Abstract

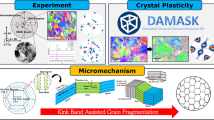

Crystal plasticity simulation is an important tool for advanced Integrated Computational Materials Engineering for metals and alloys. The current work presents a calibration and validation framework for crystal plasticity finite element (CPFE) simulation of extension twinning in the Mg alloy WE43 using the scanning electron microscopy with digital image correlation (SEM-DIC) technique. Rolled Mg alloy WE43 was subjected to in situ uniaxial compression along its rolling direction. Full-field displacement maps were captured using SEM-DIC during load pauses, and twin variant maps were obtained from the strain maps using post-processing analysis. CPFE was used to investigate the experimental results via a multi-scale twinning model developed for HCP polycrystals. In addition to macroscopic stress–strain curves, crystal plasticity parameters were calibrated using the variation of twin fraction area versus the applied strain obtained from the SEM-DIC results to accurately capture the twinning parameters. A new SEM-DIC pipeline was created for the open-source PRISMS-Plasticity CPFE software that can read in the precise deformation map generated by SEM-DIC as an input boundary condition for the finite element simulation and conduct the CPFE simulation. The performance of CPFE was evaluated versus the SEM-DIC obtained strain and twin maps. The results show that the CPFE can successfully model the macroscopic stress–strain response and the twin area fraction and that it can additionally capture microscale strain and twinning.

Similar content being viewed by others

Data Availability

The experimental data and PRISMS-Plasticity simulation input files and results are available on Materials Commons https://materialscommons.org/ and can be found at https://doi.org/10.13011/m3-thgc-jj93.

References

Cole GS (2016) Summary of “Magnesium vision 2020: a North American automotive strategic vision for magnesium.” In: Essential readings in magnesium technology. Springer, pp 35–40

Begum S, Chen DL, Xu S, Luo AA (2009) Low cycle fatigue properties of an extruded AZ31 magnesium alloy. Int J Fatigue 31(4):726–735

Beyerlein IJ, Capolungo L, Marshall PE, McCabe RJ, Tome CN (2010) Statistical analyses of deformation twinning in magnesium. Phil Mag 90(16):2161–2190

Mirza FA, Chen DL, Li DJ, Zeng XQ (2013) Low cycle fatigue of a rare-earth containing extruded magnesium alloy. Mater Sci Eng A 575:65–73

Mokdad F, Chen DL (2015) Strain-controlled low cycle fatigue properties of a rare-earth containing ZEK100 magnesium alloy. Mater Des 67:436–447

Yu Q, Jiang Y, Wang J (2015) Cyclic deformation and fatigue damage in single-crystal magnesium under fully reversed strain-controlled tension-compression in the [1010] direction. Scripta Mater 96:41–44

Murphy-Leonard AD, Pagan DC, Beaudoin A, Miller MP, Allison JE (2019) Quantification of cyclic twinning-detwinning behavior during low-cycle fatigue of pure magnesium using high energy X-ray diffraction. Int J Fatigue 125:314–323

Yaghoobi M, Allison JE, Sundararaghavan V (2020) Multiscale modeling of twinning and detwinning behavior of HCP polycrystals. Int J Plast 127:102653

Capolungo L, Beyerlein IJ (2008) Nucleation and stability of twins in hcp metals. Phys Rev B 78(2):024117

Wang J, Hirth JP, Tomé CN (2009) (1¯ 012) Twinning nucleation mechanisms in hexagonal-close-packed crystals. Acta Mater 57(18):5521–5530

Beyerlein IJ, Tomé CN (2010) A probabilistic twin nucleation model for HCP polycrystalline metals. Proceed Royal Soc A Math Phys Eng Sci 466(2121):2517–2544

Beyerlein IJ, McCabe RJ, Tomé CN (2011) Effect of microstructure on the nucleation of deformation twins in polycrystalline high-purity magnesium: a multi-scale modeling study. J Mech Phys Solids 59(5):988–1003

Zheng SJ et al (2012) Deformation twinning mechanisms from bimetal interfaces as revealed by in situ straining in the TEM. Acta Mater 60(16):5858–5866

Barrett CD, El Kadiri H (2014) The roles of grain boundary dislocations and disclinations in the nucleation of 1 0 1 2 twinning. Acta Mater 63:1–15

Beyerlein J, Arul Kumar M (2018) The stochastic nature of deformation twinning: application to HCP materials. In: Andreoni W, Yip S (eds) Handbook of materials modeling: methods: theory and modeling. Springer, Cham, pp 1–39

Tomé CN, Lebensohn RA, Kocks UF (1991) A model for texture development dominated by deformation twinning: application to zirconium alloys. Acta Metall Mater 39(11):2667–2680

Kalidindi SR (1998) Incorporation of deformation twinning in crystal plasticity models. J Mech Phys Solids 46(2):267–271

Staroselsky A, Anand L (2003) A constitutive model for hcp materials deforming by slip and twinning: application to magnesium alloy AZ31B. Int J Plast 19(10):1843–1864

Abdolvand H, Daymond MR, Mareau C (2011) Incorporation of twinning into a crystal plasticity finite element model: evolution of lattice strains and texture in Zircaloy-2. Int J Plast 27(11):1721–1738

Fernández A, Pérez Prado MT, Wei Y, Jérusalem A (2011) Continuum modeling of the response of a Mg alloy AZ31 rolled sheet during uniaxial deformation. Int J Plast 27(11):1739–1757

Zhang J, Joshi SP (2012) Phenomenological crystal plasticity modeling and detailed micromechanical investigations of pure magnesium. J Mech Phys Solids 60(5):945–972

Fernández A, Jérusalem A, Gutiérrez-Urrutia I, Pérez-Prado MT (2013) Three-dimensional investigation of grain boundary-twin interactions in a Mg AZ31 alloy by electron backscatter diffraction and continuum modeling. Acta Mater 61(20):7679–7692

Liu Y, Wei Y (2014) A polycrystal based numerical investigation on the temperature dependence of slip resistance and texture evolution in magnesium alloy AZ31B. Int J Plast 55:80–93

Ardeljan M, McCabe RJ, Beyerlein IJ, Knezevic M (2015) Explicit incorporation of deformation twins into crystal plasticity finite element models. Comput Methods Appl Mech Eng 295:396–413

Kabirian F, Khan AS, Gnäupel-Herlod T (2015) Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions. Int J Plast 68:1–20

Qiao H, Barnett MR, Wu PD (2016) Modeling of twin formation, propagation and growth in a Mg single crystal based on crystal plasticity finite element method. Int J Plast 86:70–92

Lévesque J, Mohammadi M, Mishra RK, Inal K (2016) An extended Taylor model to simulate localized deformation phenomena in magnesium alloys. Int J Plast 78:203–222

Hama T, Kobuki A, Takuda H (2017) Crystal-plasticity finite-element analysis of anisotropic deformation behavior in a commercially pure titanium Grade 1 sheet. Int J Plast 91:77–108

Yaghoobi M et al (2019) PRISMS-plasticity: an open-source crystal plasticity finite element software. Comput Mater Sci 169:109078

Yaghoobi M, Voyiadjis GZ, Sundararaghavan V (2021) Crystal plasticity simulation of magnesium and its alloys: a review of recent advances. Crystals 11(4):435

Staroselsky A, Anand L (1998) Inelastic deformation of polycrystalline face centered cubic materials by slip and twinning. J Mech Phys Solids 46(4):671–673

Abdolvand H et al (2015) On the deformation twinning of Mg AZ31B: a three-dimensional synchrotron X-ray diffraction experiment and crystal plasticity finite element model. Int J Plast 70:77–97

Hama T, Tanaka Y, Uratani M, Takuda H (2016) Deformation behavior upon two-step loading in a magnesium alloy sheet. Int J Plast 82:283–304

Prasad NS, Narasimhan R, Suwas S (2017) Effects of lattice orientation and crack tip constraint on ductile fracture initiation in Mg single crystals. Int J Plast 97:222–245

Wang H, Raeisinia B, Wu PD, Agnew SR, Tomé CN (2010) Evaluation of self-consistent polycrystal plasticity models for magnesium alloy AZ31B sheet. Int J Solids Struct 47(21):2905–2917

Oppedal AL, El Kadiri H, Tomé CN, Vogel SC, Horstemeyer MF (2013) Anisotropy in hexagonal close-packed structures: improvements to crystal plasticity approaches applied to magnesium alloy. Phil Mag 93(35):4311–4330

Ostapovets A, Molnár P, Jäger A (2013) Visco-plastic self-consistent modelling of a grain boundary misorientation distribution after equal-channel angular pressing in an AZ31 magnesium alloy. J Mater Sci 48(5):2123–2134

Wang H, Wu PD, Tomé CN, Huang Y (2010) A finite strain elastic-viscoplastic self-consistent model for polycrystalline materials. J Mech Phys Solids 58(4):594–612

Wang H, Wu PD, Wang J, Tomé CN (2013) A crystal plasticity model for hexagonal close packed (HCP) crystals including twinning and de-twinning mechanisms. Int J Plast 49:36–52

Kumar MA, Kanjarla AK, Niezgoda SR, Lebensohn RA, Tomé CN (2015) Numerical study of the stress state of a deformation twin in magnesium. Acta Mater 84:349–358

Ardeljan M, Beyerlein IJ, McWilliams BA, Knezevic M (2016) Strain rate and temperature sensitive multi-level crystal plasticity model for large plastic deformation behavior: application to AZ31 magnesium alloy. Int J Plast 83:90–109

Feather WG et al (2019) Mechanical response, twinning, and texture evolution of WE43 magnesium-rare earth alloy as a function of strain rate: Experiments and multi-level crystal plasticity modeling. Int J Plast 120:180–204

Segurado J, Lebensohn RA, Llorca J, Tomé CN (2012) Multiscale modeling of plasticity based on embedding the viscoplastic self-consistent formulation in implicit finite elements. Int J Plast 28(1):124–140

Knezevic M et al (2013) Integration of self-consistent polycrystal plasticity with dislocation density based hardening laws within an implicit finite element framework: application to low-symmetry metals. J Mech Phys Solids 61(10):2034–2046

Prakash A, Nöhring WG, Lebensohn RA, Höppel HW, Bitzek E (2015) A multiscale simulation framework of the accumulative roll bonding process accounting for texture evolution. Mater Sci Eng, A 631:104–119

Abdolvand H, Daymond MR (2012) Internal strain and texture development during twinning: comparing neutron diffraction measurements with crystal plasticity finite-element approaches. Acta Mater 60(5):2240–2248

Abdolvand H, Daymond MR (2013) Multi-scale modeling and experimental study of twin inception and propagation in hexagonal close-packed materials using a crystal plasticity finite element approach; part II: local behavior. J Mech Phys Solids 61(3):803–818

Shade PA et al (2019) Exploring new links between crystal plasticity models and high-energy X-ray diffraction microscopy. Current Opin Solid State Mater Sci 23(5):100763

Abdolvand H, Majkut M, Oddershede J, Wright JP, Daymond MR (2015) Study of 3-D stress development in parent and twin pairs of a hexagonal close-packed polycrystal: part I–in-situ three-dimensional synchrotron X-ray diffraction measurement. Acta Mater 93:246–255

Abdolvand H, Majkut M, Oddershede J, Wright JP, Daymond MR (2015) Study of 3-D stress development in parent and twin pairs of a hexagonal close-packed polycrystal: part II—crystal plasticity finite element modeling. Acta Mater 93:235–245

Pagan DC et al (2017) Modeling slip system strength evolution in Ti-7Al informed by in-situ grain stress measurements. Acta Mater 128:406–417

Wang L et al (2018) Study of slip activity in a Mg-Y alloy by in situ high energy X-ray diffraction microscopy and elastic viscoplastic self-consistent modeling. Acta Mater 155:138–152

Greeley D, Yaghoobi M, Pagan D, Sundararaghavan V, Allison J (2019) Using synchrotron radiation to improve understanding of deformation of polycrystalline metals by measuring, modelling and publishing 4D information. IOP Conf Ser Mater Sci Eng 580:012017

Bieler TR, Wang L, Beaudoin AJ, Kenesei P, Lienert U (2014) In situ characterization of twin nucleation in pure Ti using 3D-XRD. Metall and Mater Trans A 45(1):109–122

Lind J et al (2014) Tensile twin nucleation events coupled to neighboring slip observed in three dimensions. Acta Mater 76:213–220

Abdolvand H, Majkut M, Oddershede J, Wright JP, Daymond MR (2015) Study of 3-D stress development in parent and twin pairs of a hexagonal close-packed polycrystal: part II–crystal plasticity finite element modeling. Acta Mater 93:235–245

Wang L et al (2017) Direct measurement of critical resolved shear stress of prismatic and basal slip in polycrystalline Ti using high energy X-ray diffraction microscopy. Acta Mater 132:598–610

Sutton MA, Li N, Joy DC, Reynolds AP, Li X (2007) Scanning electron microscopy for quantitative small and large deformation measurements part I: SEM imaging at magnifications from 200 to 10,000. Exp Mech 47(6):775–787

Sutton MA et al (2007) Scanning electron microscopy for quantitative small and large deformation measurements part II: experimental validation for magnifications from 200 to 10,000. Exp Mech 47(6):789–804

Kammers AD, Daly S (2013) Digital image correlation under scanning electron microscopy: methodology and validation. Exp Mech 53(9):1743–1761

Martin G, Sinclair CW, Lebensohn RA (2014) Microscale plastic strain heterogeneity in slip dominated deformation of magnesium alloy containing rare earth. Mater Sci Eng, A 603:37–51

Githens A et al (2020) Characterizing microscale deformation mechanisms and macroscopic tensile properties of a high strength magnesium rare-earth alloy: a combined experimental and crystal plasticity approach. Acta Mater 186:77–94

Paudel Y et al (2020) Characterization and modeling of 101¯ 2 twin banding in magnesium. Acta Mater 183:438–451

Ganesan S et al (2021) The effects of heat treatment on the response of WE43 Mg alloy: crystal plasticity finite element simulation and SEM-DIC experiment. Int J Plast 137:102917

Qiao H, Agnew SR, Wu PD (2015) Modeling twinning and detwinning behavior of Mg alloy ZK60A during monotonic and cyclic loading. Int J Plast 65:61–84

Wu PD, Guo XQ, Qiao H, Lloyd DJ (2015) A constitutive model of twin nucleation, propagation and growth in magnesium crystals. Mater Sci Eng, A 625:140–145

Chen Z, Daly S (2018) Deformation twin identification in magnesium through clustering and computer vision. Mater Sci Eng, A 736:61–75

Chen Z et al (2018) High-resolution deformation mapping across large fields of view using scanning electron microscopy and digital image correlation. Exp Mech 58(9):1407–1421

Chen Z, Daly S (2020) Automated identification of deformation twin systems in Mg WE43 from SEM DIC. Mater Charact 169:110628

Yaghoobi M et al (2021) PRISMS-Fatigue computational framework for fatigue analysis in polycrystalline metals and alloys. npj Comput Mater 7(1):1–12

Kammers AD, Daly S (2013) Self-assembled nanoparticle surface patterning for improved digital image correlation in a scanning electron microscope. Exp Mech 53(8):1333–1341

Githens A, Daly S (2017) Patterning corrosion-susceptible metallic alloys for digital image correlation in a scanning electron microscope. Strain 53(1):e12215

Voyiadjis G, Yaghoobi M (2019) Size effects in plasticity: from macro to nano. Academic Press

Christian JW, Mahajan S (1995) Deformation twinning. Prog Mater Sci 39(1–2):1–157

Kondo R, Tadano Y, Shizawa K (2014) A phase-field model of twinning and detwinning coupled with dislocation-based crystal plasticity for HCP metals. Comput Mater Sci 95:672–683

Liu C et al (2018) An integrated crystal plasticity–phase field model for spatially resolved twin nucleation, propagation, and growth in hexagonal materials. Int J Plast 106:203–227

Liu G, Mo H, Wang J, Shen Y (2021) Coupled crystal plasticity finite element-phase field model with kinetics-controlled twinning mechanism for hexagonal metals. Acta Mater 202:399–416

Ma R, Sun W (2021) Phase field modeling of coupled crystal plasticity and deformation twinning in polycrystals with monolithic and splitting solvers. Int J Numer Meth Eng 122(4):1167–1189

Acknowledgements

This work was supported by the U.S. Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering, under Award#DE-SC0008637 as part of the Center for Predictive Integrated Structural Materials Science (PRISMS Center) at University of Michigan. We also acknowledge the financial cost-share support of University of Michigan College of Engineering and Office of the Vice President for Research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

-

PRISMS-Plasticity software can be freely downloaded from the following link: https://github.com/prisms-center/plasticity.

-

SEM-DIC pipeline implementation for PRISMS-Plasticity can be found at: https://github.com/prisms-center/plasticity/tree/master/src/ellipticBVP/.

Rights and permissions

About this article

Cite this article

Yaghoobi, M., Chen, Z., Sundararaghavan, V. et al. Crystal Plasticity Finite Element Modeling of Extension Twinning in WE43 Mg Alloys: Calibration and Validation. Integr Mater Manuf Innov 10, 488–507 (2021). https://doi.org/10.1007/s40192-021-00229-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-021-00229-0