicates the emission and excitation spectra of Y-α SiAlON ceramics HIP-treated at 1800 °C. The samples with the same Ce3+ concentration had almost the same spectrum independent of the HIP temperature. Xie et al. fabricated Y-α SiAlON:Ce3+ with x = 0.5 at different values of m and n from those in the present study 18 They reported that the excitation spectrum has two peaks at 284–286 nm and 385–386 nm, and that the emission spectrum has a broad peak at 500 nm when excited 385 nm. The spectra obtained in this study were generally consistent with this report. In particular, the luminescence of Y-α SiAlON:Ce3+ ceramics was found to be concentration-dependent when they were fabricated with the same m and n and the same firing conditions. Li et al. investigated the Ce3+ concentration dependence on the fluorescence properties of Ca-α SiAlON:Ce3+ and reported that both the emission and excitation spectra were red-shifted with increasing Ce3+ concentration, 30 similar to that of Y-α SiAlON:Ce3+ in this study. In this previous report, two reasons are given for such a red-shift. One is that the crystal field around Ce3+ changes, causing the splitting of 5d electrons, and the emission shifts to longer wavelength because of the higher transition probability of 5d electrons from higher to lower energy levels as the Ce concentration increases. The other is that there is an effect of reabsorption due to the overlap of excitation and emission spectra. Although the host cation in this experiment is different from the previous study, the redshift is considered to have occurred for the same reason.

Figure 6. Emission and excitation spectra of Y-α SiAlON:Ce3+ ceramics HIP-treated at (a) 1600 °C and (b) 1800 °C.

Download figure:

Standard image High-resolution imageα-SiAlON is able to incorporate a variety of rare earth ions into its strcture. 12 These rare earth ions exhibit unique luminescence behavior due to their electron configuration and energy level. Therefore, it will be possible to develop innovative optical materials for scintillators and lasers as well as solid-state semiconductor lighting, by utilizing the findings of this research for transparency. In addition, many non-cubic oxynitride phosphors have been reported. It is also expected that these phosphors can be made transparent by the liquid phase sintering technique using the same high-density homogeneous green body.

Conclusions

Dense Y-α SiAlON:Ce3+ ceramics were successfully fabricated by GPS and HIP treatment using high-density green body prepared by C-CIP of raw powder mixtures. In particular, it was found that the Y-α SiAlON:Ce3+ was able to be densified with suppressed grain growth by setting the HIP temperature at 1600 °C, resulting in the high transparency. Furthermore, the Y-α SiAlON:Ce3+ ceramics HIP-treated at 1600 °C showed the emission and excitation spectra attributed to the 5d-4f transition of Ce3+, which became red-shifted with increasing Ce3+ dopant contet.

Acknowledgments

This work was supported by JSPS KAKENHI Grant Number JP 19K22045.